Finishing putty "Miners": advantages and disadvantages

With the help of putty, the surfaces of walls or ceilings acquire the evenness necessary for the subsequent finishing. A good option is a mixture of the company "Miners". It is not expensive, but at the same time it is able to create a quality top layer on the plastered surface, which can serve as a base for subsequent finishing works (wallpapering or painting) and the final decorative coating.

Special features

The main distinguishing feature of the Finishing Putty putty is a high degree of adhesion to the base, which contributes to a long period of operation and prevents cracking or delamination of the coating.

Another feature that the company relies on as a competitive advantage is the high quality of the mixture. This organization pays close attention to production using modern technologies and almost fully automated quality control processes for dry mixes. Moreover, this control is carried out continuously at all production sites, starting from the receipt of raw materials and ending with the shipment of the finished product to the warehouse.

For over 20 years, the company has been constantly improving the formulations of manufactured repair compounds in order to improve their operational and technical parameters. In the production of dry blends, only selected raw materials from proven and well-reputable suppliers are used.

The production facilities of the company are constantly being upgraded, which contributes to an even greater accuracy of dosages and, accordingly, an increase in the quality of the finished product.

Other properties inherent in the finishing putty "prospectors:

- Easy to prepare. It is enough just to dilute the dry mixture with water in proportions according to the instructions.In this case, you can mix it manually without the use of special tools.

- The ability to prepare a spackling mixture of different viscosity by increasing or decreasing the amount of water added.

- Ensuring the creation of a smooth finish layer. The putty lies flat on the base, does not flow, does not form lumps, shells and cracks. Well masks all the flaws of the previous layer.

- High degree of elasticity, which ensures ease of application of the composition. Putty mixture is convenient to apply, it does not create "tracks" and does not stick to the spatula.

- The speed of hardening plaster layer. The material dries out in about 2-6 hours. It all depends on what layer was putty putty.

- Ease of surface treatment. After drying, the putty base is well polished with a mesh or fine emery paper.

- High degree of hygroscopicity. The putty absorbs well and at the same time gives off good water and air, which means it creates a kind of breathable coating.

- Abrasion resistance.

- Good compatibility with building materials from other manufacturers. If the base layer of plaster coating is made of one name putty,and the finish is supposed to be applied with the help of putty “Miners”, then there is nothing wrong with that. Due to its good adhesive qualities, this material will fall well on any basic foundation.

- Safety for human health. Each type of finishing putty has a certificate or conclusion confirming the compliance of the product with sanitary and hygienic standards, both Russian and European.

- The presence of a variety of degree of readiness to use putty: dry mix and solution.

- Convenient packaging options. Dry material is packed in bags of 5, 12 and 20 kilograms, ready solution - in buckets of 7 and 15 kilograms.

- A long period of storage of the product in unopened form is one year. Moreover, the effect of low temperatures.

- Convenience of transportation and storage.

- Low price.

But the “Stargers” finishing putty has some drawbacks: the finished mixture should be immediately used in the work, otherwise it will be unusable in an hour due to hardening. And from this follows a second drawback: an increase in material consumption and an increase in the time spent on repairs due to the need to prepare a new mixture.

Types and characteristics

Currently, the company "miners" produces the following types of finishing compositions:

- "Putty finishing";

- "Hard putty front and finishing";

- "Hard putty finishing Plus Moisture resistant";

- "Ready putty Superfinish";

- "Putty finishing KR".

"Putty finishing" - this is a dry white gypsum mix used for plastering surfaces indoors.

The composition includes modifying additives.

The recommended thickness of the applied layer is 0.3-5 cm. The consumption of material, if this condition is met, will be 900 g per square meter of surface.

It can be applied on plastered, concrete and brick foundations for subsequent painting or wallpapering.

Suitable for use in areas where regular wet cleaning is expected.

It is not allowed to use this material in places where contact with food or drinking water will occur.

