Heat pumps for home heating: device, rules for selection and installation

Quite often, the owners of private houses that do not have central heating are upset that the rooms are heated unevenly. To avoid this, install a circulating pump for heating. It is this equipment that affects the level of comfort of the residents, so its choice must be taken seriously.

Characteristics and principle of operation

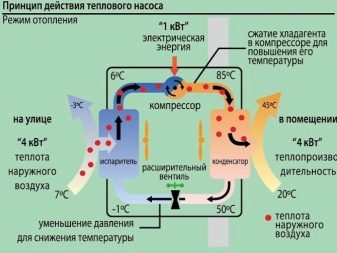

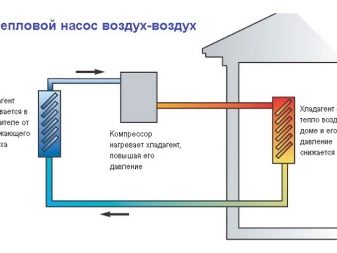

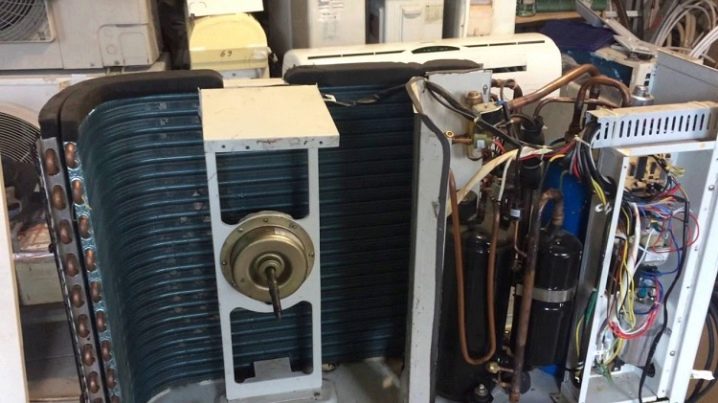

In a simplified form, the pump device is very similar to the design of the air conditioner, only on a larger scale. It does not require a fuel boiler.The essence of the work - the pump transfers heat from a source with a small charge of energy to the coolant, which has a high temperature.

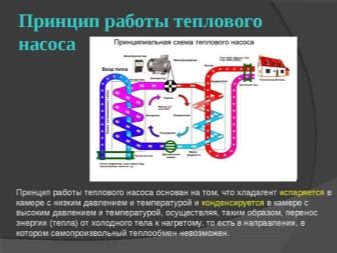

In reality, a polypropylene system works like this:

- The coolant is transported to a pipe hidden in the soil or elsewhere, and its temperature becomes higher.

- The coolant is transferred to the heat exchanger and transports energy to the circuit.

- There is a coolant in the outer casing - this is a material with a minimum boiling point with low pressure. In the evaporator, the refrigerant temperature rises substantially and it is converted to gas.

- The gas circulates in the compressor, and under the influence of high pressure, it contracts and heats up.

- Combustible gas is transferred to the condenser, where the energy flows to the coolant of the internal heating system.

- As a result, the refrigerant, whose temperature decreases, re-enters the inside in a state of liquid.

Refrigeration structures work according to a similar scheme, so some types of systems in the summer can be safely operated as air conditioners.

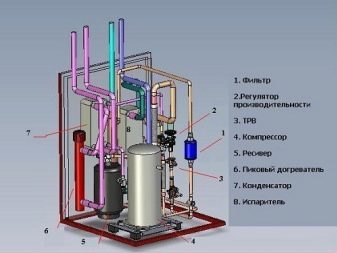

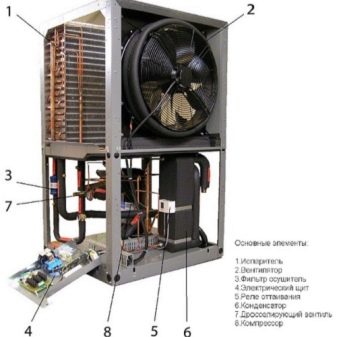

The design of volatile heating devices has 3 main components:

- Compressor.Designed to raise the temperature of the vapor and pressure, which are formed due to the boiling of the refrigerant. Today, spiral compressors are popular, which can be operated in freezing temperatures. Elements of this type work quietly, they are compact and light weight.

