We select and install a sump for the heating system

In any heating system, the section inside the circuit decreases with time. Rusty water with harmful suspensions during operation reduces the permeability and water pressure, which is often the reason not only for the poor performance of the entire system, but also for its breakdowns. To cope with the problem will help a special device - sump, however, his choice has a number of nuances.

Special features

A sump is a device for filtering and cleaning water inside heating systems. This filter prevents the formation of deposits on the inner walls, it filters out foreign objects in the pipeline. Such a device has a number of modifications, each of which has its own characteristic differences. They are subject to GOST standards, they are chosen taking into account the diameter of the cross section of pipes.In general, the purpose of the device is to clean the coolant before it enters the system itself.

The devices operate on the principle of a colander: the water goes through the branch pipe inside the sump, at the bottom of which sediment is suspended. The purified liquid continues to flow through the outlet and enters the heating system. Changing the direction of the watercourse in the water supply system, the sump divides the water into clean liquid and dirt, which is deposited in a special filter container.

This device is functional, with it you can do the following:

- increase the efficiency of the heating system;

- equalize the thermal efficiency of the batteries;

- extend the life of each element of the heating system;

- reduce the cost of heating the home;

- reduce the risk of an emergency and leaks;

- eliminate the need for manual flushing of the system.

Such products protect the main components of the system from dirt and clogging of working channels. They eliminate pipe channels, taps, air valves, expansion tank nozzles from overgrowing with dirt. It provides increase in high-quality warming up of the heat carrier several times.During normal operation, the state of the water will be acceptable for circulation in the system without the deposition of lime and alkaline salts. The heat supply inside the pipes will be correct, without waste of energy.

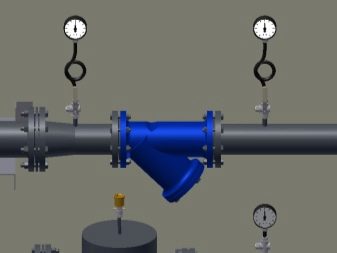

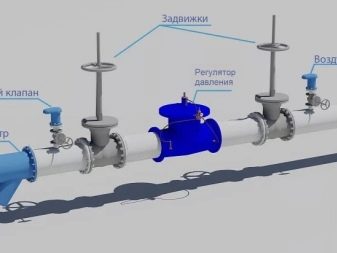

The sump is a tool to improve the system, a node for the expansion of the pipeline system with a change in the direction of water flow. Usually, pressure gauges are installed around it, indicating the degree of hydraulic resistance. They are installed on both sides of the filter. A distinctive feature of the installation is the fact that the sump should have a direction in the direction of the flow of coolant. For ease of installation, manufacturers on the body make an arrow indicating the direction of movement.

Over time, large debris and dirt accumulated in the sump, and it will need to be removed. To service the sump, pre-block the system, then unscrew the nut located on the bottom of the hull. After that, take out a special glass with suspensions. The tank is emptied, then put in place and fasten a nut. The location of the sump determines the frequency of its purification. For example, if a customer buys a product with a vertical glass arrangement,clean it more often.

The principle of the sump is very simple. This process is cyclic and repeated many times. However, the choice of the product is impossible if you do not have at least a superficial idea of the features of its varieties. After all, not every type of device is suitable in a particular case. And the matter is not even in price, but in the different cleaning possibilities of individual modifications.

Kinds

Classify mud drains for heating systems can be on several grounds.

Particle separation type

By the type of separation of particles, the products are divided into three types.

Sumps

Filters of this type operate on the basis of gravity forces. When the volume rises sharply and the flow rate drops, solid particles in the water settle to the bottom under the influence of gravity. The use of gravitational forces can be complemented by a sharp change in the direction of flow. In this case, turbulent and centrifugal forces are connected to the work. They release water from more inert heavy particles.

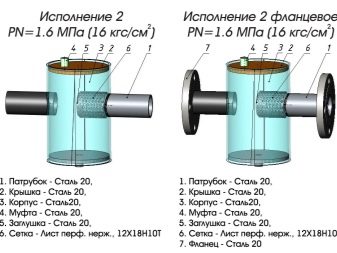

This filter has a cylindrical body, which is located vertically, as well as two nozzles for inlet and outlet with flange connections.From above, the body of the sump is tightly welded. At the bottom it closes a flange-type plug. The flange cap in the middle has a nozzle that is necessary to clean the filter (washing it or draining the dirt). The upper nozzle is necessary in order to remove accumulated air from the system.

