Heating systems: features of the device and installation recommendations

The choice of a heating system for a private house is an important step that needs to be approached responsibly. Each person constructing a private house should study the features of the device and recommendations for the installation of the heating system.

Special features

In Russia, heating systems are very popular, in which water is used as a coolant. Electric devices are convenient, belong to the category of environmentally friendly systems and do not require equipment for the boiler room, but the operation of such a design is accompanied by significant material costs. The air heating system is also not in demand in the territory of the Russian Federation, as it has certain specific features, which are not fully mastered.

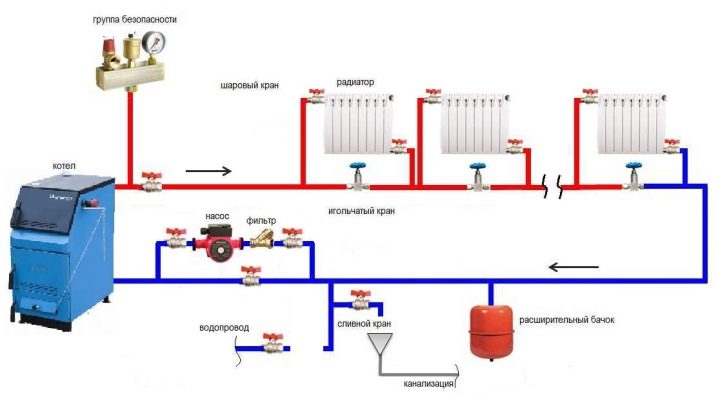

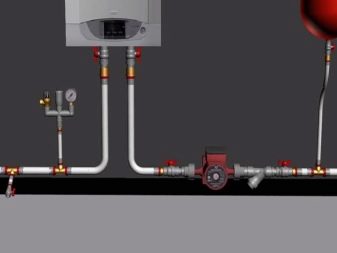

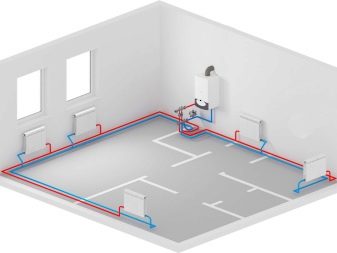

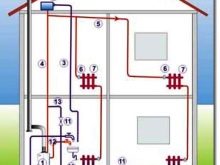

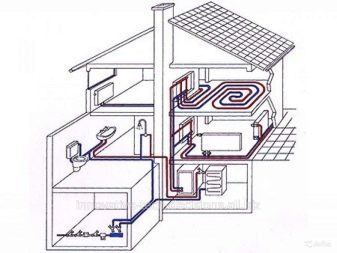

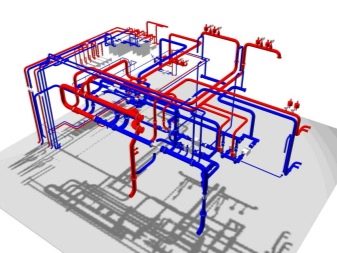

In the scheme of the heating system there is a closed design. The key element of the design is the boiler, which is entrusted with the task of heating the coolant to the required temperature.

The coolant moves through the pipes over the entire area and returns back to the boiler chilled for further heating. The necessary temperature is maintained by radiators, which, due to the quality of heat transfer, retain the necessary degree of air heating.

During the creation of communication systems, the arrangement of a special room in which a boiler with a boiler plant will be located will be required. The last device will be required if you plan to create a hot water supply. A ventilation system must be created in the boiler room that will be responsible for safety.

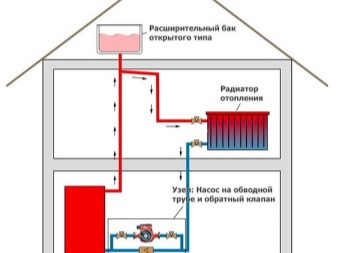

Installation of the expansion tank should be made in the attic. This component is responsible for maintaining the required level of water pressure in the system.

The following additional elements are present in heating systems:

- circulation pump;

- temperature sensors;

- automated systems contributing to emergency shutdown.

These components facilitate the use of structures, are responsible for the effectiveness and safety of the device.

Heating methods

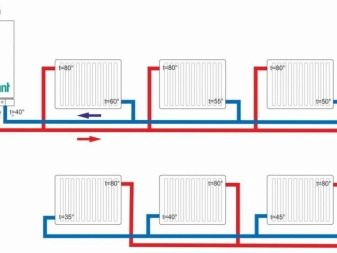

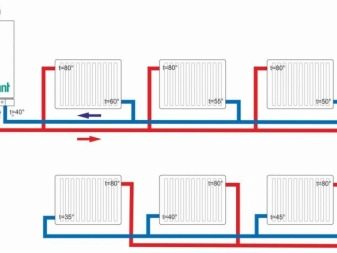

Based on the option of summing coolant to the radiator Two systems for private buildings are in demand:

- single pipe;

- two-pipe.