- Evaporator. In it, the liquid refrigerant is converted to steam, after which it is transported to the side of the compressor.

- Capacitor. It is used to give energy to the contour of the heating equipment.

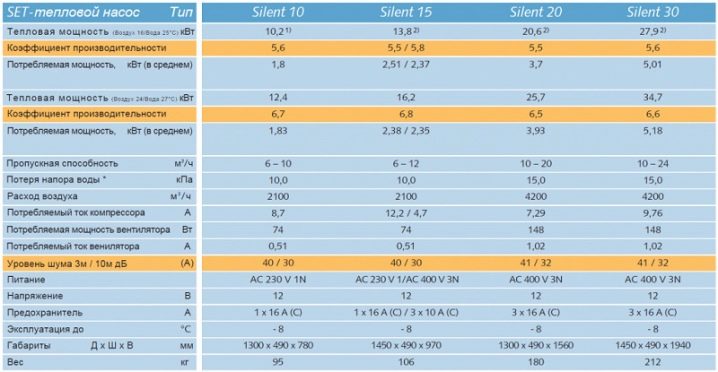

For the operation of the pump you need to connect to the mains, but the performance and power of this equipment is much higher than the electric heater, and the cost of electricity is less. The heating coefficient depends on the type of equipment.

The pumps also differ in power - the 12-volt designs are in demand.

Advantages and disadvantages

Installation of the pump and its connection to the heating system has several advantages:

- Autonomy - from the centralized element it is worth allocating only connection to the power supply network.

- Substantial savings on expensive energy carriers, they are used for heating and allow you to reduce financial costs for utilities.From 1 kW of electricity, the device produces from 3 to 7 kW of heat - these are the highest ratios among boilers that operate on different types of fuel.

- Environmental safety - the equipment does not harm the environment or the health of residents.

- Fire resistance and non-flammability of elements. Such a pump does not overheat, does not burn and does not emit carbon monoxide.

Accordingly, it is safe to operate at home, does not cause discomfort.

- The equipment can cool or raise the temperature in the room, creating the necessary microclimate in the room. It is suitable for use in both winter and summer.

- Long service life - on average, the system can last 40-50 years, and with proper installation and comfortable operating conditions, the period increases by another few years.

- Noiselessness during operation - the system is controlled automatically, which is very convenient.

- Installation of the pump does not require permission, such as the installation of gas equipment. You can buy and install any model of the device at any time, without going through various instances and without waiting for permission.

But like all equipment, such pumps have disadvantages:

- The purchase and installation of the device is quite expensive, and not everyone can afford it. The payback of the equipment depends on the intensity of its use. But even in the best case, the purchase will pay off at least 5 years.

- For installation, you should seek help from specialists. Drilling and other equipment is necessary for arranging a geothermal pump with a vertical contour with a depth of up to 200 m. You can install it yourself if you have the necessary knowledge and tools.

- In regions where the temperature in winter is below -15 degrees, it is necessary to use another heat source. For example, a bivalent heating system, where the appliance heats the room, while on the street -20 degrees. When he does not perform his tasks, an electric heater or gas boiler is turned on.

Circulation pumps are in demand among homeowners and companies that are located in low-rise buildings. These devices have earned only positive feedback.

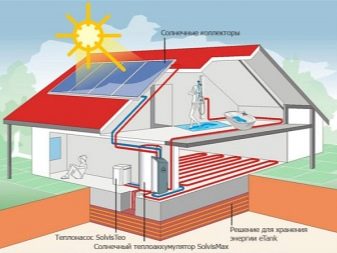

The use of heat pumps for home heating is, above all, a significant financial savings.The most effective is the heating system on the ground heat pump. Each month, the cost of it is much less than the cost of gas or pellet heating. By installing a heat pump, the user receives in one design and air conditioning, and efficient heating of the house. Some models can be controlled from a distance, for example, using a smartphone via the Internet or using a thermostat located in the house. And by installing solar collectors or batteries, you can make the system completely autonomous, and the increase in energy tariffs will not bother you at all.

Kinds

Depending on the operation, they emit absorption and compression heat pumps. For the work of the second, another energy source is needed, and the first model makes it possible to fully exploit the heat to perform all the tasks.

First of all, the pump group is divided by the source of heat extraction:

- geothermal systems - closed and open type;

- air;

- from the exploitation of secondary heat.

