Hydro arrows for heating: principle of operation and connection

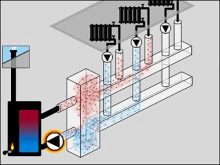

There are complex heating systems, which includes several circuits. Moreover, these lines are designed completely for different equipment with different technical parameters, for example, coolant temperature and pressure. Such a multitasking challenge to the engineers seemed to be an unsolvable task - to establish the stable operation of each link of the autonomous heating system. so indispensable in a multi-circuit heating system.

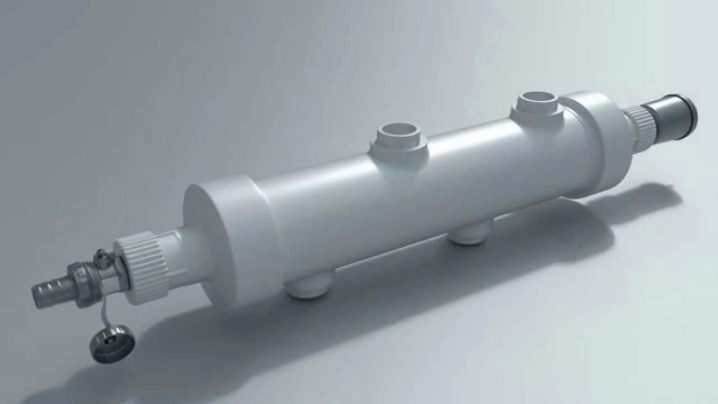

This device is called a hydraulic separator, or otherwise,shooter. The main task of the hydraulic separator is the separation of heat carrier flows along the highways. In other words, it is a hydraulic buffer. In more detail about its device and the principles of work we will talk below.

What it is?

One of the components of the heating system is an element such as a hydraulic needle. It is installed before and after the boiler, and its main function is to equalize the pressure and temperature in the system.

Installation of the heating system is always associated with one problem - its unstable work. Each device must perform its function and not affect the adjacent links of the system. And if there are many contours and branches in the system, then its adjustment becomes a complex task.

As a rule, each circuit is characterized by bandwidth, coolant pressure, temperature gradient and thermostatic control circuit. To make the work of all these devices harmonious and stable, use the hydraulic separator heating.

What is it for?

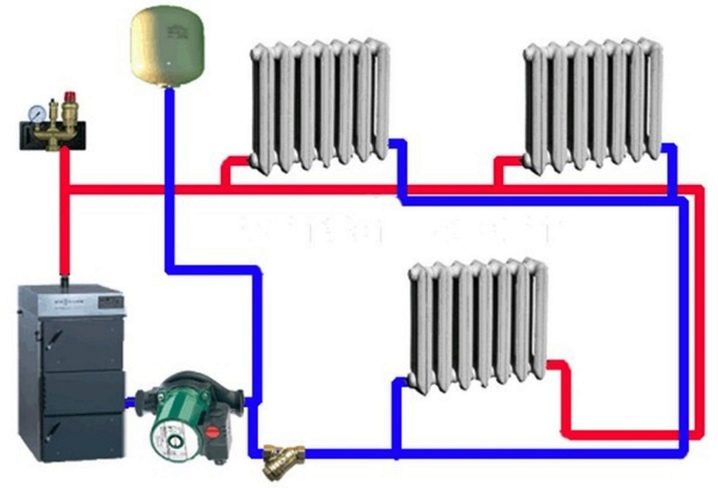

To find out for what purposes the hydraulic switch is used, it is necessary to understand the principle of functioning of the simplest heating system with forced circulation of the coolant.

The main components of the above scheme are:

- boiler;

- radiators or convectors that are placed on the same circuit (the number of heaters may be different);

- pump - a device with which the heat carrier circulates through the highway.

In addition, the system also includes other elements, for example, an expansion tank, but we will not focus on them, since they are not so important for explaining the principle of the hydrotreater.

Note that the choice of the pump is very important for the normal operation of the autonomous heating. The choice of this device depends on various factors: the length of the circuits, the technical parameters of the heat exchange devices, the thermal power of the system.

