Do-it-yourself septic tank: types, schemes and production

The dream of the owner of a country house is the sewer system, which works without interruption and the cost of a large amount of electricity. It is precisely these qualities that a septic tank has, which provides a high rate of sewage treatment. It is not always possible to acquire these mechanisms, because the cost of such structures from well-known manufacturers is quite high. But you can solve this problem by building a structure with your own hands.

Special features

Several years ago, under the treatment facilities understood cesspools in which the accumulation of sewage took place and their subsequent pumping out.The modern construction market offers an improved mechanism used to collect and pump wastewater. In a private or country house, designed for permanent residence, sewage treatment system is simply necessary.

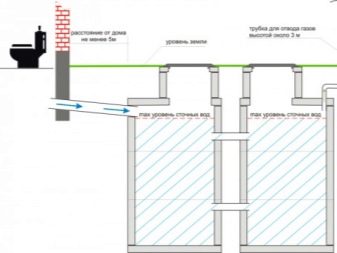

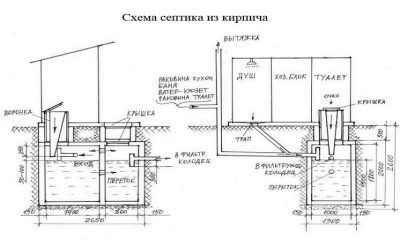

Before proceeding to the manufacture of a septic tank with your own hands, you need to familiarize yourself with the scheme of the device.

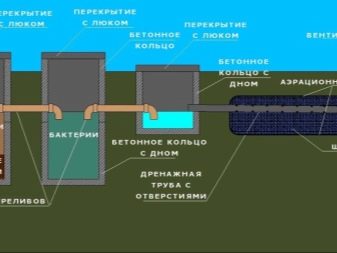

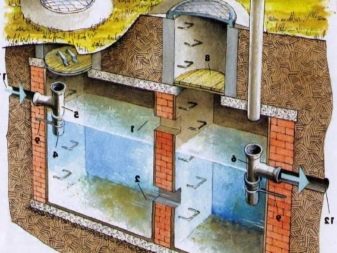

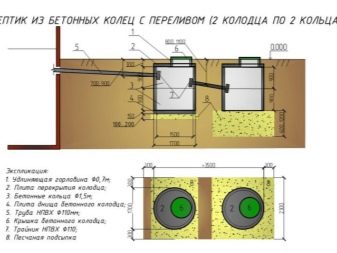

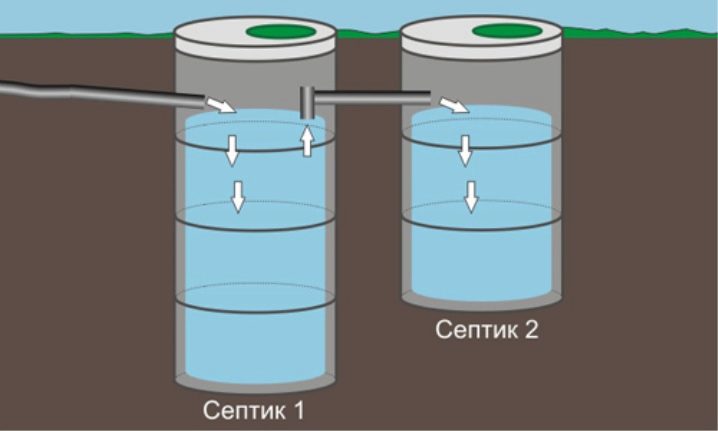

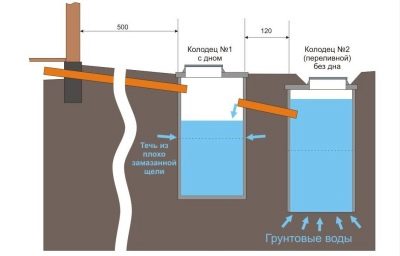

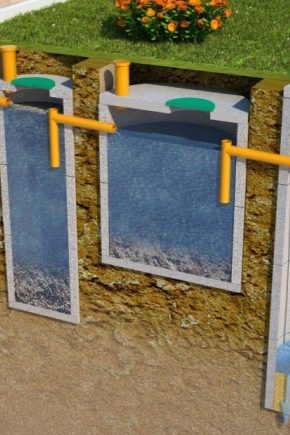

- The design consists of 2 or 3 tanks, which are interconnected by a pipe.

