Varieties and installation of two-pipe heating systems

Of the large number of options for distributing heating mains around the house, a two-pipe (dual-circuit) heating system is especially popular. It is stable in operation, practical, and easy to implement, especially if you use modern materials to install highways and batteries. If desired, the average user is able to assemble a similar heating system with his own hands, without the help of installers.

What it is?

The two-pipe heating system is a traditional heating system that has proven itself for many years of exploitation as well as possible.

The two-pipe heating system has recently been practiced more and more, and this despite the fact that the installation of a single-pipe system usually costs a little less.Such a model makes it possible to make temperature adjustments in each of the rooms at its discretion, since a specialized control valve is provided for this.

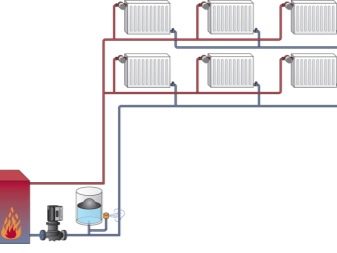

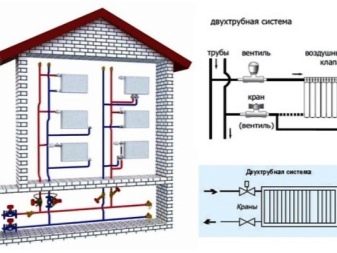

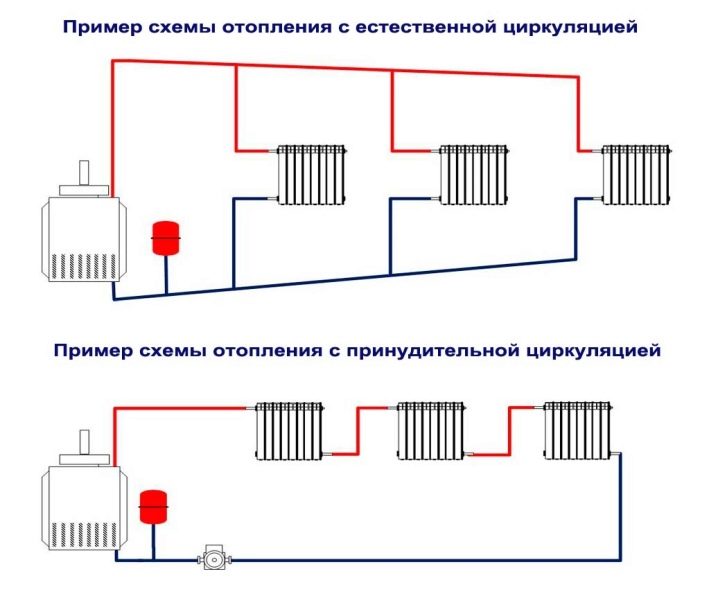

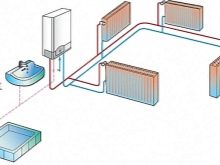

The two-wire heating system includes in its structure 2 branches of the heat carrier. The first line directly implements the movement of heated water through all components of the heating system, and after cooling, the second branch sends it back to the boiler, as a result, natural circulation is obtained. The great advantage of a two-wire heating system is the ability to supply the same temperature coolant to all distant points of the system, thus providing an even and excellent heat supply to all the rooms.

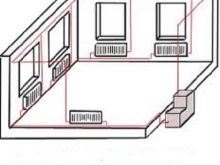

This heating system will organically fit into the interior, and if necessary it can be hidden at all.

Advantages and disadvantages

For the most part, single-loop and double-loop heating can be used for the same building. Regardless of the fact that the schemes with separate supply and return pipe gradually win back the positions, the first place is the efficiency of the two-pipe wiring.

The advantages of twin-tube heating are obvious:

- All heating devices are supplied with approximately equally hot heat carrier. There are usually no issues with the lack of heat for remote from the boiler or the general heating network of batteries.

