Varieties and features of the selection of heating systems

In the cold season without heating can not do. It's so nice to go home, feel the warmth and comfort. Probably, few people know exactly how this heat is formed and what are the heating systems.

Special features

The word "heat supply" speaks for itself, it clearly implies the supply of heat to any buildings and structures, including residential ones. Moreover, the heat is divided into local - it is also called autonomous, and centralized (central). Autonomous or individual heating is initially necessary for individual houses - for example, cottages.

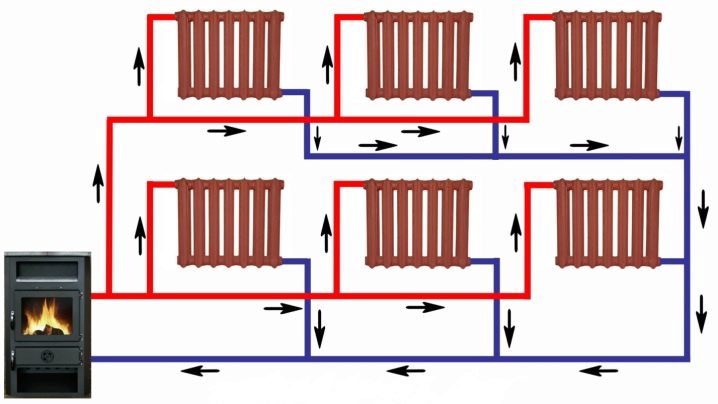

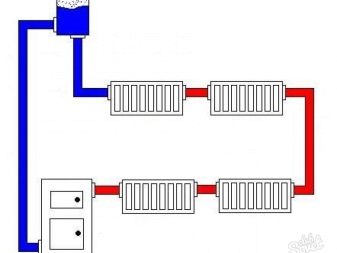

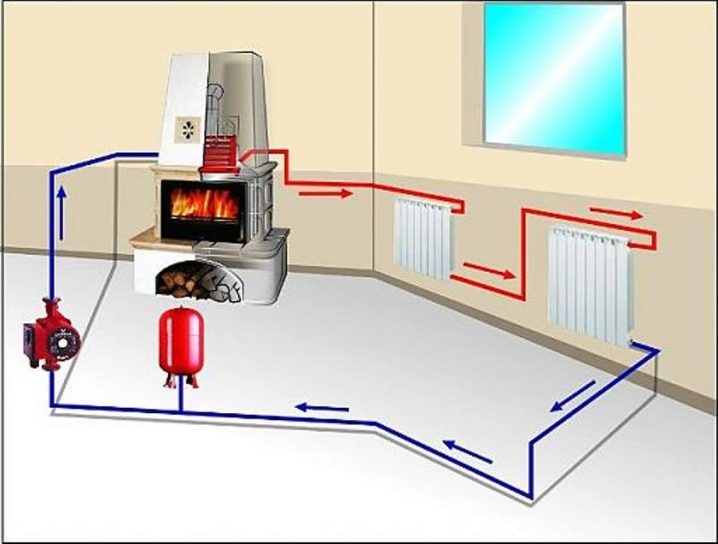

The most common water heating. It involves a boiler, heating elements (radiators), pipes for connection. The boiler heats the water so that it goes through the pipes to the radiators.Heat transfer occurs in them, and then again the water enters the boiler and the process repeats again. Quite often in heating systems, water is called the heat carrier.

