How to choose a putty for drywall?

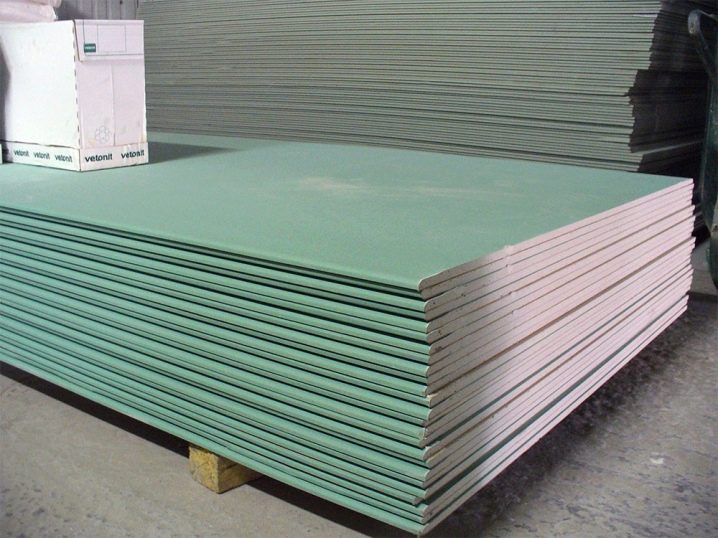

Drywall is an excellent building material that many people use today. Products have a relatively low price, so it is available in any store. But, regardless of this, work with the material should be carefully, because it is fragile. To improve strength and decorative characteristics, drywall is often puttyed. There are several types of such solutions, so it is important to consider certain nuances of each of them when choosing mixtures.

Surface features

Drywall is a sheet material consisting of a filler (gypsum) and an outer retaining layer (paper). Sheets have a smooth surface, which attracts many builders, as this speeds up the alignment procedure.

But the use of putty on top of this product is mandatory.

This is due to several features of the material:

- The ends of the sheets are less thick than the entire main canvas. Therefore, when docking several elements in these places, a small cavity is formed. It can drastically affect the decorative appearance of the finish. Therefore, experts recommend filling it with special solutions.

- Mount drywall occurs on the previously prepared frame. But the base can also have small drops, which will not allow to obtain a perfectly flat surface after docking. Sometimes the level of sheets can differ by 1 cm. It is possible to fix this flaw only with the help of a full putty for all the material.

- Drywall has a weak strength, so the installation may be accompanied by the appearance of cracks. Close up and strengthen these places with the help of solutions and a special polymer mesh.

Putty plasterboard in one way or another is almost always, because it allows you to strengthen the structure and increase the strength of the upper layer of material.

Types of putty

Putty is a mixture that is designed to align various surfaces and eliminate microcracks. Gypsum plasterboard can be covered with various compositions, differing technical parameters and operating conditions.

Depending on the purpose, the putty for such materials can be divided into several subtypes:

- Lineups. Apply them for the purpose of rough alignment of the bases. They are distinguished by the presence of large fibers that do not allow to obtain a perfectly flat plane. This type of mortar is used to seal large cracks, seams and other damages in places where the smoothness of the surface does not matter.

- Finishing putty. The materials differing in a fine-grained structure perfectly level the top layer, creating a uniform surface. But these products do not allow to impose a thick layer, which requires pre-alignment of the rough base. After drying, the mixture becomes white, which allows it to be covered with paints or other similar mixtures.

- Universal products. Compounds of this type are used to solve any problems related to the plasterboard puttying.Mixtures are not always suitable, as they have a coarser structure than finishing solutions, and this does not allow controlling the evenness of the protective layer.

Depending on the consistency of the putty for drywall can be divided into 2 main groups:

- Ready. Mixtures are sold in the form of semi-liquid solutions, which can immediately be applied to the material. The disadvantage of such compositions is their high price and the impossibility of re-using the product after some time after opening.

- Dry This type of putty is available as a dry mix. To prepare them, simply add a certain amount of water and mix thoroughly. Today this type of product is very popular. Use dry mix can be parts that allows you to control the flow.

If the fillers are properly preserved, then their lifespan is practically unlimited. The advantage of dry formulations is also their low cost and availability in the building materials market.

The putty for drywall is made on the basis of various materials.

Depending on the composition, there are 3 types of such products:

- Plaster putty. If the material includes gypsum, which is also present in gypsum plasterboard, then these products can be considered the most suitable for finishing such coatings. Putties are completely safe for humans, as they consist of natural ingredients.

The frozen solution is durable and fast drying speed. But gypsum absorbs moisture well, which can lead to the formation of cracks on the screed. Therefore, experts do not recommend their use in bathrooms and other rooms with high humidity.

- Cement mortars. The putty is moisture resistant, so it can be laid almost anywhere. Also, the material easily tolerates high temperatures, but it dries for a long time. Experts recommend the use of cement putty in the bathroom or in the kitchen. To obtain a high-quality and even coating, the mixture is applied in several thin layers that are easier to control.