- The system is easily hand-balanced. It is possible to install an automatic duct regulator on each of the heating devices, and this will not have negative consequences for the heating of the remaining radiators.

- It is much easier to arrange heating for large and complex structures. Two-pipe heating of a 2-story building or an apartment building is often the only correct solution in cases where it is sometimes impossible to implement productive single-pipe heating of a 2-story building at a technical level.

- Smaller diameters of pipes, stop valves, control valves and fittings are used. In addition, due to the relative stability of the pressure in the system and the optimal characteristics of hydraulic losses, pumps that create forced circulation (the coolant moves under the influence of pressure),may have a lower efficiency (such equipment is mostly cheaper and does not spend a lot of electrical energy).

- The autonomous connection of devices (with shut-off accessories to each radiator and detachable connections) makes it possible to install and dismantle them without shutting down the heating system. This is important for the maintenance of the battery, as well as, for example, in the process of repair, pierce inaccessible surfaces in a niche or stick wallpaper there.

The disadvantages that are attributed to two-pipe schemes:

- a lot of money needs to be invested in the project;

- two lines of thermal communication are more difficult to navigate along the structures of the structure than one;

- more technical requirements and more time is needed to complete the work.

There is a judgment that two-pipe wiring (due to doubled demand for pipes) nearly doubles the cost compared to one-pipe. This does not correspond to reality, since fittings, locking and regulating components will not require much more, in addition, pipes with a minimum diameter are usually used.Connecting batteries requires the same number of tees as when connecting heating devices in a single pipe system in parallel. The same set of regulating devices is used.

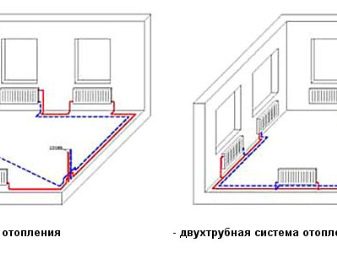

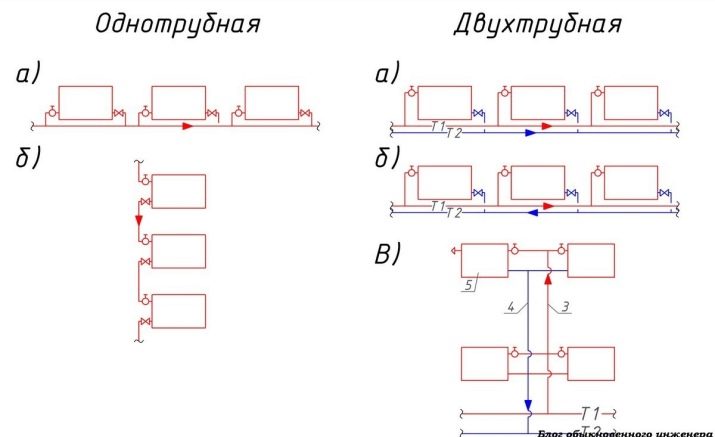

The main differences

Heating systems using a heat-transfer fluid are divided into 2 main types - one-pipe and two-pipe. The differences in these circuits are in the method of connecting the heat radiators to the main line. The trunk of a single-pipe heating system is a closed circular circuit. The heating main is laid from the heating device, the batteries are connected to it in series and pulled back to the boiler. The heating system with a single pipeline is simply installed and does not have a large number of components, therefore it gives an opportunity to save a lot on installation.

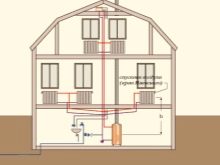

Monotube heating structures with natural movement of the coolant erect only with the upper wiring. Distinguishing feature - in the schemes there are risers of the supply line, but there are no risers for the return pipe. Movement of the coolant of the dual-circuit heating system is implemented on 2 lines.The first one is designed to deliver the hot coolant from the heating device to the heat-giving circuits, the second is for draining the cooled coolant to the boiler.

