Basement: the subtleties of designing and creating a basement

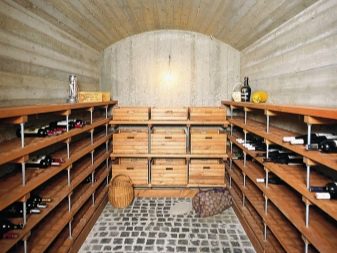

The basement today performs many functions and is an important part of any dwelling. It can act not only as a building for storing food or things of seasonal use, but also to be a full-fledged residential area. Proper arrangement of the basement will help organize a reliable place to store food, to perform the function of a wine cellar, gym or boiler room.

Special features

What is usually called a basement has many variations and individual names.

There are many types of basements, differing in functionality and location, namely:

- basement. The base is located below the zero level. Comfortable temperature is reached in a natural way or byvarious heating devices;

- the underground is the territory under construction between the soil and the basement of the first floor;

- technical underground. It houses engineering communications: electric cables, water supply, sewage system. In the technical underground can also be located boilers and pumps;

- Underground with ventilation. In buildings constructed in areas with very low temperatures, it is necessary to constantly ventilate the room between the soil and the building itself. This underground is located under the basement or technical overlap;

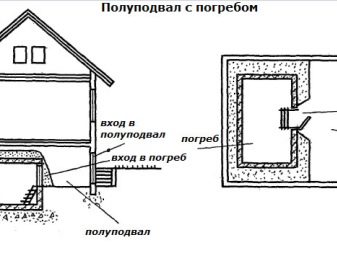

- the basement is located below the zero mark. Often used as a workshop, sauna, garage or boiler room;

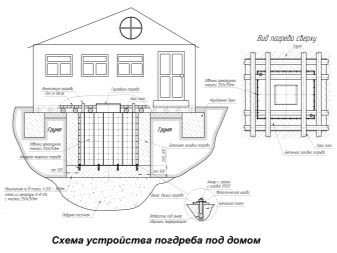

- The cellar is often used to store food. It can be placed under the living room, or separately on the site.

In this article, the term "basement" will be understood as a room located under a residential building. It is worth considering its device and features of construction.

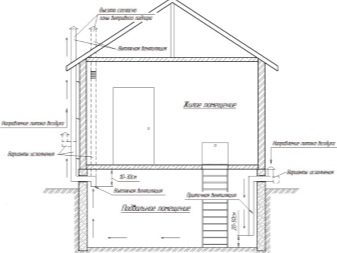

Projects

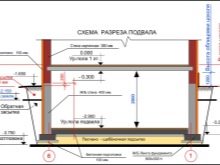

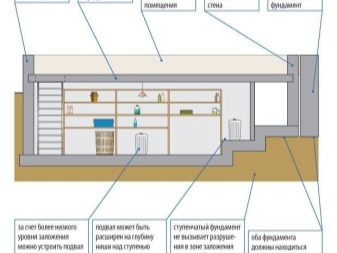

Construction of a private house with a basement requires special procedures before starting work. These include the geological study of bearing soil.Only after it you can start drafting a basement and be sure that it will not violate any requirements of regulatory documents. If the project provides for a separate basement floor, commensurate with the entire area of the building, it is necessary to equip arched and door openings in the foundation. The recommended height is about 2 meters. It will give the opportunity to use the basement in full.

Equipping the entire basement below the soil level is illogical, the average height of the walls above the ground should be from 50 to 100 cm. It is important to remember that the construction of the basement with a depth of more than 150 cm can lead to flooding with groundwater. With a foundation equipped below the groundwater level, a drainage system will be needed. Sometimes, instead, you can artificially lower this level or build a basement above it. But these options incur significant financial costs.

And also in the development and design of the basement should pay attention to engineering and communication channels. So that during the construction it was not necessary to destroy the walls and the ceiling, it is necessary to think in advance about the location of the pipes for supplying and discharging water, power lines and similar communications.The foundation structure is subject to lateral pressure, which can lead to the destruction of walls. The strength of the basement can provide internal walls. To do this, it is necessary to equip the foundation of concrete and combine it with the supporting elements of the building reinforcing mesh.

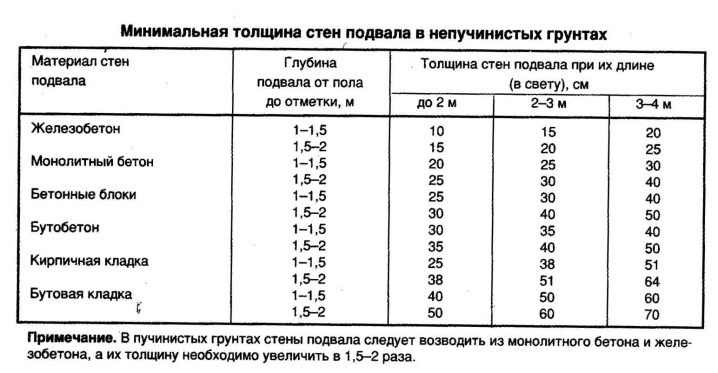

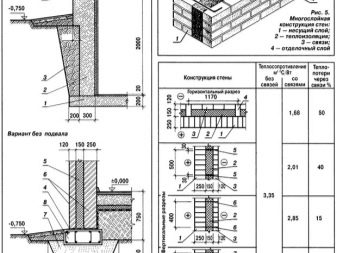

Wall thickness

There are special tables that show the basement wall thickness and the bottom depth. Focusing on them, you can develop an optimal construction plan. The greater the length of the walls, the more they are subject to lateral pressure.

Building

The best option is the project basement, which is equipped in the early stages of building construction. In this case, a strip foundation is needed - it is concrete that is laid along each of the future walls of the building.