- Polymer putty made on the basis of various polymers, which allows you to give the necessary physical properties of the material. Elastic acrylic putty has a high level of security.

Products are versatile, as it can be used in domestic and industrial premises. The protective layer is well resistant to moisture, which is very important for drywall, which quickly absorbs water. But it is used relatively rarely, as the material has a high cost.

Manufacturers

The quality of putty depends not only on its composition, but also on the company producing it. The modern market is saturated with many options for these products, among which there are several main manufacturers:

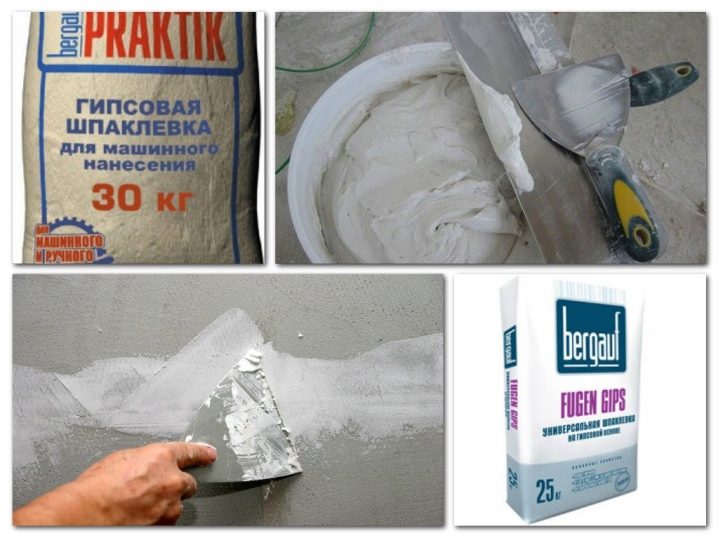

- Knauf. Hard putties of this brand differ in an optimum ratio of the price and quality. The company produces many modifications of solutions, among which are the models Fugen and Uniflot. The first type is made on the basis of gypsum. The mixture dries quickly, so it is often used to glue drywall sheets to other surfaces.

Uniflot putty is moisture resistant, as it contains cement. The mixture does not shrink, and also has a high ductility with a minimal probability of cracking.

- Volma. The company produces materials based on gypsum. Use them to align sheets and seal cracks.The model range is represented by several brands, differing from each other in composition and physical properties.

- Ceresit. Under this brand produce many types of solutions that are of high quality and versatility. Especially it is necessary to highlight the mixture on the polymer base.

How to choose?

Buying putty for plasterboard is a challenge.

To make the right choice, you should consider several factors:

- The quality of the material. This characteristic depends mainly on the manufacturer of the putty. Therefore, before the acquisition, it is desirable to get acquainted with the builders' reviews about specific companies. Similarly, you can choose the best value for money.

- Environment of operation. Many putties are intended for dry rooms. This often includes gypsum-based solutions. For unheated buildings, only a cement or polymer mixture is needed that can withstand temperature extremes and high humidity.

- Quality finishes. The surface of the walls can have large drops that require a thick layer of mortar. The best option here is a plaster or cement putty.If you only need to form a finishing layer, then polymer-based compositions will do the best.

When choosing, you should also consider the irregularities of the walls, which will affect the consumption of material. Many experts recommend puttying the ends with a corner. This technology requires the use of compositions capable of high-quality fix the product on drywall.

How to use?

Before applying the putty, it should be properly prepared. This applies only to dry formulations, as you can immediately coat drywall with ready-made mixtures after purchasing them.

When mixing water and putty should follow a few simple rules:

- Use only the proportions of water and mixtures recommended by the manufacturer. This will allow to obtain a solution of the desired consistency.

- Add dry foods to the liquid, and not vice versa. When you add water, small lumps will remain under the mixture below, which will be difficult to stir and turn into a homogeneous mass.

The technology of applying putty on a drywall sheet consists of the following sequential operations:

- Primer.For such materials use special solutions that do not destroy the structure of the paper. If you apply too aggressive mixture, then the strength of the structure can be broken.

- Preparing for puttying. Sachal should check whether the screws are protruding over the drywall sheet. It is important that their heads are slightly embedded in the material. After that, it is necessary to cut the edge of the product at the seam joints in order to form a recess. This approach will further reinforce these areas.

Before applying the solution, all joints and corners should be glued with a special fiberglass reinforcement tape.

- Puttying The process begins with the sealing of the seams between the sheets. It is important to evenly distribute the solution inside the fossa in order to finally get a flat surface. In some cases, it is necessary to apply the mixture in several layers. Similarly, close up and pits, formed from screws.

- After that, puttying corners. For their additional reinforcement use metal corners, which are applied to the ends of the drywall. Fix these constructions with a solution, trying not to move them.

- The procedure is completed by applying the mixture over the entire surface of the sheet.For such purposes, use a large spatula, with which they form a one-piece screed of a certain thickness.

Drywall puttying is a simple operation, requiring only the choice of quality material and compliance with the manufacturer's recommendations.

How to putty drywall, see the following video.