Fum-tape: rules of choice and use

To ensure the efficient operation of many designs, products are required that will help the system to function smoothly, as well as provide a holistic mechanism. Among such products is to highlight such material as fum-tape.

What it is?

Most construction and installation works require the solution of the problem of sealing joints and joints of various kinds of constituent elements. In particular, this task is relevant in the course of laying the water supply system of the central heating system, as well as gas distribution communications. Installation of structures, where the occurrence of a certain level of pressure is expected, requires the use of a similar material. Previously, flax fibers were preferred for sealing.Today, due to the expansion of the product range, the fluoroplastic fum-tape acts as a sealing and sealing material.

In plumbing systems, quite often you may encounter a leakage problem. Such problems occur due to the loose fit of the construction details to each other, since they may have slightly different sizes and diameters. Such a tolerance provides free screwing and, if necessary, extraction of any separate part of the system in the event of a breakdown, but does not allow the elements to be fixed as tightly as possible.

In order to protect the pipeline from water leakage and seal the joints, you can use fum-tape. Products are sold in the public domain and have a low cost, so the purchase of such a useful product will not cause any difficulties.

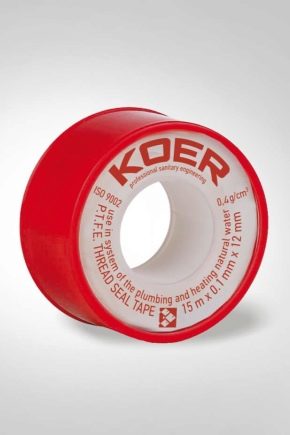

The product has a second name - most people quite often use it for domestic purposes, while referring to the silicone tape. The material is a seal made in the form of a narrow, non-sintered film. The raw material for the production of the product is fluoroplastic.Based on this, the abbreviation "FUM" is interpreted as follows: fluoroplastic sealing material. During production, the fluoroplastic harness is rolled into a film to the required thickness. It can have different sizes, and the tape is already wound on a reel.

Fum-tape also should be called a deformable filler and threaded lubricant, so that the resulting compounds have a high level of tightness. The product contains fluorine, which increases the heat resistance and strength of the tape. The product is not torn, does not stretch and is resistant to contact with chemicals. In addition, the product quality listed above retains a fairly long time. The main positive feature of the product is its performance and a wide range of conditions in which it can effectively cope with its task.

Products belong to the group of slow-burning goods and non-explosive materials. But when the tape is heated with a temperature higher than + 260ºС, the fluoroplastic, the main component, begins to actively evaporate the fluorine compounds of the volatile type, which have a high level of toxicity and therefore are unsafe for human health.In order to understand the designations applied by the manufacturer to their products, one should know that the fum tapes are marked as follows: the product indicates its brand, the length of the material roll, and the width and thickness of the film. In order to have the most complete picture of the products in question, it is necessary to study the positive and negative characteristics that are inherent in the product.

The advantages of fum-tapes include such features as:

- the main characteristic of the material is resistance to mechanical and thermal effects;

- the tape has high plasticity during operation;

- on a working basis, a high-quality tape retains its qualities for a long time - it does not become hard, does not crack, and also does not move away from the places where it forms a joint of construction details;

- the material does not react with chemicals and is resistant to their effects;

- with the exception during the operation of the tape its heating to the maximum permissible temperature, the material is absolutely non-toxic, therefore safe for humans;

- working temperature range of products ranges from -70 to + 200ºС. The ignition of fum-tape can occur when exposed to a temperature of about + 520 º C;

- the working pressure level can reach about 41.2 MPa;

- elongation at break in some cases is about 100%;

- material resistant to corrosion.

For an objective assessment it is necessary to conduct a comprehensive study of the products, so it is worth noting the existing disadvantages of fluoroplastic sealing materials.

Product disadvantages include the following properties:

- A high level of tightness of the joints is difficult to achieve when using a tape for pipes having a large diameter

- often due to temperature fluctuations, the material can expand, which adversely affects the tightness of the connection of structural elements;

- for highways, where the joints will be subject to vibrations and movement with the help of fum-tapes, the tightness of the formed joint of the parts will be broken.

It should be noted that when using a sealant to perform installation work at the household level inside the premises, for example,when arranging hot and cold water supply or heating systems, the disadvantages of the products are not critical, and the results of the work have high quality indicators, as well as the aesthetic appeal of all educated compounds.

The warranty period for product storage is 13 years from the date of manufacture. Storage conditions of the product require a certain level of humidity, which should not exceed 80% in closed and dry rooms. In addition, fum-tapes should not be stored in close proximity to sources of heating, the minimum distance between the products and the devices is at least one meter.

Kinds

Manufacturers distinguish several types of products.

- FUM-1 - products of this group are recommended for use in water and gas networks, as well as in highways with aggressive chemical media, mainly of industrial type. The tape can be used in designs where there are concentrated or diluted solutions of alkali and acids. The product contains a lubricant - about 20% vaseline oil.Such a product is most in demand because the lubricant included in it protects metal parts from oxidation, and also facilitates the friction of the metal on the metal during installation. However, there are some restrictions for the operation of fum-tapes - these products are not suitable for work with threaded connections of oxygen equipment, because from oxygen the oil begins to oxidize and release thermal energy.

- FUM-2 - similar products are intended for use as a sealing material in systems where the movement of potent oxidizing agents and oxygen occurs. Lubricant in the composition of the tapes of this group is not included or is contained in a minimum quantity.

