Ground siding: pros and cons

A plinth is an element located between the foundation of the structure and its first beam, the frame of the building or the first row of bricks. In other words, it is a transitional element from the foundation of the house. Such an arrangement causes an increased load on the basement part, which is stronger than others, is subject to destruction and corrosion.

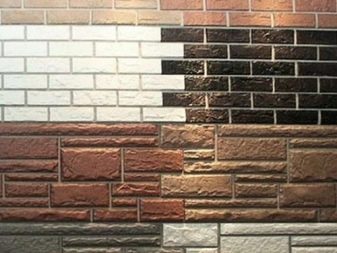

In this regard, the basement needs reliable protection, which is not afraid of exposure to moisture and road reagents, frost and mechanical damage. Such a finishing material is a basement siding. It is a panel whose surface imitates natural materials: stone, brick, wood, etc.d.

Special features

Plinth siding is a panel based on polyvinyl chloride, metal and some other materials that have a lock connection for installation and are used for cladding the plinth part of a building. The panels are thicker than facade counterparts, which explains their increased strength and resistance to stress. At the same time, the weight of the basement siding is insignificant, so there is no excessive load on the supporting structures of the building. Material weight per 1 m2 on average is 3-5 kg.

Installation is quick and easy: panels interlock with each other due to the presence of special locks, and additional elements are provided for corners and protruding elements. If we talk about the basement metal siding, then it is true that it is economical. This is due to the fact that the material is easily bent, so the amount of residual material is minimal. Unfortunately, there is no need to talk about this vinyl analogue, since the material is not bent.

Installation of basement panels can be carried out on any type of basement. The material is attached directly to the surface of the wall or metal or rack batten.In the latter case, you can not worry about the careful alignment of the walls of the building: siding panels allow you to hide irregularities, cracks and other imperfections of the walls.

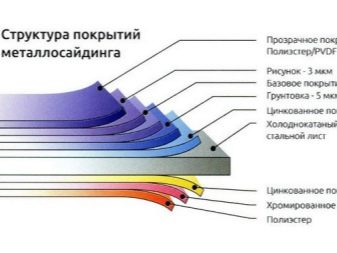

Due to the fact that the basement panels protect the lower part of the building from the negative impact of the environment, it is possible to significantly extend the life of the structure. Siding resists corrosion (metal profiles have a special polymer processing), is not afraid of frost (due to a small coefficient of expansion, the material does not crack at low temperatures, withstands up to 60 freezing cycles), endures heat fluctuations and gusts of squally wind . Temperature range of operation - from -50 to +60 C.

Finally, on the surface of the siding does not appear mold and fungi, insects are not divorced. In addition, it does not fade in the sun and retains an attractive appearance and performance over the entire service life (30-50 years).

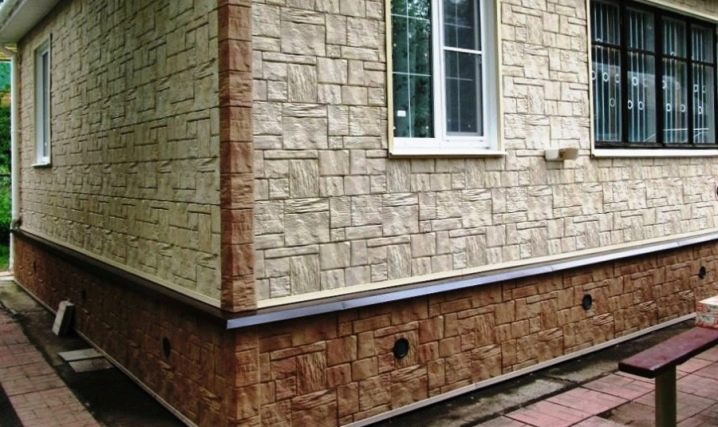

Due to the variety of textures and colors, you can choose basement panels for any style of home and exterior. At the same time, modern profiles imitate the surface of stone, wood, brick, tile as closely as possible, so the building looks elegant and noble. It is important that, compared with the cost of facing a brick or stone, the purchase and installation of basement siding will be much cheaper.

Perhaps the only "minus" of the material is its flammability when in contact with an open flame. Fire hazard class for vinyl models is G2 (moderately flammable).

The scope of the material is very wide:

- plinth facing;

- registration of a porch, verandah;

- decoration of rooms characterized by high levels of humidity;

- facing of baths, arbors, fences, wells.

Kinds

Depending on the material on the basis of which the basement siding is performed, several types of it are distinguished.

