How to properly dilute the putty for walls?

The question of how to plant a putty is often asked by people who decide to do the repair themselves. Puttying is one of the important preparatory stages on which the quality of the final result depends. Not everyone can afford ready-made formulations; therefore, a huge selection of dry powders is offered on the construction markets, which, given the correct proportions of breeding, can be a worthy alternative to expensive ones. It is about how to properly dilute the putty mixture for walls at home, and will be discussed in this article.

Special features

Dry putty mixture is a powdered material, which consists of binding components, the main filler and various additives.Before applying to the wall to be smoothed, it should be diluted with water in the ratio that the manufacturer indicated on the packaging.

Dry putty has a number of undeniable advantages:

- long service life;

- resistance to different temperatures (can be stored both in warm and cold rooms);

- the ability to control the consistency;

- low cost;

- ease of use;

- ease of transportation.

The prepared solution can not be used:

- with increased humidity, as over time it will begin to peel off from the walls;

- with rapid temperature changes, which will quickly lead to its softening.

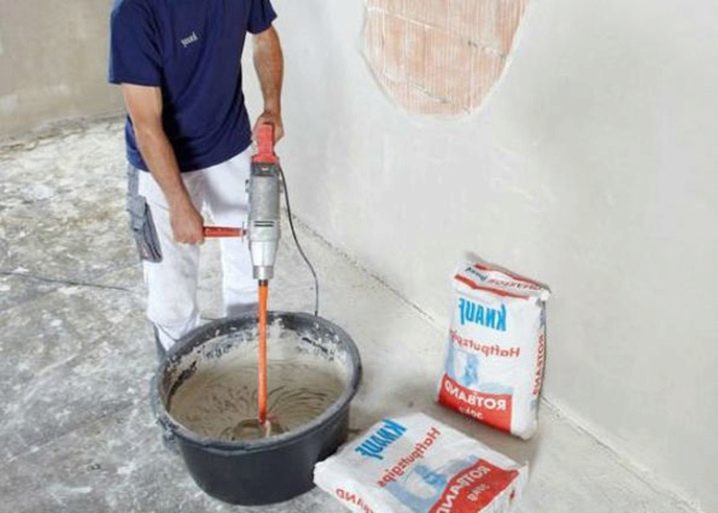

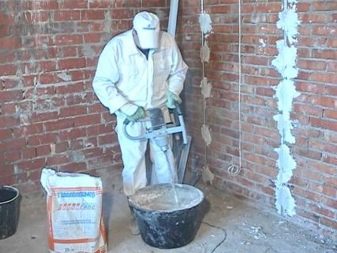

To dilute and mix the putty, experts recommend a drill with a special mixing tip. With its help, the mass is more homogeneous than when using available tools.

How to choose?

When buying a dry putty mixture, pay attention to the following points:

- safety - only harmless substances should be included in the composition;

- adhesion - adhesion to the leveling surface must be good;

- convergence - the formation of a smooth surface should occur without the use of additional tools and materials;

- resistance to external influences;

- the possibility of grinding.

In addition, when choosing, it is necessary to decide at what stage of the finishing you plan to use a leveling coating.

Depending on the purpose, plaster can be of the following types:

- Basic (starting). She carried out all the rough gruberelefnuyu surface treatment: correct irregularities, close up the gap, fill the hollows. Such a composition is applied with a layer thickness of up to 7-8 mm. If the flaws from the first time could not be eliminated, then the layer is applied again. After such an initial alignment, the surface is even and slightly rough due to the coarse fractional components of the putty.

- Finish Designed to finish the surface and bring it to a perfectly smooth state. It is applied once with a thin layer on the pre-dried starting putty.

- Universal. It is used both for roughing and for finishing works, but it is characterized by increased cost and not always due efficiency.

The main component of the mixture has an important value on where and under what conditions it will be used.

Depending on the composition of the putty is the following types:

- Cement. It is used when finishing the facades of buildings, as well as wet and unheated premises: bathrooms, kitchens, swimming pools, basements. It is moisture resistant and resistant to extreme temperatures. After applying to the wall, this putty begins to shrink strongly, as a result of which the mortar layers have to be applied again for better alignment. The rate of hardening it is small and is 28-30 days, which significantly slows down the process of finishing.

- Gypsum. It is intended for dry premises inside the building: living room, bedroom, corridor. In this case, the solution on the surface dries in a few days, but it also quickly decomposes under the influence of moisture.

- Polymer It is a universal mixture for leveling polyurethane, cement, concrete and gypsum surfaces. It combines the properties of cement and gypsum plaster, resulting in a high cost.

- Oil-adhesive. It is applied before painting on concrete, wood and plastered surfaces.

- Water dispersion. It is applied to partial alignment of the bases from various materials: a tree, a gas concrete, a brick.

- Polyester. It is used during the work on metal, a tree, a paint and varnish covering, concrete, a natural stone. It is successfully used to seal holes and through holes, getting rid of rust and corrosion. Such a composition is distinguished by good adhesion, increased strength and water resistance.

Proportions

The diluted putty solution should be characteristic consistency and density. To achieve this, it is necessary to observe the correct ratio of water and dry matter. For each species, these proportions are different.

Compositions based on gypsum are diluted in a ratio of 1: 0.8, that is, 1 liter will require 0.8 liters of fluid. For cement compositions of water it will be required 2 times less: 0.37-0.42 liters per 1 kg. 1 kg of polymer putty diluted with 0.25 liters of liquid.

