Three-way valves for heating: recommendations for selection and installation

In order to maintain the heat balance of a house or apartment, a three-way valve is connected to the heating circuit, which contributes to the uniform distribution of heat in the heated space. Despite such an important technical feature, this device is not very complex.

Special features

Water flowing through the central heating pipes enters the radiator system with a certain temperature, which is not possible to influence. For this, a three-way valve is installed in the heating system. Its main task is to adjust the amount of fluid to be passed. This eliminates the need to change the area of the radiator.The rooms receive the necessary level of heat corresponding to the power of the heating system.

The appearance of a three-way crane resembles a tee, only the functionality they have is different.

Three-way cranes are divided into three types:

- Dividing. It is used in the case of simultaneous supply of heat in several fluids. This node can be represented as a mixer, which forms the stability of the flow of air at a given temperature. Installation is made directly to the network.

- Mixing. Used to combine threads and their subsequent adjustment. Incoming flows with different temperatures enter the valve through two openings, the output occurs through the third.

- Switching This type of valve is engaged in switching water in different directions.

You can purchase a three-way valve and temperature controller separately, but a more acceptable option would be to purchase a design with a thermostat as a whole.

Kinds

All models of three-way cranes have a number of differences - functionality, installation system, material and pricing policy.

All cranes on the market are divided into two types:

- shut-off or adjusting;

- thermostatic

The shut-off type of cranes has the task of controlling the flow of water. By sight the adjusting valve differs in an angular form and a straight line. Thanks to these devices, you can repair or clean any radiator without disconnecting the entire heating system.

Choosing a model, you need to focus on the material of the crane - it must be different resistance to the possible occurrence of corrosion. In addition, the method of installation depends on the material of the product. Currently, synthetic brass is the most commonly used metal in valve manufacturing. Manufactured products have thinned threads that can be freely mounted with metal and plastic connections. Sometimes plumbing fittings may be involved in the installation.

To date, valves made of high-quality polypropylene have become quite popular. Their surface is coated with metal. To install such a crane will have to use welding. But if the valve needs to be replaced, then one cannot do without partial cutting of the heating system.

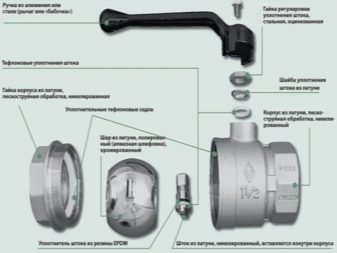

The most common and simple device is a ball valve. Its main task is to pass the coolant. Because of its simplicity, it is equipped with only two positions - open and closed. If necessary, it can be left in an intermediate state, but this will increase the level of wear of the product.

Ball valve is often made of bronze, a little less products made from other types of metals. The latest production technology carefully polishes an internal ball. The smoother its surface, the less the risk of the flow of hot coolant. The smooth surface of the ball contributes to the easy rotation of the valve. The ball valve is attached to the battery by means of a nut.

Features of the access system share ball valves:

- Standard. The amount of fluid to be passed is about 70% of the total flow.

- Full bore. The amount of fluid to be passed is 100%.

For high performance, a full bore crane is required on radiators.

Ball valves also have variations, for example, flange models, which are used in domestic radiators, while coupling and welded models are designed for the pipeline.They are durable and durable, able to withstand excessive pressure.

Buying a ball valve, you need to understand which pipes will be connected to - plastic or metal. The process of mounting the ball assembly is quite simple: one end is attached to the pipe with the feed fluid, the other is attached to the discharge side.

Along with the ball valve, there are several other products responsible for the flow and pressure of the coolant. For example, a cone valve. A distinctive feature of the conical product is smooth operation. With it, the flow of hot liquid is easily regulated.