- Each tank has vents.

- The tanks are equipped with tight sealed covers.

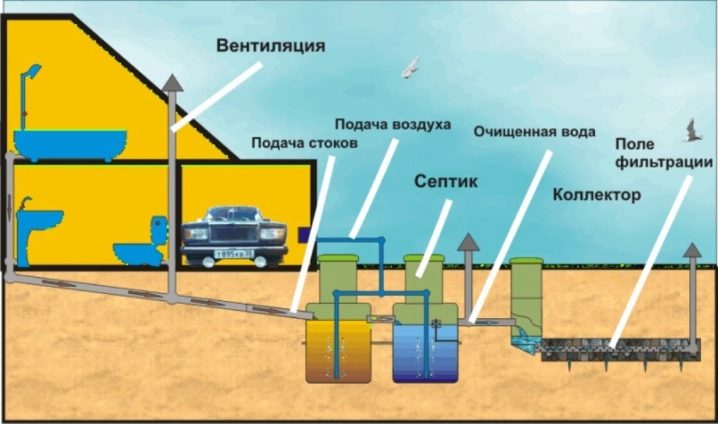

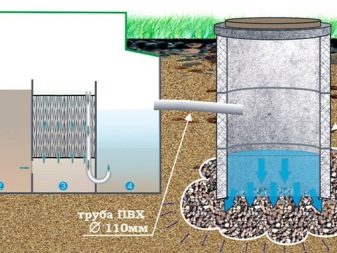

- Filtration field, in which the final treatment of wastewater. Traditional filters are: drainage well, infiltrator.

The most effective are the mechanisms consisting of 3 chambers, in this case there is a more thorough cleaning of wastewater. When preparing to perform even a home-made mini-septic tank, one must remember that the structure of the future cleaning mechanism will include 2 cameras.

The principle of the treatment plant:

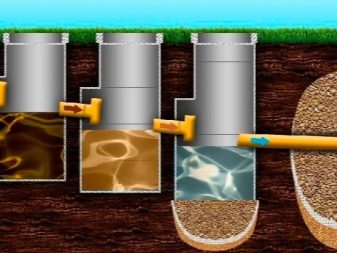

- drains enter the acceptance chamber of the mechanism (settler);

- large waste is screened by settling;

- all waste elements undergo a fermentation process through bacteria living in the cleaning system;

- impurities decompose and release gases that escape through the air vents;

- within a certain time the contaminating components dissolve in the liquid;

- at the outlet of the septic tank, 95% purified liquid flows out; this water can be used in household and household needs.

The budgetary septic tank without pumping due to its performance in most parameters exceeds the cesspool, because It has many advantages:

- high level of wastewater treatment;

- no unpleasant odors;

- hermetic system does not allow waste elements to fall into the soil layers and does not harm the ecosystem;

- pumping out of liquid is carried out once a year.

The disadvantages of this device include several features.

- Complicated design.

- Strict rules for the use of detergents.

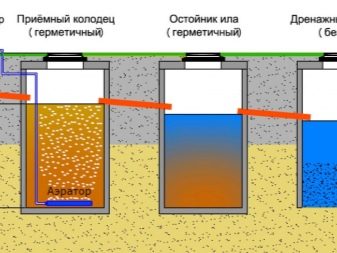

- The activity of bacteria decreases at low temperatures and lack of oxygen, which leads to a decrease in the level of purification. For additional ventilation, you can purchase a special aerator.

Design and preparatory work

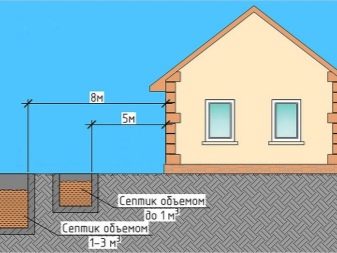

When placing the sewer system it is necessary to take into account the remoteness of the structure from residential buildings, open water bodies, sources of drinking water.