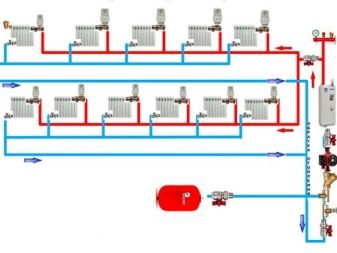

Heating radiators are connected in parallel - the heated coolant enters each of them directly from the supply circuitBecause of this, it has almost equal temperature. In the battery, water gives off energy and is cooled and sent to the discharge pipe - "return flow". Such a system needs double the number of pipes, fittings and fittings, however, makes it possible to organize complex branched structures and reduce heating costs due to individual regulation of batteries. The dual-circuit system effectively heats large rooms and multi-storey buildings. In low-rise buildings (1-2 floors) and houses with an area of less than 150 m², it is more rational to construct single-loop heat supply from both a financial and aesthetic point of view.

Kinds

All types of heating systems are divided into closed and open. An enclosed expansion tank is installed in closed boxes, which allows the system to perform its functions at high pressure.Such a system allows not only water to be used as a heat carrier, but also aqueous solutions, the basis of which is ethylene glycol, which have a low freezing point (down to -40 ° C) and are called antifreeze.

For the normal functioning of equipment in heating systems, specialized formulations should be used., created for such purposes, not general purpose, and moreover, not intended for cars. The same applies to the additives and additives used. It is especially strictly necessary to adhere to this principle when using expensive modern boilers equipped with automatic control - repairs for any faults in this case will not be guaranteed, even if the failure is not directly related to the coolant.

In the open-type construction, an open expansion tank is arranged at the top point. To it, as a rule, they connect a pipe to remove air from the system, and also arrange a pipeline for draining excess coolant in the system. At times, heated water can be taken from the expansion tank for household needs, but in such a situation it is necessary to make an automatic system replenishment, as well as not to use additives and additives.

For security reasons, more promising closed-end systems, so the majority of modern boilers are created for them.

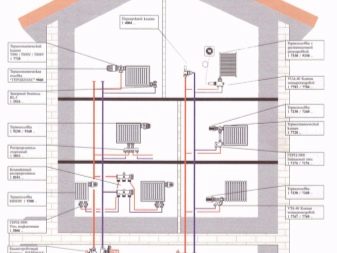

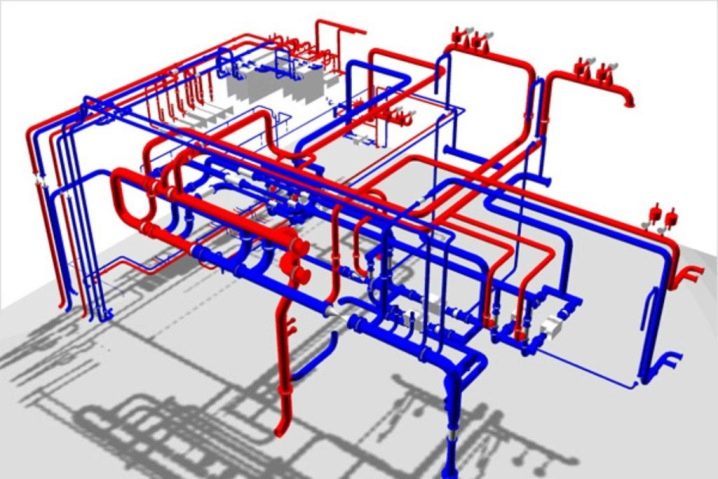

The division of the heating system into horizontal and vertical is determined by the location of the pipelines, which unite all the devices together.

Horizontal double-circuit heating systems are predominantly typical of a one-story or, at the most, two-story house with a greater length. In such buildings, it is more expedient to connect batteries to a pipeline that is laid horizontally. This method of heating is suitable for panel-frame structures, housing, where the wiring is carried out from risers located on the landing or in the corridor.