The first two types are successfully used for space heating by heat extraction from groundwater or air,and the equipment of the third type is suitable for operation only in industrial premises, where it has recommended itself from the best side.

For the comfort of customers, heat pumps for heating a country house are also divided by circular heat carriers, which are used in the inlet circuit and go to the return pipe. Each of the types listed below is distinguished by its installation, it is operated in various regional conditions,

They have their advantages and disadvantages, which are described below:

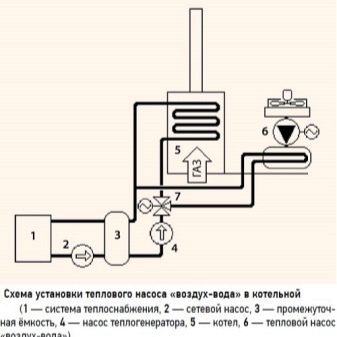

- "Air - air." The best option for buyers. The essence of the work of air design - taking heat from the air, the system immediately lets it into the rooms. This type is used for space heating or for heating water. Sometimes you can turn it on in order to reduce the temperature of the air, this option is ideal for hot summer children. The air-to-air devices function very quietly. They are equipped with improved ventilation.

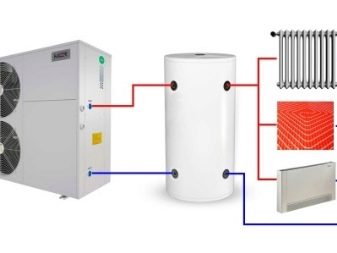

- "Air is water." The essence of the functioning is very similar to the air-to-air system. Differs in easy installation, it is not necessary to carry out works in the earth and costs relatively cheap.In the heating circuit of the structure there is a continuously circulating fluid supplied to the return pipe, due to which it is appropriate to use such pumps for the operation of the heating system.

- "Ice - water." The model is not claimed, but is adapted for operation in Russia. It functions according to the principle of the “air - water” model, only with cooling does frozen water apply. The resulting energy is enough to complete the tasks

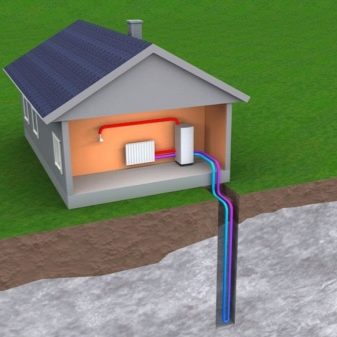

- "Soil - water." High-quality device, which for its operation uses the heat of the planet. But for high-quality pump operation, pipelines must be laid in the soil where the circulation process of the fluid will take place. This is necessary so that the soil, which gave up the heat, warms up, and the pump further functions. Such a model is expensive.

- "Water is air." Heat pump for heating a private house, which needs warmth of ground and other waters for operation. In this equipment, heating is performed with the help of air. This is not the best choice for home.

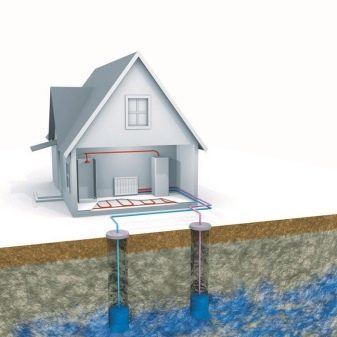

- "Water - water." Recycling device with the best performance, whose work consists in the use of groundwater and other waters with a constant temperature.

It is best of all if there is a reservoir on the site, but two wells can be made - this will be enough for the operation of the water pump.

Each type of equipment has several pros and cons. Some models are suitable for specific sites, and some are characterized by low efficiency in specific regions. That is why the choice of such equipment should be made taking into account all the nuances, operating conditions. In order to choose the right model, it is recommended to carefully study all the criteria or to seek the help of professionals.

Criteria for choosing the right one

Pump selection is a serious and responsible process. In this procedure, it is necessary to take into account the heating medium heating medium in the primary circuit. The choice also affects the temperature where the equipment will operate. The coolant temperature must be at least 6 degrees, otherwise the pump will not provide the desired efficiency.

A huge impact on the quality of the equipment has a place of installation. It is advisable to install the system in a dry heated room.This will avoid additional heat costs.

In order to correctly choose a heating device, it is necessary to take into account such nuances:

- necessary for the operation of the power equipment;

- heat efficiency coefficient.