This type of putty is applied on a dry, clean and strong base. If the base has flaking or unreliable areas, they should be removed. Gypsum and other hygroscopic bases must be pretreated with a primer.

The filler solution is prepared at the rate of 400-580 ml of water per kilogram of dry matter.

This type of material is sold in containers of 5, 12 and 20 kg.

"Hard putty front and finishing" - This is a mixture for plastering work, mainly outside the building. The material is also suitable for interior work.

The functional defines the following properties of this product: frost resistance, weather resistance, resistance to cracking.

The composition of the facade-finishing mixture includes white cement, modifying additives and natural filler fines.

The topcoat can be applied to cement, concrete and reinforced concrete under the subsequent application of decorative plaster, painting and wallpapering.

Suitable for application in wet areas. It is not recommended to apply in places where contact with foodstuff is supposed.

The recommended thickness of the applied layer is from 0.3 to 3 mm. Consumption is one kilogram per square meter with a putty layer thickness of 1 mm.

The solution is prepared at the rate of 320-400 ml per kilogram of dry powder.

The prepared solution maintains its viability for three hours after kneading.

Packaging - only in bags of 20 kg.

"Hard putty finishing Plus Moisture resistant" - it is a white polymer polymer material with increased resistance to moisture.

It can be applied on the bases covered with plaster plaster, concrete and gypsum cardboard.

The thickness of the filler layer recommended by the instruction is 0.3-3 mm. Material consumption - 800 grams per square meter (layer thickness 1 mm).

The base for the application of the solution is prepared similarly to the putty finishing.

The solution is prepared at the rate of 350-400 ml per kilogram of dry powder.

The prepared solution maintains its viability for six hours from the time of kneading.

Packaging - only in bags of 20 kg.

"Ready putty Superfinish". This material is a ready-made putty mixture in the form of paste.

It consists of: reinforcing fibers, polymer binder, fine fraction fillers, antiseptic fraction and modifying additives.

Apply ready-made paste only for interior work in rooms with a normal level of humidity. It is applied on plasterboard bases, gypsum plaster, tongue-and-groove slabs, fiberglass. The subsequent coating can be in the form of wallpaper or paint layer.

The recommended maximum thickness of the putty layer putty is 2 mm. Paste consumption with a layer of putty 0.3 mm is 500 g per square meter.

Adhesive ability of the material - up to 0.5 MPa.

Drying time of a layer of putty in 1 mm - 4 hours.

The base for the application of the solution is prepared similarly to the putty finishing.

Packaging - in plastic buckets of 7 and 15 kg.

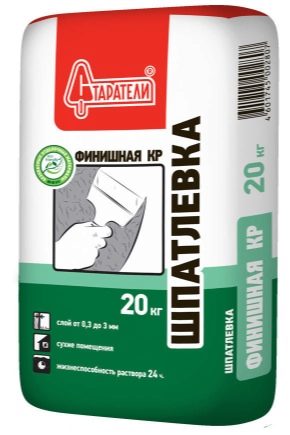

"Putty finishing KR" - is a finishing polymer material of high elasticity for repairing interior spaces. Recommended for use in dry rooms only.

It can be applied on concrete, gypsum-based plaster, but is most suitable for plasterboard processing. Boiled white color of this material and good covering ability significantly save the cost of subsequent painting of the treated surface.

It is recommended to apply this type of putty in a layer of 0.3-3 mm. Material consumption per 1 mm layer with an area of 1 square meter. will be 1.1 kilograms.

The finished mixture of putty KR has an increased indicator of viability - the solution can retain its properties within a day from the moment of preparation.

The mixture is packed in small and large containers - in bags of 5 and 20 kg, respectively.

How to choose?

If before the start of repair and plastering works, it was decided to use the “Stargers” finishing putty, then it would be quite easy to choose a specific type of this product. The determining factors in this case will be:

- The scope of work. If you need to putty the facade of the building, then the only choice will be "Putty front-finish", if internal works are supposed, then we continue the choice.