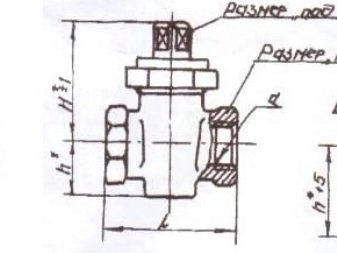

The main components of a cone valve are a threaded rod and a handle. Turning the handle, the rod moves along the thread, thereby opening the flow of water, or, conversely, closing it. When the rod reaches the bottom level, the water flow is blocked.

In the manufacture of cone valves, brass and bronze are used, but a polypropylene base is used to make budget models. According to its characteristics, polypropylene can not boast a long service life, so they are installed on a plastic base.

The Mayevsky radiator valve, or, as it is also called, the needle valve, also belongs to the stop valve series. His immediate task is to eliminate the airlock in the heating system.

Air enters the battery with a stream of liquid, forming an airlock, which subsequently reduces the heating temperature. The unwanted air gap rises over the battery and stops at the very top. Therefore, the crane Mayevsky is located on the top of the radiator from the side.

The variety of a model range of needle cranes means various type of opening. This may be a screwdriver or a special key. In practice, many users claim that it is necessary to install a model with a screwdriver, since the key is easily lost.

The principle of their work is quite simple. To open, turn the tap on the valve counterclockwise until a hissing sound appears, indicating that unwanted air leaves the battery. After the final release of the airlock valve is twisted in the opposite direction.

A distinctive feature of the Mayevsky crane is a small throughput system, so it is installed on steel and aluminum radiators.

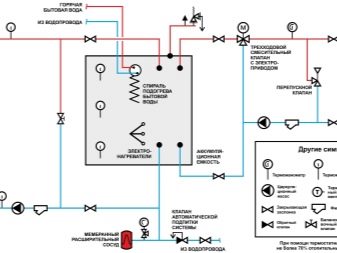

Mayevsky's crane is a mechanical device that is capable of removing air through human intervention. But along with mechanical products, automatic devices appeared on the market. Large copies are installed in autonomous heating systems, and small devices are suitable for room batteries. An important feature of the automatic crane Mayevsky is the independence of his work. If necessary, the relief valve opens, air exits, and the system automatically closes the outlet valve.

Thermostatic taps are equipped with the ability to automatically control the flow of water, as well as maintain a comfortable air temperature in individual rooms.

The main component of the device is a siphon, which is located in the handle of the product. There is a liquid or gas inside the siphon. As soon as the temperature rises, the contents of the siphon begin to expand. The increase in internal volume causes the rod to descend and shut off the flow of coolant. When the temperature in the radiator decreases, the rod returns to its original position, and the fluid flow increases.

The price ratio between thermostatic valves with gas and liquid filling is almost the same. But in the matter of functionality between these products there are differences. Gas products instantly sense a change in the temperature of radiators, and liquid-filled models react more clearly to the flow of hot coolant.

The initial setting of the required parameters of the thermostatic valve is made by a mechanical unit, but it is better to use an electronic thermostat that will allow you to adjust the thermal valve. These devices help determine the extreme positions of the crane, thereby determining the range of operation.

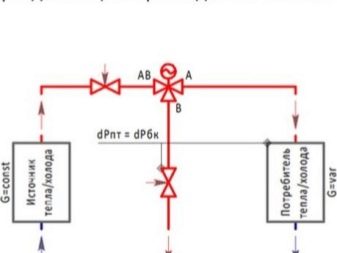

It should be noted that when installing a three-way valve in an autonomous heating system, it is necessary to additionally mount a balancing valve.

Along with the thermostatic valve is considered a valve with an electric drive. In his device there is a small motor - an electric motor. The work process of the product consists in giving a command from the electronic control unit to the engine, which changes the position of the rod inside the product.

Recently, a safety valve has become common in heating systems. Its main task is to ensure the safety of users of heating radiators. Due to temperature fluctuations and a surge in pressure, a malfunction may occur, which can lead to the most dire consequences. Almost the same protection is engaged in the valve bypass system.

In the standard heating system there are many different elements, each of which is responsible for certain functions. Including there is a check valve, which is the main unit that controls the flow of coolant.