Similar options differ. Each type has its own list of advantages and disadvantages.

Single pipe

Heating scheme consisting of one pipe classified into two categories of layout:

- vertical;

- horizontal.

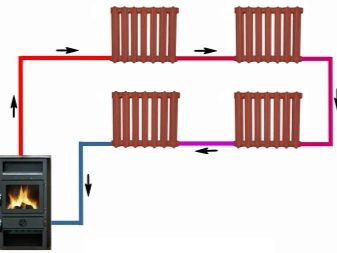

In such a scheme, the supply of hot heat carrier to the battery, as well as its discharge, is carried out through one pipeline. All elements that contribute to the direction of circulation of the coolant should be connected to each other using a serial circuit.

In this regard, the temperature level of the thermal carrier, when it enters the radiators, significantly decreases. The level of heat release is also reduced. Such schemes are in demand in the old-style central water supply systems for high-rise buildings, as well as in autonomous country-house type systems where natural circulation is present.

The main disadvantage of one-pipe systems is the inaccessibility of the control of thermal efficiency on each radiator.

To eliminate this drawback, experts recommend using a one-pipe circuit using a bypass. Bypass is a channel that is located between the supply and return pipes. However, even when using this option, the radiator, which is located earlier, has the highest temperature, and the last element - the coldest.

For multi-storey buildings use a single pipe system with a vertical position. This method is different savings on the length and cost of networks for liner. In most variants, vertical risers are used for the system, passing through all levels of the structure.

Calculations on thermal return indicators are made at the design stage and cannot be controlled using radiator valves and other fittings for adjustment. The selected system does not satisfy modern needs for a comfortable climate in rooms that are located at different levels, but join a single heating tower.People in these areas experience overheating or underheating of the temperature in them in the fall and spring.

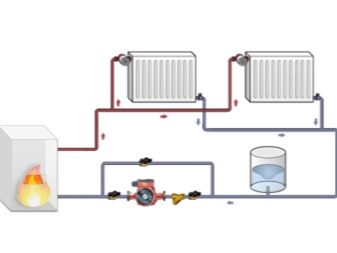

In private country houses one-pipe schemes are used for gravitational heating systems, where the movement of heated water is carried out due to the different density of the hot and cooled thermal media. For this reason, such solutions are called natural.

The key advantage of the scheme is its non-volatility. If the system does not have a pump for circulation, which functions due to electricity, or there is a power outage, the equipment operates in the usual way.

Among the shortcomings can be noted the uneven placement of the temperature of the thermal carrier on the batteries. Radiators, in which the coolant falls in the first place, will have the highest temperature, and the rest, according to the degree of distance from the heat source, will be cooler. The strength of gravity systems is always greater than forced ones, since they have an increased pipeline diameter.

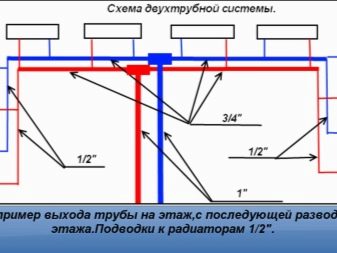

Twin tube

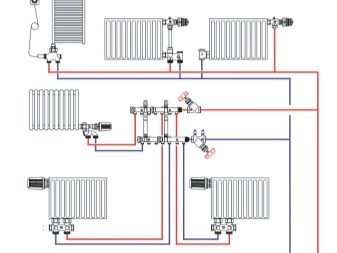

The design of two-pipe systems assumes that the supply of the heated heat carrier to the radiator, along with the discharge of the cooled one, will be carried out along divided pipes of the heating system.

The two-pipe scheme is divided into several types:

- classical (traditional);

- passing;

- fan-type scheme;

- ray.

In traditional schemes, the carriers of thermal energy of the injection channel circulate in the opposite direction to the flow moving towards the boiler. This option is considered the most popular in modern heating systems. It can be used in the arrangement of country cottages and multi-storey buildings.

Due to the two-pipe system, the coolant is measured distributed over the radiators without loss of temperature. Due to this quality, it is possible to control the thermal return in each room along with the use of a thermostatic valve with a thermal head.

The passing pattern has a different name - the Tichelman loop. It is considered to be an analogue of the classics, however, the direction of movement of the heat carrier during connection and return flow coincides. A similar option is used for heating systems equipped with long or remote branches.

Due to the associated scheme, it is possible to reduce the level of hydraulic resistance and to ensure uniform distribution of thermal carriers in all batteries.Often this option is used for a 2-storey residential building.

