How is a membrane expansion tank used in a heating system?

The volume of the coolant varies depending on the change of temperature regimes, which can lead to dangerous consequences. For safe and long-term operation of the coolant it is necessary to maintain its stable characteristics. A membrane expansion tank can be used for this.

Purpose and design features

In heating systems, heat transfer fluids are liquids that are in the process of weak compression. For the safe operation of the heating system, it is necessary to use a stabilizing device - membrane expansion hydraulic tank,which is able to take a certain amount of fluid in the process of increasing pressure and volume, and then return it to the circulation loop with a decrease in these indicators.

Diaphragm expansion tanks have several advantages over other devices of the same purpose, namely:

- suitable for any water, even if it contains a large amount of calcium;

- safe to use for drinking water;

- possess the big displaced net volume, than a pressure head tank without membrane;

- need minimal air pumping;

- economically and quickly mounted;

- low operating costs.

However, these devices also have disadvantages, namely:

- the large size of the expansion tank makes the installation process quite problematic;

- due to the return of its heat carrier to the expanzomat, heat losses increase;

- increases the risk of rust.

To avoid uncontrolled heat loss, experts advise to warm the device.

Differences from the hydroaccumulator

The design of hermetic expansion tanks is similar to the design of accumulators, however, the purpose of these devices is different.The expansion tank compensates for water expansion due to heating in the heating system. The accumulator accumulates the volume of water under pressure in the water supply system that has a pressure pump in order to reduce the frequency of switching on this pump and smooth out hydraulic shocks. In addition, more often inside the accumulator is a pear made from food rubber. It is precisely this one that is pumped with water, as a result, the water does not contact the tank body. The broad tank for systems of heating is made with the membrane made of technical rubber. It divides the case into two compartments, and the coolant has contact with the case.

Device and principle of operation

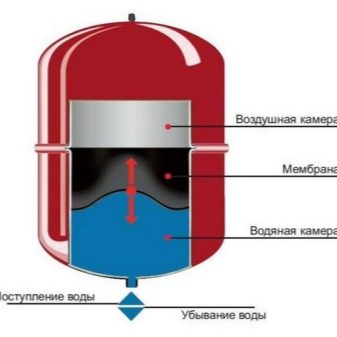

A membrane tank is a hermetically sealed metal container divided into two compartments (chambers) by an elastic membrane. One of these chambers is the pneumatic chamber, which contains gas or air under pressure. In the second chamber - the hydraulic chamber, the coolant enters.

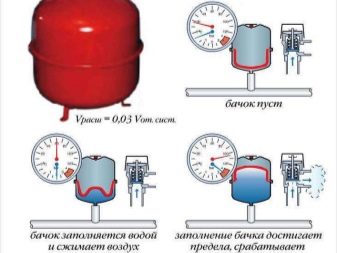

The operation of the device is as follows:

- the air pressure in the state of equilibrium in the pneumatic chamber compensates for the pressure of the fluid in the heating system, the volume of coolant and hydraulic chambers are minimized;

- when the fluid pressure rises in the system, including when heated, there is an increase in pressure in the hydrochamber, where excess heat transfer occurs;

- due to the elasticity of the membrane, the volume of the pneumatic chamber decreases, which is accompanied by an increase in gas pressure;

- when the pressure in the pneumatic chamber increases, the pressure in the hydrochamber is compensated, and the system returns to equilibrium.

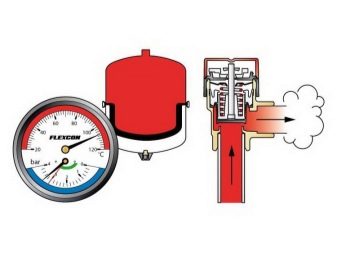

By reducing the pressure of the coolant in the system, opposite actions occur. The gas (air) compressed in the pneumatic chamber expands and forces the fluid from the hydraulic chamber into the system until the pressure difference is restored. The design eliminates the possibility of contact between the coolant and air, reducing the likelihood of rust, not only in the tank, but also in the remaining parts of the heating system - the pipeline, the boiler. Hermetic expansion tanks are equipped with safety valves that allow limiting the maximum pressure in the heating system to an acceptable level. It characterizes the tank and as a protection device for the heating system.

