How to choose a putty spatula for walls?

Every family sooner or later comes the need to carry out repairs. Whether it is the purchase of a new spacious apartment or the need to renew an old dwelling, one would like this serious and laborious event to go as smoothly as possible. An important role in this process is to take the choice of high-quality and convenient tools and accessories. If you prepare everything you need in advance, you can save time and money in order not to be distracted by unnecessary shopping trips.

A spatula will almost always be used during repairs.and certainly not one. This tool is useful for carrying out several types of repair work, including for the putty of walls.

What it is?

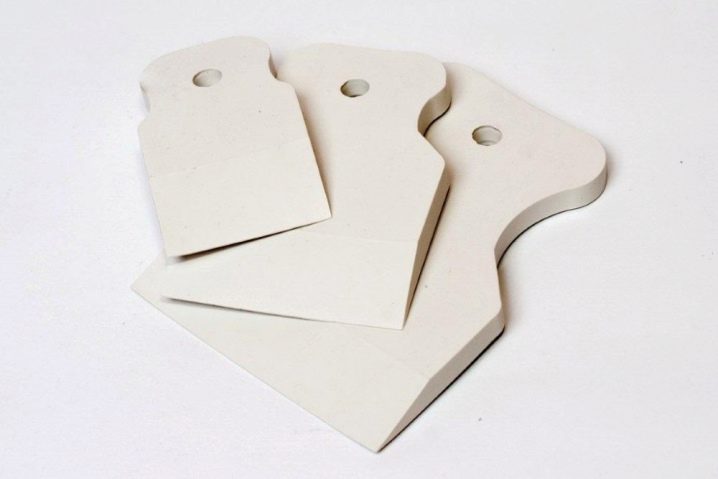

In German, “spatel” means “spatula”. It is a plate with a handle. The plate can be of different shapes and sizes, depending on the purpose of the spatula. The materials from which the working part of the tool is made also differ.

There are different versions of the trowel - some are suitable for removing old wallpaper, others are suitable for grouting or laying tiles and even applying an adhesive layer. There are tools for coating surfaces with cement mortars, for scraping old paint, puttying walls, leveling surface materials or laying bricks.

The working part of the spatula can be made of plastic, glass, rubber, steel or wood.

Species

Spatulas used for different types of work should be chosen strictly in accordance with their purpose. At different stages of repair may need different versions of this tool. Below we consider the types of spatulas used in the plastering of wall surfaces.

Facade

This kind of tool is used to cover the surface of walls with plastering and putty mixtures, as well as for subsequent leveling of the applied solution and removing irregularities.It is advisable to use front spatulas for work on large areas of surface prepared in advance. These products are characterized by relatively high cost due to improved instrument characteristics. Facade spatulas are made of materials of increased strength and durability.

As a rule, the working part of the tool is made of high-quality metal alloys, which makes it possible to increase its resistance to deformations arising under pressure, compression and the application of serious efforts.

The blade of the working part is rigidly attached with an aluminum profile to the tool handlethat minimizes the risk of bending and breaking the product. Handles front spatulas comfortable, rubberized, lie firmly in hand and do not slip out when working. The width of the working canvas varies between 150-800 millimeters.

Gears

These products are sold in any building supermarket. They are a working surface with a toothed outer edge, fixed in a rubber or wooden handle. These spatulas are specially designed to create on the surface of the floor or walls an even layer of glue of the required thickness.The tool is indispensable for laying tiles, ceramics and porcelain tiles.

The larger the tile, the larger the teeth should be at the chosen model of the spatula. Conversely, for a small mosaic you need a specimen with frequent and fine teeth.

Proper selection of tools will save glue mortar, as well as provide high-quality contact of the tile with the wall or floor material. In addition, it is convenient to use a serrated surface to remove excess glue already applied with working materials.

Corner

The angular type of the tool looks like a working canvas curved at a right angle from metal with a convenient handle. This spatula is used for spackling works in the corners of rooms. The shape of the tool allows you to conveniently align the surface of the corners between the adjacent walls or under the ceiling. A problem with the use of an angular spatula can occur if the initial planning of the room was done with improper angles.

In the "Khrushchev" often with the repair it turns out that the angle between the walls is clearly acute, or vice versa, dull. Such features of the rooms make it difficult for an angle spatula to access the work area and reduce the quality and uniformity of the putty application in hard-to-reach places.Therefore, often when carrying out repairs, preference is given to installing decorative corners at the joints where the design project allows.

