How to calculate plaster consumption per 1 m2 of wall?

Putty - a fairly common type of finishing work in construction. This is one of the last stages of finishing, carried out immediately before the wallpapering or painting walls. It is used in cases where it is necessary to level the surface of the wall, get rid of roughness. To obtain the most even surface it is necessary to take into account many factors, and the most important thing is to know the material consumption rate.

Special features

In the course of work, the most important principle is gradualism. The essence of leveling consists in the complete filling and smoothing of first large and then smaller defects.

For competent work it is worth following the rules:

- The air temperature in the room should remain within + 10 - 30 degrees.

- Humidity should not exceed 50%.

Before starting to putty, it is imperative to carry out the priming of the walls, so that the surface will be protected from dust and dirt, and the adhesion between the putty mixture and the wall will improve.

It is also important to properly prepare the solution, guided by the manufacturer's instructions. The quality of the finished mixture is influenced by the cleanliness of the tank, the literacy of the mixing process, and the maintenance of proportions.

In order to calculate the flow rate, it is necessary to determine the type of putty mass, since they all have individual features. The appearance of the filler, in turn, depends on the material of the surface and the extent of its damage, as well as on what to do with the wall further: paint, glue it with wallpaper or tile it.

Types of mixtures

The modern construction market is represented by a variety of putty mixtures. There are many different classifications, but the main one is the distinction between types of putty according to the degree of readiness for use. According to this parameter, the putty is divided into two types:

Dry

This type of filler mixture has a lot of advantages and is quite a popular solution for finishing work. The price for it is much lower than for the ready putty, it is kept longer and is more convenient to transport. Prepare a dry powder for application is easy, the consumption of the prepared material will be small. However, it is necessary to strictly observe the proportions in the preparation of the solution, and also knead the new solution every half hour, as the old one will dry by then.

Ready

This putty will cost the buyer a bit more expensive, but it will significantly save time when kneading. Moreover, working with the finished mixture, there is no need to try to guess the ideal proportions. The disadvantages of this type of mixture is that the consumption of the finished material increases, and the shelf life, on the contrary, becomes smaller.

Types of putty differ in their interaction with the type of surface to be treated.

In addition to the main varieties, which will be discussed below, the mixtures are divided into the following groups:

- Adhesive mixture used for painting works. It is plastic, dries quickly and can last for a very long time.However, it is not suitable for use in outdoor work, it is not resistant to moisture and mechanical damage.

- Latex putty Suitable for all types of surfaces. The cost is higher than that of glue, but this is offset by better technical characteristics. Easy to apply, does not crumble under the influence of loads. The disadvantage is low resistance to temperature fluctuations.

- Putty Tex is in high demand due to the possibility of applying to almost any surface, as well as a variety of color palettes. It has high stability, poorly tolerates only freezing temperatures.

- Water-dispersion mixture - the most economical form, while having good performance. The disadvantage is the difficulty of storage - it is desirable to do it in an airtight container.

- Front view of putty used for finishing the outside of the house. This mixture is characterized by high resistance to temperature, moisture immunity, low cost. Minus - after finishing the finish may begin to crack.

Types of mixtures can also be distinguished among themselves depending on the manufacturer. Despite the huge number of different brands, there are several quality products that can definitely be used in the repair process:

- Putty "Vetonit" - This is a quality mixture for plastering walls before finishing. "Vetonit" is used only in dry rooms, for one square meter will need a little less than one and a half kilograms of the mixture. If you lay the material with a layer thickness of 1 mm, when using putty for wallpaper / painting the consumption will be equal to one and a half kilograms per square meter. meter surface.

- "Shitrok" - putty mixture, which is characterized by relatively low consumption. With a layer thickness of 1 mm, it is equal to 0.5 kg per 1 m2. It is a polymer putty, divided into latex and acrylic solutions. Can be used for walls of gypsum board, does not contain asbestos, is sold ready to use.

What does the expense depend on?

How much putty will be needed to perform the repair, what parameters affect its consumption - this is the main question that needs to be solved before starting the work. To avoid getting into an unpleasant situation, when shortly before the end of the work it turns out that there is not enough material, it is necessary to calculate the necessary amount in advance.

Influencing factors:

- the condition of the walls (degree of roughness, the presence of cracks) and the material from which they are made;

- type of putty (front, decorative, for interior work);

- technology of putting putty;

- correct mixture preparation;

- the next stage of repair (painting, whitewashing or wallpapering).

But first of all, the type of putty affects the consumption of putty. Depending on the type of work, the putty is divided into three basic groups:

Starting (leveling)

This type is characterized by the greatest expense. This putty is used in the first stage of work, used to level the surface, seal cracks and chips. Penetrates deep inside the wall, superimposed on top of the plaster

Universal

The second type of putty is consumed in slightly smaller quantities than the starting one. It can serve as a transitional stage from the start to the finish, or it can replace both types at once, but only if it is necessary to eliminate very minor flaws.