There are several ways to build a basement, namely:

- digging trench;

- fill in the ground;

- construction of the basement in the already finished room.

It is worth staying in more detail on the first two methods.

Digging pit

According to generally accepted standards, the pit should not exceed the dimensions of the basement around the perimeter by more than 50 cm.The bottom of the excavation is carpeted with rubble and sand, and a slab of reinforced concrete is placed on this layer. Further, this plate will serve as the foundation of the room. It must be isolated from moisture and poured on top with a layer of concrete, which will later serve as the basis for the wall. The walls are made of concrete blocks, bricks or other materials.

The reinforced concrete slab often serves as an overlap, less often - wood or beams. After the construction of the wall and carrying out waterproofing works, the free space is filled up with earth. The method of digging the pit has one major drawback - the need to rent special equipment. Without it, equip the basement will be impossible.

Pouring in the ground

To begin with, it is necessary to dig ditches in depth from 150 cm to 200 cm and widths from 50 cm to 70 cm at the site of installation of concrete walls. A reinforcing mesh is laid at the bottom of the ditch, and then it is poured with concrete. Frozen concrete forms a wall that needs waterproofing and drainage work. Next, you must remove the ground to the level of the floor of the future basement. The excavation is carpeted with gravel and sand, then reinforced and poured with concrete.

With the construction of the basement under the already finished one-story house is much more complicated. In this case, it is recommended to make the basement under the part of the building so that their walls are not connected. This method will be more profitable from an economic point of view. For the correct calculation of the basement wall, it is necessary to take into account such components as the soil properties, the groundwater level, the height of the future construction, the materials used, the features of the underground communications and others. If the level of groundwater is high, then you will have to do with a shallow basement. If the study of the soil showed that the soil is dry and there is no danger of wetting the building, you can safely proceed to construction.

It is unlikely that it will work out to make a basement under a ready-made building, but everyone can dig a small basement. First of all, it is necessary to determine the room, under the floor of which it is planned to place the basement. Often this is a kitchen or corridor for purely practical reasons. Before construction, it is necessary to completely dismantle the floor to the very soil. At this stage, it is important to think about the place where it will be most convenient to carry the soil.

If the soil has a loose texture, then it is important to provide additional strengthening of the walls of the pit with wood shields. They can then serve as the external partition of the formwork when concreting walls. It is also important to take into account the fact that the floor of the future basement should lie about 27–30 cm above the bottom of the basement. If the depth of the basement is small and the basement is planned to be deep, the situation is complicated by the necessity of adding another foundation to the one that is already equipped. This is a very laborious process, the quality of which can depend on the stability of the whole house. In order to prevent serious miscalculations, it is better to turn to professionals to perform such tasks.

Device

There are parts required for absolutely every basement - it is ventilation, a staircase (entrance hatch), waterproofing, insulation and surface drainage. It is worth considering the features of each of these elements.

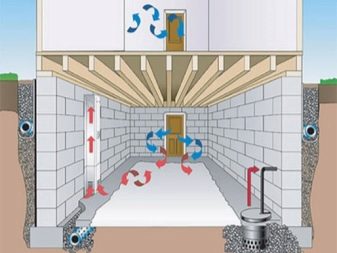

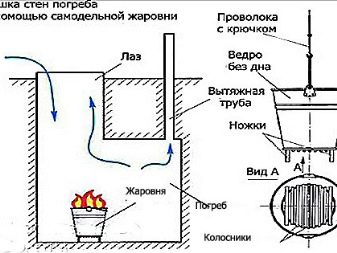

Ventilation

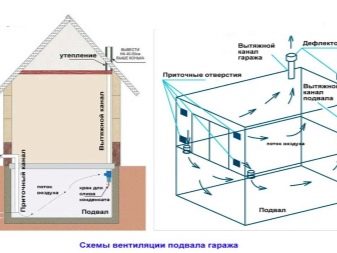

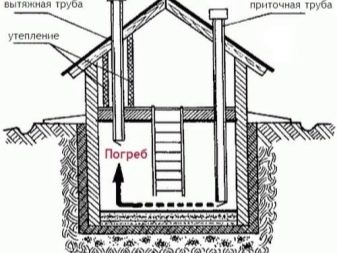

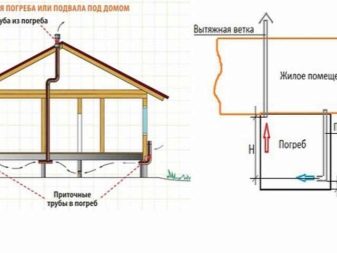

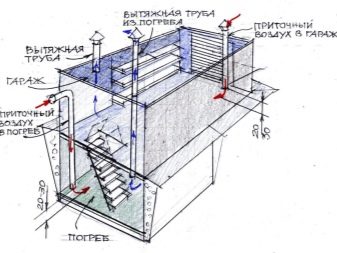

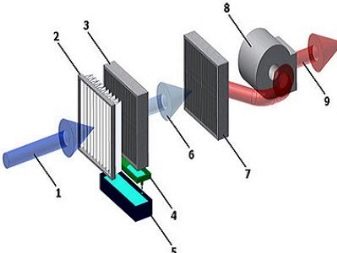

Arrangement of ventilation is mandatory for absolutely any basement, since most of the dangerous or poisonous gases are heavier than air, which means they settle down below.Often in the basement do non-volatile natural ventilation. To organize a system of natural ventilation, you need to equip two holes. The first is needed to exit the pipe, it is installed at a height of half a meter from the floor. The second is designed for exhaust, so it must be placed on the opposite wall from the ceiling. This placement will allow air to circulate throughout the room.

It is also important to remember about the protective grilles that are installed at the end of both pipes. They will protect the ventilation from the penetration of birds and rodents. In the cross section of pipes, gate valves are mounted to regulate the air flow.