Metal

The panels are basically galvanized steel coated with a protective polymer layer. The peculiarity of the material is its increased strength, resistance to mechanical damage, fire safety. Due to the polymer layer, the surface of the material is protected from corrosion.

Metal siding can imitate various textures, but its cost cannot be called low.

Vinyl

The basis of this material is polyvinyl chloride. Vinyl siding is characterized by durability, affordability and variety of textures and colors. These panels can have both an unusual pastel range, and rich shades (red, bright blue). In addition, they can imitate wood, stone, brick surfaces.

As for performance, it is frost resistance, moisture resistance, wind resistance. By their strength indicators vinyl profiles are inferior to metal counterparts.

A variety of PVC based panels is acrylic siding. Due to the presence of polymers in the base, it is characterized by improved technical properties. They are optimal for outdoor decoration in difficult weather conditions, resistant to temperature differences and the action of chemical reagents. Their service life is longer (up to 50 years) compared with the period of operation of vinyl models (up to 30 years), however, the cost is higher.

Fiber cement

It is based on cement, modifiers and cellulosic reinforcing fibers.The latter give the material strength and solidity. The panels are resistant to moisture and fire. However, they are not always suitable for finishing houses, since during installation there are noticeable seams and gaps.

There are also ceramic and concrete siding. The first is environmentally friendly, as part of the clay and other natural ingredients. By their strength, ceramic panels are comparable to similar tiles of increased reliability. The advantage of concrete siding is resistance to sunlight, moisture, low temperatures.

However, the material has an impressive weight, and therefore often requires strengthening the foundation, and the height of the basement should not exceed 2 meters. Finally, in order to cut the panels, a grinder with a diamond disc is required.

All of these types of panels can be used in conjunction with insulation. Foam polystyrene and polystyrene foam are suitable for these purposes, and when organizing waterproofing protection of the surface of walls, it is permissible to use mineral wool heat-insulating materials (basalt is better, but if an economy option is considered, fiberglass will do). On the warmed surface of walls the obreshetka usually fastens.

Speaking about the varieties of basement siding, the following groups of materials should be highlighted.

Flexible panels

They are exclusively vinyl, used for lining spherical surfaces. The ability to bend, without breaking, due to the presence of binding threads on a synthetic basis, which are located between the panel form factor and the nail panel. The length of such products is usually 3-3.8 m, width - 17-24 cm. The thickness of the panels is small for the basement material - 1.1-1.5 cm. This is understandable, because too thick material will not be able to take a spherical shape.

Modular panels

They represent the usual profiles, which can be long (their length is 2-6 m) or represent rectangular profiles (on average, their dimensions are 1150 * 450 mm).

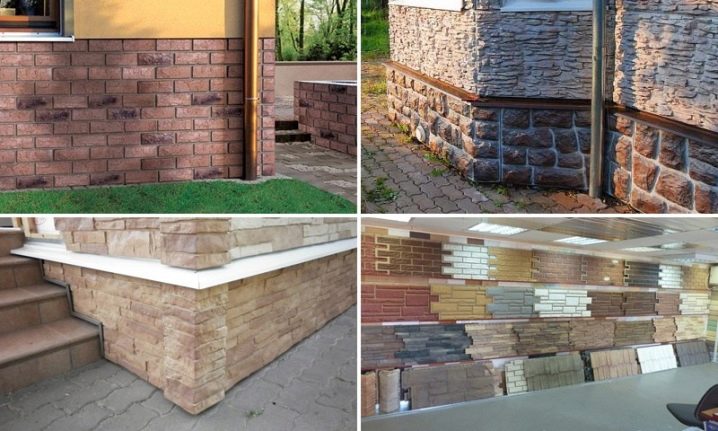

Siding for the base can mimic different surfaces.

- masonry from natural stones;

- masonry of hewn stones (allows you to get noble, expensive facades, imitates the facing of natural stone, is presented in more than 60 color variations);

- brick (smooth or chipped) masonry of white or red brick (available in about 11 colors);

- imitation of timber, board, shingles, wood chips (roughly hewn boards).

The most optimal basement siding are metal panels. The plinth areas finished in this way easily tolerate negative environmental conditions and are not afraid of mechanical damage.

However, if the front material has bright or unusual pastel shades, then the same color palette may be required for the socle. In this case, it is better to stop the choice on vinyl profiles.