The cavity of the cylinder can have several jumperswhich contribute to the change in the movement of water flow when passing through the filter. Thus, the suspensions settle down and await purification as the sludge accumulates. Such mud collectors are installed mainly in industrial-type enterprises.

Their use in home heating systems is not always rational. Although the principle of water purification by the gravitational method is widely used in other types of purifiers.

Mesh

This type of gryazeviki are the most common products on the market.

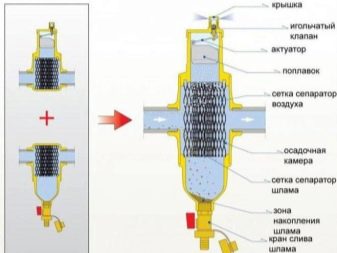

Its constituent elements are as follows:

- cap;

- needle valve;

- actuator;

- float;

- air mesh separator;

- sedimentary chamber;

- sludge screen;

- garbage accumulation site;

- faucet drain dirt.

According to the type of mesh installed inside the hull, such mud collectors are divided into two types: coarse and fine cleaning. In this case, during the rough cleaning, the mesh removes particles of 5–300 microns in size from the flow. Analogs of fine cleaning cope with smaller fractions of harmful impurities (no more than 5 microns). Usually, the elements of fine cleaning are used where additional purification of water is necessary so that it is suitable for domestic needs. Often used for heating systems analogs coarse.

Due to the presence inside the design of the needle valve, it is possible to avoid emergency situations when the heating system is gassed. Such designs are of two types: straight and angular. Experts usually use angled varieties for mounting, considering that they more effectively retain large suspensions of rust and dirt. However, the efficiency depends, among other things, on the increase in the hydroresistance in the pipeline. If the pressure is constantly changing, particles of dirt and rust will be forced through water through the mesh, which will make the device less efficient.

Magnetic

The main cleaning element of such structures is a magnet. It attracts metal suspensions, so the water in the coolant gets rid of rust.This filter helps to reduce the amount of scale on the internal walls of the circuit radiators and pipes. Its distinguishing feature is the fact that it does not slow down the flow of water in the system and does not change the pressure in the pipes. For this reason, the installation of such devices can be carried out even in the suction areas of the pump.

Such a mud trap is characterized by a two-stage purification. First, the water passes through the mesh cleaner and disposes of large metallic particles. After that, it is subjected to a more thorough cleaning, getting rid of small suspensions. According to expert estimates, such filters are more efficient than mechanical analogs of a conventional mesh type. Options with a magnetic principle of operation are more expensive, but the efficiency of their purification is higher. In the process, these varieties create a magnetic field that not only purifies the water, but also makes it softer, which helps reduce the amount of salts and prolongs the life of the radiators.

Type of service

By type of service, mechanical mud filters are divided into three types such as:

- self-flush;

- washing;

- non-flush

Products of the first group effectively remove debris from the heating system.however, they are easy to maintain and do not need to dismantle the part of the system on which they were installed. Self-washing counterparts are distinguished by the fact that they have a flushing valve at the bottom of the device. If it is necessary to clean it, it is opened, at this time the flowing coolant stream washes away the adhered dirt and cleans the filter screen. The advantage of such products is the fact that the described method of cleaning allows you to remove even densely entrained dirt particles.

Non-flush-type versions are rarely used in heating systems, as they need dismantling, which is extremely inconvenient.

By type of installation

For each case, it is necessary to take into account not only the type of material, but also the method of connection, which can be flanged, threaded or welded. On stand-alone systems and with a small cross-section of the pipe, coupling sleeves are more often installed. These varieties are characterized by the presence of couplings with internal and sometimes external threads. For ease of mounting the body of such filters has a hexagonal shape. This allows you to connect it to the pipe with an open-ended wrench, adjustable wrench or gas wrench, or dismantle it if necessary (for example, replacement).As a rule, filters of this type are immediately incorporated into the system.

If the diameter of the threaded connection is more than two inches, it is easier to install mudflanders with flanged fasteners in such areas. They are sealed with a special ring, which is bolted. The installation of such a cleaner is different from the connection of the clutch analog, since in this case it is impossible to do without welding. It is necessary to weld return flanges to the pipe in a strictly selected position. It is important to consider the installation length.