The advantages of natural ventilation are as follows:

- the system is very easy to equip yourself in a short time;

- does not require additional electric fans;

- low cost of materials;

- running silently.

The disadvantages include a decrease in the efficiency of the ventilation system at the same air temperature outside and inside the building. After all, the speed of air flow directly depends on these indicators. But in this case, you can simply install any heater in the basement.It will heat the air inside, create the necessary pressure and start the circulation process. Pipes are often used in galvanized sheet or plastic. The latter are very convenient to install and in demand with independent ventilation equipment.

The equipment of metal channels requires special professional knowledge and skills.but their reliability is well worth the effort. Sometimes the ventilation boxes are made of wooden boards treated with sealant at the joints. This option is cheap, but very laborious. To check the exhaust pipe to bring a burning match. If the flame deviates into the pipe, it means - there is a thrust. If not - most likely the ventilation system is not working and it is necessary to check the location of the pipes and, possibly, replace them with pipes with a larger diameter.

Stairs

Equipment ladders should be given special attention, since it is this element that can cause domestic injuries. In addition, often the stairs need to enter in a very limited space.

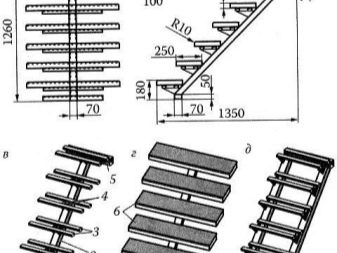

Varieties of designs may be as follows:

- straight is the easiest and most convenient option;

- Transit - Transit trapezoidal steps are used in order to save space;

- the goose step is a completely safe construction, the steps of which have a special shape and alternately adjust to the person’s step;

- a ladder is not a very convenient staircase, but it is very simple to make it yourself.

The picture below shows all 4 types of designs.

The best option for the basement is a straight staircase. Screw designs are less secure and take up much more space.

Before proceeding to the construction of the stairs, it is necessary to make calculations based on certain requirements.

- Bias The angle of the stairs can reach 60 degrees, but it is important to provide the possibility of descent and ascent with busy hands. If the staircase is steep, then the choice is better to make in favor of a direct project with the widest possible step.

- Magnitude go ahead The standard is considered to be a step in 20 cm, but it can vary depending on the angle of the stairs.

- Width. 75–80 cm is enough for moving one person, and in order for two people to be able to cross each other, you will need 90–100 cm.

- The height of the steps.If the task is to increase the slope and save space, the height can be made 23-25 cm. Risers are usually not done. When making calculations for steps, it is important to consider the width of your step.

The staircase leading to the basement, special requirements for the indications of strength, moisture resistance and ease of operation.

Based on these indicators, it is worth considering the basic materials for construction.

- Metal. Perhaps the most durable of all possible materials. The metal ladder can have almost any configuration, and the welding connection will make it as reliable as possible. Corrosion can be avoided with special types of metal or protective compounds. Corrugated steps will secure movement.

- Tree. It is inferior to metal in strength, but also very common for the manufacture of basement stairs. The advantages of the material include the relative cheapness and ease of processing. The best option in this case would be oak species.

- Concrete. Stairs to the basement of concrete are more often used in apartment buildings. For such buildings material is ideal, considering all their features.But it is quite difficult to work with concrete, therefore, in the rating of materials for the stairs, it can take a third position.

Important: for the construction of a wooden basement stairs, you can use only solid wood. A cheap tree will not last long because of the dampness typical of a basement and the danger of destruction by rodents and insects.

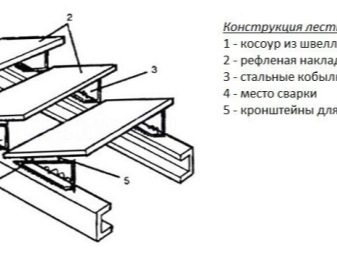

Having chosen the type of construction, you can begin to make a project. The first thing to determine is the location of the optimal point of support. Most often, ladders are made of metal themselves, so it is worth considering the manufacturing process using its example.

Necessary details are such as:

- profiled tube;

- metal plates and anchor bolts;

- sheets for steps (corrugated or cellular).

Mounts are mounted in the floor and wall at the top of the future stairs. For this, metal plates and bolts are needed. The size of the span determines the desired length of the bowstring - this is the distance from the floor to the first step. Cutting part of the profile pipe of the required size, you need to fix it on the supports. Further, it is necessary to calculate the distance between the steps and divide the length of the support by this indicator.To maximize the strength of the stairs, it will not be out of place to fix the steps to the wall on both sides. Then the frame for the steps is welded, and a metal sheet is mounted on it. After studying the principles of building a staircase for the basement, you can show imagination and create a variation of the design, taking into account the characteristics of your basement.

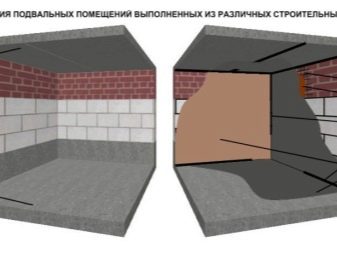

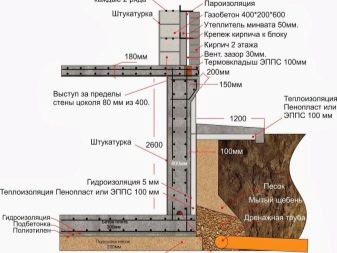

Waterproofing

To the air inside the room was not constantly wet, you need high-quality waterproofing equipment. And the problem is not only in water vapor, but also in moisture, which comes from the ground through the smallest cracks in the walls. And also without waterproofing, an equipped layer of insulation will not bring the desired effect. For waterproofing, you can use a variety of materials, from mastic to roofing material. But today more effective ones have been created - these are special waterproofing mixtures based on cement. Such compositions are applied with a roller, spatula or hard brush. The composition penetrates the microcracks, forming a kind of crystals that prevent the penetration of moisture. The main advantage of penetrating waterproofing is that it prevents the ingress of moisture inside, but allows moist air to go outside.