Dual-circuit heating systems of multi-storey buildings for the most part of a vertical type. Such a device costs more, but air jams do not prevent efficient operation. All devices in this case are connected to a vertical riser, and each of the floors is connected separately.

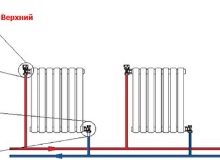

By the method of distributing the flow, the systems are distinguished from the bottom and from the top feed. With the upper wiring diagram, the pipe passes under the ceiling, and from it down the supply pipes run down to the batteries. The return pipe runs parallel to the floor. This method is attractive because you can easily build a system with natural circulation - the height difference forms a flow of sufficient power. To ensure a proper circulation rate, it is only necessary to withstand a slope with the required angle.

But such a system is gradually losing its popularity for aesthetic reasons. However, if you hide the pipes from above under the tension or suspended ceiling, then only the pipes connected to the devices will remain open, and they can, in effect, be immured into the wall. The lower and upper interchanges are practiced in vertical double-type systems.

In the lower wiring diagram, the supply pipe passes through the bottom, but higher than the return pipe. The supply pipeline can be placed in semi-basement or basement rooms (the return flow is even lower), between the finishing floor and the basis for the flooring of the finished floor covering, and so on. You can make the connection and discharge of the heat carrier to the batteries by pushing the pipes through the holes in the floor.At this location, the connection is the most hidden and aesthetic. But here it is necessary to select the location of the boiler: in systems with forced circulation, its location relative to heating devices does not matter - the pump pumps, but in systems with natural circulation, the batteries must be placed above the level of the boiler, for this purpose the boiler is lowered deeper.

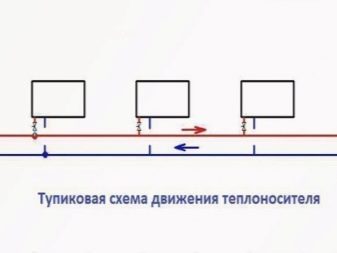

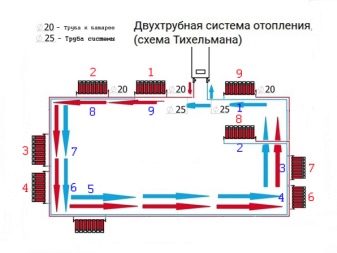

The counter system is a structure in which the movement of the heat carrier and the return flow are directed in different directions. In most cases, such a method of moving a heat carrier is practiced in their homes, as this makes it possible to select pipes with the smallest diameter. There is a system with a fair movement. She also referred to as a scheme or loop Tichelman. The system according to Tichelman is easier to configure and balance, mainly with long networks.

If there are batteries with an equal number of sections in the Tichelman scheme, it is an automatically balanced system, with the opposite scheme, it will be necessary to mount a needle valve or a thermostatic valve on each battery.

Even if in the Tichelman loop there are different battery sections in number, but valves are still needed to be installed, the prospect of balancing such a scheme is much higher than that of a dead-end one, especially if it is quite long.

However, the installation of a dual-circuit heating system is often implemented in a dead-end type. The reason for this is that in associated systems, the return pipeline has a large length and installation work is more complicated. Moreover, with a small heating circuit, the heat return from each radiator can be balanced.

If the contour is large, it can be divided into 2 wings. Nevertheless, it must be remembered that in order to form a system with two wings, it is necessary to start from the technical feasibility of its construction. In both circuits, valves must be installed to adjust the flow rate of the coolant. Balancing is not possible without valves.

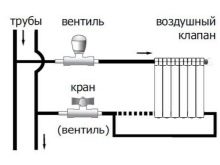

Forced circulation is realized by means of a pump supplied in the return pipe. Such a system requires the installation of air discharge valves Mayevsky or valves.For the natural circulation of the coolant, the pipes are laid with an obligatory slope; an expansion tank is installed in the upper part of the system.