To accurately select the equipment, it is recommended to use the following scheme:

- If the territory is not more than 15 acres, and the building is not more than 100 m2, it is recommended to choose an air-to-water or air-to-air pump for heating.

- If the area is about 20 acres, and the area of the house is up to 250 m2 and the rooms in it are large, it is better to install an air-to-water device. But such equipment is suitable for home use only if the floor is insulated or a high-power radiator is attached to the system.

- If the area of the house is more than 250 m2, then in this situation it is appropriate to use a geothermal pump with a large heat exchanger for the premises.

It is better to install it in several wells with a depth of at least 80 m.

The effectiveness and performance of the equipment depends on its configuration. New types of pumps are complemented by various functions and devices, such as the option of drying.

If the selection of a heat pump for water circulation is made taking into account all the requirements and features of the site, then the house will always have a comfortable atmosphere, regardless of the weather. In addition, you can save your budget. Consider, if the purchase of the system was expensive, after a couple of years of intensive use the equipment will pay for itself.

When choosing equipment, it is also worth considering user reviews - the system with the highest rating will delight you with its work.

Payment

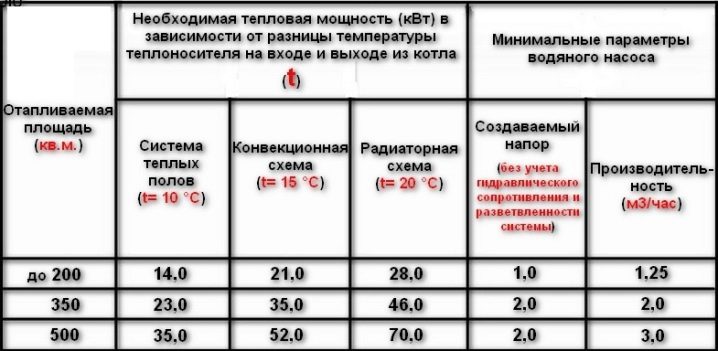

Having understood the work of the circulation pump, it is necessary to correctly calculate its power. This process is not as simple as it seems at first glance. It is better to entrust it to professionals, but you can do it yourself. Pump power depends on the area of the room, which it will heat. For example, if a building with an area of 200 m2, then for its heating you will need 20 kW of power. To ensure the optimum temperature in the room, it is necessary to adhere to the following ratio - 1 kW of thermal energy per 10 m2.

Then it is necessary to calculate the temperature difference at the flow and return flow. It is best to choose an indicator of 10 degrees.

The calculation of the pump is also performed on the volume of the required heat, power consumption and the maximum temperature level.

How to install?

Heat circulation pumps are expensive, moreover, the high price is set on the installation of equipment. You can save money by installing the pump yourself. But always remember that if some stage of the installation is done incorrectly or made a mistake, this can lead to a loss of efficiency of the structure.

During self-installation, you should remember the following nuances:

- The entire pump is a single system in which each component is very important for the operation of the equipment. There are no extra details.

- When drafting a device, be sure to consider its technical features.

- The depth of the wells must be chosen according to the capacity of the equipment. It is necessary to carry out tamponazh.

- Geothermal probes, which are used to operate in a harsh climate, are best done in each well.

- Batteries, convectors, underfloor heating system should work in conjunction with the pump to ensure high-quality space heating.

- Underground collectors can harm the plants growing in the garden, about this nuance in no case should not be forgotten during installation.

- Equipment can be installed not only in the basement, the installation of two pumps or an additional pump can be planned in the bathroom or in the kitchen. But do not forget that even the minimum noise during the operation of the structure is available.

- Once a week, the collector must be heated to 60 degrees in order to prevent the proliferation of bacteria in the system.

The installation of the pump and installation at the end of the circuit is as follows:

- First of all, it is necessary to prepare all the structural elements, equipment and materials. It is necessary to take a set of keys, and it is recommended to seal the thread connections with tow or paste.

- Assemble and pack on tow 3 knots - two for mounting the pump “loop” and one is a crane, on one side of which there is an outlet for return, and on the other side is a jack.

- Assemble the "loop" of the pump, the nuts "American" with gaskets must be strongly scrolled, but not tighten.