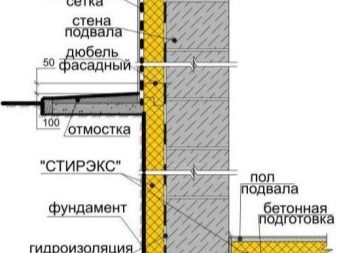

Drainage

Surface drainage is necessary for homes that are on terrain with heavy rainfall during the warm season. As well as the drainage can simplify the basement waterproofing equipment, increase its efficiency and reduce the amplitude of oscillations of the groundwater level. A house with drainage has a much smaller effect on the underground runoff than a house without it. The figure below shows the surface drainage equipment. The dumping field is often placed above the garden, because the precipitation collected in drains is well suited for irrigation.

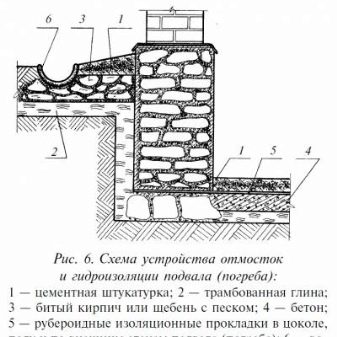

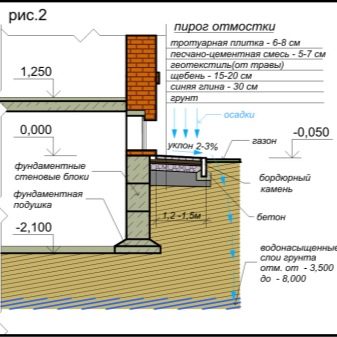

Blind area device

Arrangement of the blind area around the perimeter of the house is the first step to protect the building from rain and melt water. If the turf around the house is left unchanged, then during the precipitation moisture will seep to the foundation. This will eventually lead to the resolution of the walls. Concrete slabs, cobblestones, asphalt or brick may be materials for blind area. This element not only protects the building from moisture penetration, but can also act as a decorative element on the site. The blind area varies from 50 cm to 100 cm and depends on the type of soil and the distance that the cornice stands for the contour of the building.

To begin with, a layer of soil 10-15 cm deep is removed around the foundation. The resulting ditches are filled with soft clay, which is compacted with gravel or rubble. The slope of such coverage should be about 5-10% of the level of the house. This figure is calculated as 5-10 cm per 100 cm wide. After that, gravel or brick dust is poured, poured with cement mortar or laid with asphalt. At the edges of the blind area, small grooves for digging out water are dug up. Professionals advise to put a PVC film 200–250 cm wide at a depth of approximately 35–40 cm. This stage is guaranteed to ensure the removal of moisture from the entire foundation.

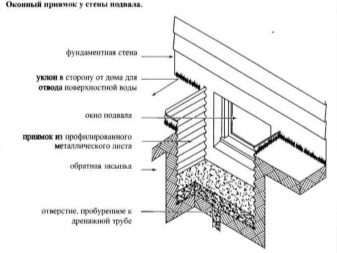

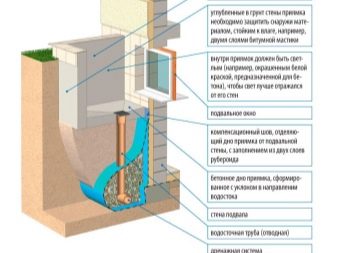

Pitholes

Light pits in the basement should be made in such a way as to get as much sunlight as possible inside. The presence of windows in a subfield of a house helps to save considerably on electricity, since it becomes possible to use the entire daylight hours. And if the basement involves placing people there, then daylight makes being inside much more comfortable. It turns out that the light pit is not only a design to protect the building, but also an element with many functions. And also you can go to work with creativity and make the original element of the decor of the facade of the house.

The dimensions of the pits are directly dependent on the size of the windows and the level to which they are buried in the ground. Often, the length of the pit, namely the element of the pit, which is parallel to the wall, is 1.5–2 times the width of the window. And its other side, which is perpendicular to the wall, protrudes no more than 1 meter. The ideal option is 70–80 cm. The depth of the pit depends on the position of the window frame: the bottom is located approximately 20–25 cm below the window. It is also recommended to provide for a pit of the bottom of the pit approximately 4–5 degrees.

Today, construction companies provide a large selection of ready-made parts for equipment priyamkov. Having bought such a part, it will only be left to dig a pit under its dimensions. Prefabricated pits are made of various materials: galvanized steel, propylene, polyester or plastic. The most durable and popular is the option of polyester with the addition of fiberglass. Such a design can withstand enormous loads without deforming at all.

Metal bases for pits are not affected by moisture due to galvanized coating. Moreover, most of the foundations are equipped with anti-vandal devices.This option will be ideal for owners of private sites whose owners do not live in the house all the time. Iron grates on the pits are able to protect windows from damage, and the building itself from thieves.

The elements included in the standard equipment of the factory priyamkov are as follows:

- housing;

- window grille;

- fasteners.

In order to design and manufacture pits of your own, you need to face some subtleties in technology and have skills in this area. But to mount ready-made parts is much easier. Everyone loves to cope with this task without recourse to professional builders. The first thing to do is to carefully study the installation instructions. It shows the dimensions of the parts, based on which you need to dig a pit of the required size. Do not forget about the system of outflow of water, which was described earlier.

