Features and subtleties of the installation of one-pipe heating system

If you have planned installation of the heating system in a private house, then you will need to decide on the heating system. The relative complexity and size of the water heating system, however, does not prevent it from becoming the most popular for installation in buildings. This is the perfect combination of cost, performance and price.

What it is?

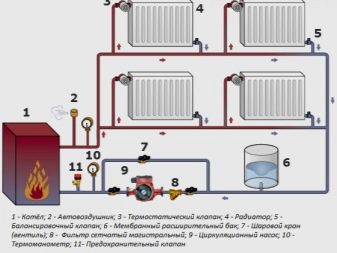

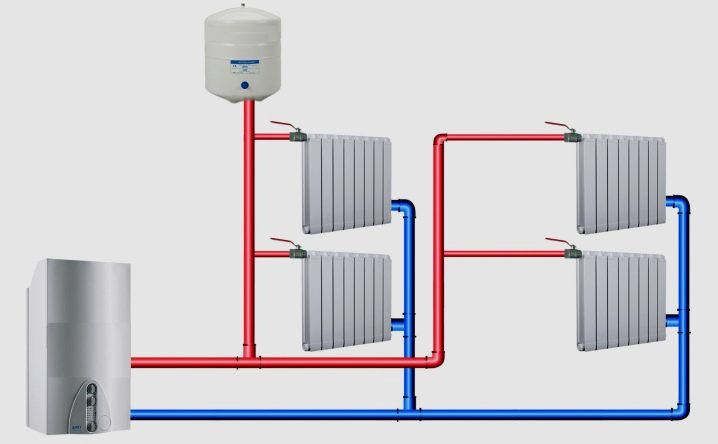

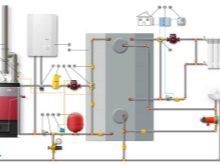

The scheme of water heating works on the basis of continuous movement of the liquid coolant. Moving through the pipes from the boiler, which is considered a source of thermal energy to the heating components and in the opposite direction, the coolant distributes thermal energy, and thus the room is heated.

As the coolant can be used air flow, water or antifreeze, used in buildings of temporary residence. The most popular are heating installations, where the heat carrier is water.

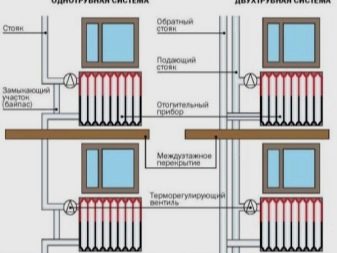

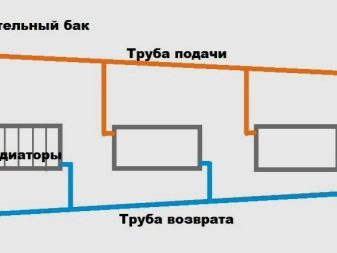

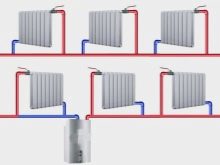

There are two main heating structures: two-pipe and one-pipe. The second option is considered the easiest to carry out installation activities. Simply put, the system is a tube that is connected to the boiler and goes through all the rooms, then returns back to the boiler. The principle of operation of the boiler device in the case of a single-circuit system can not be considered. Its only task is to heat the coolant supplying the one-pipe structure.

This type of heating can be prepared and installed on its own, without involving a specialist. In addition, for its assembly does not require a large number of locking parts.

Single-circuit type of heating can operate at the expense of any type of boiler. So, gas, wood or electric models are considered ideal. The only thing you should pay attention to when choosing a boiler is the presence of fuel.

In the case of a gasified building, the owner can install a gas boiler. If the gas pipe is not connected to the house, then it remains to purchase an installation with a wood heat generator. The electric model is suitable if there is no gas pipeline and a plot for building a room where coal raw materials or firewood can be stored. Gas is the cheapest fuel, electricity is expensive. The best would be the use of wood, pellets or coal.