- FUM-3 - these products are manufactured for work with water and gas communications, in addition, allowed to be installed in systems in which aggressive media circulate. Lubrication in the product is not available. This product is made from the edge parts of the materials belonging to the first two groups of goods.

Fum tapes can also be divided into types, taking into account their size - thickness, length and width, namely:

- product thickness ranges from 0.075 mm to 0.25 mm;

- minimum width is 10 mm;

- The minimum tape length is 100 cm.

Tape FUM-1 has the following characteristics:

- elongation at break - 100%;

- thickness - from 0.1 mm to 0.14 mm;

- the width of the seal is: 10, 15, 20 and 60 mm;

- breaking stress –40 kgf / cm²;

- The lubricant content is between 17 and 20%.

Tape FUM-2 has the following indicators:

- product thickness can be from 0.035 mm to 0.2 mm;

- the percentage of lubricant can sometimes be equal to 0.3%;

- tensile stress is 60 kgf / cm².

FUM-3 has averaged characteristics, since this product consists entirely of scraps of material used in the products of the first two grades. In addition, the sale can be found gas strip yellow. The thickness of such a product is 0.25 mm.

A scope of this production are the systems which are responsible for gas supply which work under the minimum pressure. However, in some cases, the gas pipelines use the usual unspecialized fum-tape.

Scope of application

The areas of operation of the fluoroplastic sealing material are as follows:

- the tape is in demand during the installation of plumbing devices and communications;

- the product can be used in the process of installing instrumentation and control valves;

- fum-tape is used in work with steel pipes whose diameter does not exceed one inch;

- to seal sections of the copper pipe, where threaded fittings are used for the connection;

- sealing material is used in piping systems consisting of polymer-type raw materials and metal-plastic;

- to connect elements of copper, brass and bronze using thin-walled fittings with fine threads.

How to use?

Before starting work with the fum-tape, it is necessary to perform a number of obligatory preparatory measures with a working basis.

These works include the following steps:

- the surface to be used for winding the seal should be clean, so all existing dirt and rust should be cleaned and removed. To do this, use a metal brush;

- working area is degreased. For these purposes, you can use gasoline or the same solventthat will help avoid sealing seal on the parts;

- It is possible to work with a fum-tape only after complete drying of the working base.

In addition, despite the fact that the installation work with the product is quite simple, in the process of their implementation it is necessary to follow a certain technology of tape winding, otherwise it will not be possible to avoid depressurization of the connection made. Works should be carried out, adhering to the following scheme in strict sequence of the described steps.

- After the preparatory activities, the seal is wound. The tape must be wound on the thread strictly in the direction of the movement of an hour hand, since the connection pipe will be mounted in the same direction. The movements should be smooth, since overly energetic work with the tape can stretch the product and deform it. However, weak fixation can also have a negative impact, since the turns in this work will be loose.

- The number of layers of the seal depends on the diameter of the connection, as well as on the thickness of the fum tape. If the diameter of the pipe is larger, and the sealant purchased for sealing is thinner, the more it will be necessary to make turns of material.For example, for a pipe with a diameter of 30 mm you will need at least three layers of tape, and for a product with a cross section of 40 mm - at least 4 turns. In addition, the depth of the thread depends on the diameter of the connection. It should be borne in mind that all the voids present in the joint will need to be filled with the material as tightly as possible.

- After testing the system can detect a leak at the junction. In this case, the entire procedure will need to be performed again. To do this, it is necessary to disassemble the entire connection, removing the remains of the seal, and then, using the new tape, perform the work in the same way, but increasing the number of turns made. It is impossible to wind the new product on top of the old, because it will not ensure tightness.

In order to organize the most comfortable conditions in the process of working with a fum-tape, it is worth remembering its physical features, which primarily concern the fact that the product is rather slippery and it can be inconvenient to work.

Tips

Before purchasing a product, you need to familiarize yourself with the instructions for its use, the specific features of sealing with a material such as fluoroplastic, and also take into account your own requirements for the quality of the future compound, weighting them with the capabilities of the material.The first rule when choosing a fum tape is the selection of a quality product. Reliable tightness of the joints can be ensured only by the film that will stretch well during the work. Those products whose properties do not imply its stretching will very quickly turn into crumbs or crack. Cheaper products, during the production of which they tried to save money, soon after winding, will lose elasticity, and in the coil they will not stretch or will break into fibers.

In order to avoid mistakes when buying a fluoroplastic seals, experts recommend focusing on the recommendations of more experienced masters.

For domestic needs when installing a pipeline in an apartment or private house, it is best to purchase the following types of products:

- works with coarse thread should be performed with tapes 19 mm wide, with a thickness of from 0.12 mm to 0.2 mm;

- fine threads can be wrapped with a sealer with a width of 12 mm and product thickness up to 0.1 mm.

The cost of production depends not only on the manufacturer of the material, but also on the length of the coil. For minor repairs, you can purchase a small hank. At the end of the work, a certain amount of sealant may remain on the reel,worry about the fact that the product will lose its properties is not worth it, because in this form it can be stored for a long time, and if necessary, the material will already be at hand.

Previously, except for flax fibers, there was no alternative for sealing water supply connections. Today the situation has changed, allowing the use of materials for such work that have proven themselves in practice. In addition, in comparison with sanitary flax, the use of a fum-tape is an easier process, since there is no need to treat the working surface with a layer of sealant, as required by sealing joints with flax fibers.

In this video, Alexander Kuznetsov talks about the advantages and disadvantages of sealing joints with a fum tape.