Next, the well body is placed in a dug pit, then drainage, drainage, protective elements on the pipe and so on need to be connected. The final step will be the installation of a grate or other barrier on the pit. All parts are attached with special dowels, which are included in the product package.Factory pit does not need additional weatherization, which significantly saves time and effort. The main drawback is the high price. Therefore, without having extra funds, you can try to build a pit yourself.

Warming

A very important stage in the construction of the basement is the proper insulation. Often, insulation and waterproofing works are carried out in parallel. Soils at a depth of 150–200 cm have a constant temperature, which practically does not fluctuate throughout all seasons and is approximately 7–10 degrees. With high-quality insulation of the basement, it is possible to organize the maintenance of this temperature throughout the year. If there is a need to increase this indicator, for example, for residential basements, you will need heating equipment.

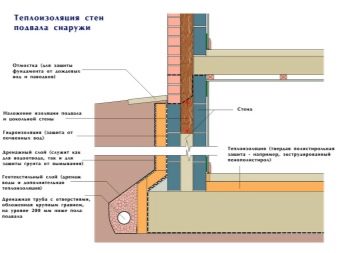

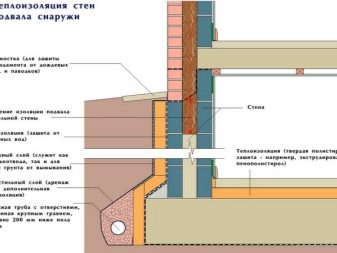

In addition to maintaining a stable temperature, the basement insulation will significantly save on heating the entire building. Plus, the supporting structure will retain its durability due to gentle operation. Today, there are many ways to work on the insulation of the basement.The most effective is the insulation outside, which is exclusively at the stage of the beginning of the construction of the entire premises. It is impossible to insulate the basement walls in an already finished building with this method.

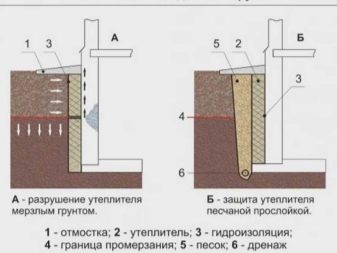

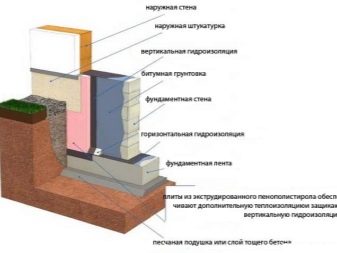

With external warming of walls dampness and frost penetration is not terrible. The main disadvantage of this method is the pressure of the soil and moisture, which can lead to deformation, wetting or destruction of the thermal insulation layer. The material that copes with almost all the common problems of thermal insulation is extrusion foam. It consists of pores that do not let moisture through. As well as the material can withstand a fairly strong pressure of the soil, without being subjected to deformation.

The technology of insulation should be carried out clearly by all the rules. After 6 days after the equipment of waterproofing walls, you can install insulation plates. And they are mounted directly on top of the waterproofing. As an adhesive, bitumen mastic or any other composition based on bitumen is used. It is important that in this composition there are no solvents that can destroy the insulation material.

Plates of foam should be dotted with adhesive mastic and pressed to the wall.After 25-30 seconds, the composition will grab and you can proceed to the installation of the next plate. Installation of foam is made strictly from the bottom up. All plates must be of the same thickness and fit snugly together. For the protection of insulation during soil compaction professionals recommend the use of asbestos cement slabs. After the foundation has been poured in, it is possible to move on to the equipment for horizontal thermal insulation around the perimeter of the building, and the insulation should project about 45–50 centimeters above the ground.

Inside walls

This method is not very popular, because in the absence of a good ventilating system, moisture will condense at the joints, which can lead to dampness, unpleasant smell and the formation of mold. These shortcomings are not immediately felt, but some time after the completion of construction. It is necessary to conduct insulation of the basement wall so that the insulating layers inside and outside overlap by about 50 centimeters. Thus, the heat flow will go a longer way and heat loss will be minimal. Insulation is placed on a flat surface of the walls, then revetted.If the next stage of finishing is a layer of plaster, then extruded polystyrene foam will be the best option as a heater. If the walls are sheathed with plasterboard, the insulation can be protected with a vapor barrier film.

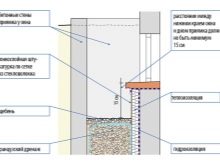

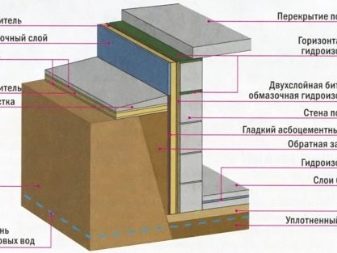

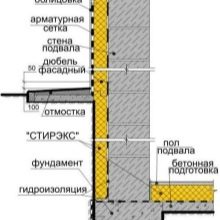

Base

On the ground floor often relies overlap the lower floor of the building. For him equip horizontal waterproofing. This system is able to prevent the rise of moisture, which leads to the dampening of the walls and the ceiling of the basement. For the construction of the base using the most durable materials such as baked bricks or concrete blocks. They are faced with ceramic or stone tiles, plaster mortar. Expanded polystyrene, which is known for its heat-insulating characteristics and resistance to moisture, is best suited for insulation.

When choosing glue or mastic for fixing polystyrene foam plates, it is important to choose a product without acetone and other components that dissolve polystyrene. Hot bitumen mastic is also not suitable for such work. In order to protect the installed insulation plates from the effects of sunlight, it is necessary to cover them with a layer of plaster on the grid. Suitable as metal mesh, and fiberglass.It is important that the wet soil does not come into contact with the outer plaster. To do this, remove the soil that is adjacent to the base. Plaster, which is below ground level, must be treated with bitumen mastic, and the resulting space covered with gravel.

