Vinyl block house siding: features and benefits

Classic wooden houses have always been a priority for developers. Their appearance speaks for itself. They are comfortable and cozy. Many people dream of having a wooden country house, but this is not so easy. In order to build it, you need to overcome a number of difficulties, ranging from the choice of a log house and ending with the exterior trim.

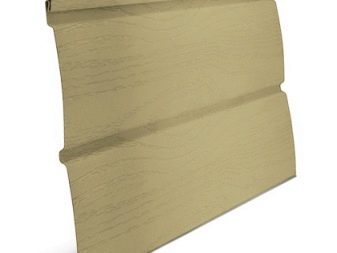

Vinyl siding can be called one of the classic types of exterior trim. But it is so common that by using it, you deprive your home of an individual style. Siding manufacturers have decided to keep up with the times and have developed a completely new model of cladding panels.

This is a vinyl block house that creates an imitation of a wooden log house. It has thought through all the technical details and elements, so it is not difficult to mount it. The result is a house of new modern materials that protect the traditions of the past.

Production

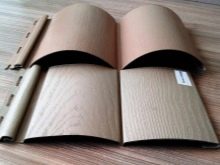

A block house is a wall lamella made of polyvinyl chloride, imitating the shape of a log or a wooden bar.

They are made by coextrusion - forcing molten materials through an extruder. Its peculiarity lies in the fact that two dissimilar substances are used. At the end of the process, a profile is obtained that has several properties. It consists of two layers. The first layer occupies about 80% of the entire product, the second plays the role of a decorative element. The inner layer has the workload and it is responsible for the geometry of the profile.

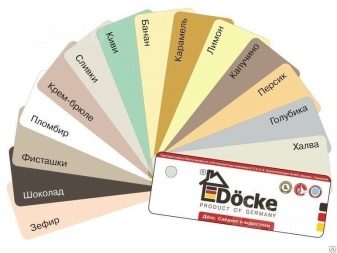

The acrylic component gives the surface resistance, protects against external environmental influences, and also gives the color to the product. The choice of color can be adjusted by adding a different amount of coloring matter.

The thickness of the product is 1.1 mm. In the manufacture of siding used vinyl powder, so the coating has a uniform structure and the same color over the entire surface.

Benefits

- It is characterized by a high level of material resistance to external influences with the application of force. It is resistant to the applied shock load.

- The composition of PVC has several advantages. It does not decompose, does not rot, is not subject to corrosion. Most importantly, it is environmentally friendly. Acrylic surface eliminates the appearance of microorganisms on the surface. Mice and rats will not harm the coating.

- The composition of the mixture for coextrusion includes fire additives. They reduce smoke generation in case of fire.

- The temperature range of operation of the siding from -50 ° C to + 50 ° C. That is, in our climatic conditions, it can be used everywhere.

- UV-resistant siding, the color remains the same as the manufacturer intended. He is not afraid of precipitation. Such coverage with minimal care will last more than half a century.

- The weight of the finished product is relatively small, so it has no effect on the load of the base of the house and on the walls. During installation, common tools are used, so you do not need to hire specialized workers, which can lead to additional costs. Enough small team of builders, which quickly and efficiently do the work.

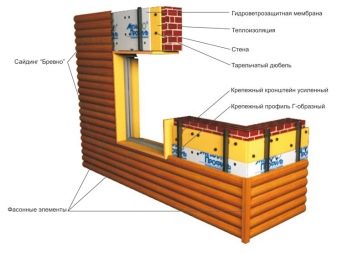

- The type of siding is great for the device system ventilated facades.In addition, the walls can be further insulated and soundproof. This allows the design of the system. So, the house will be even better and it will keep warm.

- Last but not least, the plastic block house masks the defects of the walls. If there is a drop in degrees or the slope is incorrectly drawn and it is impossible to correct it, siding will come to the rescue.

For all its merits, the material has several drawbacks. For example, it does not burn, but melts near an open flame. Vinyl block house does not provide additional facade insulation.

Dimensions

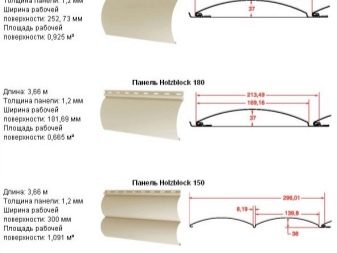

There are block houses of different types and sizes.

Standard slats, in appearance resembling a single wooden log:

- width - 180 mm;

- width - 250 mm.

They are suitable for outdoor use.