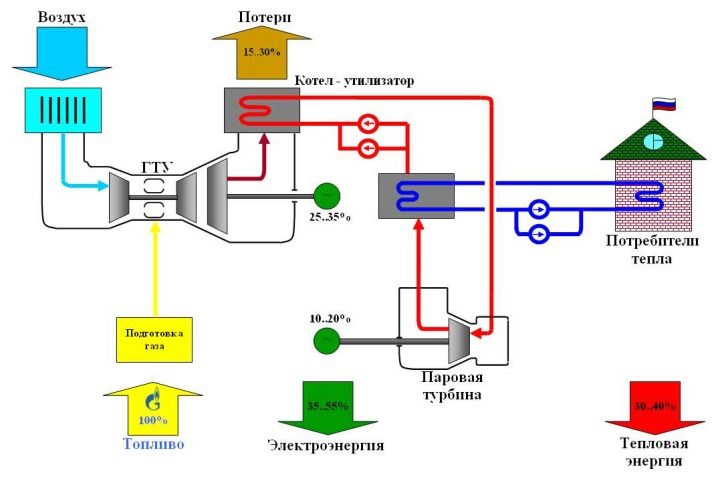

Central heating is necessary for the maintenance of industrial as well as residential areas. Arranged such heating is similar to local, the difference is solely in scale. In this case, instead of the boiler, central boiler rooms are used and they can heat a large number of buildings at once.

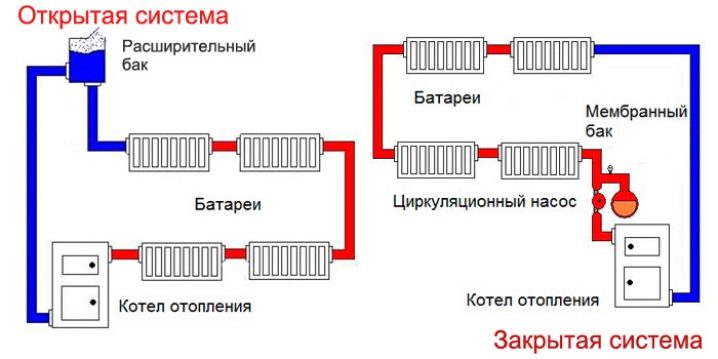

Local and district heating can be open or closed system.

A local heating system is called open if it communicates with the atmosphere through an expansion tank. If there is no contact with the atmosphere, it is closed.

In a centralized open heating system, water from it also flows into the taps. In a closed central heating system, the heated water coming through the pipes into the building heats the water in the heat exchanger.

It is better to consider the principle on which the central system works, in a little more detail. In the boiler room or CHP, the water is heated and the expansion of the water is compensated for when the temperature changes.After that, the already hot water enters the heating network by means of a pump that circulates. To the thermal network of connecting homes occur in the direct and return pipelines. Through a direct pipeline the water enters the house, and then part of it goes to the heating, and some provides the residents with hot water.

Kinds

Heating systems are open, closed, independent, dependent. This separation is based on how they are connected to the heating and hot water systems.

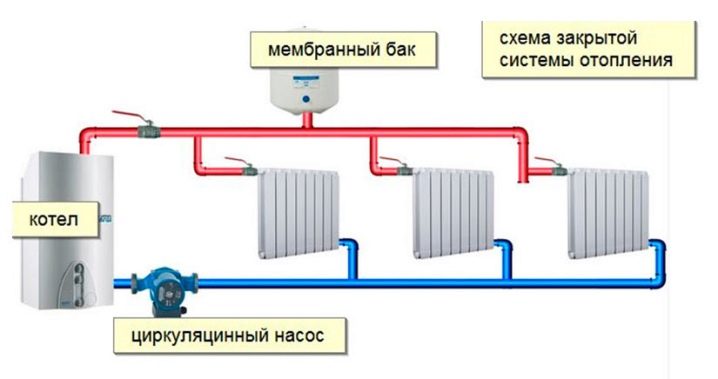

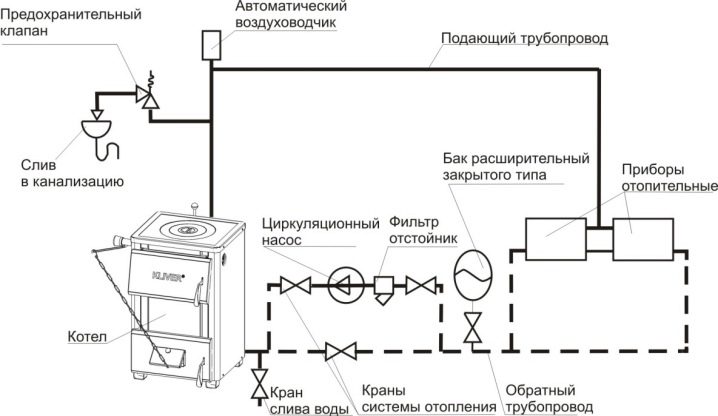

Closed

In these heating designs, the water entering the pipeline acts exclusively as a coolant. It is also not used for the DHW system. This scheme implies that the system is closed and not communicated with the atmosphere.