- Cut off the end of the return pipe must be set exactly on one axis, in some cases it is necessary to make stops or supports.After that, it is necessary to note the areas where the pipes will be mounted on the body of the return pipe. Then you can start welding all the joints.

- The lower part is being assembled - the docking and packing of the wedge. After that, fix the pump in the designated area, adjust the axis of its rotor horizontally and securely tighten the American nuts with gaskets.

At the end of installation, make sure that the equipment itself is installed without errors. The flow direction arrow must match the actual coolant flow in the pump. It remains only to connect the equipment to the mains and check its operation.

How to do it yourself?

Understanding the scheme and features of the action of the heat pump, you can easily assemble it and install it yourself. Before embarking on an independent assembly of equipment, it is necessary to carefully calculate its main parameters. For this procedure, you can use software to optimize cooling systems.

The easiest way to do this is an air-to-water pump. The works are coming up quite simple, and even a person without special knowledge and skills will be able to independently make this model.For installation, only two channels are needed - air will circulate through one of them, and the second will output working off.

You will need to purchase a fan and compressor of suitable power. You can use a compressor designed for split systems. It is not necessary to buy a new part. If you have old equipment, you can remove the compressor from there, for example, from the refrigerator. Experts advise the use of a spiral type, which is characterized by efficiency and increased pressure.

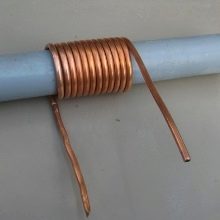

To assemble the condenser, it is necessary to prepare the tank and the copper pipe, from which it will be necessary to make a coil. For its production, an optimum diameter cylinder is used, which can be coiled into a pipe. The finished component is installed in a container pre-cut into two even parts, for the production of which it is necessary to use materials resistant to the formation of corrosion.

After the coil is mounted in the designated area, the halves of the tank must be welded.

To find out the area of the coil, it is necessary to multiply the coefficient of thermal conductivity (0.8) by the temperature difference of the liquid,after which the power of energy divided by the resulting figure. When choosing a pipe for the coil be sure to consider the thickness of the walls. It should not be less than 1 mm. If you choose a smaller thickness, then when wrapping the pipe will lose its shape. The pipe through which the refrigerant enters is installed on top of the tank.

The equipment evaporator can be produced in the form of a coil tank and in the form of a pipe in a pipe. Due to the fact that the temperature in the evaporator does not reach too high a temperature, the container can be made of plastic. It is necessary to install a contour made of copper pipe into it. It is important that the coil helix be selected according to the thickness and height of the tank. If the evaporator you do according to the “pipe in pipe” method, it is necessary that the coolant pipe be installed in a large plastic pipe, and the liquid will move along it. The length of the pipe is influenced by the power of the device, and on average its dimensions are from 25 to 40 m. It is shaped into a spiral.

Thermostatic valve is part of pipeline fittings. The locking part is the needle, its position is influenced by the temperature in the evaporator. The design of this component is quite complicated.All components may become faulty due to elevated temperatures. That is why the valve must be separated from the negative effects of asbestos cloth.

After all the parts are made separately, you need to do the assembly of all components into a single unit. The most serious procedure is the injection of coolant or coolant into the design. This work cannot be done independently, as special equipment is needed. And the wrong process can lead to system failure or even injury.

It is better to immediately seek help from specialists. They will not only do the specified work, but also check the operation of the equipment.

Great attention should be paid to the choice of refrigerant - this is the main substance that transports the useful thermal energy. Freon is in demand. Specialists recommend choosing this type of refrigerant.

If all of the above works are done correctly, you will have a closed loop device where the refrigerant will circulate, taking and transporting thermal energy from the evaporator to the condenser.

When connecting equipment to the heating system, remember that the fluid temperature at the outlet is a maximum of 60 degrees.

Due to the fact that the temperature of the energy is low, the consumer of heat can be different heating devices - a heated floor, aluminum radiators. Self-made pumps will be an excellent accessory that will improve the performance of the main heat source.

The market is offered annually by upgraded heat pumps, whose performance is constantly improving. Moreover, modern models do not harm the nature and human health. There is no open flame in the pumps, so their work does not constitute anything dangerous. Both during installation and operation with the system there should be no problems.

Possible faults

The heat pump is equipped with a simple design, so if it suddenly stopped working or its performance has weakened, you can try to repair it yourself, without the involvement of specialists. Serious equipment malfunctions include wear of the turbine wheel, damage to components, or electrical circuit breakdown.