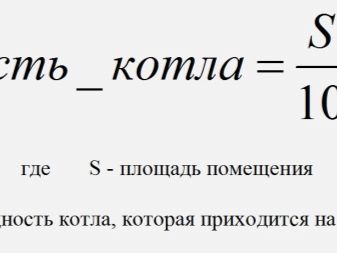

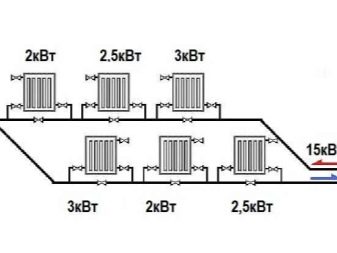

Having determined the type of boiler equipment, correctly calculate the required power. To do this, use a ratio of 10 m² = 1 kW. The length of the house is multiplied by its width (calculated in meters). The result is divided by 10, and then the answer is multiplied by 1 kW.

As an example, assume that the facade of the building has a length of 12 meters, width - 8 meters. Then the heat generation capacity is calculated by the expression ((12 x 8) / 10) x 1 kW. As a result, we get 9.6 kW. However, remember that during the purchase of the installation, you need to "throw" an additional 20-25% to the obtained power value for severe frosts.Total we get 11.5-12 kW.

When choosing a boiler, also pay attention to which way the heated water will move - to the left or to the right, that is, where the pressure and return pipes are directed. The desired direction is selected on the spot, based on the direction of the coolant from the boiler to the first section.

When the fluid moves from left to right, it will be necessary to install a heat generator with right branch pipes or vice versa.

Principle of operation

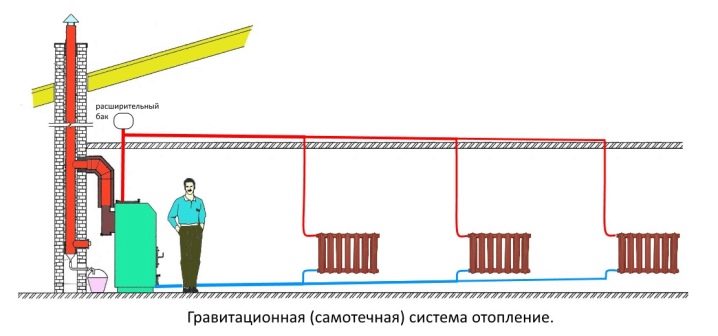

Standard heating is based on physical laws: thermal expansion, convection, gravity. When heated from a source of thermal energy, the coolant expands and pressure builds up in the pipeline. Moreover, it becomes less dense and naturally light. Heavier and denser cold liquid pushes the heated up. Related to this is that the pipe that comes out of the boiler is mounted at maximum height. It is the water heating boiler that represents the central element of the whole scheme located in a private house.

The created pressure, convection, and also gravity force water to move to radiator elements where they are heated and in parallel cooling. As a result, heat energy is given by the coolant, heating the room.Then the liquid is returned to the boiler in a cold state, and the process is repeated again.

However, this building has its own characteristics: the smallest temperature indicator of the coolant (40-50 degrees Celsius) before returning to the boiler is fixed, once in the most remote (the last in the chain) radiator. This is not enough to warm up the room properly.

To avoid a decrease in temperature indicators at the extreme radiator components, one should increase the heat capacity of the battery or heat the liquid in the boiler for longer. However, these solutions will require additional costs.

As an alternative solution, another method of supplying hot water is used, which consists in placing a circulating pump in a pipe loop. She will be able to disperse the coolant throughout the scheme.

The performance of this technology will be better compared with the previous two methods. However, in the conditions of the suburbs, a technique based on the use of a pump may not be very effective due to the probability of power failures.

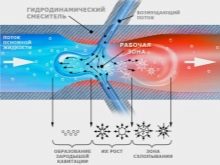

The problem of the delivery of hot liquid to all the radiators of the circuit in this case can be solved by the accelerating collector after its installation.The device appears as a straight high pipe through which the heated liquid coming out of the boiler accelerates to a speed that prevents cooling in the intermediate radiator before entering the last section.

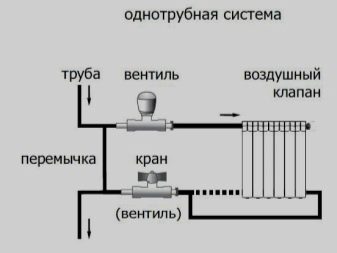

As a result, the absence of a return pipe (return pipe) is considered a characteristic feature of the one-pipe circuit.necessary to return the cooled liquid to the boiler. The second part of a single trunk pipeline will be considered a return line.