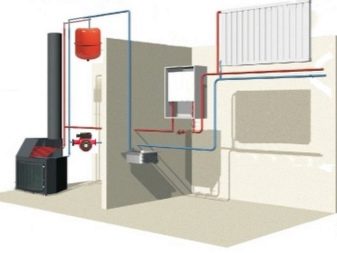

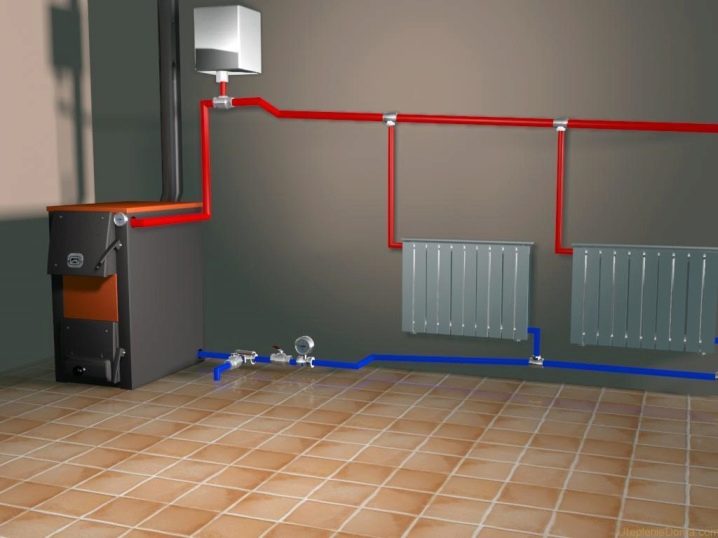

The connection scheme of the closed structure is as follows:

- boiler;

- pump;

- taps for draining water and heating systems;

- filter;

- membrane expansion tank;

- return and supply pipelines;

- heating devices

- automatic air diverter;

- valve;

- drain

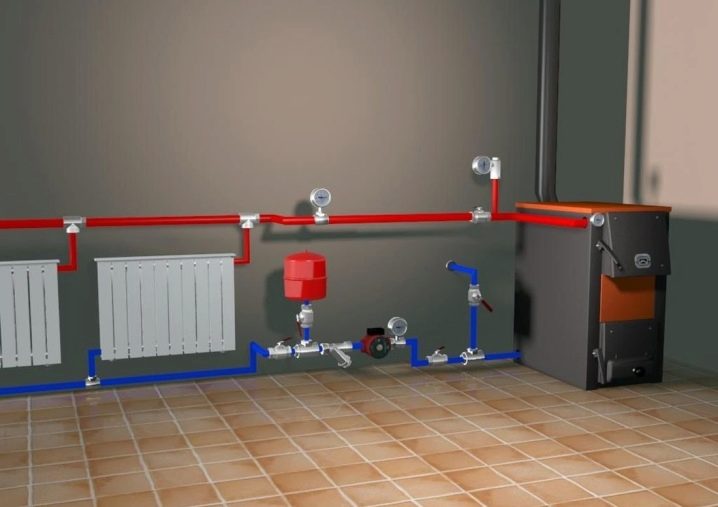

You can also use additional elements that will simplify the design of the structure and its operation as a whole.To do this, use valves for pressure control, a device for draining, thermometers, pressure gauges, a crane Mayevsky and others. It is worth noting that the closed system is sealed. This allows you to increase the operating time of all equipment.

Before choosing the volume for the tank and the pump, it is necessary to carry out some calculations. Thus it is necessary to take into account the total volume of water, as well as the intensity with which it circulates.