Basic sanitary and technical requirements are specified in SNIP:

- treatment facilities are allowed to be installed at a distance of 5 m from the residential premises, 1 m from agricultural buildings;

- the distance from drinking water sources (well, well) depending on the type of soil can vary from 20 to 50 meters.

But it must also be borne in mind that for pumping out the sludge, you will need the help of a sewage truck, which should be free to go to the cleaning mechanism.

Both ready-made tanks and self-made tanks are used for the installation of the treatment plant chambers: metal and plastic barrels, monolithic concrete structures, and stills tanks.

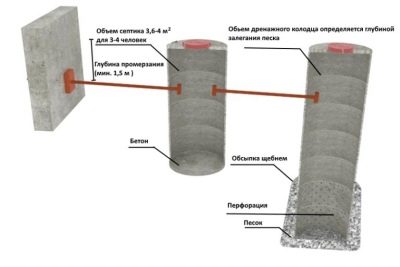

Correctly made calculation of the amount of necessary building material depends on the volume of the sewage treatment plant. Therefore, the calculation will require the value of discharged effluent per day. It is not necessary to accurately determine this value, it is enough to take water absorption of 150-200 liters per 1 family member.To determine the volume of the receiving compartment of the septic tank, the resulting value is multiplied by 3. If there are 6 people living in the house permanently, then you will need a capacity of: 6x200x3 = 3,600 l.

The second compartment of the septic tank is calculated based on the parameters of the receiving chamber. If its volume accepts 2/3 of the liquid of the entire size of the purification plant, then the parameters of the after-treatment chamber are 1/3 of the mechanism volume.

For designing a septic tank, you can use ready-made working drawings and diagrams of the device.

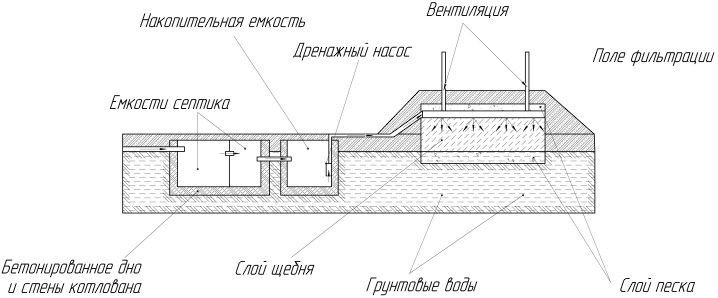

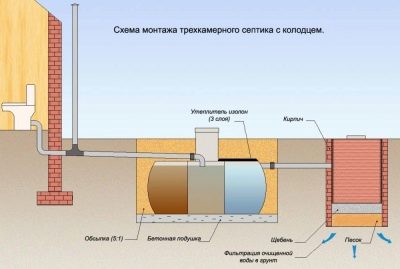

In most regions of Russia, the treatment plant will not freeze in winter due to the warm wastewater coming from the house. And also bacteria that actively behave in a septic tank are an obstacle for freezing. But the design still have to deepen. The distance between the lid and the upper level of wastewater should be equal to the value of soil freezing in winter. At this level the drain sewer passes. Therefore, it is necessary to take into account that the structure must be located below this level.

If the high level of groundwater does not allow the system to be deepened below the level of soil freezing, it is necessary to make insulation. As the warming materials used:

- polystyrene foam;

- Styrofoam;

- expanded clay.

How to do it yourself?

There are two variations of making a septic tank with your own hands.

Variation number 1

In this case, the sewage treatment plant consists of two chambers. Pits can be of various shapes. The depth of the pit should be not less than 2.5 m.

When digging a hole, it is recommended to reach a drying layer consisting of a mixture of sand and gravel. After both trenches are ready, it is necessary to align and seal the walls. Next, set the internal form for each pit (board). Both chambers are connected through a pipe. The inner area of the formwork is covered with plastic wrap. The gap between the boards and the walls of the pit is filled with cement-sand mixture in the ratio of 1 to 3. When the concrete dries (3-5 days), the internal form of the boards disassemble.