Scope of application

The three-way valve is able to ensure maximum tightness of the fastening in the pipeline system and minimize the number of leaks. The scope of application of this valve is very extensive. Valve receives special attention during pipeline installation work. Heating systems will not be able to work evenly without the presence of a three-way valve in the circuit.

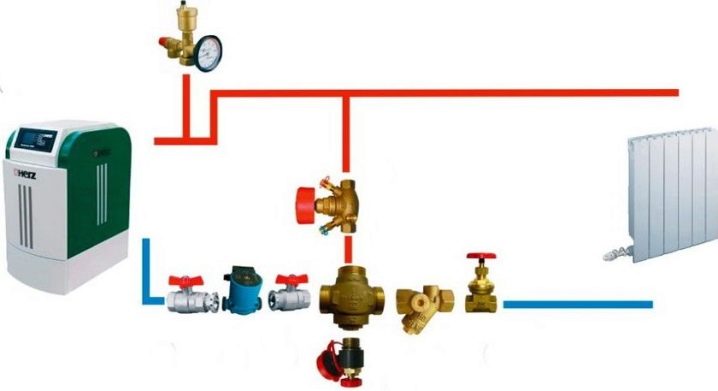

Wiring diagram

Having studied the design of the three-way valve, it becomes clear how it works.

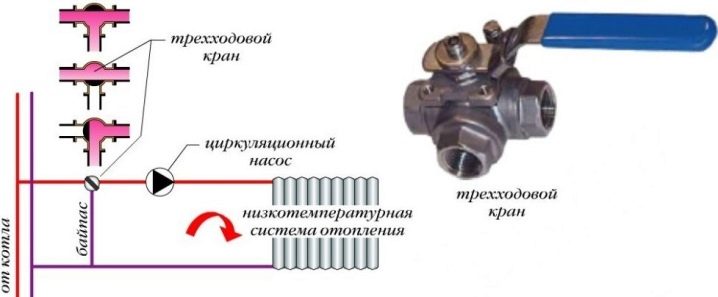

To a greater extent, the demand for a crane occurs in several cases:

- Protection of the heating boiler against condensation and possible temperature increase associated with power outages.

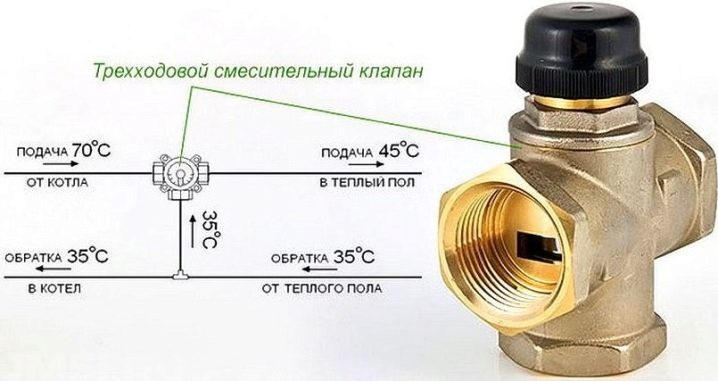

- In a warm floor system, a mixing valve monitors temperature fluctuations, where the maximum heating level is 45 degrees. In the event of an increase in heat, the device takes the necessary measures to reduce the temperature.

- The three-way valve maintains the required temperature at various points.

In order to preserve the thermal device from condensate occurrence, it is important to know that in the process of heating the boiler it is not possible to supply cool fluid from the radiator system to the tank.

The liquid begins to circulate in a small circle, passing through the bypass, and so on until the heat generator has warmed to its operating state. When returning, the water temperature is about 55 degrees, which means that a three-way valve should start working. It begins to open slightly and add cold liquid to the coolant. At the next exit, the bypass is blocked, and the main part of the coolant flows through the room radiators.

In a warm floor system, a three-way valve performs identical functions.The pump directs fluid along the contour of the flooring system until the temperature starts to fall. As soon as the temperature drops, a special device works, and the three-way valve immediately supplies the hot liquid.