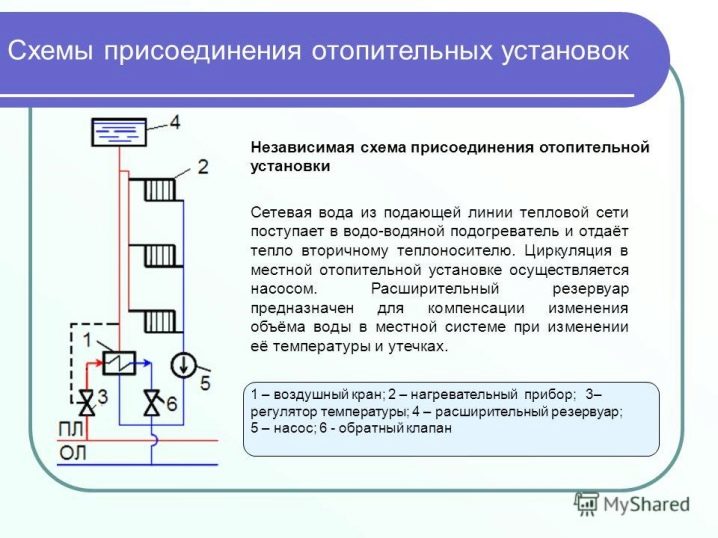

The closed type of heating works on a more complex principle. The main functions are performed by the boiler, the pump (needed for water circulation) and the expansion tank. When thermal expansion occurs, a portion of the water enters the membrane tank. That is why the important point is the calculation of its volume. After cooling, water is pumped in the opposite direction - into the pipes.

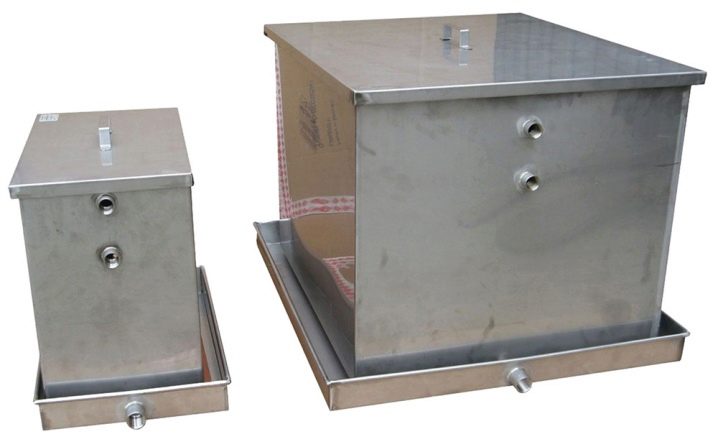

In a closed system, the pressure value is kept at a certain level, which was set in advance. For the system to work stably, you need an expansion capacity. Ideal are containers made of very strong metal. Most often, it is a sealed tank, which consists of two parts, the last rolling.Inside the tank there must be a durable membrane made of rubber and a small amount of gaseous substance - for example, air.

The membrane divides the expansion tank into two parts. One of them contains a liquid, and the second - gas. Water and gas are not in direct contact with each other. It turns out that when heated, the liquid enters the tank. Then, when the water cools, the gas pushes it back.

The closed design assumes that the volume of fluid in the system is constant. The heat consumption in the whole heating system depends on the temperature value. The heated water having a certain temperature enters the heat points. Here the temperature is brought to the desired value automatically.

In a closed type of heat supply, water leaks as a heat carrier occur, but it is worth noting that they are insignificant and easy to fix. If the volume of water in the system decreases, then it is replenished automatically, thanks to a special regulator.

In a closed structure, the pressure is always higher than the open one, and it also depends on the temperature of the fluid in the system. Therefore, for such a design, it is mandatory to install a safety valve if the pressure rises to a dangerous value.Also mandatory is the installation of a device that will allow air to escape.