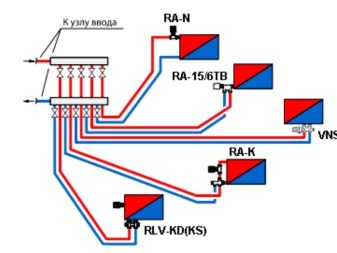

Fan or beam

Such a scheme is in demand during the construction of multi-storey buildings for heating each apartment. In this embodiment, there is the possibility of installing a separate heat meter in each apartment, and in country houses at each level the pipes are installed. At all levels of the building there is a collector in which there is a pipeline exit to each apartment. Such a decision contributes to the fact that every homeowner can record only the heat energy they have spent.

In private buildings, the fan system is used when the pipeline system is located on floors., as well as for the radial connection of an individual battery to a common collector. Thus, a separate pipeline is connected to each radiator for leading and return. The selected connection option ensures maximum dispersion of heat carriers over radiators and reduces the loss of hydraulic character for all components in the heating system.

When choosing a fan distribution scheme on one floor for installation, it is allowed to use pipes that do not have branches and gaps.If copper or multi-layer pipes are used, it is allowed to lay such a pipe under a layer of concrete. Thus minimization of gaps and leaks at the joints of the components is achieved.

Criterias of choice

When choosing a heating system for your home should be based on the following indicators:

- is there a gas pipeline;

- availability of the selected fuel type;

- approximate cost of thermal energy (the calculation is made in KW per square meter. If water is used as the coolant, all calculations are made in Kcal);

- availability of communication systems;

- use of autonomous or connected to central heating networks.

You should also consider the secondary criteria, which include the following indicators:

- type of material from which the house is built;

- climate features in the region;

- the lowest possible temperatures present in the climate zone.

The technology of heating systems has long been stepped forward, so there is no need to use furnaces. Independent heating works with the help of free energy paired with different types of boilers.

The most popular is the water heating system. This is the most economical option, as users can independently adjust the temperature level depending on weather conditions. Modern heating technology makes it possible to fully automate the functioning of the entire system. Autonomous heating of country houses is a complex solution of engineering and technical nature.

The disadvantages include installation costs and installation itself. However, if you compare the autonomous heating with alternative types of fuel, the cost of installation work will be justified.

To achieve maximum performance, you will need a competent drawing up the scheme. Due to the correct approach, the entire autonomous system in the house will become an integral complex that can solve two problems at once: heating and the presence of hot water in the rooms.

Types of boilers

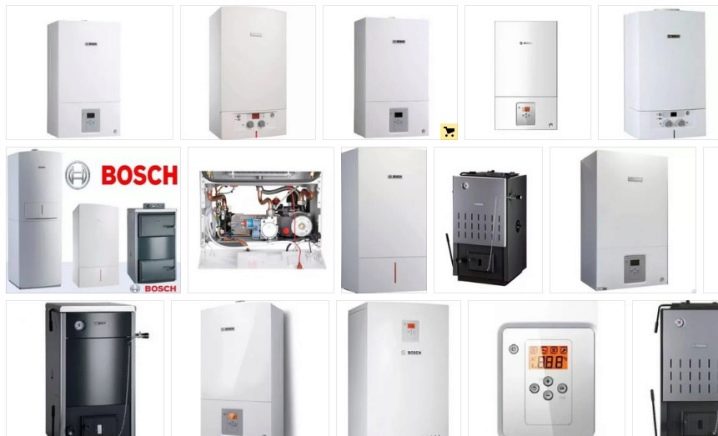

Residents of country houses should choose a boiler that will influence the effective functioning of the entire heating system.

Currently, the following models are available in stores:

- gas;

- electrical;

- working with solid fuels;

- liquid fuel;

- combined system that can operate on both liquid and solid fuels.

In each option, you will need to choose the type and type of autonomous heating system, installation of which in the cottage will be the most efficient and cost-effective. Despite the fact that the market has a wide range of boilers, for private constructions where there is a central gas pipeline, the installation of a gas boiler is the best option.

When compared with electric boilers whose performance reaches 99%, gas models are notable for their reliability, practicality, and cost effectiveness. Electricity as a source of energy is an expensive pleasure.

There are various options for home heating. Each type should be reviewed before installation.

Electric

The electrical system is considered the most efficient heating option. The performance of electric boilers reaches 99%, for their installation does not require ventilation equipment and chimney. Products practically do not require maintenance. Once every three years only cleaning is required.

Users choose this equipment because the installation is affordable, while the automation level can be of any type.

The lack of electric boilers is the cost of electricity. Even with the use of multi-tariff meters, it will not be possible to bypass the wood heat generators. Payment for electricity is a decent price for comfort, high performance and reliability.

Also among the negative qualities is the fact that the required power level is not always present on the supply network. If this condition is not met, installation of the boiler is considered unacceptable.

Solid and liquid fuels

Boilers that operate using solid fuels are of three types:

- direct combustion boiler;

- pyrolysis equipment;

- pellet devices.

