Plastic septic tanks: principle of operation and installation features

In order to increase the comfort of operating a summer house or a private house, it is necessary to properly equip the sewage system. Such tasks are solved in several ways, one of which is the installation of plastic septic tanks.

Specifications

Thanks to the rapid development of modern technologies, even domestic issues can be solved with the help of simple but fairly effective measures. Not long ago, in order to build a septic tank, one had to use rather heavy structures made of concrete or bricks. But today, high-quality sewage treatment plants can also be made of plastic,in comparison with more massive designs, PVC containers also perform well the assigned functional tasks.

The issue of disposal of products of human activity in private homes has always been relevant. Non-volatile septic tanks began to be used to solve problems everywherewhich do not harm the environment, are quite economical, do not require frequent maintenance, as well as feeding from any source, for example, from the mains.

Containers for septic tanks are made of plastic with a high level of strength, the material is fully eco-friendly, having a sufficient level of resistance to the effects of various chemical environments.

The raw materials are not subject to rotting, besides, the material does not rust and does not crack. It is convenient and easy to use, and cleansing is done using a cesspool machine.

Underground plastic containers can be used for waste disposal, as well as for water and diesel fuel, as evidenced by the relevant certificates.

The tightness of the device is ensured by the absence of welds. As a rule, products have a reinforced body with stiffeners, which perform a protective function, protecting the material from overloads.The temperature range in which you can use plastic equipment ranges from -30C to + 60C.

It should be noted the main positive characteristics of the product:

- the tightness of the septic tank makes it possible to install it in the immediate vicinity of the house without the risk of having an unpleasant smell near the structure;

- for installation and transportation of plastic products there is no need to use special equipment;

- plastic tank has a long operational period of about 50 years;

- production differs in low cost;

- for operation of a septic tank there is no need to provide the device with the electric power.

In addition to the above advantages, it is worth noting some of the drawbacks of the devices. Due to the small mass of products, there is a risk that in the flood season, groundwater will squeeze light plastic to the surface. However, such situations can be avoided by securing the structure during installation, which, in turn, implies additional construction work.

Device

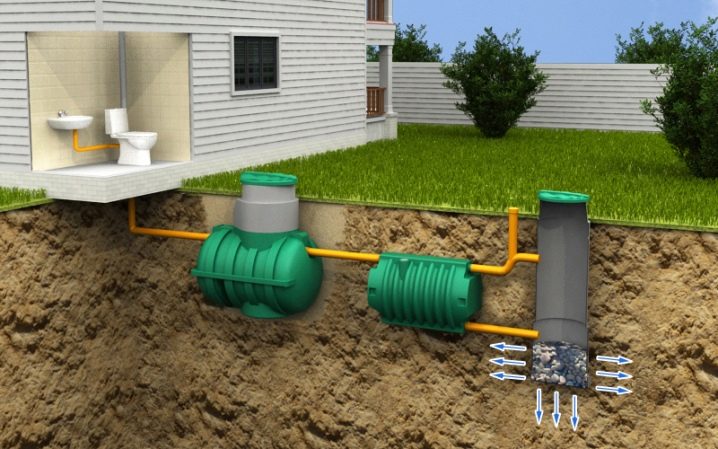

Plastic septic tanks for sewage are a container, divided among themselves by several partitions, which, in turn, form several storage compartments.

- Sewage and drains from a residential structure enter the first chamber, freely draining, while solid inclusions are deposited on the bottom. Fat deposits form a film on the surface of the liquid, gradually developing into a crust.

- The second compartment in the septic tank is designed for anaerobic purification of water.

- The third chamber has a removable filter for cleaning.

- The last compartment usually acts as a pumping well with drainage, where the fluid passes the last stage of filtration and goes into the soil.

In some models, in the first compartment, special preparations are additionally used to clean the fluid from the worms.

The basic equipment of plastic septic tanks assumes the presence of polypropylene pipes for arranging the sewage system, they allow wastewater to be cleaned in a natural way. Plastic septic tanks are of several types.

Polyethylene tanks

They have high strength, so that they can be used in contact with aggressive media. In addition, the devices tolerate heat well. The specificity of the production excludes the presence of any seams on the surface, and the shape and configuration of the barrel prevents the accumulation of various deposits on the base. The production technology of septic tanks of polyethylene involves the manufacture of containers from several layers of material, so that the products are suitable for installation in any climatic zones.

For arranging the dacha such type of device, according to consumer reviews, is the most acceptable option for removing sewage on the basis of their cost. Products are classified according to the size, volume of containers and the shape of the whole structure. To increase the stability and strength of the tank, on the basis of septic tanks of cylindrical or round shape, stiffening ribs are made, this feature increases the resistance of the container to mechanical stress.

The recommended temperature in which a septic tank made of polyethylene can be operated is from -50С to + 70С. As a result of more heating, the structure may be deformed, and low temperatures increase the brittleness of the material.