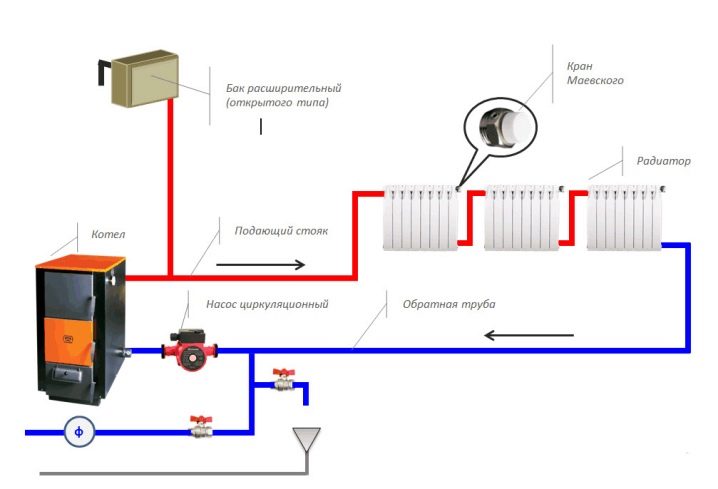

Open

In open heating constructions, heated water is taken for various needs directly from the heat pipe. It is worth noting that water can be taken in whole or only partially. The remaining heated fluid in the system is consumed for heating or ventilation. Compensation of water consumption is carried out by supplying fluid from the heating plant.

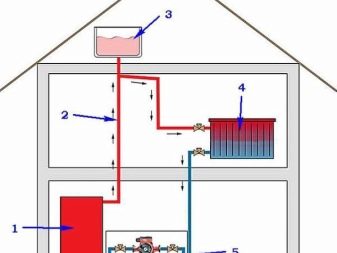

Connecting an open structure occurs according to the scheme:

- boiler;

- taps for draining fluid and heating systems;

- return and supply pipelines;

- heating devices;

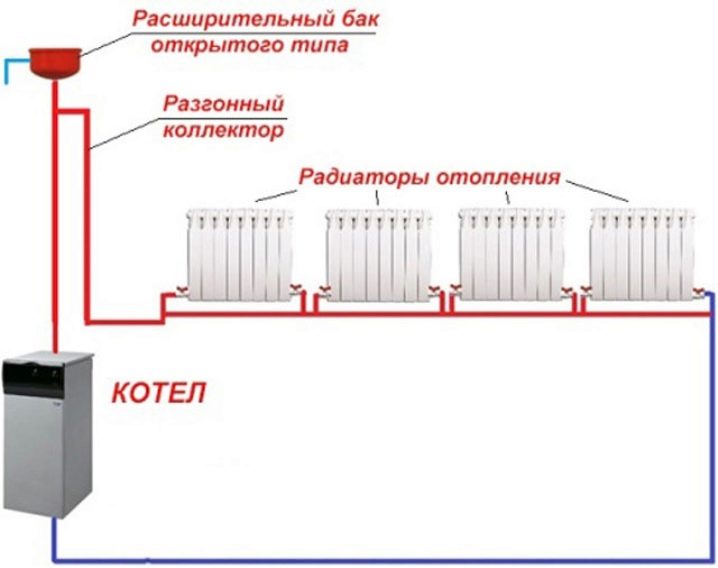

- expansion tank (tank);