The units are in great demand due to low costs of use, as compared with other types of fuel, coal with firewood has an affordable price category. Natural gas in Russia is an exception, but only joining it will cost more than the entire heating system along with the installation.For this reason, coal and wood heating equipment is bought more often.

The use of heat sources that function on the basis of solid fuels is similar to conventional heating using a stove. The device requires time and physical costs for the procurement of firewood and load them into the furnace. Also required measures for tying the boiler to ensure safe and uninterrupted operation. This is due to the fact that simple solid fuel assemblies are not characterized by inertia, since after closing the valve the heating of the water does not stop immediately. A productive application of the generated energy is available only in conjunction with a heat accumulator.

Boilers that burn solid type fuels are not able to demonstrate a high level of efficiency. Classical equipment of direct combustion has an efficiency of 75%, pyrolysis reaches 80%, and pellet - no more than 83%.

Pellet heat generators are the best option when it comes to comfort. They have increased automation and are not characterized by inertia. The boiler does not need a heat generator along with regular visits to the boiler room.However, the high cost of products scares most users.

Fuel oil boilers are also in demand, as heating is the most costly measure in the line of expenses of residents of private houses. Gas lines are not present in every district, electricity has a high cost, and wood burning stoves have lost their relevance. Many users have resorted to an alternative option - the installation of boilers that operate on waste oil.

A liter of this fuel costs about 10 rubles and is considered a material for waste. Installation of the system does not require significant financial investments and has an affordable scheme.

The boilers working on mining will be suitable for heating non-residential buildings. Often they are installed in garages and warehouses. If the town where the country house is being built does not have a gas main, it is possible to heat any premises using the waste oil system. Not only automobile oil is used as a fuel, but also diesel fuel, waste from furnaces, vegetable and animal type oils.

Among their advantages are the following qualities:

- mining has a low cost;

- ease of operation;

- smooth operation at low temperatures;

- adjustment of heat supply;

- long term of use which exceeds 10 years;

- environmental friendliness.

Disadvantages of the system:

- inconvenience in storing oil;

- increased noise emitted during operation;

- fire safety;

- such a boiler should not be installed in a pair with the “warm floor” system and a heated towel rail;

- requires the arrangement of the chimney.

The boiler consists of the following parts:

- burners;

- combustion machine;

- heat exchanger;

- evaporator bowls;

- oil pump.

The oily liquid from the tank is sent to the evaporation chamber. This helps her a special pump. In the chamber, the burner begins to heat the lubricant to 71 degrees, due to which it is converted into steam. Then the steam goes to the next bay. In order for the liquid to burn completely, a fan installation will be required at this site. The coolant heats up and gives off heat to the water jacket or throws out hot air vapors to the room. All excess elements are eliminated in the chimney.

According to European terminology, heating without water components should be called a stove for testing. However, not everyone complies with European standards, as the camera device may differ depending on the manufacturer. This fact has an impact on the effectiveness of the device, so the technical documents indicate the efficiency. Finnish manufacturers offer equipment, the efficiency of which reaches 98%, Koreans produce products reaching 80%.

Some boilers can be equipped with a platform for cooking, other models have an elongated shape, which facilitates the location process.

Gas

Gas boilers - a good option for arranging heating, which will work at the expense of the main gas. Water heating equipment is considered reliable and efficient. Simple models have an efficiency of 87%, more expensive products reach 97%.

Heating equipment is compact, automated and safe. It is necessary to service boilers once a year. A visit to the boiler room will be required only to adjust the heating settings. Budget boilers are cheaper than solid fuel equipment, so gas models are considered an affordable option for all categories of the population.The gas boiler will require the arrangement of the chimney and ventilation system.

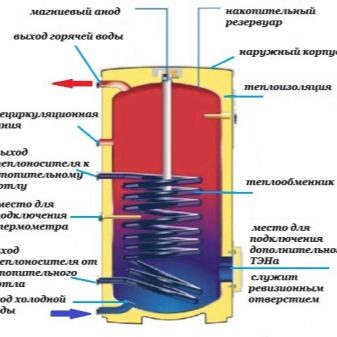

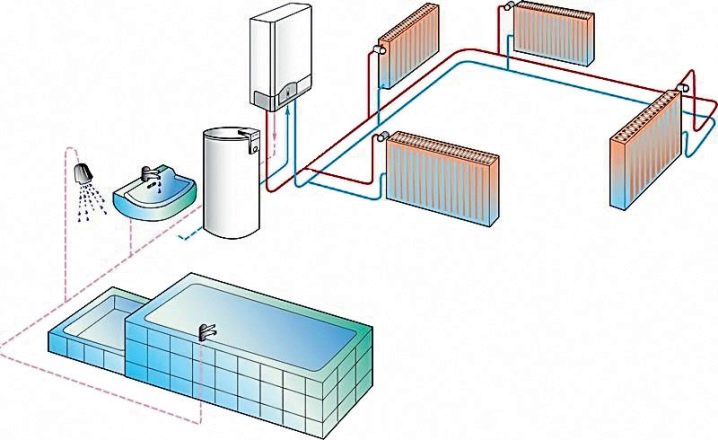

With indirect heating boiler

An indirect heating boiler is a heating element or tank, due to which the building is equipped with hot water.