How to dry?

If the basement is damp, it should be properly dried before starting repairs. To begin with, the walls, the ceiling and the floor are moistened with water using a soft plastering brush (it can also be a roller, but it will give the worst effect). Drying with a simple stream of warm air will not bring the result. This requires the use of infrared radiation. And it should be "near" - the light source should be in close proximity to the surface.

Radiation is practically not absorbed by the air and penetrates deep into brick or concrete. Bulbs should be hung in the form of a garland throughout the room at the rate of 70–100 W per 1 cubic meter. After a week of such drying it is already possible to apply bitumen. But wait a few days never hurts. The only question is how much electricity it is not a pity to spend on this venture. If there is no time and desire to equip the dryer with your own hands, then you can purchase a special air dryer.Choose it based on the dimensions of the basement and financial opportunities.

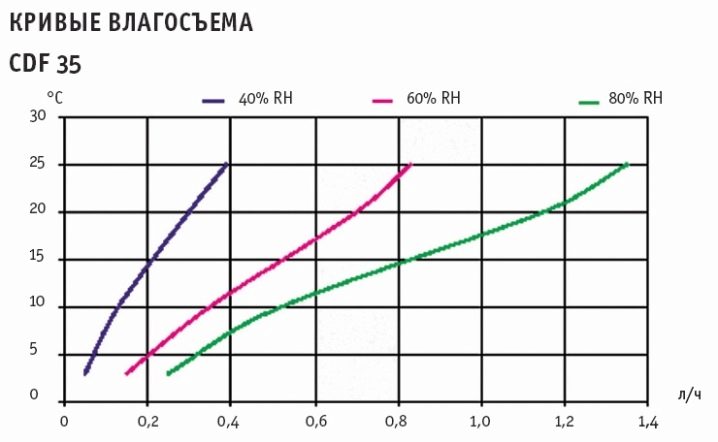

There are several types of air dryers.

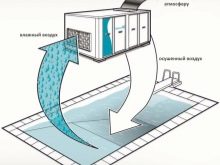

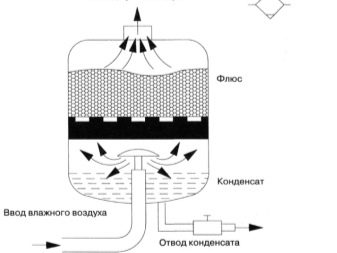

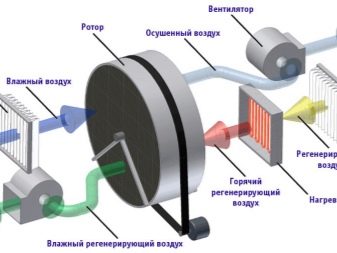

- Assimilatory. The basis of the operation of this device is forced ventilation. This means that moisture is drawn out of the room and converted to dry air at the outlet. Such dehumidifiers are often used in large-scale buildings. Its main drawback (besides constant energy consumption) is the inability to dry the air if it is raining or snowing outside (or just a very humid climate).

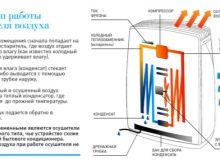

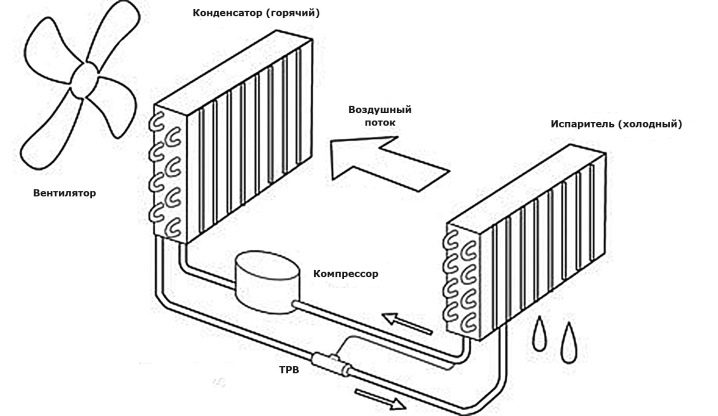

- Condensation. The mechanism of its operation can be compared with a refrigerator: humid air is cooled in pipes with inert gases, condensate fills the tray in the form of water, and air flows back into the room. The disadvantage is that it is necessary to constantly drain the liquid, otherwise the operation of the device will be stopped.

- Adsorbing. This option is used for drying at temperatures below +10 degrees. The air passes through adsorbents that neutralize moisture. Then they need to be changed or dried. The frequency of change of adsorbents is the main disadvantage of this mechanism.

The type of air dryer mechanism directly determines the quality of its operation.

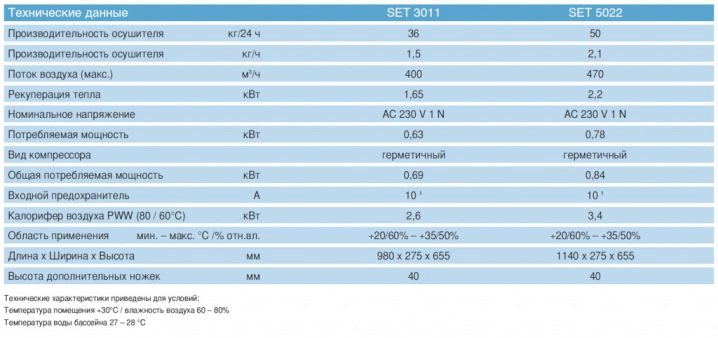

When buying a device, you need to pay attention to its technical characteristics.