- drain

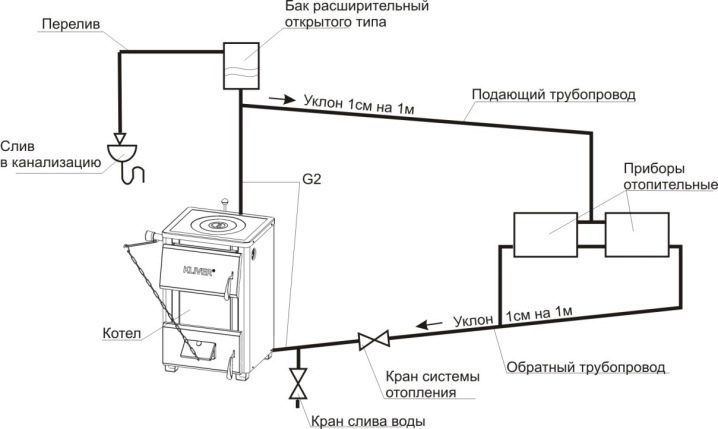

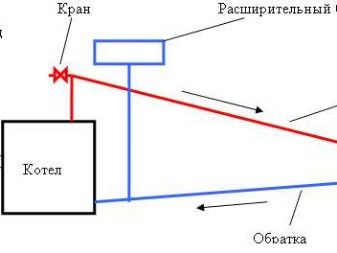

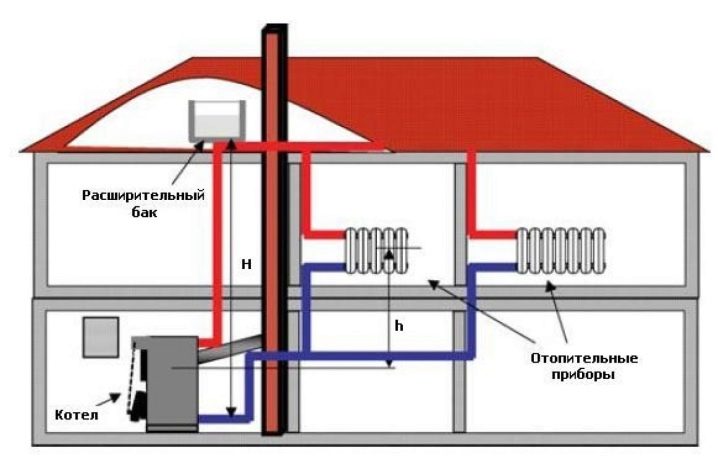

In the system of this type, the heating operation is carried out due to the natural circulation of the fluid. The scheme of work is extremely simple. The design does not need additional devices and elements. The main thing in the system is the boiler, expansion tank, radiators. The connection of elements occurs sequentially.

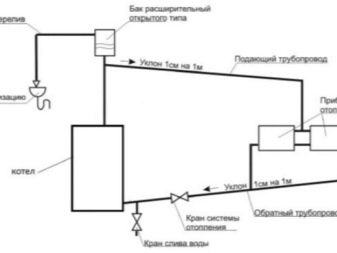

The important point is the exposure of the angle of inclination of the pipes so that there is free circulation of hot water. For proper operation, the boiler must stand at the lowest point of the heating circuit, and the expansion tank at the highest.

For an open structure, it is important that there is an expansion tank, since when heated, water expands. The tank should be filled with liquid that expands during the heating process, and then as it cools, it should return to the system. It should be borne in mind that the tank has poor tightness and water may evaporate, so you should constantly monitor its level. Other fluids other than water are not suitable for such a system, since they evaporate very quickly.

Circulation of water in this type of heating occurs at low speed. That is why the heating of the pipes should occur gradually, otherwise damage will occur, and the coolant will boil. As a result, all equipment can fail prematurely.

With the right choice of tank volume, the water level in an open system will need to be checked only before turning on the heating. In such constructions, the water pressure is completely analogous to atmospheric pressure. Moreover, it remains constant, even if the temperature of the fluid in the system changes. Thus, it is not necessary to set the security groups from increasing pressure values.

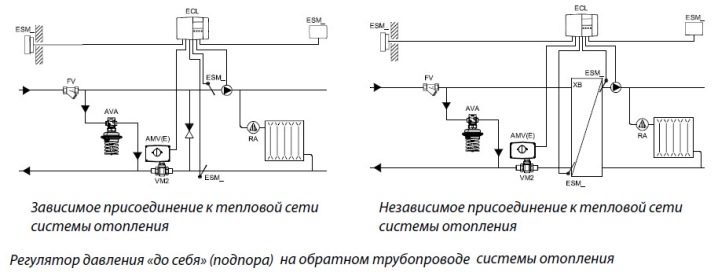

The heat supply is connected to the heat networks by a dependent or independent method.

With the dependent method, the water through the pipeline will directly flow into the system, providing heating. In this case, there are no intermediaries in the form of heat points, heat exchangers. The drawing according to which such a scheme is assembled is simple in its construction and very understandable.

The maintenance of the dependent system is completely uncomplicated. In addition, there is no need for additional elements, such as circulating pumps, control or regulation devices, heat exchangers, and so on. The greatest advantage of such a connection is its efficiency.

Of the disadvantages, there is only one - it is impossible to regulate the heating in the autumn and spring, when there may be too much heat. This affects the comfort and also causes heat loss. As a result, profitability is significantly reduced.