On sale there are two types of products:

- direct heating boiler;

- indirect heating boiler.

The latter option is different in that the tank generates the heat it receives from the heating system. Externally, the boiler looks like a barrel. However, some manufacturers offer models that have a cubic or square shape. Cubic tanks are made in the same style with the boiler, so they can be located directly under it. This option allows you to save space in the room.

The operation of the equipment is based on the fact that the water supply is carried out into the boiler on 2 circuits. The first circuit is the heating component that is connected to the heating system. The second circuit is responsible for heating the fluid that comes from the plumbing system. In the future, hot water is distributed to the water intake points.

The implementation of the heating circuits in this boiler is performed using two methods:

- "Tank in the tank."Such a boiler is a structure in which the contour is formed by arranging a smaller vessel in the main tank.

- Installation in the main tank coil.

Two circuits must be connected in parallel to the heating system. Heat carrier enters the system from the system through pipes. To provide the necessary circulation efficiency, the arrangement of a pumping and mixing system will be required.

Acquiring a boiler for gas boilers will require an estimate of the power of the boiler. It should be enough to ensure the one-time operation of the heating and boiler.

Cold water is supplied to the heating tank, and the heated water is taken by consumers. At installation it is necessary to consider that similar boilers can possess several heat exchangers.

Such devices are effective, but rarely found.

Electrode

Electrode heating is the best example of a system by which you can warm up a room quickly and efficiently. Such boilers are used only in closed heating systems.Rapid heating and performance is achieved through exclusive technology, which is the ionization of thermal media.

This method is based on the direct transfer of energy, which is present in electricity, to water molecules. Due to this action, the necessary performance indicators are achieved.

Indicators include the following qualities:

- The rate of heating water. Due to the influence of electricity, instantaneous heating of the coolant occurs. This feature affects the rate of heating of the room. At that time, while gas models are only engaged in heating the fluid in the system, the electrode equipment is already engaged in heating.

- Output to rated power. According to calculations, it can be understood that the heating of the heating system will require large expenditures of the fuel material. Heat transfer at this point is at its minimum. Electrode boiler ensures the operational output of nodes to the nominal power level.

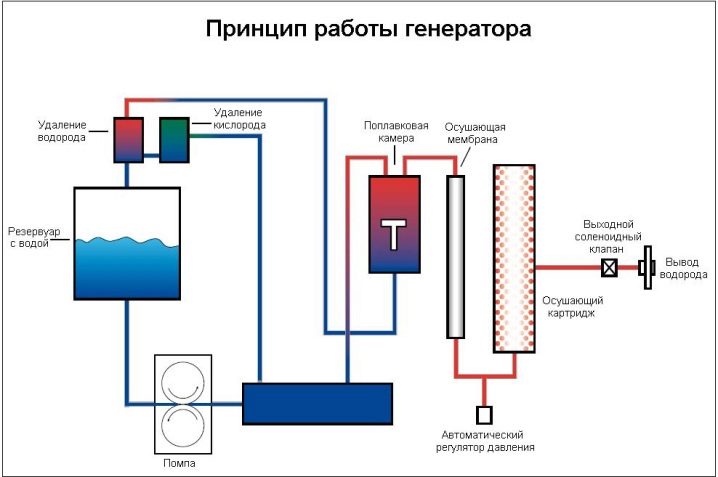

Hydrogen

Hydrogen heating system is considered one of the achievements of technical progress.Currently, hydrogen boilers are not popular in Russia, as people are not sufficiently informed about such a heating system. Western countries, on the contrary, are actively using similar heating equipment, as it is clean and economical. The second name of such boilers - the electrolyzer.

Previously produced hydrogen heating units for industrial facilities. Products differed in the big sizes and took a lot of place. The efficiency level of the boiler was small - 80%. Now manufacturers have been able to improve the products and offer boilers, allowing to heat residential buildings.

The procedure by which hydrogen is produced is simple. This will require electricity and water. Electricity contributes to the splitting of water molecules into oxygen with hydrogen, which is subsequently used for the heating process.

Hydrogen coolant is the cleanest and safest component. Heating in this way is different performance and usefulness.

The principle of operation of the device is concluded on the reaction, which is formed between the molecules of oxygen and hydrogen.Due to the reaction of particles, Brown gas is observed with the release of a large amount of thermal energy.