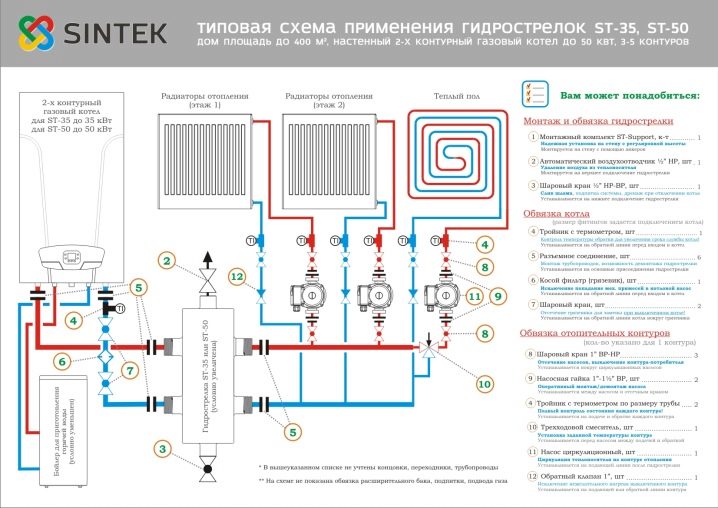

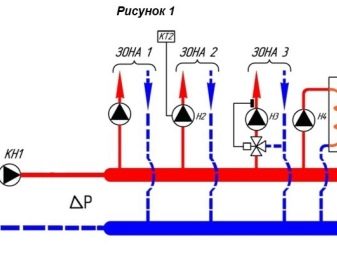

The scheme described above is suitable for a dacha or a small house, but if the building has a larger area or several floors, then a more complex heating system will be required using a collector scheme.

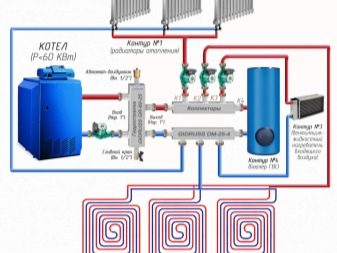

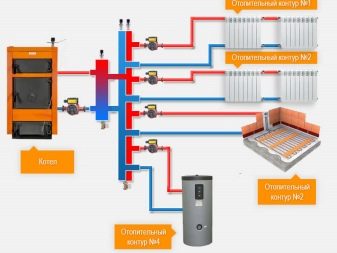

The diagram shows that the following devices are connected to the collector:

- Contours with a different number of radiators. The contours may be several and their length may also differ from each other (in the diagram P).

- Systems of water heat-insulated floors to which other temperature parameters of the heat carrier are presented. In addition, the length of warm floors is much more contours, which increases the level of hydraulic resistance (in the scheme of the STP).

- Indirect heating boiler. The task of this equipment is to provide hot water. Completely different requirements are also placed on the boiler (in the BGVS scheme).

You do not need to be an expert to understand that one pump cannot cope with all components of an autonomous heating system, even if it is of sufficient power. It is worth considering that too powerful a pump will create increased pressure, and this will adversely affect the operation of an expensive boiler and lead to a reduction in its service life.

The factor is also taken into account that each individual circuit is distinguished by pressure and other technical characteristics. Therefore, using a single pump, it is impossible to achieve a coordinated operation of the system.

What if you try to use not one pump, but several? That is, a separate circuit will be equipped with its own pump. Alas, such a decision would not save the situation.On the contrary, it may lead to other malfunctions in the heating system.

For normal operation of several circuits, maximum precision in setting up the pumps is necessary., but to achieve a similar effect is impossible. This is explained by the fact that such quantities as head, capacity and degree of heating are variables. There are many situations in which one circuit can affect the state of another. They can manifest themselves in different ways. For example, the pressure or temperature of the coolant will change dramatically, but in any case, the effect will be negative. Such disorders will adversely affect the pump and the state of the boiler.

It is known that a collector is responsible for the separation of hydraulic systems. But is it possible that the contours of the boiler were autonomous? This means that the boiler must supply a certain amount of heat carrier for each circuit, and the circuit, in turn, would receive a certain amount of liquid.

This task is very real. To do this, you must select a small contour of the boiler, which is carried out using a hydraulic distributor. That is, this element can change the direction of the coolant when it is required for the correct operation of the heating system.

How does it work?