- Moisture. The performance of the model is directly affected by moisture removal. It reflects the amount of moisture the device can take from the air. To make the right choice, you need to know the humidity indicators specifically in your basement. The standard instructions describe the parameters that are observed at 80 percent humidity and an air temperature of +30 degrees. In fact, most of the premises have a temperature of no more than + 20–22 degrees with a humidity of around 50–60%. Given this, you can immediately mentally reduce the efficiency of devices by an average of 20-25%.

- Temperature mode. It is worth considering the presence of heating in the basement in the winter. Condensation dryers work most effectively when the temperature exceeds +15 degrees. As the temperature rises, moisture removal rates increase. If the thermometer shows less than +15 degrees, then an adsorbent dryer will be more effective.

- Air exchange - This is one of the most important parameters that you should pay attention to when choosing a device. This indicator tells you how much air can handle the mechanism in 1 hour. The best indicator will be a number that exceeds the basement volume by several times.

- Energy costs - this value may vary depending on the manufacturer and model. Exact figures should be checked with the seller directly upon purchase.

- Capacity for condensate. A large tank is necessary if it is not possible to descend into the basement several times a day and pour out the liquid. Some solve this problem with drainage through the sewer system.

Air dryer can be made by hand. To do this, before starting work you need to decide on the method of extracting moisture from the air.

Do-it-yourself adsorbing dryer

This is the most budget way to drain the basement. To create it, you need a cooler - this is a kind of fan that can be removed from an unnecessary computer unit, and two plastic containers, ordinary bottles will do.

The manufacturing process includes the following steps:

- Bottles must be cut in two and made a hole in the bottom. To do this, you can use a heated awl or knitting needle;

- the upper part of the bottle is turned down the neck and placed in the second half;

- cork also need to pierce in several places;

- about 250 grams of silicone filler is poured into the container;

- from the other bottle you need to cut the bottom, put the cooler inside, it should blow towards the cut hole;

- 7–10 centimeters from the bottom of the bottle a pressure knot is made;

- then the entire structure is put on the first bottle;

- all joints must be sealed with ordinary tape, and the cover of the second bottle must be removed or replaced with gauze, which will facilitate the free flow of air.

We get a simple design: the desiccant gains air masses with the help of a fan, then the air through the gauze gets out. When the gel loses its ability to absorb, it can be replaced or dried in the oven for about three hours. The dehumidification of air organized in a similar way does not make noise and has quite noticeable effect.

DIY Condensing Dryer

Independently, you can make such a device, but it will take several times more work. For manufacturing, you will need an unnecessary refrigerator, heater, coolers, rubber hose, screws and sealant.

The manufacturing process includes the following steps:

- it is necessary to remove the door from the body of the refrigerator, and in its place put a piece of plexiglass 3 mm thick;

- Fans are inserted into this glass with indents at the edges of 35–40 cm. After that, they are treated with a sealant and fixed with self-tapping screws. This part of the system will serve to ensure that air enters the body of the refrigerator;

- In the upper part of the plate, several holes must be made through which cooled air will flow out. The dimensions of all openings should correspond to the dimensions of the fan;

- using a hose attached to the bottom hole, you can remove the settled moisture;

- the connection of the panel with the hose must be carefully sealed;

- there is an option and the air outlet through the second fan, which is installed above the first. This will reduce the temperature by about 5 degrees.

Such a homemade model can be improved by adding a fan.It should be attached on plexiglass or on top of the device. It is important: to correctly organize the intersection of air flow - a desiccant entering inside and going out. Dehumidification often starts when the 80 per cent moisture level is reached. Of course, from an aesthetic point of view, such a homemade dehumidifier is not very pleasing to the eye, but it can be hidden behind a small screen or door. And efficient work and substantial financial savings are undeniable advantages.

Heating

The process of heating the basement is very laborious, but it is able to accommodate the room. Having some knowledge and skills in such matters, you can safely get to work.

Getting to the heating equipment, it is worth solving such issues as:

- basement heating method;

- calculation of materials;

- installation method.

Ways of heating - this is the first point to decide. There are only two options - stove and water heating. The first requires only a stove, the second - the presence of a boiler and batteries.

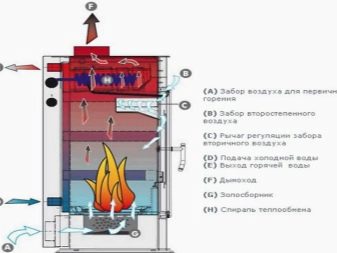

- Stove heating. An equipped oven or stove in the basement is a more economical option due to ease of installation and operation.Yes, and it takes less space than the bulk boiler. The main issue will be the implementation of the chimney. This is problematic, as it is necessary to correctly calculate the length of the pipe to ensure good traction. The scheme of the standard furnace is shown in the figure.

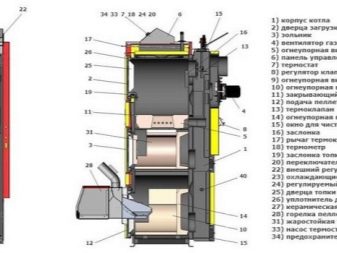

- Water heating. This variant of heating is quite simple to make by yourself, so it is chosen most often. Schematically arrangement of water heating is shown in the figure.

This method is implemented using a gas or electric boiler. But there is a nuance: the heating takes place by rising steam, which means that the temperature at the top of the basement will be higher than at the bottom. The temperature can not be evenly distributed throughout the room. Despite the low level of efficiency, there is a significant advantage - the presence of hot water. Both of these options are suitable for heating, because the system can heat both the whole house and the basement separately.

