Varieties and features of heat exchangers for hot water from heating

To increase the level of comfort of their homes, the owners resort to the use of various devices. Uninterrupted water supply with hot and cold water remains the most pressing issue. Among all sorts of devices that provide such needs, you can select the heat exchanger from the heating for hot water.

Special features

This device makes it possible to significantly expand the functionality of the equipment, the main purpose of which is space heating. Since the supply of hot and cold water is a factor testifying to the well-being of a residential building, the availability of effective equipment for this purpose is mandatory.

With cold water in private homes, the situation is somewhat simpler than with the DHW. Hot water is a more complex system, where the productivity of work is directly dependent on the heating mechanism. The role of such an element is often the heating boiler.

On sale there are a huge number of such units, which differ in their design features. On this basis, the heating of the fluid will be carried out in different ways. One of the options that has recently become widespread is to include a heat exchanger for hot water.

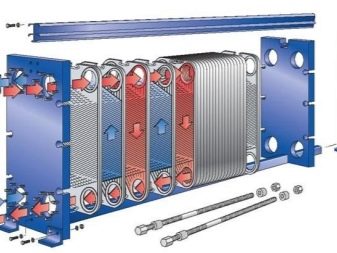

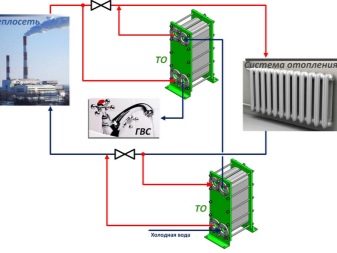

The device has this name due to its main function - temperature exchange processes occur in heat exchangers. And since it comes to hot water supply, it becomes clear that the heat energy from the hot water from the heating is transferred to the cold so that it reaches the desired temperature. Some enterprises use air heat exchangers with fans, in addition, there are heat exchangers for the chimney, which allow to save thermal energy.

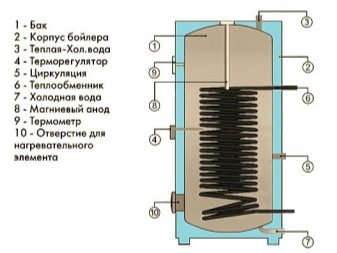

The peculiarity of the process is that hot water from the heating system is circulated through a heat exchanger, while delivering a certain part of the heat from the cold liquid in any container. Usually in the role of the tank acts as a boiler. And the whole process is referred to as indirect heating technology, since in the course of ensuring the required temperature, water does not directly contact the energy carrier with the heating system for the water supply system.

The following factors affect the operation of the heat exchanger:

- contact area of two media and the unit itself;

- thermal conductivity of materials used in the manufacture of the structure;

- the difference in temperature between cold water and water from the heating system. The greater this value, the less will be the efficiency of the device.

Some home craftsmen use home-made products as such a device that will transfer heat between liquid media.

Types and principle of operation

Heat exchanging equipment on the modern market is represented in a large variety.

The entire range of products available in this line can be divided into two types, such as:

- plate aggregates;

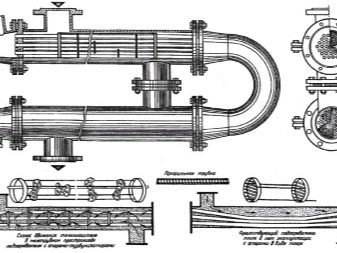

- shell-and-tube devices.