Planning and calculation

When choosing the most optimal type of heating system for a private house, a summer house, it is necessary to take into account the area of the house. This is important, since, for example, the one-pipe scheme with natural circulation perfectly shows itself only in houses with an area not exceeding 100 m2. And in a house with a substantially larger quadrature, it will not be able to work due to a sufficiently large inertness.

It follows that the primary calculation of pressure in the heating system and the design of the heating system are needed in order to find out and design a system, the application of which in the house will be more rational. At the stage of preliminary drawing up a plan, you should try to take into account all the specifics of the architecture of the building. For example, if the house is quite large and, accordingly, the area of the rooms to be heated is also large, the most rational will be the introduction of a heating system with a pump that will circulate the heat carrier.

That is, for a longer service life of this type of equipment, it should be put on a return circuit, in which the already cooled coolant returns to the boiler for secondary heating.

At the same time there are certain characteristics that the circulation pump must meet:

- long period of service;

- insignificant level of electricity consumption;

- high power;

- resilience;

- ease of operation;

- lack of mechanical vibrations and noiselessness during operation.

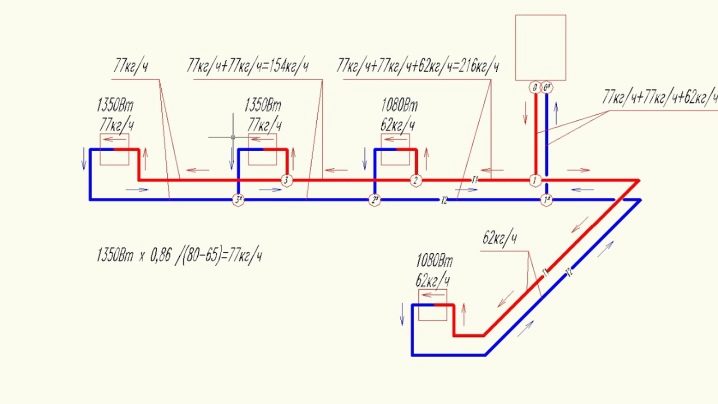

When planning a heating system, whether it is a private house or a multi-storey building, the most difficult and crucial phase is the hydraulic calculation, in which it is necessary to establish the resistance of the heating system.

Calculations are made according to a previously created heating scheme., on which all components present in the system are marked. They realize the hydraulic calculation of a two-pipe heating system using axonometric projections and formulas. For the calculated object take the busiest ring of the pipeline, divided into segments. As a result, an acceptable cross-sectional area of the pipeline, the required surface area of radiators, and hydraulic resistance in the heating circuit are established.

Calculations of hydraulic characteristics carried out by various methods.

The most common:

- Calculations using the specific linear pressure loss method, which provide equivalent changes in the temperature of the coolant in all components of the wiring;

- calculations based on resistance parameters and conductivity indices providing for variable temperature fluctuations.

The result of the first method is a clear physical picture with a specific distribution of all observed resistances in the heating circuit. The second calculation method makes it possible to obtain clear information on water consumption, on the values of temperature in each element of the heating system.

Assembly work

When working on the installation of a two-pipe heating system on its own you need to adhere to certain technological procedures:

- First of all, it is very important to navigate the choice of the heating system, which is provided for an individual house. Of course, the most optimal will be the installation of the system, the energy resources of which will be available and at the same time economical.Actually, the efficiency in heating a private house is currently very important for the majority of homeowners.

- If a gas supply is carried out to the house, you can install the water heating system equipped with two boilers without thinking about it, one of which is gas-fired, and the second one is back-up for solid combustible substances or electric.

- The next stage is to contact the design documentation development bureau. There the necessary calculations will be made, all the project documents are drawn up and the drawings for heating the house are made. After that, you can engage in the acquisition of the required equipment and materials.