- Moisture level air in the repaired room. If a room with high humidity, then for finishing it can only use a special moisture-resistant mixture "Putty finish Plus Moisture-resistant." For dry fit any kind of finishing putty "miners". So, go to the next step in the selection.

- Base Type. If the base is to be leveled, with cement plaster applied on it, then we stop at the “Finishing Putty” or “Facade-Finishing”, if the base is covered with fiberglass, then - on the “Ready Superfinishing Putty”. For other types of surfaces - gypsum plaster, concrete, drywall, reinforced concrete any type of mixes will do.

- Type of subsequent coverage. If it is intended to apply decorative plaster on the finishing layer, then to level the walls it is necessary to purchase “Finishing Putty”, “Finishing Plus Moisture-proof Putty”, or “Facade-Finishing” Putty. Under the sticking of the wallpaper and painting, you can use any kind of putty material.

- Viability of the finished mixture. If this parameter is important during the work, then it should be noted that “Finishing Putty” loses its qualities (after an hour), then comes “Finishing Facade Finishing” (after three hours), after six hours the moisture-resistant composition hardens. The most viable is putty labeled "KR". The finished solution does not harden at all when stored in a container.

- Mixture consumption. If you place all finishing putties in order of increasing solution consumption per square meter, you will get the following row: “Putty Plus Plus Moisture-proof Putty”, “Ready Superfinishing Putty”, “Finishing Puttying”, “Finishing” Putty, Finish Putty, Putting Finish Putty ”,“ Putty Facade Finishing ”,“ Putting Finish Putty ”,“ Putty Finishing ”,“ Putty Finishing ”,“ Finishing Putty ”, .

- Packaging. If it is necessary to perform minor repairs, then it is enough to purchase the material in a small package, for example, 5 kg each.For large-scale works, it is more profitable to purchase material in large containers of 20 kg each.

Reviews

Based on the reviews, the finishing putty mixtures of the company “Starateli” are very well evaluated by consumers. The material is easily and quickly applied, well corrects all the irregularities of the surfaces and dries quickly, made with it, the finish coating does not crack. Due to the fact that the manufacturer has a small package, it is possible to economically carry out minor repairs - putty cracks or treat the seams between sheets of drywall. In addition, with all these advantages, the material also has a more attractive lower price than that of foreign-made putty compounds.

Application Tips

Before applying the filler mixture, the manufacturer recommends that the base is treated with a primer (also from the company “Starateli”).

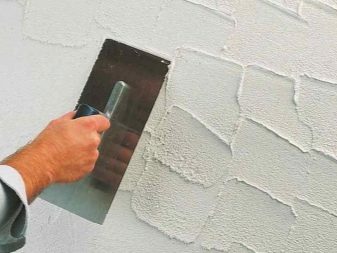

After the soil dries out using a spatula, fill all existing cavities with a solution. After this, the solution is leveled. During the work it is important to observe the temperature regime (optimal - 10-30 degrees). You should also not perform work on puttying in direct sunlight.

If it is necessary to apply several layers of material, then each subsequent application is carried out not earlier than four hours after the end of the application of the previous layer.

Usually putty-up putty gives a flat and smooth surface that does not require additional grinding, but if necessary, the surface or any part of it can be easily polished with fine emery paper.

The final surface finish (wallpapering, applying a paint layer or decorative plaster) is possible only after the final drying of the finishing putty layer.

If it is necessary to seal the seams between the sheets of drywall, it is first necessary, using a trowel, to fill the gaps between the sheets with material and attach reinforcing tape along the seam. Pressing it directly into the seam, remove the excess putty from the drywall with a spatula. When the solution is dry, you can start applying the next layer. And this should be done until the seam is completely equal to the surface of the sheet of drywall. In the same way, putty mixture is applied to the areas of sheet fastening.

How to putty the walls yourself, see the next video.