Wood siding: features of choice

Among the huge variety of options for exterior decoration especially popular is wooden siding. It is a practical, stylish and wear-resistant material that attracts the attention of others. This product has a number of features and advantages that have played an important role in the distribution of finishes.

The tree used in the production process creates a comfortable microclimate. In addition, it is a natural and environmentally friendly material.

Characteristic finish

Siding is a separate type of cladding material. It is mounted on the wall with a special frame, which is pre-installed on the building. This finish is very popular in Canada and throughout North America. For its manufacture can be used a variety of materials.

Wooden panels are ideal for finishing a country home and other similar buildings. Due to the fact that the wood passes air particles, the life of the building increases, and the formation of condensate and mold becomes impossible. Natural material, which is used in the field of production, has individual characteristics that are absent from artificial analogues. Other advantages of finishing we will look further in the article.

Benefits

In the manufacture of wooden siding to the base material is added various components. Additives play an important role in the strength and durability of the material. Due to high-tech equipment and special techniques, ordinary natural raw materials are transformed into reliable, practical and stylish finishes. Manufacturing companies use different types of wood.

The advantages of finishing materials include several points.

- Strength. Quality product has high strength. Wood siding perfectly tolerates constant loads, keeping its shape and hardness.

- Life time. This type of finish boasts a long service life.From year to year, wooden veneer will delight with beauty and practicality. Due to this characteristic, this material can be called a profitable and practical acquisition.

Using wooden siding, you will long forget about changing the lining of the outer part of the building.

- Persistence Facing demonstrates resistance to the vagaries of bad weather: wind, rain, snow. Direct sunlight and sudden changes in temperature will not damage the skin. Color, shape and hardness will remain unchanged. Finishing material is able to withstand frosts up to -50 degrees Celsius. In this case, the structure of the coating will remain.

- Treatment. The material is easily processable. If necessary, you can easily adjust the size of the plate yourself.

- Security. It is a natural, environmentally friendly and safe for health material without harmful and dangerous impurities. The tree is recommended to be used for cladding houses that are allergic, small children or animals.

- Vapor permeability The material "breathes" by passing oxygen. This factor prevents the formation of mold and mildew. Air circulation is very important for creating a comfortable microclimate, regardless of the weather outside the window.Experts note that the vapor permeability of wooden siding is very high.

- Installation. Using this material, you can carry out the installation process yourself, saving money on the services of professional craftsmen. For lining does not require special expensive equipment and additional consumables.

- Aesthetics. Wood used to create finishing materials has special aesthetic qualities. It is associated with naturalness, comfort and home warmth. The material fits perfectly into the classical and ethnic decor, as well as the style of country music. A variety of wood species have the original color: some panels are uniform and evenly painted, others are supplemented with lines and patterns.

- Warming Cladding of this type may act as an additional protection from the cold. The material will help to keep the precious warmth inside the house, and without it a comfortable atmosphere is impossible.

disadvantages

If you have decided to use wood siding for cladding a dwelling or any other construction, you should be familiar with not only the advantages, but also the disadvantages of the finishing material. Only knowing all the characteristics, you can make the right choice:

- Fire resistance. The product has a low resistance to fire. If a high degree of fire danger persists in the region, it is recommended to either completely abandon this finish or use special solutions to protect the wood. The flame will cause irreparable damage to the lining, even if it is treated with protective compounds.

- Exposure to moisture. Despite the fact that the material has vapor permeability and resistance to moisture, moisture has a negative effect on the finish. To prevent this, you need to invest in special formulations.

Solutions will provide protection from excess moisture, keeping the shape of the wood and the beauty of the finishing material.

- Care. Finishing material made of wood needs careful maintenance and constant inspection, otherwise you will have to partially or completely change the trim. To clean wood panels from dust and dirt, do not use aggressive chemical compounds.

- Cost Natural raw materials, as a rule, are more expensive than artificial options. The cost of such finishing is not available to everyone.The difference between the price of wood siding and the same lining of other materials is about forty percent.

- Extra work. During the installation of panels, it is necessary to build separate ventilation gaps, which are placed between the wall of the house and the casing itself.

Species

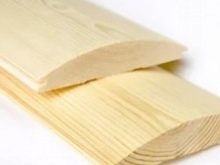

Wood siding is divided into two main categories: false bars and block house. These two coating options are similar to each other, but have certain features. Consider their distinctive characteristics.

Block house

Type of facing boards for exterior work. Externally imitates a planed tree. In the process of manufacturing material used a variety of wood species. Each individual grade has certain characteristics that are transferred to the finish.

In the production of siding uses a variety of wood.

- Pine. The coniferous tree known to all boasts high durability and reliability. The material is resistant to reproduction processes of harmful organisms. They are the cause of many unpleasant consequences.

- Cedar. When using siding of this type of wood, there is no need to use special protective measures against dampness or waterproofing materials.Cedar perfectly regulates the level of optimum moisture content.

- Larch. This is the most expensive option siding boards. The high price is fully justified by excellent durability, wear resistance and practicality. Breed is not exposed to the negative effects of moisture.

In turn, the products of the block house group are divided into three classes with specific performance characteristics.

- Class A. Finishing products belonging to this class is of the highest quality. One plank can contain no more than two blind cracks and no more than one knot one and a half meters of length. The presence of a small amount of resin pockets.

- B. Second class quality material. On a surface 1.5 meters long there can be no more than four small knots. The maximum number of cracks (non-through) is 2. Not more than two resin pockets.

- C. Third, last class. The maximum diameter of the knots on such panels should be 25 millimeters. It is allowed to have no more than two through cracks.On an area of five meters, pockets with a maximum size of 50 millimeters are allowed.

Raised beam

This species appeared on the domestic market relatively recently. This siding has excellent water-repellent characteristics, while maintaining high reliability of the material. Finishing allows to receive a flat and ideally equal surface. Suspension beams can be used for interior and exterior plating.

In the stores of domestic materials you can find a huge variety of products of this type, which is different in color and texture.

A huge assortment gives maximum freedom of choice. Manufacturing companies use both common and rare tree species to make a false beam.

Installation Features

Experts identify three options for facing the building with wooden siding.

- Sheep groove. The most popular and widely used type. This technique can be used when working with a block house or a false bar. Boards are fastened together by special joints on the edges.

- Overlap.The reliability of the finished coating is ensured by joining the panels at different levels.

- Butt. Finishing material is tightly docked on the wall. The installation process takes into account ventilation gaps.

Before laying, it is necessary to equip the frame to which the boards will be attached. For high-quality and durable fastening, lathing is used (wooden product made of strong and moisture-resistant rails). If the region remains high humidity, it is better to make a choice in favor of the bars. The first siding strip is attached using a starter rail.

For fixing the panels need 50 mm nails. The lowest boards should be placed at a distance of at least 15 centimeters from the ground.

Siding - the leader among the finishing materials made of wood for facing houses and other buildings. The modern market is rich in products of both domestic and foreign brands. Especially popular are products of Finnish and Canadian production.

On how to make the frame under the siding of the profile, you can see in the next video.