Dimensions

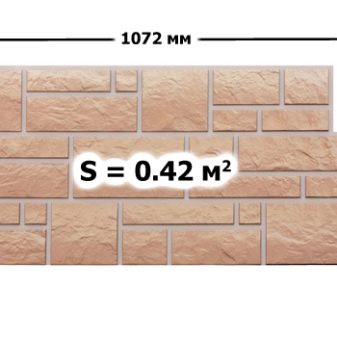

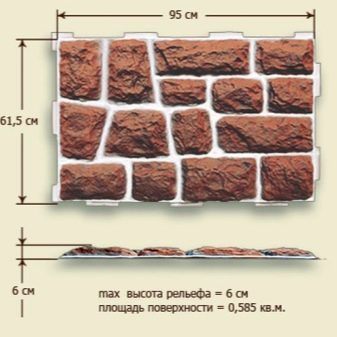

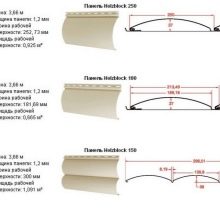

Siding sizes are not regulated by state standards, so the dimensions of the panels from different manufacturers may vary.

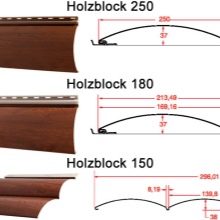

As a rule, the length of vinyl siding ranges from 2.5 to 4 m, and width - 20-30 cm. The length of the metal siding varies from 60 cm to 6 m. And the sizes of fiber cement panels of most brands are similar: length - within 3-3.6 m, width - from 10 to 30 cm.

The thickness of the basement panels exceeds the thickness of the wall profiles and is within 2-4 mm. The most popular profiles are 1 m long and 0.5 m wide.

When choosing a siding, you should take into account that the manufacturer indicates the full width of the panel and is useful. The calculation of the number of profiles should be conducted on the basis of the coefficient useful.For example, the “rubble stone” profiles from the Nailite brand have a full size (length-width) of 116 x 49 cm, and a useful one — 102 x 46 cm.

Regardless of the issuing company, all profiles can be divided into three groups.

- thin, whose width is up to 15 mm (characterized by low weight and flexibility);

- medium, whose width varies within 15-25 mm (the most demanded material);

- thick - their width is about 25 mm (for models, the presence of a thick layer of polyurethane is typical, and therefore the material has high thermal insulation performance and can be mounted without using insulation).

Design

Due to the variety of design options for panels, the protruding part of the foundation and basement can have a different finish. Panels made of stone have become very popular: due to the presence of roughness, it is possible to achieve the effect of natural stonework. If it is necessary to achieve originality of the exterior, then we can recommend an imitation of a rubble stone of various sizes.

No less popular is the imitation of masonry. Due to the impression printed on the original material, the panels have all the characteristic roughness and chips.Another advantage of the “brick” profiles is the simplicity of cutting (brick by brick), so it is often used for finishing buildings with a large number of projections and turns.

Beige profile, the so-called "burnt brick", lovers will appreciate the refined luxury. It stands out against the background of other siding options for its exquisite nobility.

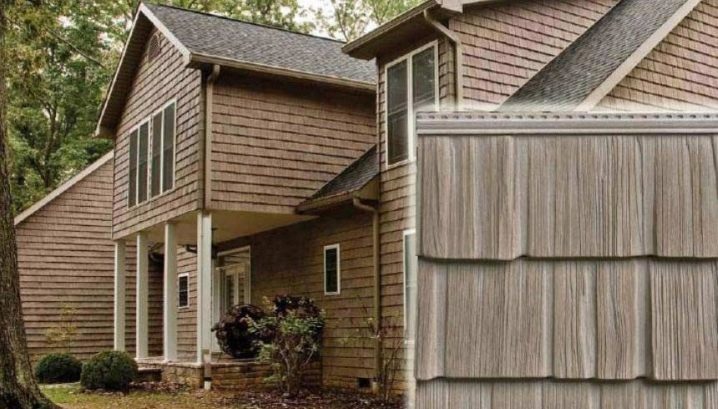

The siding under a tree will ideally fit into style of a "rural" country house. It will create the illusion of trimming the base with natural wood. For houses in the country or colonial style, it is recommended to choose a white and light shade of profiles under the board, for buildings in the spirit of alpine chalets - wenge shade, cherry or dark brown color.

Manufacturers

Among domestic brands are the following companies.

- "Dolomite", which has been producing its products since 2008. The basement profiles imitate a wild stone, you can choose the material from one of three collections: single-colored stone, exclusive, stone with colored seams. The width of the panels - 22 cm, length - 33 cm. The thickness of the material - 1.6 mm.

- Brand siding Docke Available in 3 variations: brickwork, ashlar, layered sandstone.According to customer reviews, the material is characterized by good quality at a fairly affordable price.