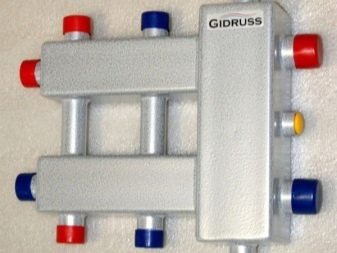

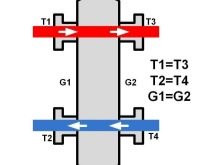

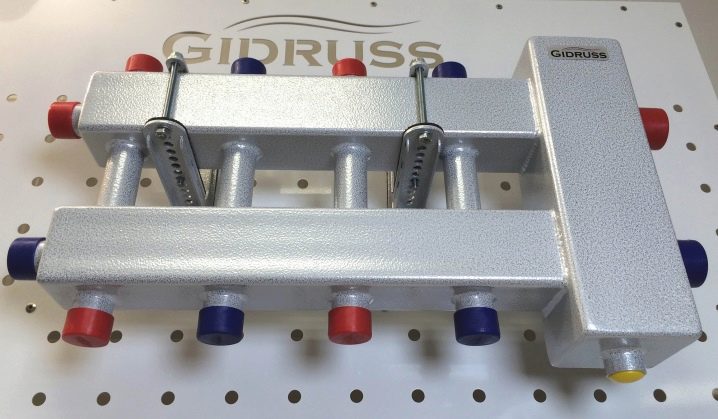

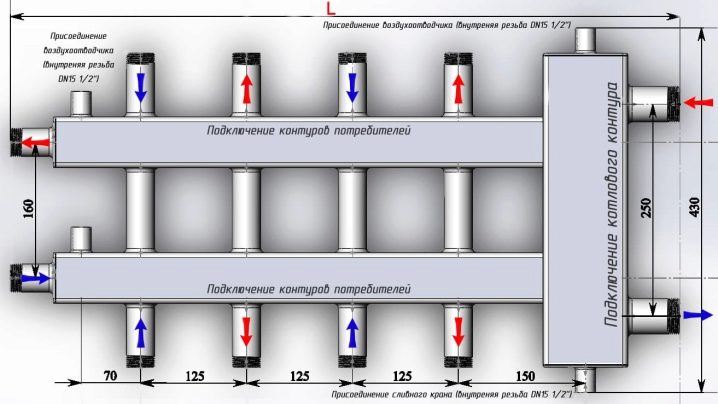

Although the hydraulic needle is very important in the heating system, its structure and design are quite simple. This is a fragment of a round or square pipe, in which there are two openings on the side of the boiler and the same number of openings on the side of the heating system. To prevent the hydraulic separator from clogging, it can be equipped with a mesh filter that traps the debris formed in the coolant. After a certain period of time, the nets may become clogged and will need to be cleaned.

Installs the device in a vertical or horizontal position, but it does not really matter. However, most often the hydraulic needle is mounted vertically, since it allows you to additionally install an air vent in the upper part, and a valve through which the garbage is removed at the bottom of the device.

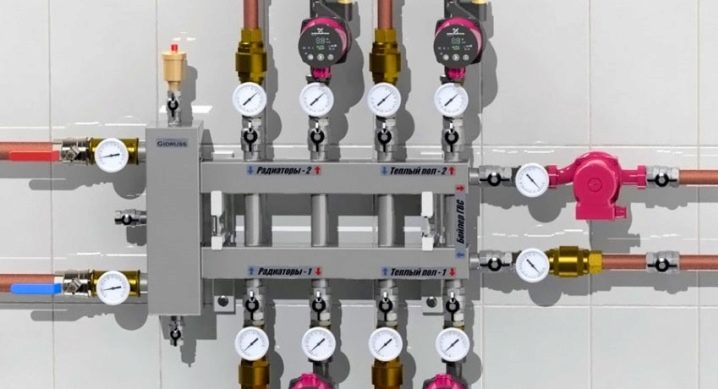

Using this device, it is possible to separate the hydraulic systems of the heating unit and the heating system itself. Moreover, the hydraulic separator is allowed to be used with a collector for four, three, two circuits and with one boiler branch. The contour of the heating system and the boiler get their hydraulic mode.

Choosing a hydraulic needle, you need to understand its principle of operation and the advantages that it has:

- provides good performance, minimal pressure loss and performance;

- creates hydraulic balance and necessary temperature conditions;

- protects against heat shock;

- saves energy;

- lowers hydraulic resistance.

In this equipment, there are additional features. In advanced models of factory production, there are temperature regulators and separators. A special temperature control valve controls the temperature gradient for the different circuits of the heating system.

The valve for the removal of air removes oxygen bubbles from the device, thereby saving the rest of the equipment from corrosion, prolonging its period of use and ensuring its stable operation. The same applies to filters that trash garbage.