In order for the hydrogen boiler to work well, you will need to comply with the list of conditions:

- Providing water supply. As a rule, this is ordinary tap water, but distilled water is allowed. Consumption indicators are dependent on device power.

- The presence of electricity. Electrolysis is only available through electrical energy.

- Systematic replacement of catalysts. The frequency will depend on the performance of the boiler and the model.

Project development

Before proceeding with the installation of a heating system, a project development will be required.

Its creation consists of the following sequence:

- first of all, a detailed building scheme is created;

- then zoning facilities and determining the level of comfort of each room will be required;

- calculation of heat loss for each room;

- detailed layout of the radiator in each room;

- determination of the required number of sections for each battery;

- selection of the best heating scheme (it will be necessary to decide whether the upper filling will be used or low, the number of pipelines);

- calculation of the power level of the boiler, the number of materials (length of pipes, tees, valves, automation).

Room zoning

Properly distributed heat makes it possible to feel the comfort in the house and save finances.

Each room will need its own temperature regime:

- The overall temperature in the house should be about 20-24 degrees.

- For the bedroom will need a fever, which is 22-25 degrees.

- Bathroom, bathroom and guest rooms must maintain a temperature regime of 21-24 degrees. This condition should also be observed for each room in which households spend most of their time.

- In the kitchen, in the dining room and office should ensure a temperature of 18-22 degrees.

- For the hallway, garage and walk-through areas will be enough 12 degrees.

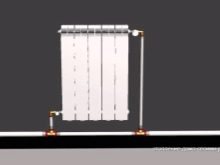

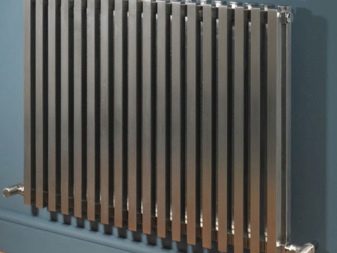

Batteries

The choice of battery is an important event. The service life of the heating system and the temperature conditions in the building depend on this step.

There are 4 types of radiators on sale:

- cast iron batteries;

- steel products;

- aluminum batteries;

- bimetallic structures.

Bimetallic radiators are made of steel pipe and a shirt of aluminum, which qualitatively gives off thermal energy to the room.

Cast iron batteries are characterized by better heat and long life. However, they are distinguished by complex installation, since they have a large mass. For this reason, most users choose bimetallic counterparts.

Radiators made of aluminum and steel are not popular, since aluminum has a short service life, and steel is not able to cope with the heating of a room in winter frosts.

In order not to spend a lot of time on calculations, you can use the following rule: for every two square meters one section is required. This condition is relevant if the ceiling height does not exceed 3 meters.

It is best to install radiators under the window opening. Such a solution helps to reduce heat loss through the window. However, in this case, the radiator will begin to give some of the heat to the walls, which is undesirable. Therefore, many experts have resorted to installing on the wall "screen". It is made of foil and acts as a heat reflector. Heat flows are reflected and enter the room, heating the air.

Power calculation

One of the most important moments when creating a heating project is considered to be the correct calculation of the boiler power indicator. The heat transfer of the entire system, built according to the layout of the dwelling, will depend on the correct selection of the unit. For heating a small house is not required to install the most powerful boiler, since such equipment will run empty. The unit is required to select, given the area of the building. After the area, an important factor will be the climatic conditions of the region.

To select the heating boiler most accurately, you can use the calculation technique provided by SNiP II-3-79.

This technique includes all the necessary requirements for the units:

- temperature chart of the region, taking into account the lowest temperatures;

- the material used to insulate the house;

- arrangement scheme of the heating system;

- characteristics of each room;

- the percentage of the area of the supporting structure to the door and window openings.

The initial method of calculating the power of the boiler includes the following rule: for every 10 square meters. m of a house built with the use of thermal insulation and ceiling heights of up to 3 meters, requires at least 1 kW of heating.Do not forget that in the case of using the boiler, in addition to supplying hot water, it is necessary to add at least 25% to the calculated power.

One of the factors that should be considered when choosing the power of the boiler, is the presence of heat loss. They are present both in electric boilers and in boilers with natural or liquefied gas.

The simplest calculation of heat loss:

- if the house is constantly ventilated with the windows open, it takes at least 15% of the energy;

- with weakly insulated walls, from 30 to 45% of heat is spent;

- if old windows are installed in the house, about 20% of heat energy is consumed through them;

- if single-circuit heating is used, heat losses for heating pipes will be minimal;

- with the old roof about 20-30% of heat will be blown out.

It is required to take into account each of these factors during the calculation of the required power for the future boiler. All heat engineering calculations must necessarily be rounded up and increased in order for a certain power reserve to be present.

For the initial determination of the required power, you can apply the formula:

W = S * Wud.

In this formula:

- S is the total area of the house;

- Wood-specific power, which takes into account the climatic features of the region;

- W- required boiler power.