Types and selection criteria

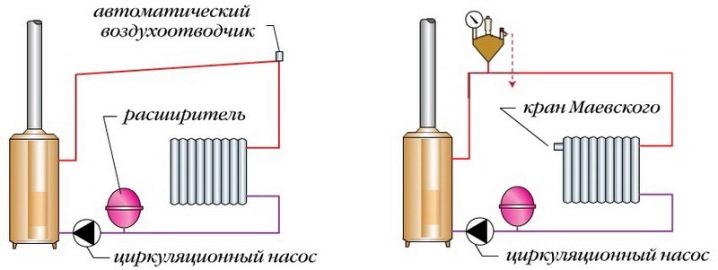

In order to compensate for the volume of coolant in the system during a temperature change, two types of expansion tanks are used: open and closed (airtight).

Open expansion tanks are widespread, but have the following disadvantages:

- high installation costs, since they mount such tanks at the top of the system to create the required level of increased pressure;

- you must constantly monitor the level of fluid;

- There is a risk of rust in the system due to prolonged contact of the heating medium with air.

Sealed expansion tanks do not have these disadvantages. For heating systems, tanks are available that differ in the use of the membrane. Membranes are divided into balloon and diaphragm types. The balloon membrane is a tank installed inside the tank, made of high quality rubber that can withstand significant temperature fluctuations. Flange mounting of such a membrane allows you to replace it quickly and easily.

Balloon type membranes have the following advantages:

- a wide range of operating pressures, making it possible to apply a sealed expansion tank;

- the ability to change the membrane, which helps to make the repair of this device cheaper and faster;

- simple task of the minimum pressure for any systems.

The diaphragm membrane is a fixed partitionwhich, most often, is made of elastic polymer or thin metal. This membrane is distinguished by its own small capacity and the ability to compensate for small pressure drops in the system. At failure of such a tank, its full replacement will be required. One of the privileges of this device is the low price. In addition, the tank having a diaphragm membrane is simply designed and reliable in operation.

To choose the right expansion tank is to ensure safe operation of the heating system, therefore choosing an expansion tank, you should pay attention to these basic characteristics:

- membrane material, its resistance to high absolute values of temperatures, pressures and differences of these parameters;

- case material and coating, rust resistance;

- compliance with hygiene standards;

- execution (installation method).

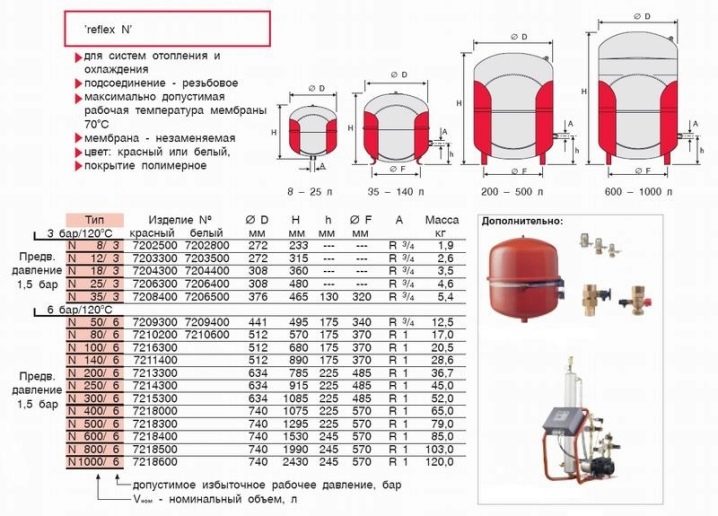

Restrictions

On the use of membrane expansion tanks manufacturers impose certain restrictions, which depend on the design and materials used in the manufacture of the device. Manufacturers have clear requirements for the properties and composition of the fluid in the heating system. The content, for example, of ethylene glycol in antifreeze solution is limited. The use of a membrane expansion tank at pressures that exceed permissible limits is prohibited. Mandatory installation of a security group that controls and limits the pressure in the tank. In the heating systems of autonomous heating apartments and private houses, equipment is used whose working pressure is at least 3 bar.

Volume calculation

Volume is the main characteristic by which the expansion tank is selected. Many sources advise choosing an expansion tank within 10% of the total coolant volume in the heating system. This method of determining the capacity of the device is based on the fact that the coefficients of thermal expansion of the coolant even when the glycol content is up to 90% and heating of +100 degrees does not exceed 0.08.This method of calculation does not take into account the pressure in the system, so it can give inaccuracies. There is a more accurate method for calculating the volume of the membrane expansion tank. It uses the ratio:

V = C * Bt / (1 - (Pmin / Pmax)), where

- С - volume of heat carrier in the system;

- Bt is the coefficient of thermal expansion of the coolant;

- Pmin - initial pressure in the tank;

- Pmax - allowable pressure in the system.

