Garage of foam blocks: the pros and cons of buildings, installation features

Having a car or going to buy it, you need to take care of the garage. If there is a desire to make this room individual and convenient for a particular owner, then it is better not to buy it, but to build it yourself. Foam blocks are the easiest and most convenient option to quickly and efficiently build walls and build a garage on your own.

Special features

Any owner at the appearance of the car first of all thinks about the place of his parking. Leaving the car outdoors is undesirable and also risky. Weather phenomena will significantly spoil the appearance of the car and reduce the service life, in addition, the risk of theft or other injury from the hands of vandals increases. To avoid all this, you need to buy or build a garage.

Purchase simplifies the task of the owner of the car, because in addition to finance, it does not require other significant investments. But to get a garage that will meet all the requirements of a particular person, the easiest way to build it. To make this process fast enough, you can build it from foam blocks, which are several times larger than bricks, because the work is going at a much faster pace.

For such a garage can not do without the foundation, which is poured, taking into account the soilon which the building will be located. It is necessary to initially calculate the dimensions of the garage in order to properly fill the foundation. By itself, the garage can be built-in, that is, be part of the building, attached when it is completed to the already finished building. A detached house for cars, which is being built on the existing free space, is more convenient.

Location relative to the ground can also be different - the garage is located on its surface, it can be half buried in the ground if the ground is dry and strong, or completely placed under the ground, if there is very little space for a garage and several objects need to be placed in the same area.

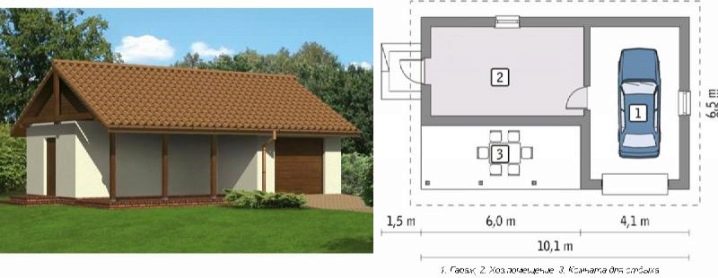

In order for the car to fit in the garage and there is a place to store various things, the width of the building is recommended to be at least four meters, and the length - at least six. If the soil is solid and dry, then it is easy to build a viewing pit, and for soil with groundwater nearby it is better not to do such a building.

Foam blocks for their dimensions are light enough and very durabletherefore it is convenient and pleasant to work with them. Such elements are connected with the help of special glue, which fixes the blocks well, not letting in cold or heat, creating optimal conditions for storing the car. The length of the foam block is 60 centimeters, width and height - 30 and 20 centimeters, respectively. It is important to note the good external characteristics of the material, which practically does not need external finishing and can be suitable without any of it.

Projects

As soon as a decision was made to build a garage, the first thing to think about is the creation of a project. This type of work can be done independently or use the services of a specialist. Depending on the availability of the territory, it is possible to plan the size of the future construction and the structures adjacent to it, if necessary.

If the family has two drivers and two cars, then the garage is being built accordingly.The building for 2 cars should be spacious, so that cars could fit in it under one roof and there was a place to store inventory, tires and other trifles. When there is a catastrophic lack of space for one car, you can make a two-story garage, where a car will be on the first floor, and a full-fledged workshop will be located on the second floor. With the second floor there is an opportunity to equip not only a working area, but also a place for a hobby, someone has music, someone has collecting and so on.

The most successful are the size of the garage 6 on 4where it turns out and put the car, and supplement the construction of a variety of household trifles and staffed working area. If there is a desire to make not only a comfortable garage, but also a beautiful one, it can be completed with an attic, where you can perform part of the work or have the opportunity to rest after the repair work. Fans can warm up, you can organize the appropriate extension. Bath can be part of the garage, but in this case it is important to isolate both rooms as much as possible, so that water and moisture from one does not fall into the second.

Having planned a viewing pit, it is important that its depth be maintained within the limits laid down for it and be no more than two meters. When planning the construction of a garage, it is necessary to calculate the amount of materials that will be needed in the work. If the length of the building will be six meters, then 10 foam blocks will be required for one row. Also calculated and their number in height.

Once the issue with the walls is resolved, you can go to the roof. It can be shed, built with a bias in one direction or have a standard form of the roof of a residential house, but not high raised from the ceiling of the garage. It is worth paying attention to the material with which it will be covered. To do this, you can use slate, tile, metal or corrugated. Each of the above options has its advantages and disadvantages, but the first thing you should pay attention to is the presence of any materials with which you can perform a number of works.

Materials

In order to build a good and high-quality garage, you need to decide on the material from which it is best to build it. Foam blocks have several varieties, because it is important to know the difference between them in order to make the right choice.