The resulting value of power in the future must be adjusted, taking into account the peculiarities of your heating system.

Instruments

For a quality process of installing heating systems, it is necessary to prepare list of tools, which consists of the following positions:

- building level:

- special tape measure for construction;

- pliers;

- a set of screwdrivers with nozzles of different shapes;

- set of wrenches;

- pipe or gas wrench;

- pipe cutter made of polypropylene;

- soldering equipment for pipes;

- electric grinder;

- perforator;

- construction hammer.

Assembly technology

Installing a heating system is not considered a difficult task, so almost every person can do this kind of thing with their own hands. The work will require construction skills, the ability to handle a soldering iron, grinding machine. Follow all rules to properly install the heating components.Otherwise, the heating will not function or will work incorrectly.

The first step is to install the heating unit. It is placed on a stand made of concrete or a mixture of asbestos and cement. After the chimney is installed, it will be necessary to seal all the welded joints that are present between it and the boiler. Sealing is best done using clay, since cement is prone to cracking.

The installation of batteries begins with the installation of the brackets, which are fixed with dowels to the external walls of the building.

The best way to accommodate heating radiators is under the window opening.

The following rules have been developed for the installation of heating equipment:

- distance from wall surfaces should be at least 20 mm;

- distance from the floor surface should be 70-150 mm.

The installation of the battery has the following sequence of work:

- the implementation of marking for attachment points;

- mounting each element at the same distance from the floor surface;

- there are no slopes that complicate the movement of water in the system;

- radiator unpacking is carried out only after the heating system is installed and tested.

Pipeline installation

After the radiators are installed, you can proceed to the installation of pipes with the remaining nodes. First you need to embed the drain pipe under the water. Its fixation is made from the lowest point of the system, which is located between the main riser and the heating unit.

Installation methods of the heating system may vary. Some users lay pipes in the floor screed, others prefer to install the pipeline directly on the walls. It is also allowed to lay in the ground with the help of special protective boxes and foam cases.

Damping tank must be located 3 meters above the boiler. In both nodes must be present ball valves, due to which will be the overlap of water.

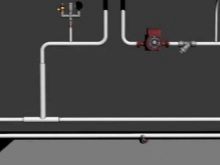

The heat pump must be located on the side of the flow of waste liquid into the boiler. The circulation should be set up as follows: in the event that a compressor breaks down, auxiliary pipes with ball valves will be put into operation.If required, these pipes will be used as primary or used during emergency situations.

Each component must be equipped with a ball valve. This equipment makes it possible to carry out minor repairs or replace damaged parts without difficulty. If there is more than one central riser in the selected system, the piping should be equipped with tees and valves. The valve will be responsible for the balance of hydraulic resistance in each branch of the system.

All connections are attached to each other with a special soldering iron, equipped with two nozzles. Each pair of nozzles coincides with a specific pipe diameter. One nozzle is responsible for heating the outer part of the pipe segment, and the second heats the inner part.

Heating takes about 7 seconds, after which the connection must be docked. When heated and connected, parts are not allowed to rotate. After connecting, hold the components for about 30 seconds, allowing them to cool. All sections are connected in series.

Upon completion of the installation will require testing the system.This event should be carried out only under the supervision of a specialist to prevent the formation of emergency situations.

The installation of a gas heating system for a small house should be done in a certain sequence:

- making calculations and filling in project documentation;

- the acquisition of the necessary materials and tools;

- installation and test run of the system;

- start of the heating equipment.

During the design, the technical characteristics should be taken into account:

- the main data of the heating equipment;

- Pump efficiency;

- indicators of power level of the heating device;

- the possibility of organizing air-type heating and supplying FGP.

Wall-mounted models of gas boilers are suitable for small houses. They are suspended on supporting walls and they do not need the equipment of a special boiler room. Floor models should be in a special room - the boiler room. Auxiliary components are in the configuration with the boiler. According to safety regulations, the installation of a gas boiler in basements and basements is not allowed.

Some users decide to install a gas oven in their home. It has a body part of a brick, which is located on the foundation of concrete. The chimney is attached to the body.