Polypropylene containers

They are the second most popular products for use in private homes. Products are characterized by lower strength values compared to septic tanks made of polyethylene, however hardness and resistance to abrasion compensate for low values of strength.Septic tanks made of polypropylene can be operated at temperatures up to + 140 ° C, therefore, in addition to private use, such products are in demand for collecting industrial effluents in production.

Since the material is resistant to aggressive effects, such containers are recommended for installation in country cottages with permanent residence of residents. It is worth noting some of the advantages of products made of polypropylene.

- Large temperature range in which the bases of the containers are not deformed. That is why the tanks can be operated for the arrangement of anaerobic septic tanks, where during the cleaning process a lot of gases are released, which contribute to an increase in the temperature inside the compartment.

- The strength of the material allows you to maintain its shape when exposed to internal and external pressure on the container. In addition, a septic tank of polypropylene does not crack and does not burst on impact.

- Low cost of production.

Fiberglass septic tanks

The main purpose of products from this raw material is the processing of aggressive liquids. The construction of the septic tank includes several chambers, which makes it possible to withstand pressure,which exerts soil outside, as well as external pressure, during thawing or, conversely, freezing inside the liquid.

Fiberglass septic tanks, in fact, are containers made of acrylic resins and fiberglass. In the manufacture of structures used method of pressing. Features of the fibrous structure of the material increase the strength of the entire container.

However, due to the complexity of manufacturing septic tanks made of fiberglass and expensive components, the products have a rather high cost in comparison with the above listed designs, which is considered the only drawback of septic tanks.

The material has the following positive features:

- raw materials do not react with most chemicals and corrosive media;

- fiberglass tanks have a wide range of applications, including operation in the private or industrial sector;

- products are resistant to deformation due to the specifics of the raw materials used for production;

- fiberglass septic tanks have no limitations on the displacement;

- resistance to heat is inherent in the products - the container remains completely sealed even when exposed to a high local temperature on the surface.

Features of use

The principle of functioning of the septic tank and the features of its configuration practically exclude the possibility of its freezing. As a rule, structures are installed in the ground at a depth of about two meters, where, most often, the soil temperature can only drop to + 5 ° C, moreover, the substances inside during decomposition emit additional heat.

But if, in light of the climatic features of the region where the plastic septic tank is installed, there is a risk of it freezing, an additional warming of the container is carried out. Special materials are available for such works, for example, extruded polystyrene foam or industrial foams. With the help of these products, the upper part of the tank is insulated to avoid interruptions in the operation of the sewer system due to freezing. In some cases, conduct insulation of pipes.

For those summer residents who prefer to use septic tanks at the dacha instead of a cesspool, but live and operate the structure only in the summer season, it is necessary to carry out the system conservation procedure with the arrival of the first cold weather to reduce the risk of damage to the tank during the winter period.

The power supply of the sewer system is disconnected in the first place, the dismantling of pumping equipment and the compressor is carried out. Then you need to reduce the level of wastewater inside the tank by a third. Then plastic bottles filled with sand are lowered inside the tank. Their presence will prevent damage to the base of the tank if the liquid is frozen and frost forms on it. After which the septic tank closes tightly and its lid is insulated.

If it was not possible to avoid freezing of the liquid, it is necessary to pour hot water into the drain holes of the bath or sink. This technique will give the opportunity to melt the frozen water in the tank.

In the absence of a result, you can use a saline solution, which is guaranteed to return the septic tank in working condition. In the most extreme cases, you can use a submersible heating cable directly in the septic tank compartment. This technique will allow you to maintain a constant temperature in the pipes.

Installation rules

For installation of a septic tank made of plastic there is no need to use heavy machinery. After creating the project of future construction, you can proceed to the installation of the tank.All design work must be performed taking into account SNiP and SanPiN, which set certain requirements for the distance where the septic tank should be located relative to the residential building.

An important nuance that should be considered when creating a project is the minimum number of turns of the pipes. A competent scheme of laying the pipeline will help reduce the cost of acquiring material, as well as facilitate the installation work.

Works on installation of a septic tank are performed according to the following scheme:

- the device of the pit, which must be larger than the size of the tank, which will be in it;

- in order to prevent the septic tank from floating up, in some cases a concrete sarcophagus is arranged;

- after which the anchor belts are fastened, for this purpose products made of nylon with a clamping mechanism are usually used;

- after the concrete has completely set at the bottom of the pit, a sand cushion is performed;

- after the preparatory work it is necessary to proceed to the laying of pipelines, for which it is best to use corrugated polyethylene pipes;

- the final stage is the installation of the structure itself, the tank is immersed in a pit at 1.5 meters;

- during the instillation of the container, it is necessary to gradually supply water to it in order to avoid deformation of the walls under the external pressure of the soil;

- if the device design assumes the presence of a compressor, an electrical cable is laid;

- based on the individual characteristics of the climate where the septic tank will be used, it is possible to carry out additional warming of the structure.

How to install plastic septic tanks with their own hands, see the following video.