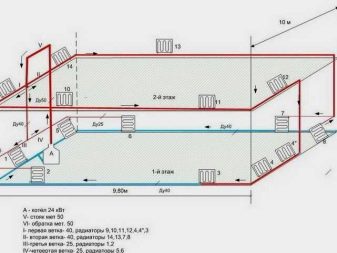

When choosing a heating circuit, keep in mind that the single-circuit model will not work if the last radiator section is below the level of 2.2 meters. It is suitable for use in two-level buildings.

The higher the direct collector will be above the boiler, the faster the fluid will move in it, and the whole installation will function without creating much noise.

Advantages and disadvantages

The advantages of a single-circuit heating system include the following features. allowing to make a choice in its favor:

- The only pipe fittings can be laid both inside the room and under the surface of the wall.

- This heating design will save the budget allocated for the installation of the entire system.

- The possibility of a gradual connection of all parts of the room heating system allows you to connect the circuit elements to the wiring pipe: radiators, a device for drying towels, floor heating elements.

- The heating level of the radiator units can be adjusted by connecting the sections to the system in series or in parallel.

- If you prefer the one-pipe model of the heating system, then when choosing a boiler you can stop on the solid-fuel, gas or electric models. If one of the boiler models is excluded, the second one can be immediately switched on, and the room will be further heated.

- This construction of the heating structure will provide an opportunity to direct the flow of hot coolant to the areas that need to be heated.

- If you lay pipes under the surface of the floor, then you should carry out the procedure of heat insulation of fittings to avoid heat loss.

- The single-circuit version makes it possible to lay the pipe under the door opening. The result is a reduction in material consumption and cost of the entire circuit.

As with any design, this scheme has some flaws in the work:

- After a long system downtime, it may take a long time to start up.

- If the house has two or more levels, then the owner will have difficulty trying to evenly distribute heat on the floors. To compensate for the decrease in temperature indicators in the lower part of the pipe, it is possible to place many radiator sections on the first floor, which will require considerable financial expenses.

- In the case of repair activities on any floor, you can not turn off any of the elements of a multi-component scheme.

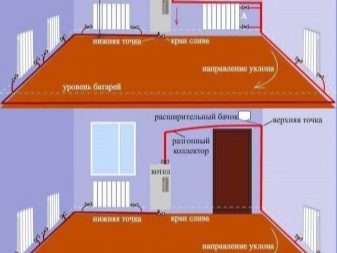

- In the absence of the required slope in the system, air traffic jams may form, which cause a decrease in heat transfer.

Species

On sale you can find various options for single-circuit water heating structures, or in another way, "Leningradok". The low price allows you to use them for heating apartment buildings. In addition, the aesthetic appearance eliminates the creation of a visual cluttering of the room. The single-circuit "Leningrad" chain was mounted in low buildings and barracks of the post-war time.

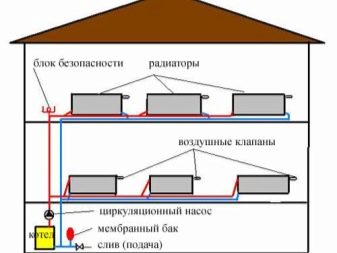

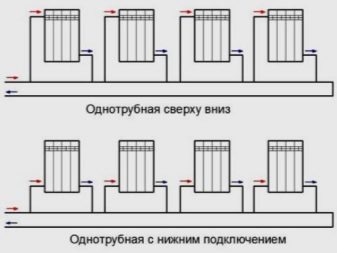

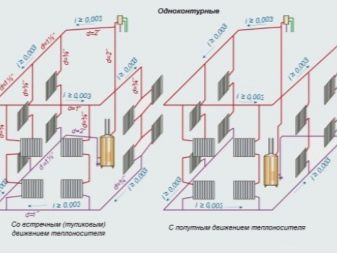

Single circuits operating on the basis of natural circulation should be mounted using only top wiring. Performance is ensured by equipping the locking sections along which the hot fluid moves. A similar connection scheme is based on the fact that the heated coolant rises from the boiler along the main supply line to the pipes of the risers; here it is distributed to the heating sections starting from the last floor.