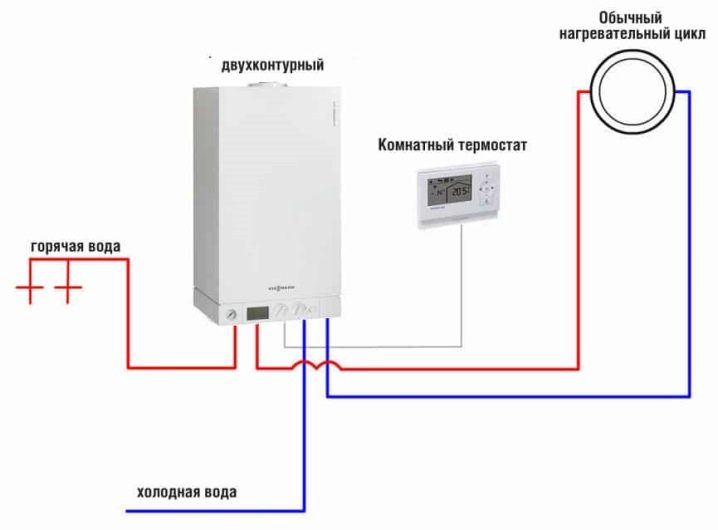

Based on the selected wiring (one pipe or two pipe), a gas model of heating equipment with one or two circuits is selected. Single-circuit unit has a special device for heating water under high pressure. Such a device is called a boiler. Special output system, which is supplied to the tank, allows you to equip the process of supplying hot water.

When installing double-circuit boilers, the liquid is heated in an internal-type steam generator. Additionally, you can connect air heating type. Due to the installation of two-circuit units, an increase in the productivity of heating and a decrease in the cost of components is observed.

Water is heated in a heat exchanger, after which the coolant is transferred to the battery. Circulation takes place by means of a pump with a forced system. Installation, in which there is a natural circulation of water, must have a damping capacity, which is located at the maximum allowable height.

Common mistakes

By installing the heating point, you can make a lot of mistakes. However, most often allowed only five missteps that can lead to serious consequences.

The main mistakes when installing heating:

- illiterate selection of heat source;

- making mistakes when tying heat generators;

- improperly selected heating circuit;

- careless installation of the pipeline with fittings;

- improper installation;

- erroneous connections of heaters.

The choice of insufficient capacity boiler is a common mistake. It occurs when choosing a heating unit, which is aimed not only at heating the house, but also at providing residents with hot water.

If you do not take into account the auxiliary power that is required for heating water, the heat generator will not be able to cope with the tasks. Ultimately, the heat carrier, as well as hot water, will not be able to heat to the required temperature.

Components for tying the boiler are not only functional, but also for the safety of equipment. For example, the installation of the pump should be done on the return pipe before the heat generator on the bypass line. It should be borne in mind that the pump shaft should be horizontal.Some users make another mistake, which is the installation of a valve between the heating unit and the security group. Such action is not allowed.

When connecting boilers that operate on solid fuel, it is not allowed to install a pump in front of a three-way valve. Installation must be carried out in the direction of movement of the heat carrier after the valve.

The volume of the expansion tank should be 10% of the total amount of water in the entire heating system. If an open system is selected, the installation is performed at the highest point. For a closed system, the installation is carried out in the return channel in front of the place where the pump stands. Between these elements there should be a mud trap installed horizontally. The cork should be placed at the bottom. Wall-mounted models of boilers are fixed on the pipeline with the help of American women.

If the heating system is chosen incorrectly, users run the risk of overpaying for materials and installation, after which they will have to pay additional funds to bring the system to mind.

Often, mistakes are made when arranging a single-pipe circuit, when they try to install more than five batteries per branch. In the future, the batteries simply do not heat the rooms.Errors in slopes, connections of poor quality, installation of unsuitable reinforcement are also common.

At the radiator inlet it is necessary to install a thermostatic valve or a simple ball valve. The outlet should be located balancing valve, providing the ability to adjust the heating. If you mount the pipe to the battery on the floor or on the wall, you will need warming products. This eliminates cooling of the coolant during circulation.

During the junction of polypropylene pipes, it will be necessary to work carefully with a soldering iron so that the joint is distinguished by reliability.

Useful tips

Pipes are one of the key elements of any heating system.

Below are a few tips on the use of various pipes that will help in choosing the right type of pipe:

- Metal pipes have recently begun to relate to the relic of the past. They are subject to corrosion, prone to a gradual narrowing of the flow area, their installation requires welding skills. However, when laying pipes inside the boiler room, the use of metal pipes is justified.They are able to withstand high temperature and pressure, while not capricious to external conditions. All these shortcomings are absent in pipes made of non-ferrous metals, but their price is the highest in our time.

- The category of budget materials include pipes made of polypropylene. The price of products will be several times lower than when using pipes from other materials. The disadvantage of the system is the problem when they are connected. In case of violation of the soldering technology of the pipe and fitting, a leak is formed, which cannot be visually determined. Another drawback of propylene pipes is the elongation of the pipe material during heating. In order to avoid bends due to heating, it is necessary to leave the distance between the wall and the pipe.

- The simplest in terms of installation are polyethylene or metal-plastic pipes. These types are suitable for laying in absolutely any places. These pipes are used for the device of warm water floors. It is important to remember that when laying these pipes in a screed or wall, you need to use press fittings, not collapsible. Another advantage of these pipes is the absence of the “memory” effect, that is, these pipes remain even, without waves and bends.

About what scheme of the heating system to choose, described in the next video.