Glue for ceiling tiles: types and application

Glue depends on the smoothness of the ceiling surface and the absence of unpleasant surprises in the form of endless alterations. Repair with the use of decorative finishes will succeed if two factors are taken into account. First, the tile corresponds to the design idea and purpose of the room. And secondly, the installation on the ceiling is made without gaps and distortions, with a properly selected adhesive composition.

Properties

It is necessary to consider that the tile is made of polyfoam and expanded polystyrene. These are light and fragile materials with a thickness of 0.6 to 1.4 mm. Depending on the massiveness, the size of the elements select the composition of the adhesive. It is not necessary to buy a universal fixer, but the materials of the tile and the surface of the ceiling should be mentioned in the instructions for its use.

Choosing glue for ceiling tiles should be oriented:

- On viscosity Too liquid composition does not hold even a light tile, and excessively deforms the thickness and finally damages the product during installation.

- At the time of adhesion to the surface. The best option for work at a height of less than 30 seconds. It does not take a long time to stand with arms outstretched above your head, and it is quite sufficient to adjust the position of the tile and remove excess glue. A higher drying rate does not provide such chances.

- On safety for health. For the design of living rooms is important. The most environmentally friendly among water-based adhesives.

- On color. White and transparent compositions do not shine through a thin surface, not visible at the joints. For dazzling white tiles, this characteristic is almost of paramount importance, because instead of a beautiful decor, attention will be focused on dark spots on the ceiling.

Accuracy of appearance, reliability, durability of fastening, duration and ease of installation largely depend on the choice of properties.

Species

Regardless of the type, glue is produced in various forms: universal in plastic bottles, glue-mastic, in a cartridge for a pistol.When choosing a fixing composition, it is worth paying attention to the adhesion characteristics, which are suitable for your room. The smell is important. In winter, it will not be possible to work with open windows, which means that you will have to be in a dangerous environment for a long time.

A general idea of the fixing compositions for production tiles, will allow you to make a competent choice:

- Polymer - represent the substance in the form of plastic mass, which is suitable for adhesion with almost any surface. Of the three types of polymer adhesives for interior use only formulations based on aqueous solutions and dispersions. These include PVA or "Bustilat", compound adhesives - epoxy, polyurethane and others.

- Water soluble adhesive polymers. Include formulations with very different characteristics. PVA and its like have low viscosity and adhesion. The liquid consistency requires more flow, the seams dry for a long time - 24 hours for full setting. Disadvantages partially eliminates the lack of odor and environmental friendliness. Of the modern representatives of this group, products under the brand "Titan" have the best characteristic.

Retaining all the advantages of tribesmen, she added viscosity and stickiness. The drying time is optimal for the installation of plastic and polystyrene foam tiles.

- Compound adhesives. Their distinguishing feature is the ability to not spread, to acquire the shape of materials, which allows you to hide surface irregularities up to 9 mm. The compositions provide high-quality mounting, corrosion protection. If it is not possible to make a good waterproofing of the ceiling, it is worthwhile to opt for this type. Some species have a very thick texture. If there is no desire to breed, a spatula and some dexterity will be required for application, since their high adhesion speed is an important advantage.

The lack of epoxy-based compounds is toxicity and a pungent odor typical of some samples. When buying, you need to clarify this point with a consultant, especially if it is not possible to air the room during the work.

- Liquid Nails. Produced water-based and using a solvent. The compositions under this general name differ:

- high strength - 20-70 kg / cm2

- good adhesion - it takes a few seconds to dry;

- resistant to fire and temperature extremes;

- ductility to hide surface imperfections.

- Acrylic putty. In some cases, it is used as an adhesive for foam tiles. It has high rates of adhesion to various surfaces, resistance to deformations and temperature changes, water resistance, environmental friendliness and durability.