Depending on the situation, water consumption can be changed. So, with a basic finish, a thicker composition is required, so it is allowed to use less liquid.When decorating use a liquid mixture, respectively, water will need more.

Please note that dilution water must be taken at room temperature.

Process technology

The process of making the mixture at home should begin with the preparation of the necessary tools.

You will need:

- a roomy bucket with high walls without rounded corners (plastic, enamelled or galvanized);

- drill with nozzle;

- Libra;

- paint brush or spatula.

In order to properly make a putty with your own hands, you should follow the following procedure:

- Fill the bucket with the required amount of water.

- We shake it up in circular motions to wet the remaining walls of the container.

- Dry mix we weigh and gently fall asleep in the water. Then leave for 3-5 minutes to make it a little limp.

- Slowly immerse the drill and begin to knead the solution by moving the mixing nozzle in a circle, left-right, up and down.

- Having achieved the desired consistency, stop the batch. We clean the adhered remnants of the mixture from the walls of the bucket with a spatula or a brush. Repeat the batch.

- Do not touch the prepared mass for 10-15 minutes, give it time to swell.

- Add 1 tbsp. l PVA glue that will make the solution softer and more elastic, and the layer applied on the surface is stronger and more reliable.

- Repeat the batch.

- We take out the drill, put it into another container with water and run it for 1-2 minutes. In this way, the dirt from the nozzle instantly removed.

If you do not have a mixer available, you can mix the mixture manually. In the dried bucket pour dry powder putty and then pour in water. The kneading is carried out in a circular motion, gradually moving from the center to the edges. If the solution has a too liquid consistency, then add more mixtures to it, if it is too thick, add more water.

Please note that in this case, the putty is first poured, and no liquid is poured. If you do the opposite, as with a mechanical batch, there will be lumps in the composition, which will be difficult to get rid of.

The above method is suitable for compositions based on cement and polymers.

Dilution of gypsum plaster is done in a slightly different way:

- Pour 7 trowels of powder into a bucket and fill them with the same volume of liquid. Thoroughly mix everything;

- Add the remaining parts of the mixture and water and mix everything up to a state of uniformity;

- Leave the solution for 2-3 minutes to swell and mix everything again.

Unlike other types of gypsum plaster is very capricious. After drying, over time, it can crack due to a number of reasons: violation of the production technology, non-compliance with the correct proportions of the components, a thin layer of application (less than 5 mm), dirty processing surface.

Stages of breeding putty with fiberglass are not particularly difficult.

In this case, the following sequence of actions should be followed:

- Move to a warm room. The temperature on the thermometer should not be below 18 and no higher than 25 degrees Celsius.

- Open the jar with the composition, mix it thoroughly, so that the solvent rises.

- Prepare a clean container and pour back the part of the mixture that you need for work, and cover the rest with a lid. Since the diluted composition instantly dries, dilute the amount that you can produce in 10 minutes.

- Add hardener.

- Stir all with a spatula. The composition should be thick and uniform.

As a rule, such well-known companies as Novol, Sea-Line, QuickLine, indicate on the packaging the correct proportions of dilution of putty with hardener.If the manufacturer did not mention this, then the masters recommend using electronic scales with increased accuracy or their own eye. The amount of hardener should be equal to 3% of the total putty mass.

This ratio can be determined in the following simple way:

- From the container with a spatula we collect the mixture and immediately transfer it to another spatula.

- We divide the mass in half. In each part remains at 50%.

- One of the parts is divided in the same way again. It turns out 25%.

- Repeat the procedure. It turns out 12%.

- The resulting slide is evenly divided into 4 parts, thereby obtaining the required 3% hardener.

It is very important to observe the correct proportions when kneading: if you add too much hardener, its excess will not interact with the particles of the putty compound, as a result of which, after application, stains and stains will appear on the treated surface. If there is a shortage of hardener, the solution will turn out watery, it will hardly overlap the base and will unevenly harden.

Useful tips and tricks

When working with putty, experts recommend adhering to the following rules:

- Mix the mixture gradually.Start with a low speed, slowly increasing speed. Such actions will help avoid the appearance of lumps and bubbles.

- After mixing, leave the solution for a few minutes and then stir it again. In this way, the components that make up will get better.

- Use only clean containers and tools. Compounds of particles of old and new mixture will lead to a violation of the consistency and elasticity of the future composition, which adversely affect the quality of the finish.

- Do not immediately make a large amount of putty, otherwise it dries quickly and grabs into lumps. If, due to inexperience, you have mixed a whole pack with water, then leave a quarter of the mass for further work, and pour the rest into thick-walled containers and close tightly with a lid to prevent drying.

- When buying a look expiration date putty. Mixtures with expired sales dates quickly set, poorly smeared on the surface and stick to the spatula, which complicates the work and affects the durability of the finish.

- Purchase mixes in specialized hardware stores or hypermarkets.

- Combine mixtures of different companies.If you do not have the opportunity to buy a lot of packs of expensive putty, then it is allowed to mix it with a lower cost. Thus, you can get a better basis for decoration.

- Put the washed mixer with the nozzle down. Otherwise, water drops or solution residues will be chambered, as a result of which it will quickly rust.

- Only use soft, lint-free cloths to remove excess moisture from the instruments.

Video instruction on how to dilute the putty, see below.