Paint type

It looks like a facade trowel, but differs from it in construction. The sizes fluctuate around 200-450 millimeters. Painting spatulas have a thinner working edge. Often made of metals of the highest quality, which has a positive effect on their cost and availability. However, this entails a decrease in their service life and greatly increases the likelihood of breakage in case of strong compression or bending.

On the other hand, the small thickness of the working part in combination with the flexibility and elasticity of the material allows the use of such a tool for applying putty solutions in a thin layer. This property of the painting spatula determines its preferential use at the finishing stage of work when applying the final coating layer. Also, such a tool is quite suitable for cleaning walls and removing the old layer of wallpaper, putty cracks and remove minor roughness and irregularities on the walls.

From rubber

Rubber spackling tools are made from resilient, dense and flexible varieties of rubber. The price of the product will depend on the size, manufacturer and characteristics of the material. The sizes fluctuate from the smallest, intended for work with hard-to-reach areas of the processed surface, to large copies.

Rubber spatulas with a wide working part connected to the same rubber or wooden handle are used to work on wide areas of the surface, covered with liquid, fluid mixtures and solutions. Smaller spatulas are ergonomic and applicable for applying thin finishing layers of putty or plaster, for puttying joints, for grouting joints, as well as for removing defects of walls and other surfaces. Often, rubber spatulas are available for sale immediately sets of several models of different sizes. The tool is characterized by high elasticity, a wide range of applications and often has no joints, since it is made entirely of rubber.

For applying a decorative mixture

In addition to spatulas for the application of rough finishing materials, there are products that are specialized in the performance of decorative finishes.Decorative plaster is in demand in the construction market and is often used for the repair and decoration of residential premises. The standard tool for finishing is a trowel. This is a tool with a complex tetrahedral shape of the working part. The trowel usually has a wooden or rubber handle. With the help of the edges of the working part, decorative plaster is applied to the walls and ceiling, which stretches well, creating a textured layer.

A trowel is not a separate type of tool, but a type of trowel. It is also called the Venetian spatula.

The choice of trowel must be made directly by the dresser., since the convenience of the tool handle will determine how easy and comfortable it will be to work with it when painstakingly applying a patterned layer.

In addition to the trowel, special graters are used to obtain the textured surface of the decorative coating. To create an interesting relief, special plaster with the unusual name “bark beetle” is often purchased. After grating the desired model with a grater, the decorative covering created by the “bark beetle” acquires a relief resembling wood eaten by the beetle of the same name.This design option looks expensive and original. It is best used in a classic interior.

Another type of tool for decorative coatings is a special blade, equipped with a polished blade, similar to the paint version of a spatula. It is also convenient for applying thin layers of finishing material, it is of various widths and usually differs in average cost due to the use of stainless materials in the manufacture of the working part.

Dimensions

As already mentioned, repair tools can vary greatly in price as well as in quality of workmanship and materials of manufacture. Spatula models designed for professional craftsmen will last longer and suffer more than one repair.

Simple and cheap models will be thinner and more sensitive to mechanical stress, but if you work carefully, they will not ruin the wallet. Which option to choose is up to the owner.

But no less attention should be paid to the choice of a specific size of the used tool.

A wide range of spatulas of various standardized dimensions is presented in building supermarkets. When choosing and buying products should pay attention to the width of the working surface. An oversized spatula, improperly selected for a particular type of work, will deform and bend, which ultimately will lead to breakage and the need for replacement, as well as to poor quality of repair work.

The front type of spatula is better to choose a width of 300-400 millimeters, but it is recommended to take into account the area of the treated surface. The final choice will always be individual. For rough putty, models are already needed, and very small ones will be useful for areas with difficult access, crevices, cracks and corners. If there are serious potholes and pits in the walls, you will need a large tool to simultaneously apply a large layer of material to the defective area.

The choice of materials and manufacturers

The plastic handle is easier to clean from finishing materials. The cost of such models is small, but poor-quality plastic can be inconvenient for hands, especially when applying force. The same applies to the material of the working party. The stronger the working part, the less likely it is to invest in a new tool to replace the broken one, but in this case you will have to fork out for a large amount at once.

You can putty mechanized handle with replaceable cartridges or choose a homemade tool. You can replace the device at any time, choosing the one with which you prefer to work.

The range of spatulas on the construction market includes both imported models and variants of domestic production. Give preference to the products of large brands, delve into consumer reviews and do not take risks by acquiring a “nameless” model. Going to the choice of tools carefully and wisely, you can be sure that the repair will be durable.

To find out which spatula is better for plastering walls, see the following video.