After leaving the heating equipment, the cooled liquid is mixed with the hot one, which passed through the closing zone, and goes to the lower levels, and so on. Such schemes are used in most cases in small buildings.

Due to the impossibility of providing high circulation pressure, large diameter pipes are needed for the installation, which, in turn, will not bring benefits from an economic point of view.

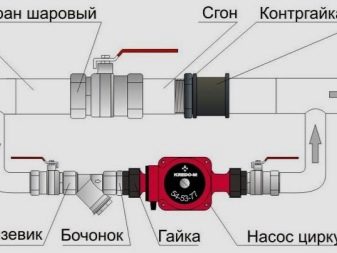

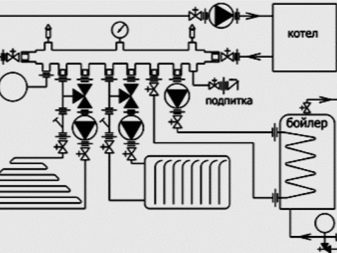

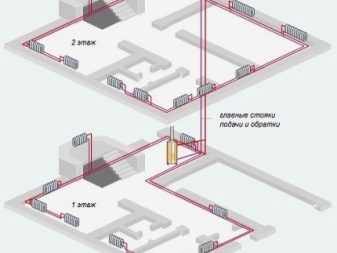

The main part of the heating mains in high-rise buildings and cottages operates on the basis of forced circulation. Here the fluid is driven by pressure drop in the heating main or by its own circulation pump, a compact device with a centrifugal impeller,the production of which is measured in cubic meters per hour and contributes to the formation of a hydraulic pressure of 6-10 meters.

The advantage is the high speed of the fluid.that implies fast and uniform heating of the heating devices during start-up, the minimum temperature difference between the first and last sections during the movement of the fluid. Achilles' heel of compulsory type is considered to be dependence on electricity, the long absence of which leads to the cooling of rooms.

Single-circuit artificial circulation units can be placed horizontally or vertically.

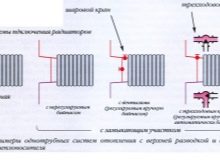

Upstream vertical models are divided into flowing, having closable areas, and offset jumpers, closing areas with a passing movement of the coolant.

Another option to build a heating line is a single-loop vertical system, built on the basis of the lower wiring. In this case, the supply and return pipes are installed in the basement. As a result, heat loss is reduced due to the absence of a pipeline in the attic.To release air from the system, it is necessary to install taps on the heating elements, which are located on the upper levels. This method of constructing the scheme involves the use of lifting and crossing risers.

The first model is raised to the last floor, where the transition to the lower one, connected in the basement with the return line, takes place. It is possible to adjust the heat transfer design with special cranes.

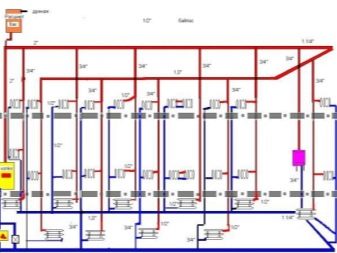

Production and public buildings or residential buildings of a small quadrature can be heated by a single-horizontal horizontal circuit. It is easy to install and can be included even in unfinished premises. In addition, the advantage is that there is no need to punch floors for risers in many areas.

These compounds are divided into flow-through and closed-loop zones.

The principle of flow is based on the fact that the liquid that comes out of the main supply riser is dispensed through horizontal risers on the floors, alternately falling into each heating equipment, cooling simultaneously. It is possible to carry out floor-by-stage adjustment of the temperature regime with the help of special reinforcement parts.

Their disadvantage is that the pipes go through the rooms, worsening the aesthetics of the premises. Another disadvantage is the inability to completely drain water from the system due to the fact that there are no inclined zones.