- Hot melt adhesive It is a thermoplastic polymer in the form of granules, beads, powder with various additives. Installation is carried out using a special gun. The technology requires laying tiles at high temperatures - 65-200 ° C, then the glue becomes viscous and quickly sets to the surface.

What is better to choose?

The answer to the question depends on the priorities: the most budgetary option, the maximum ease of work, the special conditions of operation of the room or the need to hide the irregularities with foam plastic plates.

Inexpensive building PVA is rarely used for such situations. The connection will be unreliable, but it will take a long time to hold the finish, the unevenness of more than 3 mm cannot be hidden. The best application is gluing plinths and sockets.

The main advantage of universal water-based polymeric adhesives is the optimal balance between cost and quality of connecting seams. They are thick and plastic, resistant to high humidity and temperature extremes. Adhesive composition marked "for interior use" can only be used in dry rooms.

When buying water-based products, you need to remember that they are a breeding ground for bacteria and mold.

In order to prevent the walls and ceiling pre-treated with an antibacterial composition. For plastered and plastered walls, a reinforcing primer is suitable; for bricks and concrete, with an increased ability to penetrate deep into the soil.

Not the most budgetary, but effective option - acrylic putty. It will not only glue the foam, hide irregularities, but also gently hide the seams before painting. It is sold in finished form, it does not shine through the thinnest material, it does not shrink, it is frost-resistant, it adheres to practically any type of surface.

Eco-friendly acrylic glue is suitable for the living room, bedroom and kitchen. This water-soluble type of liquid nails is used for light foam forms, including porous ones.The best option for rooms with high temperature and high humidity is made of synthetic rubber based on organic solvents. The second option dries faster, but it should not contain toluene.

Hot melt glue is best suited for gluing small parts of the finish or in rooms where the ceiling is periodically cleaned. It is easy to work with compound glue, but it requires speed: the grip is maximum from the first seconds. The compounds are toxic, require the use of protective equipment.

What can be diluted?

Modern adhesives for ceiling tiles are already produced ready for work. The issue of dilution may occur when using putty: it is diluted with water to obtain a viscous mass. To enhance adhesion, the mixture is prepared: 100 grams of PVA are added to the prepared solution of finishing putty (1 kg). One has only to consider that homemade drug shrinks after drying.

Sometimes glue thickens from prolonged or improper storage. How to dilute a specific composition - it is written in his instructions. For example, benzene is used for the construction variants of PVA, acetone and dimethyl sulfoxide are used for Moment.If the thickened universal "Titan" - medical alcohol. The diluted composition dries longer, but adheres better because it penetrates into small cracks.

How to use?

The instructions for adhesive formulations are recommended to apply them on leveled, cleaned surfaces not by chance. Opposite reviews of the stickiness of the same solution are most often caused by non-observance of this rule.

A thin layer of whitewashing is fixed with a primer., thick - wash off with water or clean with a spatula. During this procedure, the weak parts of the plaster may fall off and gaps may form. Taking advantage of this favorable moment, the flaws are sealed with fresh putty, then the new and old parts of the ceiling are primed. When gluing on drywall, concrete, various types of building boards, there are no problems.

If the old wallpaper keeps on the ceiling tightly, you can glue the tiles directly to them. The adhesive layer should be minimal. But it should be noted that the color pattern will show through through thin plates. In this case, the wallpaper will have to be removed.

The sequence of the application must be printed on the packaging, so it’s easy to attach the foam with your own hands.

At installation it is necessary to observe the following rules:

- It is better to coat polystyrene tiles around the perimeter and diagonals, spreading them out on a flat surface.

- After applying a water-based polymer adhesive to the sheet, it should be pressed to the ceiling, then set aside, after some time (determined by the instruction, on average 30 - 40 seconds) to be permanently attached to the place.

- Only liquid nails can be applied with a thick layer (up to 9 mm), in all other cases it makes sense to economically distribute the composition along the lines marked in the instruction.

- Liquid formulations are required on both bonded surfaces.