The incoming sewer pipe must be insulated with insulation materials (foam, glass wool).

Variation number 2

The principle of the cleaning mechanism is similar to the previous variation. But in this case, the construction of the septic tank will be simplified: it is necessary to dig only 1 pit and divide it into 2 chambers using a concrete partition.

In the manufacture of a septic tank with their own hands, they mainly use improvised materials, but not all such variations are hermetic and durable structures. Mainly used building materials:

- a system of plastic containers (from Euro Cup);

- concrete rings with a bottom and a filtering layer;

- cleaning mechanism of automobile tires;

- monolithic blocks;

- brick;

- iron barrels.

When choosing those or other materials for the manufacture of a septic tank with your own hands, you need to consider some points.

- Features of the sewer system (the number of incoming wastewater).

- Depth location of groundwater.

- The quality and performance of building materials.

- Building skills and financial capabilities. Not all homeowners are able to perform self-laying, and to install structures made of concrete rings will need the help of specialized equipment.

To determine the strengths and weaknesses of the listed building materials, consider in detail some variations.

From scrap materials

There are many available tools that can be used to make a septic tank.

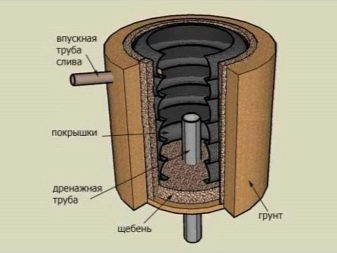

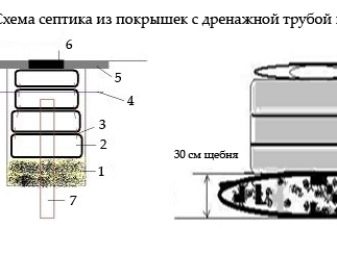

Car tires

Frequently automobile tires from wheels are used to carry out a clearing construction for giving without electricity. The system is designed for a small amount of wastewater. Under the bus dug 2 pit. Tires are interconnected by means of clamps, and the joints are treated with sealant. The bottom of the first chamber is lined with plastic wrap, and concrete is used for high-quality mounting.

The advantages of this structure are:

- availability of building materials;

- simple installation design.

The disadvantages of this design:

- freezing in winter;

- loss of shape and tightness in a fairly short period of time.

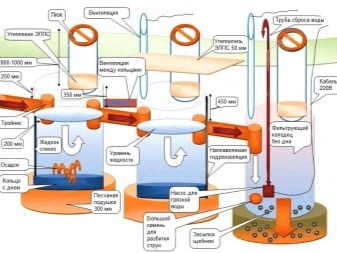

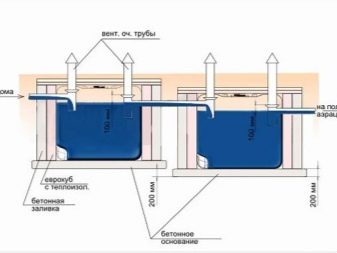

Eurocube construction

For the manufacture of a septic tank will require 2 or 3 tanks. One of them is cut to create filtering. Plastic tanks are installed in a metal frame. This will protect the structure from the negative impact of the soil. Before installation, inlet and outlet pipes are inserted into the tanks, holes are made for ventilation. The joints are treated with silicone.

The notch under the cans is digging under the slope so that the second tank is 20 cm below the first.To fix the Eurocubs, concrete is poured into the bottom of the excavation, to which containers are attached.

Advantages:

- tank tightness;

- simple installation;

- long service life.

The disadvantages include the fact that the installation must be fixed to prevent the system from rising to the surface.

Concrete Ring Cleaning System

The depth of the pit should be no more than 4 meters. The design should be installed at a sufficient depth, especially this is important for a site with a high level of groundwater.