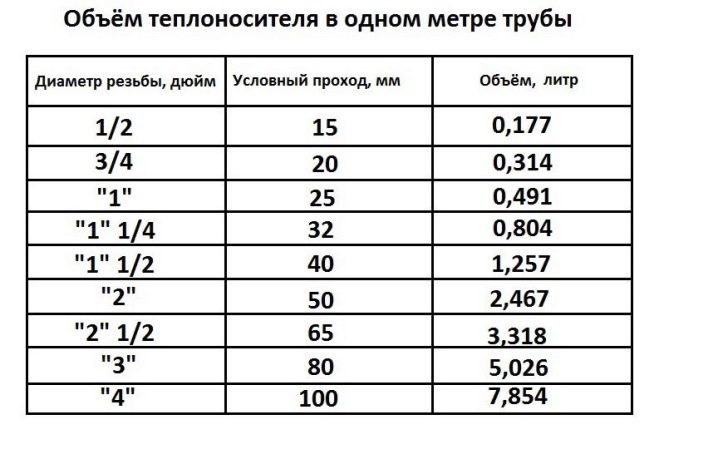

The amount of coolant in the heating system is determined, taking into account all its nodes. This parameter is obtained from the design documentation for heating. If this is not possible, you can use the approximate calculation, which is based on the fact that the volume of coolant in heating systems is associated with the heating capacity - for each kW there are 15 liters of liquid. The coefficient of thermal expansion of a liquid is determined with the help of its composition - most often, in heating systems of apartments and houses, it is possible that glycols are added to water to improve its characteristics. This coefficient may also depend on the temperature of the coolant. You can find the required values in the tables of the volume of water in the pipe.

The maximum pressure in the heating system is determined using the minimum of the values that are allowed for different nodes. The transition valve is configured exactly on it.The initial pressure in the heating system with the cooled coolant corresponds to the tuning (minimum) pressure. For many devices, it can be precisely controlled by common means (venting the air from the tank or pumping it up with a pump). The pressure in the tank is monitored during installation of a pressure gauge on it. The calculated data will give an increase in the volume of the coolant in the system during its heating. To select a tank, the fill factor is rounded up. The coefficient depends on the maximum and initial pressure and can be found using the tables provided by the manufacturers or in the special literature.

Installation

Install the membrane expansion tank is easy, but it is better to entrust it to a specialist. First of all, the device instruction should be used. When installing this unit in a heating system, it is important to carefully check the tightness of the connections. The expansion tank must not be opened or disassembled. It is simply attached to the pipeline that is closest to the boiler. To prevent an increase in pressure, install safety devices.

When installing the tank should consider the following rules:

- tank set to branch;

- the temperature in the room should be constantly above 0;

- need to double-check before installing all the calculations;

- tank volume of more than 30 liters is not mounted on the wall, and put on the legs;

- a pressure gauge is installed at the outlet of the tank to control the pressure; a check valve is installed at the inlet (if there is no pump);

- the device must be in a place comfortable for maintenance and adjustment;

- when attaching the tank to the wall, on the bracket it is necessary to maintain a height that will be convenient for access to the stop valves and to the airspace;

- the underwater pipe and crane should not overload the expansion tank with their weight, the supply pipe should be strengthened separately;

- to the membrane tank, located on the floor, you can not lay eyeliner on the floor across the aisle;

- there must be a distance between the wall and the tank for the inspection.

The small expansion tank can be hung to the wall if its carrying capacity is enough. Many recommend installing the tank so that the pipe is attached to the tank at the top and the air chamber remains at the bottom.Thus, it is easier to remove air from under the membrane, it will displace water. However, installers recommend installing the connecting pipe down and nothing else. And in some models, the fitting is initially located in the lower part of the side wall, and to put the vessel otherwise it simply will not work. This installation method is due to the fact that cracks will appear in the membrane. When installing the nozzle down the air penetrates the coolant more slowly, and the device will last longer. In the opposite case, the air quickly flows into the chamber with coolant, and the tank will require urgent replacement.

Faults

One of the most common failures of the membrane expansion tank is considered to be membrane rupture due to exceeding the allowable pressure and uneven loads. For pressed membranes use more durable materials, since they can not be changed, so replaceable membranes are torn quite often. Due to the rupture of the membrane, the expansion tank will fail because water will fall on the inner surface and the tank will rust, which is unacceptable. Therefore, the material from which the membrane is made, greatly affects the reliability and quality of the expansion tank. You need to be careful when choosing the right model, installation and maintenance of the device.First of all, it needs to be properly configured.

Review of the principle of the expansion tank, see the following video.