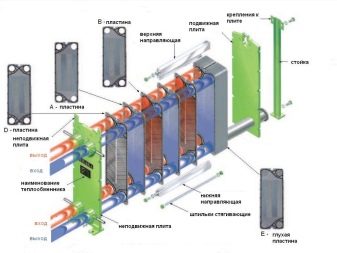

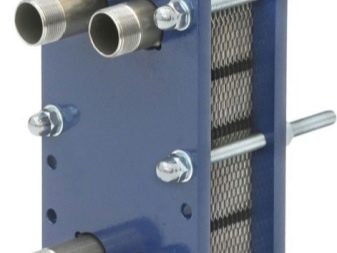

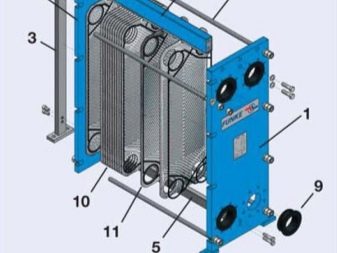

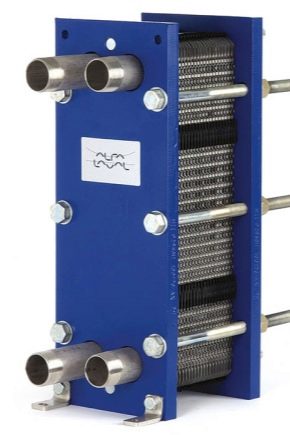

The latter type, due to its low efficiency index, as well as its large size, is hardly sold on the market today. The plate heat exchanger consists of identical plates of corrugated type, which are fixed to a strong bed of metal. The elements are mirrored relative to each other, and between them there are steel and rubber seals. From the size and number of plates directly depends on the heat exchange area.

Plate devices can be divided into two subspecies based on the configuration, such as:

- solder units;

- collapsible heat exchangers.

Dismountable devices differ before the production of a soldered assembly type in that, when necessary, the device can be modernized and adjusted for personal needs, for example, to add or remove a certain number of plates. Folding heat exchangers are in demand in areas where hard water is used for domestic needs, due to the characteristics of which water accumulates on the elements of the unit and various contaminants.These tumors adversely affect the efficiency of the device, so they need regular cleaning, and thanks to their configuration, there is always such a possibility.

In addition, collapsible type heat exchangers are compact in size due to the absence of a clamping structure in the system.

Disposable devices are distinguished by the following features:

- high level of resistance to high pressure and temperature fluctuations;

- big operational term;

- low weight

Cleaning solder units occurs without disassembling the entire structure.

If there has been a deterioration in the operation of the device after a certain period of use, then experts recommend purchasing a special reagent that will help cope with neoplasms and scale inside the heat exchanger.

From the calculation of the type and installation of the unit should be divided into two types of heat exchangers for hot water from heating.

- Internal heat exchangers are located in the heaters themselves - furnaces, boilers and others. Installation of this kind allows you to get maximum efficiency during the operation of products, since the heat loss to heat the case will be minimal.As a rule, such devices already at the stage of manufacturing boilers are built into it. This greatly facilitates installation and commissioning, since it is only necessary to set up the required operating mode of the heat exchanger.

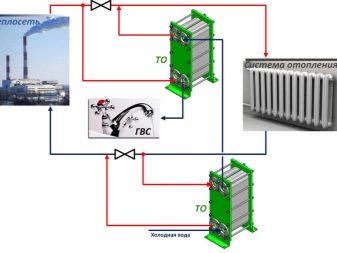

- External heat exchangers must be connected separately from the source of thermal energy. Such devices are relevant for use in cases where the operation of the device depends on a remote source of heating. As an example, there are houses in which centralized heating is provided. In this embodiment, the household unit that heats the water, acts as an external device.

External type heat exchangers have a lower performance indicator in comparison with internal devices.

Considering the type of material from which the partings are made, the following models should be highlighted:

- steel heat exchangers;

- appliances made of cast iron.

In addition, systems with copper soldering are distinguished. They are used for centralized heating of apartment buildings.

Nickel solder is recommended for heating systems that are operated in the industrial sector or during contact with chemically aggressive coolants.

The features of cast iron equipment should be considered the following characteristics:

- the raw material cools down rather slowly, which saves on the work of the entire heating system;

- the material has high rates of thermal conductivity, all products made of cast iron are characterized by properties at which it heats up very quickly and gives off heat to other elements;

- the raw material is resistant to the formation of scale on the basis of, in addition, it is more resistant to corrosion;

- by installing additional sections, you can increase the power and functionality of the unit as a whole;

- products from this material can be transported in parts, breaking it up into sections, which facilitates the delivery process, as well as installation and maintenance work on the heat exchanger.

Like any other product, such a dependent device has the following disadvantages:

- cast iron is not very resistant to sharp temperature fluctuations, such phenomena can be fraught with the formation of cracks on the device, which will adversely affect the performance of the heat exchanger;

- even having large dimensions, cast iron aggregates are very fragile, on the basis of which mechanical damage, especially during the transportation of products, can seriously damage it;

- material is prone to dry corrosion;

- the large mass and dimensions of the device sometimes complicate the development and installation of the system.