The device will require 4-5 concrete rings of standardized parameters. The height of the rings is slightly more than 1 meter. The diameter of the rings can vary from 70 to 200 centimeters. When calculating the future system, it is necessary to take into account the dimensions of the rings. The mass of one ring is 600 kg (sometimes more).

For installation will require a crane. The first ring is laid on the end of the site where the cleaning mechanism will be located, then you can start digging the foundation pit. After the upper end is equal to the ground, the installation of the second ring is performed. Digging the pit continues. So that the rings do not separate, they are connected by means of reinforcement.And you can also use specialized spacers to prevent the rings from shifting.

After the hole has been dug, the joints of the rings and the seams are sealed with a cement mortar. The bottom is poured with cement and closed with waterproofing materials. Waterproofing is carried out on the walls of the tank. You can mount one well, which will perform the cumulative function. Periodically, you will need to perform pumping wastewater.

Experts recommend to equip the design of the findings on the filtration fields.

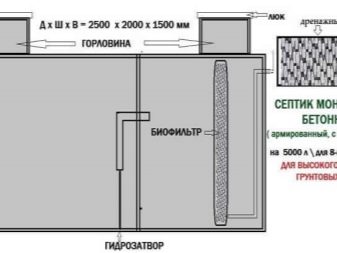

Blocking device

Manufacturing technology of a two-chamber septic tank from blocks:

- digging of the pit to the dimensions of the autonomous sewer system with indentation on the sides (25-30 cm) is carried out;

- at the bottom of the pit is laid sand and gravel pad, whose thickness is 15-20 centimeters;

- the basis from concrete mix keeps within;

- blocks are laid along the perimeter of the walls, which must also be built in the middle of the structure for the partition;

- the inner and outer walls of the blocks are covered with bitumen mastic;

- on top is installed a cap made of a monolithic slab with hatches

- ventilation and thermal insulation of the foam system is performed;

- The septic tank is filled with earth.

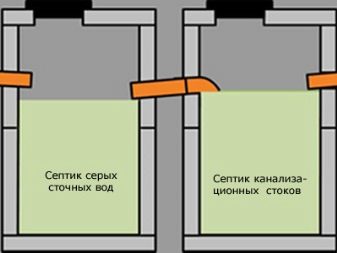

When blocks are laid in the bulkhead, an overflow is established; on the one side of the wall an entrance is made to the sewer pipe coming from the living room. On the other hand, the outlet to the drainage well or infiltrator is made. If the second chamber should be equipped with a drainage part, then it is necessary to replace the monolithic slab with a concrete foundation, and in the middle of the tank to make a drainage from gravel and sand.

The overflow between tanks is performed at a depth of 50-60 centimeters from the cover of the cleaning mechanism. Be sure to enter must be located lower than the output.

Sewage pipes are installed with a slope of 2-3 degrees from a residential building, so that waste water flows into the septic tank by gravity.

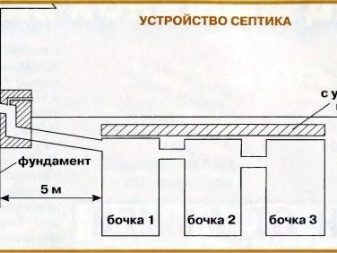

Production of a septic tank from metal or plastic barrels

Consider the option of self-performing septic tank of 3 barrels, but the principle of the equipment remains the same when performing a septic tank of 2 tanks.

- Making tech holes. In the first barrel there is an inlet for sewer pipes and an outlet for overflow into the second tank.In the second barrel there is an inlet for the overflow of fluid from the first chamber and an exit for the flow of waste into the next barrel.

- In the third barrel, one hole is made for the flow of wastewater from the second chamber, and when equipping the filtration field, two holes are made at the bottom for pipes.

- For each barrel, micro holes are made in the upper part of the structures to create ventilation.

To fill the foundation layer, stepwise formwork is installed. At the location of the barrels with a subsequent decrease in the level of the volume of tanks will be fully applied. This is important if the small capacity of a septic tank of this type prevails.

After the foundation has been poured, during the period of solidification of the solution, rings or hooks are mounted in it to fix the containers. And also at this stage a trench is being prepared for laying pipes through which it will carry out the removal of sewage from the septic tank to the filtration field.