Inside the hydraulic separator, a device with perforated partitions is provided. They are necessary for dividing the internal space in half in order not to create excessive resistance.

Materials

Hydraulic separator Made from the following materials:

- stainless steel;

- polypropylene.

The device can be made independently, but for this purpose it is necessary to have professional skills. Factory shooters have a complex device and include elements such as filters and sensors.

In addition to stainless steel and polypropylene, there are also hydraulic separators made of copper. Due to the availability and cheapness of the material, polypropylene products are increasingly common. But it is worth knowing that polymer hydraulic dividers can only be used with boilers whose power ranges from 14 to 35 kilowatts. Regardless of the material, the device is connected to the heating line with threads and flanges.

How to choose?

To select a hydraulic separator, you need to know what types they are and what are the parameters in your heating system.

Hydraulic separators are classified according to the following criteria:

- cross section are round or square;

- by the method of feeding / removal of heat carrier;

- the number of pipes;

- by volume.

Before you buy this device, you need to know the total power of all circuits of the system,as well as the volume of coolant.

The country of manufacture of the device is also important. It can be Russia, the CIS countries and the near abroad. However, all products have a similar scheme.

For example, we give the labeling of the hydraulic marks of the “Hydrouss” trademark:

- GR-40-20 - appointment - for boilers with a capacity of up to 40 kilowatts with a three-quarter connecting pipe size;

- GR-60-25 - for boilers with a boiler power of up to 60 kilowatts with a one-inch connecting pipe size ”

- TGR-40-20x2 - for boilers up to 40 kW with a three-quarter connecting pipe size;

- TGR-60-25x2 - for boilers with a capacity of up to 60 kilowatts per two consumers with a connecting pipe size of one inch.

In the last two markings of circuits in the heating system there may be not two, but more. It should be noted that hydraulic separators have different throughput, and this parameter also directly depends on the power of the boiler.

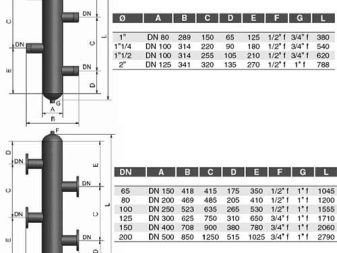

The more coolant passes through it, the wider the passage in the hydraulic needle and the greater its volume. Material production is also important.

The most durable and reliable hydraulic separators are those made of stainless steel.

Devices made of structural steel are also characterized by good performance parameters. But polypropylene products are not suitable for all boilers, as we indicated above.

Can you do it yourself?

Although the design of the hydraulic needle is nothing complicated, the price of this product is quite high. Therefore, it is often made by hand. To do this you need the skills of electric welding or gas welding, and also have to do some calculations.

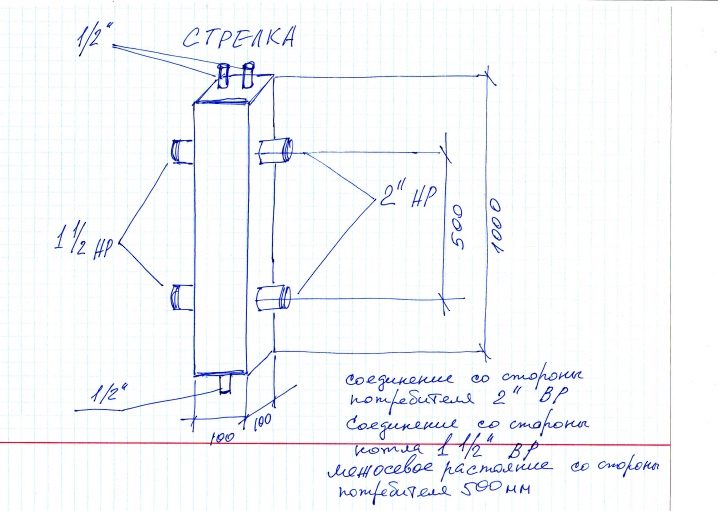

The first thing is to determine the correct dimensions of the pipe from which the hydraulic separator will be made. To calculate the internal diameter, it is necessary to divide the total power indicator of all circuits, measured in kilowatts, by the temperature difference in the flow and return flow. From the resulting number, the square root is extracted and multiplied by 49.

To obtain the height of the hydraulic separator, multiply the internal diameter of the pipe by six. To determine the distance between the nozzles, the inner diameter is multiplied by two. This is where the computational work ends.