When tying the heat generator and buffer tank, the three-way unit is an indispensable element in the connection system.

For a complete warm-up of the system in the shortest time, it is enough that the temperature in the coolant is 80-85 degrees. But for radiators this can be a critical condition. A three-way valve comes to the rescue, which can easily lower the temperature and save the system's working circuit.

When installing the heating system in country houses, where thermal energy passes from the TT-boiler, a simplified connection scheme is used. In this case, an independent three-way valve is installed. For effective work it will not need a thermal head and a temperature sensor. The control element for adjusting the coolant is mounted inside the valve and is immediately set to a certain temperature of the fluid at the outlet.The set temperature is indicated on the valve body.

Installation

When installing three-way cranes, you need to pay attention to the many nuances. Directly from these subtleties depends uninterrupted operation of the heating system. For each valve, the manufacturer has a special instruction, subject to which you can avoid trouble.

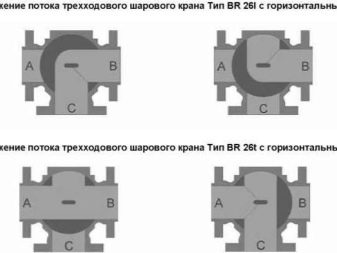

The most important thing is to install the valve in the right position. When installing, you must use the tips that are shown on the body of the product. They are presented in the form of arrows indicating the direction of water flow, as well as letters. The sign “A” indicates a forward flow, “B” indicates a perpendicular movement, “AB” indicates a connected inlet and outlet.

There are several types of valves, depending on the direction of flow:

- T-shaped scheme - water enters the faucet through the side entrances. After the merger, the coolant passes through the center hole.

- L-shaped scheme - hot stream flows from the side of the product, cold from the bottom. After connecting, water flows out through the second side opening.

Another important nuance - when installing a mixing tap, you cannot put the device head down.

Before starting installation, it is necessary to prepare:

- shut off the water supply;

- check the pipeline and get rid of possible liquid residues, which may cause poor performance of the three-way valve installation.

The valve must be installed in an easily accessible place so that in future it can be checked, changed or removed altogether. The installation of the mixing valve in the central heating system takes place in two ways, the choice of which depends on the type of connection of the heating system.

In the case when the temperature of the liquid in the return line rises, an overpressure appears. In this case, a special jumper is mounted, which throttles the excess pressure. It is installed parallel to the three-way valve.

It must be remembered, when installing some models of cranes, a small hum and a slight vibration appear. The reason for this is the incompatibility of flow movements in the pipeline and valve. For this reason, pressure may drop.

The installation of a separating valve facilitates mixing of flows, due to which at the final stage of the circuit in a radiator a standard temperature liquid flows, and not overheated.

Tips

To achieve maximum performance from a three-way crane, you must follow the instructions from the manufacturer.

Its installation is not complex, but still it is worth listening to some recommendations:

- When installing a three-way valve, you should not worry about its visible location. Installing a crane vertically or horizontally, the performance of the system will not change.

- When installing, pay attention to the front of the valve body. It will reflect the guide arrow, which indicates the direction of flow.

- It should be noted that for subsequent testing of the valve, its replacement or dismantling, it should be accessible. Therefore, it is necessary to pre-calculate and view a convenient place to install the crane.

- Installation of the valve can be done using a welding machine. To avoid possible ignition or smoke, it is better to clean the pipeline from debris beforehand.

- In addition, during the welding work it is impossible to prevent the crane from heating. To secure the product, it is necessary to provide a heat sink.

- In anticipation of the heating season, it is necessary to check the operation of the system.

Thanks to the high-quality three-way valve, which is integrated into the heating system without errors, it is possible to independently regulate the temperature regime of the heating devices, as well as to control and change the temperature of the heat and to refill the system in different rooms.

Detailed instructions for installing a three-way crane are presented in the video below.