There are blocks of:

- Aerated concrete - made from quartz sand, cement, substances for the formation of pores (aluminum powder or powder), chemical additives. The dry mixture should be diluted with water, after which chemical reactions occur and the solution is ready for final processing in an autoclave or drying chamber. The gas block has its advantages - it has the correct borders and a flat surface, it is easy to work with, drill and grind, its high vapor permeability helps to quickly remove the fumes from the room and maintain an optimal microclimate inside.

- Foam block plate consists of sand, water, cement and a special foaming agent. A distinctive feature is the closed pores that are filled with gas, which helps with hydro-resistance and thermal conductivity.

- Ceramsite blocks refer to lightweight materials. To create them mix cement, sand and expanded clay, resulting in spherical granules. Of the basic properties of expanded clay blocks, it is possible to note low vapor permeability, low price, a greater mass than in the previous embodiments, the highest coefficient of thermal conductivity, the uneven surface of the material.For the construction of this material will need both internal and external decoration of the blocks.

- Slag Obtained from granite screenings and crushed stone, sand or river gravel, in addition, other materials that are no longer suitable for use, such as broken bricks, glass or concrete products, can be used. There is a certain dependence that regulates the density of a given material, and it depends on the size of the particles of the cinder block, which affects its strength as well.

- Gas silicate blocks superior to all others in terms of strength and appearance. For the manufacture of gas silicate blocks need to use quartz sand, lime and cement. The foaming procedure takes place at the expense of chemicals. They are frost-resistant, fire-resistant, strong and have a wide variety of forms.

In order to make a solid foundation, a good master cannot do without the use of FBS, on which blocks of sand block will be placed.

The use of aerated concrete structures allows you to quickly and efficiently build a reliable structure. The use of concrete blocks saves time due to its large dimensions in comparison with the usualbrick.

Foundation selection

When planning the construction of the garage, the first thing you need to take care of the foundation. Its choice will be made depending on the soil on which it will be erected. If the soil is dense and the groundwater passes below two meters, then it will be sufficient for the foundation to make a frame forty-centimeter deep for a one-story structure and seventy centimeters for a two-story place for a car and a workshop. In this case, it is possible to make a viewing pit, since the ground allows it.

If the soil is heaving, then it is best to completely fill the platform on which the garage will be built, and then begin construction. Inspection pit in these conditions is impossible. If you want to make a basement on unstable soil, you need to dig a deep hole and make a strip or pile foundation.

Once the type of foundation has been determined, you need to make a layout of its location. At the corners, stakes or corners are dug in and a rope is pulled. When this type of work is finished, it is necessary to check the evenness of the corners, and if everything is normal, you can dig a trench, if not, the stakes are rearranged until the corners are even.

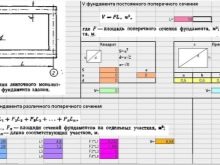

The trench is dug eighty centimeters deep or meter. The width of the foundation bookmark should be more than ten inches or fifteen inches in the garage. At the bottom of the trench, sand is poured with a layer of 15 centimeters and compacted. Next comes the rubble layer of 10 centimeters, which is also tamped. Next you need to make a formwork of the boards, which is placed in the frame of the reinforcement, welded according to the measurements of finished trenches.

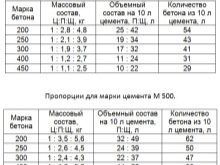

The frame is made so that the cells have a height and width equal to ten centimeters. After that, concrete is prepared from cement and sand in a ratio of 1 to 3. In addition, 4 or 5 parts are filled with gravel or crushed stone, and water is also used. Each opening is poured in turn until partially dried for three or five days. When all sides are poured, the entire foundation is leveled and left to dry for three or five weeks.

When the foundation is ready, they proceed to the strengthening of the basement or viewing pit, if it is intended in construction. Only after the completion of all these works, you can proceed to the construction of the walls of the foam block, moving to the desired goal.

How to calculate the quantity?

The construction of a garage requires a certain amount of materials, which can be roughly calculated to have an idea how much you need to buy and how much it will pour out. To calculate the number of foam blocks you need to initially consider the appearance of the garage, whether there will be windows in it and how much, what size will be the gate.

Once all the data have been received, you can make a calculation of the number of blocks for each of the walls. Since the dimensions of this material are standard, it will be quite easy to do this. The next step will be to search for the material, the cost of which will be optimal. This applies to concrete, sand, and all other materials. Every landlord is interested in building quality premises at the lowest possible cost.

In order to calculate the number of cubes of concrete, which will go to fill a particular type of foundation, there are special calculators. Entering the parameters of the future foundation, you can easily calculate the amount of necessary materials for its construction.