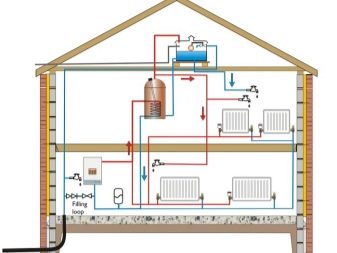

With independent heating connection, there is a need for heat points and additional heat exchangers. In such designs, the heaters are isolated at the end point.

An independent system allows you to adjust the amount of heat by adjusting the minor coolant. However, it is characterized by increased reliability. Due to the ability to make the liquid better, boiler equipment gets protection from dirt.

Very often, an independent heating connection can be seen in large cities, where heating networks are characterized by substantial length and heat loads may differ.

To date, there are technologies that allow you to reconstruct dependent designs in independent. Of course, such work is expensive, but in the end they prove their effectiveness. Despite the high cost of an independent system, it is worth it, since the water quality is much better than in a dependent one.

Which option is better?

To understand which design of the heat supply system is better: open or closed, it is worth considering what they differ in.

The main difference between a closed structure and an open one is the location of the expansion vessel. In an open structure, it must be placed in the highest place of the house.But in a closed construction tank can be installed anywhere, even on the same level with the boiler.

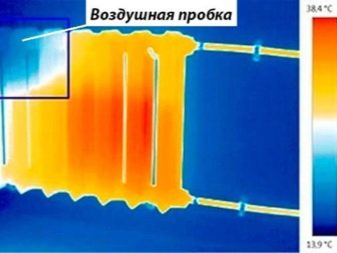

Insulation in a closed type of heat supply from the environment prevents air masses from getting inside. As a result, the service life of all equipment becomes much longer. Also in the uppermost nodes of the structure, additional pressure is created, which reduces the risk of air traffic jams in the heating elements.

Differs open type of heating pipes of larger diameter, which lead to additional inconveniences. At the same time, pipes have to be mounted at a large angle so that there is circulation. Thick-walled pipes can not always be hidden. In addition, to ensure proper hydraulics, it is necessary to take into account the inclines, lift, tapering, turning, connection options for radiators.

For a closed structure, pipes with a smaller circle are needed. This makes the construction cheaper. However, in such systems it is very important to take care of the proper installation of the pump, otherwise it will be very noisy.

The closed type of heating, in contrast to the open one, is more durable and reliable. At the same time, he is able to maintain pressure at a constant level, and it is also possible to regulate it. Coolant in this design can be antifreeze, and not water.Ease of installation and quick start are also characteristic of a closed type of heat supply.

Among the advantages, differences worth mentioning the ability to connect additional equipment. This type of heating is distinguished by its high efficiency, cost effectiveness and the absence of the need for constant monitoring.

Of course, there are differences in the closed type, which can not be attributed to the benefits. For example, the volume of the tank must be large and there must be an electrical network. The operation of a closed structure from other sources is possible, but only for a short time and in emergency cases.

The open design is characterized by a simpler installation pattern. It works more silently, in comparison with closed, and heats with greater speed. It is possible to eliminate breakages in it very quickly, as well as to make its complete shutdown. It does not need a power grid, as well as feeding in an emergency. The installation of the scheme does not require large expenses and a lot of time.

It is necessary to constantly replenish the open structure with water, and in case of untimely filling an accident may occur. Such systems work only on water, the evaporation rate of which is small.

Air can get into the open type of heating, which causes various problems - for example, air congestion, rust. In contrast to the closed type, such a system can boil or disintegrate.

The difference between the systems is very significant. To say unequivocally which one is better, you can only individually. To do this, it is worth emphasizing once again the main advantages and negative qualities of each system.

The closed construction saves energy and supplies quality water, but the process of preparing this water itself is more complicated and costly.

The open construction is very economical. However, because of its long pipelines, water is of poor quality. If you try to clean the water so that it has the best color and smell, then such a system will lose its dignity.

How to choose?

For a private home it is important that the heating system is safe, reliable, comfortable and, of course, effective. All these requirements are clearly met by an independent heating system.