Steel heat exchangers for supplying hot water are notable for the following advantages:

- high thermal conductivity;

- a small mass of products. Steel does not make the system heavier; therefore, such devices are the best option when a heat exchanger is needed, whose task is to maintain a large area;

- steel units are resistant to mechanical stress;

- steel heat exchanger does not react to temperature fluctuations inside the structure;

- The material has good elastic properties; however, prolonged contact with a highly heated or cooled medium can lead to the formation of cracks in the area of the welds.

The disadvantages of devices include the following features:

- predisposition to electrochemical corrosion. Therefore, with constant contact with aggressive media, the operational life of the device will be significantly shortened;

- in devices there is no possibility of increasing the efficiency of work;

- the steel unit very quickly loses heat, which is fraught with increased fuel consumption for productive operation;

- low level of maintainability. It’s almost impossible to fix the device with your own hands;

- The final assembly of the heat exchanger from steel is carried out in the conditions of the workshop where it was manufactured. Units are monolithic blocks of large size, due to which there are difficulties with their delivery.

Some manufacturers, in order to increase the quality of steel heat exchangers, cover its internal walls with cast iron, which increases the reliability of the design.

Wiring diagram

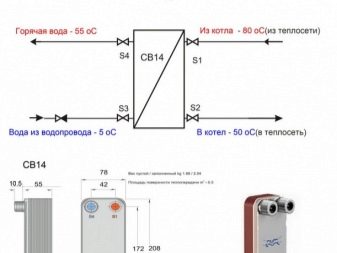

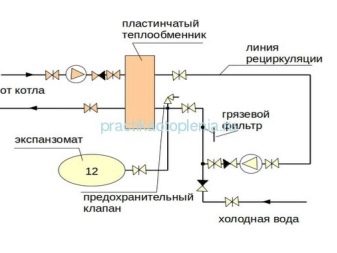

Installation work includes installation and connection of the device to the necessary communications. The technology of work depends on the type of heat exchanger for hot water, as well as on the place of its installation in the room. For installation of an internal type device, it is only necessary to connect it to the DHW system.

The technology of performance of work is reduced to the connection of the corresponding connections. into the break of the outlet from the cold water supply pipeline and the new hot water supply system. External units are located near the power supply.The device must be connected to the main line rupture, the hot water supply system is supplied to the outlet branch pipe, and the cold water supply outlet is connected to the inlet branch pipe.

After performing all of the above steps, the heat exchanger is set up and started. When connecting devices it must be remembered that all incoming and outgoing lines require special valves, due to which, if necessary, you can disconnect the heat exchanger from the heating system to perform maintenance or repair work.

How to do?

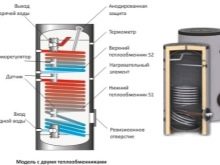

In order to independently make a heat exchanger for hot water from heating, first of all it is necessary to determine the choice of the type of device. The easiest way to make a boiler-type device. The unit is a barrel with a coolant, inside of which there will be a coil for heating the hot water supply.

To perform the work will need the following materials and products:

- metal tube and tank;

- anode;

- power regulator.

The tube is twisted into a spiral, two holes are made in the tank, the bottom one will be used to supply cold water, the top one - for the hot one.You can also make a so-called tube plate. Such a product consists of tubes that are attached to two plates with holes. Plates cut off from each other capacity, in the first there is an inflow of cold water and a conclusion heated, the second capacity is used for water circulation, increasing the length of tubes and the contact area. Such a device is lowered into the housing coolant, which will heat the water in the tubes.

Tips

The main problem that a person faces during the operation of a heat exchanger is scaling. It acts as a heat-insulating layer, which increases the time required for water heating, as a result - the power consumption increases. To reduce the risk of scale formation, manufacturers try to use special tubes in their systems, which undergo a certain polishing and are also made of materials resistant to its formation.

Modern technologies make it possible to fight scale with the help of a magnetic effect on water. To make the right choice of heat exchanger for hot water from heating it is worth considering the structure and type of the existing heating system,its parameters and the amount of water consumption.

You can learn more about heat exchangers from the video.