Lamellae look like two twin logs:

- width - 120 mm;

- width - 150 mm.

It is already allowed to use indoors. The length varies from 3 to 3.81 meters.

The appearance of the block house is similar in structure to natural wood. The color is chosen by the customer to your taste.

As a rule, these are natural shades. But modern technology allows you to change the usual shade of the tree and there are such colors as bleached oak or bronze walnut.

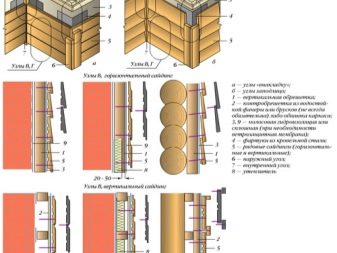

Siding sipes are recruited one by one and snap into place. Therefore, their installation is quite simple. To attach the canvas to the crate, you will need additional strips, which provide mounting holes.

Without fail, the siding manufacturer has a line of additional components. For example, wind strips, external and internal angles, starting profiles, hinged slats, finishing, window. They are made in the same color as the siding. Their length corresponds to the length of the panel.

Installation steps

For vinyl siding block house, you can apply the same installation guidelines as for ordinary siding. Before work you need to read the installation instructions.

The first step is to prepare the walls and other surfaces. For this purpose, the crate is mounted on them. It can be wooden or metal. The elements are mounted with a walking distance of 400 mm. Thanks to the crate, you can additionally install insulation and increase the thermal insulation of the structure. The construction of the lathing allows to make a gap between the wall and fasteners, which means that it will be ventilated and the appearance of condensate will be excluded.

If you want to further waterproof the walls, you can use a vapor barrier and a wind barrier. These are special films, each of which performs its function.

It is advisable to adhere to certain stages of installation. First, start and finish bars are fixed. Then put the corners on the windows and doors, fix the inner and outer corners. To dock the panels with each other, you may need a connecting rail. The set of lamels goes from the bottom up.

Any material due to temperature changes is subject to varying degrees of deformation or expansion. Fixed canvas should not be completely fixed. Fasteners do not need to tighten until it stops, experts recommend not to twist them one turn. If nails are used, then the distance between the head and the base should be about 1 mm.

On the side gaps need to leave about 5 mm of space for the natural expansion and contraction of the material. In winter, the distance should be increased to 1 cm.

It is necessary to hammer in nails and to screw in screws perpendicular to the basis and to use only the galvanized or anodized fixture.

The initial panel is snapped to the starting profile, the following panels are attached to the first one and so on.

At the finish set decorative corners, wind strips.

Instruments

- hammer, handsaw, tape measure, level;

- electric saw;

- scissors for metal;

- perforator for mounting holes;

- notch punch;

- tool for dismantling panels.

How to choose?

If you want your house to be taken from afar for a house made of natural wood, follow some rules:

- It is necessary to carefully analyze the market, read information about manufacturers, see the best samples. The color palette of companies is quite different, and in order for the finish to be pleasing to the eye, pay more attention to the choice.

- Always pay attention to appearance. Panels should have a uniform color, absolutely not allowed stains or other shades, except as stated. The surface of the siding should repeat the texture of the wood. The better this is done, the more natural the decoration will look.

- Holes for installation must be neat. In shape, they resemble an oval. This is a special technical solution to ensure that the coating is not static.

- Experienced builders advise to choose well-known companies that have been working on the market for years.

Price

Those who come across complex construction for the first time understand how costly it is. Buyers are always concerned about the price. But this approach is fundamentally wrong.You need to think about the quality and performance. Low-quality block-house can spoil the look of the house. The front and back sides of the lamella should be of the same shade. If this is not the case, then you have a poor quality sample.

The price of the material ranges from 200 to 900 rubles per 1 m2. To this price you need to add the cost of work. This is still an average of about 300 rubles.

The following factors affect the price:

- quality of performance;

- complex installation;

- seasonality;

- workload.

Vinyl block house is a new type of decoration that is rapidly gaining popularity, especially in regions where wood houses are preferred.

Its shape follows the shape of wooden logs and this is its main advantage. It replaces the impersonal standard siding panels and gives the home a more aesthetic look.

Its main purpose is:

- improves the external perception of the appearance of the house;

- masks defects of walls with little effort;

- prevents the ingress of precipitation and moisture from the outside;

- with its help they warm the house - under a siding they lay a heater.

Without much effort you get a modern, warm, beautiful house. A variety of colors will be beneficial to highlight it against the background of standard finishes.Reviews of this finishing material is only positive.

Installation of vinyl siding "block house", see the video below.