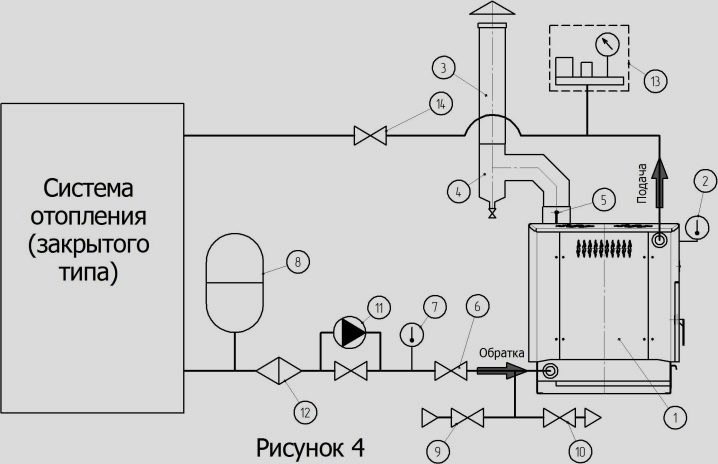

The difference between open and closed models is obvious. The open type interacts with the medium and functions by means of hydrostatic pressure, which is equal to the height of the water column.

The closed version creates an overpressure in the pipe, which is maintained by the membrane expansion tank. It is chosen in connection with the extreme simplicity of action.

The open expansion tank performs the function of the tank itself, the safety flap as well as the air vent. In fact, it is the only element of the boiler strapping.

In the closed form of the device, the liquid does not interact with the medium and is not subject to evaporation. If there are no possible leaks, the change of water is not necessary. In this case, there is no accumulation of silt, mineral deposits on the walls, and, therefore, you can observe the maximum performance of the entire structure.

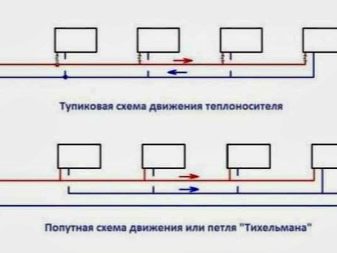

A single-pipe system can be assembled using a dead-end version; however, it has not received widespread use due to its low productivity, high costs, and installation difficulties.

If the building consists of 2-3 levels, then it is necessary to arrange the risers, and also install on each radiator equipment a product of the air vent or a Mayevsky valve.

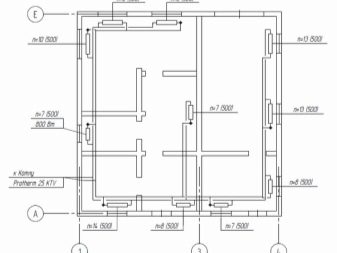

Planning

In the process of preliminary preparation of any heating scheme, it is worth considering a lot of features that may affect its effective functioning. In two-storey and one-storey houses, the one-pipe heating variant functions without creating much noise. A similar system can be installed also in apartment buildings.

The important point is the correct choice of component parts: This boiler, radiators, pipes that will be used to create a circuit, expansion tank, circulation pump.

Choosing a boiler, remember that the main requirements for it are to maintain the required temperature level in all rooms of a 2-storey private house and complete replenishment of inevitable heat losses.

We should also consider the issue of the required power of the device. It is usually recommended to be based on a ratio of 100 W * 1 m² of living space. But this option will not be able to give an exact value, since it does not take into account the difference in the climatic characteristics of different regions, the characteristics of rooms and rooms.Single-circuit schemes are found everywhere in the centralized highways of multi-storey buildings, as the heating riser is a given structure with a high velocity of the coolant.

More accurate indicators will be able to give the calculation of the required amount of energy for each individual room. Further, having added all the obtained results, we will be able to determine the minimum parameters of the power of the boiler plant.

The one-pipe heating design allows to mount any models of pipes.

Note the following facts:

- If the temperature of the fluid in the pipe is more than 70 °, then do not use polymer products (most of all it refers to polypropylene fittings).

- The procedure for tying solid fuel boiler is better to carry out metal samples.

- For distributing according to the system of natural circulation and an open expansion tank, it is recommended to give preference to steel pipes of open location.

- If you plan to hide the reinforcement in the walls, then choose stainless steel, polypropylene or PEX.