Having defined the boiler heating, it is important to consider the basement area, which must be heated. The best option in this case would be to arrange heating at once of the whole house.If it is decided to install the stove, then it is important to determine its type - it will be a stove, a brick stove or a long-burning stove. If you need a stove for placing 50-60 square meters, then, most likely, such a unit will be difficult to make yourself and you will need a factory model. Power for long-burning stoves can be calculated in the same way as for a stove. But the first ones are well suited for rooms up to 200 meters square. The best would be a simple brick stove, if properly organize its chimney and furnace.

Nuances

If the stove is located at the bottom of the room - in the basement - the heat will be distributed in an optimal way: from bottom to top, thereby spreading evenly throughout the building. But there are features of such an arrangement that must be considered. For example, closing the pipe at the right moment will help save fuel, namely, at the moment when the fuel is burnt out and no flames appear on the coals. Otherwise, the heat from the coal will go into the chimney and the furnace will not be able to fully heat the air. If you close the valve of the pipe too soon, you can prevent the ingress of smoke into the room. If too late, then the heat will be lost.Therefore, it takes time to get the hang of using a firebox with perfect efficiency.

Warm floor

Underfloor heating is a very important detail when stove heating, when there is always a draft on the floor. It arises from the peculiarities of the functioning of the ventilation and chimney.

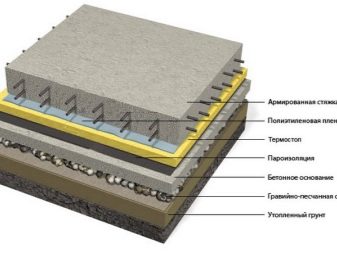

For the equipment of a heat-insulated floor in the basement it is necessary to carry out three layers of quality

- waterproofing - insulation of polystyrene foam or mineral wool;

- thermal insulation - the best option would be a screed equipment based on the “clay lock” principle, which will provide the necessary protection for the basement floor;

- screed.

Schematically, all stages are shown in the figures below.

Tips

To understand the intricacies of designing and creating a basement, you should follow the advice of experts.

- The method of pouring concrete into ditches using waterproofing is complex. Not every lover will be able to independently lay the armature. In order not to have to redo the work, it is better to rely on professionals at the initial stage. The point is also that each stage of construction should be done fairly quickly.

- Ventilation of the basement can be carried out not only by the ventilation system, but also by small windows in the walls of the basement. In the summer, they are much faster to cope with this task.

- Before you build a basement in an already finished building, you need to clearly understand what this may lead to. The first is significant financial expenses, unknowingly you can start construction, and then stop due to lack of funds, leaving the construction site unfinished. The second is the danger of damage to the foundation of a residential building, especially if the construction process is not controlled by professionals.

- So that the heat does not leave the basement longer, the heat-insulating layer should be made at least 50 mm in thickness.

- The walls of the basement should be about 30–40 cm thick. The size may vary depending on the characteristics of the soil and the number of floors of the building.

- Often the basement depth does not exceed two meters. This is quite enough to fulfill all domestic needs. Experts do not recommend placing the basement below the groundwater level. This could lead to dampness, mold and mildew on the walls in the future.

- Choosing material for the basement floor, you need to decide on its functional purpose. The best are cement and clay concrete. In order to avoid condensate accumulation, it is necessary to make floors with a slope of several centimeters, and to organize a pit in an understated corner.

- Dryness in the basement can be provided at the stage of digging the pit. To do this, leave a gap of about 20 cm between the walls of the basement and the pit, pour this space with liquid clay. Clay has excellent thermal insulation and waterproofing properties, which will keep the same temperature in the basement and prevent a noticeable increase in humidity.

- Using roofing material as a waterproofing material, it is necessary to process with bitumen not only all the joints, but also the entire area between the layers of material.

- It is better to prepare cement mortar of a grade not lower than M500. To increase the strength and fast setting, it is also recommended to add a relaxor to the solution.

You can reinforce all the walls at once, fulfilling the following conditions:

- this process should not interfere with the comfortable movement of the formwork;

- the width of the formwork should allow you to tamp the solution;

- fill should be as accurate as possible;

- In no case should you save on the quality of concrete, because the strength of the dwelling and its safety directly depend on it.

- It is important to include in the work plan the arrangement of the ventilation system during the laying and pouring, which will allow not to waste time on making holes in the right places later.

- If it is decided to put the gas boiler in the basement, then its height should be at least 2200 mm. In the opposite case, the use of the boiler for its intended purpose will be simply impossible.

- To avoid rodents from entering the basement through pipes, special protective nets of stainless steel must be installed on them.

- For the decoration of the walls in the basement premises often use plywood or wooden lining. Before starting work, it is important to treat all building materials with a good antiseptic or paint it with the content of the antiseptic component. This will help prevent mold and mildew.

- After the masonry walls of the basement are finished, the foundation itself must be plastered with cement mortar with the addition of sand in a ratio of 1: 2 or 1: 3.The outer surface should be properly fluff with hot bitumen. On the walls of the basement then you can stick several layers of roofing material on bitumen mastic to increase strength.

- It is important to ensure that in the process of laying waterproofing materials there is no damage or tears (even if minor). This will adversely affect the entire waterproofing layer and its functioning.

- If vegetables are stored in the basement, it is convenient to control the temperature with a device such as a psychrometer. It simultaneously measures the temperature of the air and determines the humidity. It is very important for the safety of products. The simplest psychrometer is several alcohol thermometers attached to one base. The lower part of one of them is immersed in a humid environment, the second thermometer remains dry.

- If the floor is installed after the walls, the air cushion should be poured with concrete. The organization of formwork in this case is not required.

- When buying a ready-made factory part for arranging the pit, it is necessary to provide a guarantee for which it can be exchanged or returned.It is not always possible to accurately determine the dimensions of all the details from the first time, so it is important to think out the error in advance in order to avoid losing money and time.

To learn how to build a basement and choose a constructive scheme, see the following video.