Next, proceed to drawing up the drawing.Here we will need the parameters that we obtained using the above formula.

According to the drawing, choose a suitable pipe of round or square section. The pipes are welded to it with a previously prepared thread, which we need to connect to the main heating system.

If you decide to make a hydraulic needle of polypropylene, then you need to know some of the features of this material. It withstands high temperatures (up to 175 degrees Celsius), has a smooth structure, so that the coolant flows smoothly, which prevents heat loss. The plastic hydraulic separator will be much cheaper than analogs made of copper house, stainless steel or ferrous metal.

Applying this material is worth remembering and cons. The plastic device cannot be used in solid fuel boilers, and the high power of the boiler will significantly shorten the life of the hydroarrow.

It is known that in different hydraulic dividers the number of nozzles is different. Their number depends on how many circuits will be used in an autonomous heating system.In order to make the maintenance of the system more convenient, collectors are additionally used.

Connection

The use of a hydraulic separator is advisable only in complex heating systems, where different devices are used and there are multiple branches. In the photographs and diagrams, we often see that the hydraulic separator is mounted vertically. In fact, it can be set as you please, including horizontally and at any angle. But making installation of this device, it is necessary to remember one very important rule.

The air vent must be strictly upright, and the valve to drain the dirt must be positioned at the bottom. If this item is observed, the hydraulic distributor will work properly in any position.

Depending on the used coolant and its speed depends on the selection of the hydraulic separator.

Thus, several device connection diagrams are used:

- Neutral. In this case, all the parameters should correspond to the values calculated during the calculations, which characterizes the device with the total power.

- Certain. This scheme is recommended to use if the heating boiler does not have sufficient power. In case of insufficient consumption, an impurity of a cold heat carrier will be needed, and at different temperatures, thermal sensors are included in the work.

If the volume of coolant in the main circuit is larger than in the secondary circuits of the system, then the boiler is working normally. In the event of a shutdown of the pumps in the secondary circuits, the coolant flows through the hydraulic distributor to the main circuit.

Tips and tricks

We already know what the hydraulic switch is used for, in what systems of autonomous heating it is recommended to use it, what parameters the device should have. But despite this, after installing the hydraulic separator, many questions arise. In this section of our review, we will provide several recommendations and answers to frequently asked questions about the operation of this device and failures in the heating system.

Why is the coolant temperature after the hydrotreater less than at the entrance?

In different circuits, the flow of coolant is different.In the hydraulic separator, there is a high temperature, but a cold coolant flows in there because the cooled coolant consumes more of the hot one.

Why is there a small vertical speed in the hydraulic needle?

The presence of debris in the heating system is the rule rather than the exception. Rust, sand and other small particles are the main cause of low vertical velocity, but after a certain period of time, the small fraction of the fine fraction settles on the distributor. Consider that low speed in the hydrodistributor contributes to the natural convection of the coolant. This means that cold liquid goes down while hot liquid rises. This effect contributes to the formation of the necessary pressure and pressure.

For example, we will give a floor heating system in which the coolant temperature is lower than in an indirect pressure boilerwhich requires a high temperature and pressure, contributing to the rapid heating of water for hot water systems. In addition, the low speed in the hydraulic needle lowers the hydraulic resistance and also removes air bubbles.

Can I install the hydraulic separator at right angles?

If there are no problems with the coolant temperature and vertical speed in the hydraulic distributor, the device can be mounted at such an angle.

Is the volume of a hydraulic needle important?

This parameter is important. Especially it is worth paying attention to the volume of the hydraulic arrows, if the solid-fuel boiler will be used in the autonomous heating system, since its work is characterized by unstable pressure and its large differences.

Summarizing, we can conclude that the hydraulic separator - A very important component in the autonomous heating system. But despite this, the hydraulic needle is not a mandatory device, and in many cases, you can do without it.

The price of the product is quite high, so many craftsmen make it yourself. If you have welding skills or you have a soldering iron for plastic pipes with nozzles of different diameters, then using the calculation formulas given in the article, you can easily build a high-quality valve.

Using the above information, you can choose the right device specifically for your heating system, given its technical characteristics and parameters.

This will save money and ensure the stable operation of all heating devices: radiators, convectors, water-heating boilers, floor heating systems without a drop in the temperature of the coolant in them.

You can learn more about the choice and feasibility of using the hydraulic arrows in the heating system from this video.