- In the brand collection Fineber You can find many options for panels with imitation of brickwork: yellow and red facing bricks, the BRITT facing bricks collection (possible palette is dark brown, dark pink, burgundy), the Brick collection.

From Western manufacturers trusted buyers enjoy the following brands.

- Recognized leader - American manufacturer Nailite. The products are of high quality and variety of design solutions. The most popular are profiles under stone, brick, wood. The service life of the material is 25 years, while it is adapted for use in the harsh Russian climate. Does not need additional staining during use.

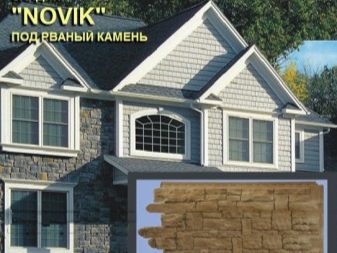

- Brand collection Novik it is presented by imitation under a bricklaying of different shades. The length and width of the panels - 1219x470 mm.

- German brand Deke, and in accordance with the German spelling Döcke, is available in 2 variations: under the stone and brick. Complete with panels are delivered doborny elements.

- Profile production VOX (Poland) is carried out in two dimensional variations: 1110х460х2.5 (Solid Mur) and 1110х477х2.5 mm (Solid Stone for a brick). The latest stone model has a panel width of 466 mm. The manufacturer managed to achieve amazing closeness with natural stone: the siding surface even has a typical stone sprinkling of the smallest fragments.

- Canadian siding NOVIK It is produced according to improved technologies, and therefore withstands even extreme weather conditions. Having more than 15-year history, the material has improved technical properties, does not require painting and other manipulations during operation. Available in 5 variations: wild and hewn stones, cedar boards, bricks, wooden shingles.

Tips and tricks

When choosing panels connect 2 of them to each other. They should fit easily and do not form gaps. Places joints should be invisible.

High-quality vinyl profile should have the same color from the outside and the inside. For cheaper models, the back side is usually lighter. In general, this does not affect the final appearance of the building, but in some cases it allows to suspect a low-quality product at an inflated price. In any case, the color of the panels should be uniform, not have streaks and stains.

For panels of a darker color, you will have to pay a slightly higher price than for analogues of light shades. This is due to the fact that the former fade faster, and therefore stabilizers are used to preserve the color, which increase the cost of the profile.

To the note: the glossy surface absorbs light, and therefore fades faster. If your house is located on the sunny side or you live in the southern region, it is better to give preference to matte options.

Look at the panel from the end: it must have the same height throughout the profile. Note that the height of the corner panels must be exactly the same as the profile width.

Perforations for screws must be identical, neat. Otherwise, moisture will penetrate too large holes, and too small if you try to screw the screws into them, they will cause the profile to crack.

It is important to pay attention to the packaging of products. Normally, it should be made of cardboard. When buying siding in plastic wrap, you risk acquiring profiles that have been deformed during transport and storage.

Following simple recommendations will allow to achieve technological accuracy of installation of basement panels:

- laying is carried out from bottom to top, from left to right;

- fix the panels to the crate with stainless nails or screws;

- nails and screws should be located strictly perpendicular to the surface of the panels, and the cap should not be buried in the panel, otherwise deformation of the siding is possible;

- when installed at negative temperatures, siding panels are pre-conditioned for 24 hours at room temperature.

Beautiful examples

Due to the variety of siding models, you can easily find the best option for a particular structure. It is important to take into account the features of the exterior: the size of the house, shades and texture of other finishing materials.

So, for country houses from a stone it is recommended to choose a socle siding under chipped basalt, a rubble stone. For houses sheathed in wood, a basement with an imitation of a reed mat, wood chips, and oak beams is suitable.

Popular options for finishing basement siding can be called the use of a dark shade of basement panels and roofing in combination with claddinglight materials the rest of the facade. In the tone of the base you can frame the door and window openings.

It is considered pleasing to the eye to make the basement, facade and roofing in the same color, but in different shades. It is preferable to choose light warm colors of materials.

The most universal type of basement panels are those that imitate masonry. However, it is important to choose the appropriate "stone" for the facade. So, for country houses in the style of country, it is better to choose a stone of light shades, combining it with a stone or wooden facade.

For the classics, you should choose a masonry gray or sand shades. The material for the basement can be repeated during the finishing of small decorative elements of the facade, which, as is well known, is replete with a classic exterior.

Buildings that use the same facade and basement panels, differing only in color, look impressive. As a rule, these are surfaces that imitate a stone. Finishing under the stone will allow to demonstrate the status and good taste of the owners of the building.

In this video you will find a master class on installing basement siding.