Sometimes the installation of a sump is completely deaf. Such filters on both sides have connections, at the edges of which there is a chamfer for the weld. These products are notable for their low price, however, in order to replace them, you will have to cut out a part of the pipe. To the variants of the welded type include mudflocks in the case of polypropylene. They are made specifically for such a connection of pipes of small diameter. Their installation and disassembly do not differ from the standard welding scheme, so they are not particularly popular with customers.

How to choose?

Not all goods offered to customers in the market are branded.In order not to get to the fake and buy a really high-quality mud filter, it is worth considering a few nuances, starting with the choice of the store. It is better to purchase at a proven point of sale, which has a good recommendation from buyers and craftsmen in the field of construction and repair. You should first choose two or three devices, then find out their technical characteristics in order to understand whether the devices are suitable for installation in specific conditions. After you can read reviews about them on building forums, and only after that return to the store and buy one of the options.

Experts recommend buying devices that combine at least two types of cleaning, for example, magnetic and mesh.

Selection of the desired variety after understanding their main nuances is not difficult. If this also seems difficult, you can ask for help from a specialist in a specialized shop or ask advice from a friend of the master, who knows firsthand what kind of sump is more effective and durable than others in a particular case. But for the purchase you need to know the type of connection, the diameter of the pipe and the parameters of the construction length and height.For example, it is necessary to understand exactly where the filter will be placed, whether it be a circulation pipe or shut-off equipment. It is worth paying attention to the features of the most popular products that are installed in heating systems.

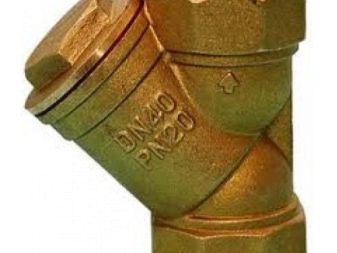

Brass slanting

These mud traps have a mesh principle of cleaning, a threaded coupling with a wide size range (1 / 2–2 inches), and are characterized by a laconic design. They are suitable for autonomous heating system. The nominal pressure in the system with a different diameter of the pipeline can be 16 and 20 bar. The pressing pressure is 24 and 3 bar, the mesh size of the varieties with different diameters can be 500 and 800 microns. The degree of transparency of the filter can be 39 and 53%.

The installation part of such mudflats should always look in the direction of the water course during installation.. When installing such a cleaner, it is usually necessary to install a shut-off valve in front of it, which, in case of cleaning the dirt collector, blocks the flow of coolant. When installing such a device you need to take into account the orientation. If it is attached to a horizontal section of the pipe, the bevelled cylinder should be located at the bottom.If it is plugged up, this leads to rapid contamination and reduced throughput. When installed on a vertically directed pipe, the oblique element must look downwards, otherwise the dirt will not be able to collect in the sump.

Cast Iron Magnetic

These water filters are structurally practically no different from previous analogues, except for the material of manufacture and the presence of the rack, which is equipped with permanent magnets in the form of disks resistant to corrosion. The cork and the device are made of cast iron. The filtering part is the grid in the form of the cylinder, made of stainless steel. They are cleaned in two directions: the network removes mechanical debris, magnets rid the water of metal particles. This type of sump is effective, for which it is in high demand among buyers.

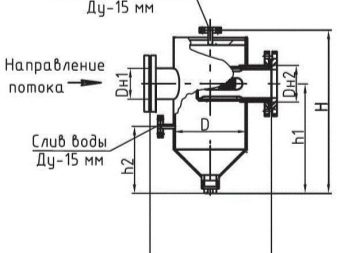

Conditional pass (DU) and the main characteristics of such options are different. For example, when the remote control is 25 mm and the diameter of the G1 pipe thread, the building height is 80 and 140 mm. In this case, the construction length can be 120 and 200 mm, and the size of the grid cells will not exceed 1.2 x 1.2 mm. If the remote control is larger, for example, it is 40 mm, its building height will be 110 and 180 cm, the building length will be 140 and 200 mm, the size of the turnkey hexagon will be larger (46 mm).The difference in cleaning such a filter is the need for washing and the rack itself with magnets.

Flanged Magnets

These products are more similar to analogs of cast iron with magnetic water purification. The differences are in size, as well as the presence of a flange-type plug instead of a threaded plug.