To see what is wrong with the system, you need:

- disconnect the pump from the mains;

- if the pump is installed in the bypass or there are taps on both sides - stop the flow of liquid, remove the equipment from the installation site;

- If repairs take a long time, experts recommend connecting an additional pump.

If in the heating system it is impossible to stop the transportation of fluid in the area where the pump is located, the masters advise to drain the coolant before starting repairs. This procedure allows you to quickly perform commissioning work on the traditional scheme.

Among the most common faults of the heat pump are:

- The equipment is buzzing, but the coolant does not circulate. This happens if the device is out of work for a long time. To bring the pump to a working condition, it is necessary to disassemble it, remove the case and the electric drive. Using a screwdriver, turn the rotor and make sure that it rotates freely. Install the pump and turn it on, check operation.

- Noise during operation - this could be caused by clogging of the motor shaft and the turbine wheel unit.To eliminate this malfunction is easy - you need to disassemble and remove all debris from the structure. In order to prevent future clogging of the device, it is necessary to install filters at the pump inlet, and if the pump is not turned on, then at least once a month it must be run for half an hour to drive the coolant through the system.

- The device does not turn on. This may be due to several reasons. Most often it is a power failure, in this situation it is necessary to check whether the power cable is not damaged. Another cause of failure may be the inclusion of a protective mode. To eliminate the problem, replace fuses or other parts. Before turning on the pump, evaluate the state and parameters of the power supply network.

- The pump turns on, but after a while it turns off. Most likely, the reason for this is the failure of the maximum load. Over time, a scum appears on the wet rotor, which impairs the operation of the device. To resume the operation of the equipment, it is necessary to disassemble it and remove all deposits. Assemble the structure into a coherent whole and check its performance.

- During operation, the device is very noisy, clicks and vibrates.This indicates that air is accumulating inside. This malfunction appears due to the fact that commissioning works are performed incorrectly or the level of cavitation is exaggerated. To restore the operation of the pump can adjust the parameters of the heating system.

All air plugs must be removed from the pipes, the same procedure must be performed by a valve on top of the system case.

- The device vibrates strongly - this may be due to the wear of the bearings. Even with excellent parameters of the coolant bearings sooner or later wear out. For a particular model there is a certain service life, which can be learned from the passport details. Note that to get the bearing, which is located in the equipment, you only need a special puller. And you need to re-do the installation using a wooden mallet. The new bearing is installed on the corresponding site and is hammered by light blows.

- Low pressure - sometimes such a malfunction is due to the fact that an incorrect rotational speed is established, which is often found at increased viscosity or a long pipeline length.You can fix the damage by re-adjusting the device or by replacing the model if it was chosen incorrectly. Three-phase pumps may generate low pressure if they are connected incorrectly.

Therefore, the first step in detecting a malfunction is to check the phasing, the state of the neutral wire and the mains voltage.

Remember that you can repair the device yourself.therefore, each owner is recommended to know how to disassemble and clean the structure. It would also be nice to have knowledge of all components of the equipment, their principles of operation and, of course, their purpose. But note that if the above methods do not help to restore the system, you should seek the help of specialists. They possess not only the necessary knowledge and skills, but also the appropriate tools. Appeal to the masters allows you to avoid deterioration of the situation in the operation of the device, so if you are not confident in their abilities, it is not worth the risk. Otherwise, you have to spend a lot more money.

The heat pump is expensive, and this equipment will pay off at least 5 years from now.But it is important to remember that this equipment is characterized by long service life, reliability and convenience, so the purchase of the system is a profitable investment.

The heat pump can heat a house of any size, even if it does not have gas and electric networks.

This device has high performance, fireproof and works automatically, it does not harm neither nature nor the inhabitants of the house. Systems can also be successfully operated in bivalent systems. Additionally, you can mount the solar collector, which will give the pump electricity in the summer, and he, in turn, will cool the room. And for the winter operation of the pump, you can also use a heat generator, which will increase the temperature of the liquid for high-temperature radiators.

Years of experience in the operation of heat pumps proves that this method of home heating is the most efficient, economical and reliable. Once the equipment is installed, you can enjoy its work both in winter and in summer, and make sure that you are right with your choice.

See how the heat pump works and how it works, see the video below.