It remains only to figure out, open or closed will be better in a particular case.

- If you calculate all the capital costs, it becomes clear that a closed structure is more expensive. However, the choice is to take into account many more different parameters.

- An open type of heat supply is not suitable for a large area or multi-storey house, as it is unlikely to handle it. But for a compact home you can save on connecting a circulating pump by selecting the option with natural ventilation.

- If there are frequent problems with electricity or there is none at all, it means that you should not choose closed heating structures. Without electricity, it will not work.

- In that case, if you want to use only antifreeze for heating, then you should stop the choice on closed structures. However, we must bear in mind that they may also have small leaks. They also need to ensure very good tightness of the joints.

- An important factor is the budget. If it is small, then it is better not to connect expensive equipment. The best solution would be to connect the heating in an open way, which can be further improved.

- For aesthetes, an open heating system is hardly suitable, because large pipes will pass through the room. And they often can not be hidden under the trim panels.

- If the area of the residential building is from 50 to 100 square meters, it is recommended to attach pipes with a diameter of at least 40 millimeters to the boiler.Moreover, the larger the area of the room that needs to be heated, the larger the circumference pipes will have to be used. It should also be noted that the pipes supplied to the radiators must have a diameter similar to the diameter of the riser. As for the supply pipes, their diameter may be slightly smaller.

Today, an open heating system is gradually becoming a thing of the past. Many believe that she has become obsolete. You can meet her quite rarely and then mostly in small houses somewhere outside the cities. However, there are modern systems in which a circulating pump is installed. It is usually installed at the point where the lowest coolant temperature is observed.

For large areas or houses on two or three floors, an ideal option would be a closed system with several pumps for better circulation, the possibility of automatic control and improved wiring.

Useful tips

Despite what option of heating is chosen, the main thing is correct operation of the heating system. There are a number of rules and recommendations, both to a closed and open system, which should be followed.

Otherwise, the equipment will not last for a long time.

- For an open structure it is very important in cold weather, if the heating is not turned on, to drain all the liquid from the system. This is necessary so that the pipes do not freeze. Also for the period of winter it is better to warm the expansion tank, especially if it is installed under the roof. When installing the pipeline in the system of this type is to minimize the turns and the number of connections.

- At the end of the installation of a closed system, it must be filled with water. The first time you pour liquid into the system, follow certain instructions. In the design of heating must be taps for draining and taps, allowing to fill with water. Moreover, the drain valves must be placed at the bottom of the system.

- In order for the closed structure to work properly, it is necessary that the pressure is always at the same level. Of course, the design is completely sealed, but it can leak. At first glance, they may seem insignificant. For example, water can leave the system if the air is removed using a Mayevsky crane or at the joints.Over time, such losses of fluid acting as a coolant can lead to system malfunction, which means they must be compensated for.

- If the system is small, then you can fill the water with a mechanical tap. In more complex systems, it is better to give preference to automatic feeding, which itself will regulate the need to fill the system.

- Airing the system is an unpleasant moment, but you can also cope with it with the help of air vent. These devices are automatic or manual. The most famous manual air vent is the crane Mayevsky. It is usually installed at the end of the battery.

- Automatic air deflectors are better, since they allow you to remove air from the system directly during operation. Usually, the connection of such devices is carried out in places where there are turns, or at the highest points of the system. This avoids the accumulation of air at critical points.

- In systems of the closed type it is possible to use pipes of small diameter. However, do not save too much by choosing the smallest. Otherwise, you can increase the pressure in the pipeline, and if the pump has insufficient power, then it simply will not cope.

- Proper installation of the circulation pump is important.It lies in the fact that the rotor of the device must be horizontal with respect to its axis. In this case, the equipment will operate silently, and friction with the coolant will be minimized.

- If antifreeze is poured into a closed system, the heating will be even better. For example, it will be possible, even in winter, to quietly leave for a long time and not be afraid of a system defrosting. In this case, the risk is reduced to zero.

For open systems, it is important that the pipes running horizontally be inclined. And it must be done in the direction of the boiler-radiators.

Overview of a simple heating system in a private house, see the video below.