Technical characteristics of these options are as follows:

- DU-50 has a building height of 140 and 200 mm, length - 230 and 280 mm with a flange bolt hole diameter of 18 mm;

- DU-65 is characterized by a height of 165 and 250 mm with a length of 290 and 355 mm and a diameter of a connecting hole of 18 mm;

- DU-80 in height is 195 and 275 cm, its building length is 310 and 385 mm, the diameter of the hole is 18 mm;

- DU-100 is 215 and 315 mm in height, 350 and 425 mm in length, the diameter of the inlet is 18 mm;

- The DN-150 has a height of 320 and 490 mm with a length of 480 and 645 mm, the diameter of the connection is 22 mm.

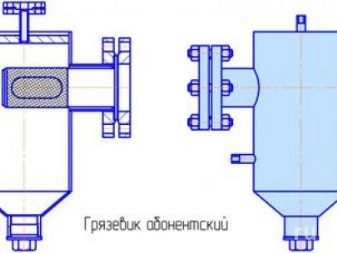

Subscriber

Subscriber gryazevik (TS) is used to install heat mains. Such filters provide vertical and horizontal type of execution, however, more often in the installation you can see exactly the vertical options. These devices are effective because they combine the strainer and the functions of the sump. They are characterized by a long service life and serviceability.Due to the available internal volume, it is possible to perform prophylaxis less frequently than when buying other devices.

These varieties can have a remote control that is equal to 40, 50, 65, 80, 100, 125, 150, 200, 250 mm. At the same time, the mass of devices, depending on the model, is 16.7, 22.7, 45, 48.9, 70, 73, 103.3, 184, 269 kg. Their mounting dimensions are larger than those previously described: the minimum parameters for height and length are 217x308 mm, while the maximum values are 785x730 mm. The products are distinguished by two degrees of purification: first, under the influence of gravitational forces, large suspensions settle to the bottom, while small particles remain on the grid.

Installation

To install the cleaner in the system correctly, you need to take into account the basic nuances and know the installation technology. Everything must be done in accordance with the requirements of GOST, according to which the fixation of any device is carried out at a temperature not lower than -20 degrees with a pressure not exceeding 2.5 MPa. Installation of the water filter is carried out mainly on the return pipe in front of the circulation pump or boiler, if the pump is already part of it. This will remove various types of contaminants from the coolant during circular motion along the contour.Installation of the filter on the heating system is performed by means of an adjustable wrench or welding.

Pre-block the valve of the main riser, the remaining liquid is poured into a previously prepared container. Since the work can be dirty, it is necessary to close the flooring with thick rags, and in the place of the drain polyethylene. Water is drained to the maximum, if necessary, washed radiators and pipes. If they are clogged before installation, you can not wait for the effective operation of the coolant. Based on the type of device, perform its installation on the pipeline. To do this, use a key or welding, while ensuring that the sludge compartment is located at the bottom: dirt and clots of rust should settle down, which is possible if the container is located at the top of the device. This rule applies to all types of mud collectors, regardless of the method of their attachment (vertical or horizontal).

If a flushing of the system was performed before the connection, it is necessary to remove residual rust from the surfaces of the attachment points so that it does not cause a leakage of the connecting nodes. If welding is planned after trimming a pipe section, you need to choose a convenient tool for high-quality chamfering.When there is no experience with welding, it is better to entrust the installation to a specialist who does the work qualitatively and tightly.

To be able to simplify maintenance, it is worthwhile to install taps before and after the filter. A shut-off valve can be installed in front of it, and a reducing valve at the outlet.

Tips

The maintenance of the device depends on its type. For example, in order to track the degree of contamination of the mesh cleaner, it is necessary to remove the mesh from time to time and inspect it for sticking sediments. For efficient operation of the sump, it is necessary that the increase in hydroresistance in terms of equipment before and after the filter is smooth.

You can place the filter in front of specific points, which include the following:

- a gas boiler;

- valve;

- stop valves;

- heating sensors;

- recharge pipes;

- plate heat exchangers.

The first maintenance of the filter can be carried out approximately in half a year from the moment of its installation. If the water in the system is not clean, constantly muddy, it is possible that it will be necessary to wash the filter more often.Masters pay attention to the fact that the installation of a sump should be correct, otherwise the device will quickly fail. In addition, when buying you need to take into account that in the house must comply with certain conditions of temperature and pressure. The device must be designed for temperatures up to +110 degrees and pressures up to 16 bar.

Next, see how to self-clean the dirt tank.