Knowing the required amount of this or that material, you can make a purchase of it and produce work.The process of building a garage is quite long, so you can safely divide it into stages and use finance in accordance with them. Such planning will allow you to acquire what you need, but at the same time be able to raise funds for other materials that will be needed in the next step. Thus, in the absence of money for the whole garage at once, having correctly calculated the amount of concrete, sand, rubble or foam blocks themselves, you can gradually continue to work.

For large construction firms, entire programs have been developed, allowing to calculate the costs for each area of work. It helps to make an estimate, place the first necessary materials and start the construction process. It is not necessary for an ordinary person to use any programs, especially since they are paid and cost a lot, it is only important to break the construction into stages and systematically buy what you need at a specific stage.

Building

In order to build a garage with your own hands, you need to know the order of work. Phased planning and construction of structures in accordance with the rules and regulations will allow to achieve a good result in the shortest possible time.

Step-by-step instruction is a list of actions that will help to systematize the work and make it relatively easy and at the same time high-quality. So, the construction begins with the fact that the site is marked with pegs, thereby determining the future foundation. You need to inspect the area for obstacles that may interfere with free to enter and leave the garage.

The next step is to determine the type of soil and the choice of the foundation. For the heaving area, it is necessary to fill the entire floor completely, the construction of the basement and the inspection pit will be impossible. For dense soil with deep groundwater, a strip foundation can be made, where both the basement and the observation pit are appropriate. They are also laid out at this stage.

Next, the swing gates are installed on the spacer pins, they serve as a guideline and will be the element that cannot be adjusted after the walls are built, therefore they need to be installed exactly and check their performance.

When this stage is done, you need to go to the waterproofing under the base of the walls, which is made of rolled materials. Only after this stage does the construction of the walls begin.It’s right to start lifting walls from a corner. The first row is placed on the cement-sand mortar. Further, a special adhesive solution is used, the blocks are shifted one third of their length.

As soon as the height of the walls has reached the end of the gate, you need to install a concrete beam jumper directly above the opening. If the roof is planned to be shed, then it is best to make a slide on the side far from the gate. In the event that an exhaust hood is not installed in the garage, then small holes should be made at the bottom and top of the wall so that air can circulate in the room.

The construction of the walls is completed by the creation of a solid reinforced belt, on which the ceiling beams will be laid. They should be laid out, keeping an interval of 80 centimeters, and the ends of the beams should be extended twenty centimeters beyond the wall. On the lower edges of the beams stacked sheet grooves, which will form the ceiling. It is on this surface that the waterproofing will be laid.

For the roof it is best to use profiled sheeting because of its lightness and durability. You can cover the beams and slate, if available.Work is performed from the back wall to the gate and ends with the formation of a visor. When all work is completed, the process of warming with expanded clay, slag or glass wool and screeding of walls is underway.

TOWhen the garage is completely ready, you can attach everything you need to the finished building. - bath, additional workshop, shed or any other building that will perform a different role than the garage.

Tips

In the process of building a garage, it is important to constantly check the level of foam concrete so that each block is completely flat. To adjust, there is a special rubber hammer that allows you to move unevenly laid masonry. It is very important to do this right away, until the glue mortar is frozen. Such activities are carried out during the entire construction. As a result, the finished garage has flat walls.

Having a smooth wall, the garage can easily be plastered for painting or apply a layer of decorative plaster and create a unique design. If you wish, you can sheathe the building with a European board so that it looks spectacular and well maintained.

When building a garage is very important not to forget about ventilation. It can be forced, which is considered the best option, but there are other ways - left a gap in the masonry above and below, installing a special mechanical hood and other options.

If the ground is unstable and there is a risk of close groundwater access, it is best to avoid building a viewing pit or basement that will protect the entire garage from moisture. If the garage was made as an extension, then additional doors can be made directly from the inside room in order to avoid using the gate if there is no need to drive out.

If precipitation falls too often, the installation of a drain on the roof of the garage or near it will become a necessity. This is done to ensure that moisture does not fall on the foundation and does not destroy it. With such protection, the garage will stay much longer, its protective properties will not be violated, and the car will be reliably protected.

Depending on where exactly the garage will be built, you can make it of various sizes. Having a private house, it is very convenient to store all working and garden equipment in a separate room. Garage in this case, you can attach to the house and create the appearance of a large overall building, enduring all in one style, or vice versa, to separate it and to focus on a different type of design.

At the cottage garage is often needed for temporary parking cars and storage of all equipment necessary for work. If there is also a basement in the garage, then it will be very convenient to store the harvest from the beds in it.

If you plan to build a garage from scratch, then it is desirable to explore the best options for planning and construction, to determine the system of opening the gate, the presence or absence of windows. Only by approaching the issue seriously and thoroughly, you can eventually get a good and high-quality garage, where everything is provided in advance and each thing has its place.

Pros and cons of foam concrete blocks, see the following video.