- It is allowed to use metal-plastic models, however, only complete with press fittings (threaded versions are not allowed to be hidden in the walls or the floor).Under any circumstances, if pipes are to be bricked up, it is necessary to apply a protective coating in order to eliminate the chemical effect of cement-containing compositions. In addition, it is necessary to take into account the probable linear expansion during temperature fluctuations, and in this regard, to perform thermal insulation, which will not allow heat losses for unnecessary heating of the walls or the floor.

Correct recommendations regarding the diameter of pipes are difficult to obtain, since this indicator is influenced by the individual characteristics of the central heating scheme. In this case, the best solution would be to contact a specialist who will help determine the necessary parameters of the valve.

The device of the circulating pump should be powered at 220V. Often, these devices consume little electricity, so it does not affect the total amount of energy consumed. Special attention should be paid to the other two characteristics.

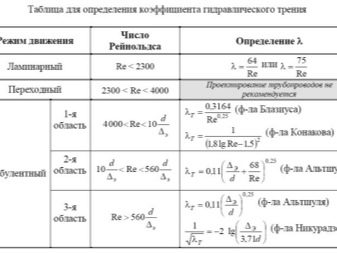

The first is pump performance, in other words, the ability to move the right amount of fluid over a period of time. As values that are needed for calculations, the coefficient of heat capacity of the liquid is distinguished,the performance of the heating boiler device, as well as the indicator of the temperature difference between the flow and return valves.

The second is the volume of pressure of the water column emitted by the circulation pump. The pressure that is created by the pump must ensure a stable current of coolant around the entire perimeter of the resulting circuit and withstand the hydraulic resistance of the pipe and the shut-off and control components.

The necessary data for the hydraulic calculations are the total footage of the entire armature of the system, including supply and return, bypasses, nozzles, and so on.

Indicator of the hydraulic resistance of pipes, which is expressed in numerical form and determines the intermediate pressure loss for one linear meter of pipe. If it is assumed that the structure will be assembled from new products with a smooth inner surface, then it is allowed to use the average indicator 150 Pa / m.

The level of resistance of fittings and locking parts should be considered. It is recommended to be guided by the value of the indicator 1.3, since in most cases single-loop circuits do not pile up two- or three-code taps eithersimilar thermostatic parts. However, if parameters are specified somewhere, then the value should be raised to 1.7.

The procedure for the installation work

Do-it-yourself installation of a one-pipe scheme will require preliminary preparation of the necessary tools: a pipe cutting knife, a soldering iron for polypropylene fittings and fittings, a key for assembling sections, and fum tapes.

First of all, it is necessary to mount the boiler, which must be placed in a certain recess. Do not place it in the basement. Basically, before installing the boiler, prepare a notch in the floor, which is poured with concrete or tiled.

Having installed the boiler, proceed to the installation of the chimney. The boiler is connected to the chimney through corrugated metal pipe products of the appropriate diameter. Next we connect the main pipe with a diameter of approximately 25 millimeters to the boiler for the main line.

The high temperature of the boiler during heating allows connection of only metallic samples to it. The use of adapters is prohibited. To stabilize the heating process, the installation of the expansion tank should be at a level of approximately threemeters, turning it into the highest point of the structure.

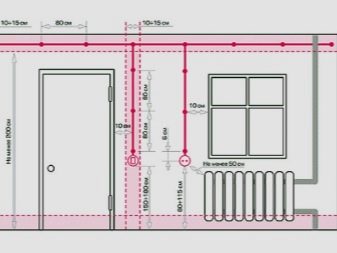

Next we do the installation of sections of radiators and pipes. At the same time we make installation of Mayevsky cranes and valves. Sections are placed under the windows. Remember to leave space between the batteries and the window sill for free movement of hot air currents. The armature is mounted straight, without creating bends. Otherwise, the normal circulation of fluid will be hampered and the performance of the heating structure will be reduced. This moment is especially important for the single-circuit heating option.

The end of the pipes of the heating installation is fixed to the reverse surface of the heating boiler circuit. Using a special metal filter prevents contamination of the boiler with unnecessary and unnecessary materials and impurities.

It is also necessary to carry out the procedure for assembling the unit, which will be entrusted with the task of filling the structure with liquid. And if necessary, it is possible to drain water through it.

Errors when installing a single pipe heating system are waiting for you in the next video.