When the foundation is completely hardened, you can proceed to the installation of containers and their fastening. The trenches of the filter field are covered with geotextiles. A mounted cleaning mechanism from the barrels is filled with earth.Plastic barrels are recommended to immediately fill with water to avoid deformation of the product.

Barrels made of metal should be treated with anti-corrosion agent.

Of brick

If you decide to build a cleaning mechanism out of bricks, then for this purpose it is better to use clinker products. They are resistant to moisture and aggressive environment. Capacities can be executed both a rectangular shape, and round. It is important to properly waterproof the structure. It is recommended to lubricate the external walls of tanks with specialized mastic. Backfilling (the distance between the outer walls of the mechanism and the pit) is made using clay. The minimum layer thickness should be 20 cm.

To seal the inside of the septic tank use a cement mixture. The bottom of the structure must be filled with concrete, so that the drains do not leak into the soil layers.

Manufacturing technology:

- a cushion of sand and rubble is being performed; the bottom of the chambers is filled with concrete;

- on the perimeter of the inner part of the pit, a brick is laid out, which is connected with cement;

- in the second chamber there is no concreting of the bottom of the pit,and brick products are stacked on the minimum amount of cement mortar, this will allow wastewater to penetrate into the layers of soil.

Tips

During the construction of the cleaning mechanism, technical errors should be taken into account, which can lead to improper functioning of the system.

To avoid them, you must follow simple rules.

- Provide a certain slope of the sewer pipe in the direction of the septic tank. This is necessary to ensure that wastewater flows by gravity.

- Do not allow sharp turns of sewer pipes, thereby preventing clogging of the system.

- The inlet pipe must be located above the outlet so that waste materials do not leave the system.

- It is forbidden to build filter wells at high rates of groundwater. This can lead to pollution of the ecosystem.

When using a purification plant it is prohibited:

- throwing debris into the sewer system - this can lead to clogging of the first chamber of the septic tank;

- use the design for the disposal of polymeric waste (cellophane, cigarette butts, bag, condom);

- use detergents, which include solvents, acids, alkalis,that can lead to the death of anaerobic microorganisms;

- pour oil products into the sewage system - engine oil, gasoline, diesel fuel.

Reviews

Many owners of country houses and country houses leave positive reviews about the independent production of a septic tank. After all, such an installation is a budget version of the sewer system. As well as homemade design has certain advantages.

- Non-volatility. The septic tank functions autonomously without the consumption of electrical energy. This is especially important in areas where the grid is intermittent.

- Minimum cash costs. A septic tank, manufactured by the manufacturer, is much more expensive than an improvised structure.

Negative reviews from homeowners who have built a septic tank with their own hands are mainly based on incorrectly made manufacturing technology and installation of the system.

Successful examples and options

Let's consider what it is worth installing a septic tank: two-chamber or single-chamber.

Single chamber fixture

For the treatment of gray wastewater consisting of soap-based special solutions and a small amount of organic matter, you can build a tank without a bottom.In it, the liquid is cleaned by passing through the filter layer of rubble and gravel. The depth of the well must be at least 1 meter. Building materials for its construction can serve:

- plastic tank with holes;

- barrel without bottom;

- rings of concrete;

- brick.

This design option cleaning mechanism suitable for suburban premises (house, bath) in the absence of a toilet. You should not install a single-chamber construction for a house with permanent residence, it is better to install such a structure for a dacha with temporary residence.

Two-chamber purification

If faecal waste is present in the effluent, then thorough cleaning is necessary. A treatment plant without pumping requires the installation of two chambers. The first will be the settling and splitting of waste particles. The clarified liquid will flow into the drainage well, which is the second chamber, seeping into the ground.

We reviewed homemade versions of the sewage treatment plant from various building materials. If you want to initially determine the level of costs, they will consist of the cost of building materials plus the cost of operating special equipment whenof necessity.

How to make your own hands septic tank of concrete rings, see the next video.

How to make your own hands a simple septic tank of tires, see the following video.