- Putty should cover a small area of the ceiling with an even and thin layer, then apply a tile to it.

- The gaps that were formed from inaccurate docking should be sealed with sealant or putty.

- It is better to immediately wash the excess glue at the joints with a damp cloth, not waiting for them to wither.

Manufacturers and reviews

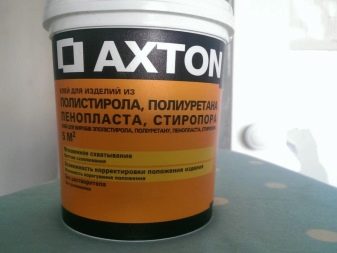

French company Leroy merlin considered the founder of the trademark Axton. Under this brand, they produce a whole line of adhesive compositions for ceiling products: polymer, polystyrene, in cartridges, bottles, and in the form of mastic.Packages come in different capacities - from 0.5 liters to 4 kg.

Glue "Axton for polymer ceiling products" Available in soft plastic packaging, closed with a special cap, which is hermetically closed when pressed. After applying to the surface you need to wait 2 to 4 minutes and you can press the tile to the ceiling. Full drying time depends on the surface - from 12 to 24 hours. It is possible to dilute the thickened polymer with technical alcohol. Airing is required during operation. Consumers rate the reliability of the composition as high.

Positive feedback deserved "Axton mounting universal white": odorless, thick and resilient, imperceptible at the joints. Tuba 290 ml enough for a strip of 15 meters. Reviews indicate a flaw: it hardens longer than the time specified on the package.

Russian company "Selena Vostok" Already produces more than a dozen assembly adhesives under the brand name “Titan” and continues to develop new polymers, focusing on European safety standards and new technologies. Reviews on the Titan lineup are mostly positive.

Among the novelties of recent years:

- Power Flex - combines the properties of polymer glue and sealant;

- Vector MS 1000 - based on MS polymer, has a strong initial grip in 5 seconds, without solvents;

- SBS 100 Multi-use - one-component, based on synthetic rubber, equally easy to set with surfaces and finishing materials;

- Classic Fix - universal, even in the updated version is not suitable for expanded polystyrene;

- Hydro Fix - transparent, well suited for interior work.

In 2017, the company launched the production of a new product. TYTAN Professional Gallop Fix. The stated advantages: the possibility of use in rooms with high humidity, despite the absence of solvents; 3 hours is enough for a strength of 240 kg / m² with a layer thickness of 0.5 mm. Glue creates an elastic connection, resistant to vibrations. Cost - 180-450 rubles per pack 310 ml.

Tytan Professional foam-adhesive 60 seconds - an innovative universal product, unlike foam does not expand after application, does not require primer, adhesion - 500 kg / dm2. Economical: one cylinder is enough for 40 meters of glue track. Completely hardens in 24 hours, allows you to adjust the location of the tile. Consumers note only advantages so far. The cost of one balloon is 400 rubles.

Products brand "Moment" from the company "Henkel" in Russia since 1979, has more than 100 items.Quality and ease of use are noted by most consumers.

Many options are suitable for foam plastic:

- Moment Installation "One for all" Superstrong. With ultra-fast adhesion there is a possibility of fitting within a few minutes, it can be applied on wet surfaces. It is recommended to process the ceiling with diluted 1 to 1 water with wood glue before pasting.

- Moment Installation express decor MV-45 - without solvents, moisture and frost-resistant, hardens in 48 hours, fills the gap to 10 mm.

- Universal moment. Ideal for tiles: a gentle chemical compound does not corrode expanded polystyrene with optimal viscosity and adhesion. An important feature is that one of the surfaces should easily absorb water. Cartridge cost from 200 r. for 380g.

This list is given as an example, does not reflect the whole variety of brands and properties of goods. For any novice builder, the best glue will be the one that helps you get the job done quickly and beautifully the first time.

How to quickly glue the ceiling tile, see below.