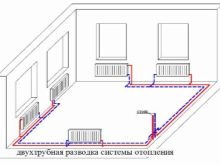

Let us analyze the installation process on the example of a one-story house.where we build the lower horizontal layout of thermal communications.

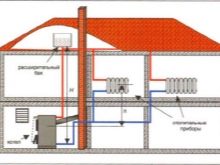

Let's start with the boiler (water heater), which must be put, taking into account its weight, on a solid foundation of concrete in a specialized room - the boiler room. It is desirable that this was a separate or basement room, equipped with good ventilation.

The boiler must be freely available, it is better to install it at a sufficient distance from the walls.The floor and adjacent walls around the boiler must be covered with fireproof material. The chimney from the boiler must be brought outside.

The capacity of the water heater is calculated according to the needs of 100 W per 1 m2 of living space.

A hot line is connected to the connecting pipe of the boiler, which is carried out further along the perimeter of the house with the connection of heating batteries. At the inlet and outlet of the radiators it is necessary to embed ball valves, which will allow the boiler to be turned off when the need arises. Also required is the installation of thermostats. Due to their presence, it is possible to adjust the required temperature or to block the flow of coolant on demand.

Near the exit from the boiler from the hot line, it is necessary to withdraw the vertical pipe to which the membrane expansion tank is connected, which corrects the pressure in the system when water is heated.

A branch pipe is diverted from each radiator, which is connected to the return pipe, which runs parallel to the hot line and eventually connects to the boiler inlet pipe.

The method of connecting pipes to highways and radiators depends on the material from which the pipes are made. If it is polypropylene, a specialized welding machine will be required.It is easier with metal-plastic pipes, - all connections are made through brass transitional connections, as a result, this option is easier to do with your own hands.

There should be no direct and acute angles in the highway, as resistance will increase. Valves and faucets must match the size of the pipes. When building a system with top wiring, the expansion tank is placed in a warm attic.

Connection

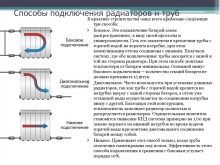

In dual-circuit heating, one of three methods of connecting batteries is used: one-sided, diagonal or lower. The best method is diagonal connection. So it is possible to achieve maximum heat transfer from heating equipment (up to 98% of the nominal value).

The general scheme of pipe wiring and the connection of heating appliances, a boiler and locking devices for a one- or two-story house might look like this:

- With all the differences between the ways of connecting the batteries, they are all used in practice, but with different tasks. In particular, the connection by the lower method is not very productive, but this is a good option if the pipe needs to be placed under the floor.

- Hidden pipeline laying can also be used in one-sided and diagonal schemes, however, in these cases, large sections of the pipeline will remain visible, which can be hidden except under the wall cladding.

- Connecting side-type batteries is practiced with a number of sections limited by 15 elements - in this case there is almost no heat loss.

If the number of sections is more than 15, a diagonal connection method is required, since only such a method is capable of ensuring the normal circulation of the thermal carrier and the heat release.

Balancing

The purpose of this procedure is to compensate for all the lines in the system and adjust the flow of coolant in each of them.

The balancing process includes a test system start-up, air bleeding by means of Mayevsky cranes (air bleed valve STD 7073V (according to TU 36-710-82)), temperature and pressure check. The optimized operation mode is set according to the temperature by means of balancing valves, taps or in accordance with the coolant flow rate, using electric flow meters for this purpose,connection of which must be carried out by means of balancing valves. More precisely, the temperature can be corrected by thermostats.

The initial start-up of the boiler is allowed only after a documentary permission from the gas industry and in the presence of one official of this organization.

Of course, this article describes the procedure for creating a two-pipe heating system is relatively shallow. In practice, this work is quite complex and is associated with numerous calculations that are available only to specialists. As a result, it is better to still instruct them to choose a system diagram and implement a heating system arrangement for them, although it is clear that I want to do everything myself.

About the two-pipe heating system with their own hands, see the following video.