Finishing (decorative)

Type, which is characterized by the lowest consumption. It is applied at the very last turn before finishing and is used to give the wall maximum smoothness.The finishing mixture can also be used as the first layer, if you want to remove only minor surface defects.

The correct calculation of the amount of material is an important step, necessary before the start of the finishing works. If the putty is less than required, it will be necessary to prepare a new one, and then try to join it with the previously applied mixture. If the amount of the mixture exceeds the norm, then it will remain unclaimed, since it will no longer be used. Any error in the calculations delays the process of finishing, postpones the completion of the repair.

How to calculate?

To calculate the exact amount of material that will be used in the repair process, you should do the following:

- find out the exact area of the room;

- measure the height and the sum of the lengths of the walls;

- calculate the wall thickness, taking into account all surface defects;

- determine the thickness and number of putty layers (taking into account surface defects).

It is important to remember that the amount of mixture used also depends on other less important factors. It often happens that a fairly large amount of unclaimed material remains in the process of working on tools, the composition hardens before it is used.It happens and vice versa: you have to redo some areas in the process of work, which will require additional mixture. In general, the inevitable losses can reach up to 10% of the total amount of material, so it is worth considering this point when preparing the mixture. In addition, the rate of consumption of putty depends on the basis of the mixture used.

The basis may be:

- cement;

- gypsum;

- glue.

Plaster

Before you start work, you need to understand how plaster differs from putty.

Both are used for finishing and are used for alignment, but between them there are important differences:

- Plaster, unlike putty, is used in much larger volumes. With the help of putty, as a rule, only small defects are masked, while the plaster levels the damaged areas on a larger scale.

- The price of putty is significantly higher than the price of plaster due to differences in composition.

To calculate the required amount of putty for the plastered surface, you need to take into account the climatic indicators and work only in the range specified by the manufacturer.

With all the recommendations given by the manufacturer, for one square.m square usually requires one and a half kilograms of putty. However, the thickness of the applied layer and the quality of the wall, as well as the area of filler should be taken into account.

For walls without significant defects, it is enough to apply a layer of 1 mm (the calculation is equal to a kilogram per 1 m2) of starting putty and 0.5 mm (0.6 kg / m2) of finish. Increasing the thickness of the layer entails a proportional increase in consumption. Do not forget about re-filler, which is better to include in the calculation before the start of work. Consumption is approximately equal to one kilogram per square meter.

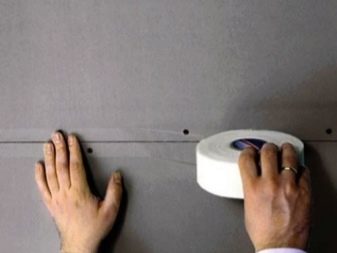

Drywall

Currently, drywall - one of the most common options for finishing the room. There is an opinion that there is no need to putty coating in the presence of drywall, because it already has a flat surface. However, this opinion is wrong. It is necessary to use finishing putty to prevent paint or glue from being absorbed into the drywall.

The exact consumption depends on the surface area that needs to be processed. There is a small trick to reduce the amount of the mixture: before filling putty sheets of plasterboard need to be treated with a primer.

The amount of material for work depends on the composition.

The flow table looks like this:

- When mixing cement-based putty, the calculation is 1.2 kg per square meter.

- A polymer-based mixture is consumed less than others - only 0.6 kg per m2, however, this type of composition is the most expensive.

- Gypsum mix is the most economical option. Consumption is 1 kg per 1 m2.

Drywall is quite simple to use. If the sheets were originally installed correctly, then you can do without careful alignment. Before finishing the coating, it will be necessary to properly seal up the fastener joints and caps of the self-tapping screws.

Other surfaces

When working on other types of wall surface should be covered with a layer of primer. In general, the amount of putty on concrete only slightly diverges from spending on the above types of surfaces. For a smooth concrete wall, you will need a first layer no thicker than 5 mm, and the second - no more than 3 mm thick. Taking into account the thickness of the layer and the calculation of consumption per square meter.

You can also putty wooden surfaces. But the layer of the applied material should not exceed 2 mm.

A prerequisite for using putty - the thickness of its layer must remain within 5-10 mm, otherwise the dried mixture will begin to break down and peel off from the wall.

Recommendations

When spackling surfaces should carefully follow the sequence of work and their technology. When preparing a dry putty from the mixture, carefully follow the instructions given by the manufacturer. Use only clean containers, thoroughly knead, add water strictly in the required quantities.

Incorrectly prepared mixture:

- Increase the consumption of material, and therefore, raise and estimates for the repair;

- Significantly reduce the quality of work.

It is important to remember about the density of the mixture - to align large defects, a thicker consistency of putty will be needed, which will entail an increase in the composition consumption.

Before starting work, you should make sure that the selected mixture is correct and that its flow rate is accurate.

The implementation of simple rules eliminates the risk of poor performance work.

How to calculate the consumption of putty, see the following video.