Finishing putty Sheetrock: the pros and cons

The market of building materials today is filled with a huge range of finishing materials. Choosing a putty, the main thing is not to make a mistake, otherwise the only mistake can pretty spoil all further repairs. The Sheetrock brand has established itself well among manufacturers of putty materials. About the features and advantages of this material will tell our article.

Composition

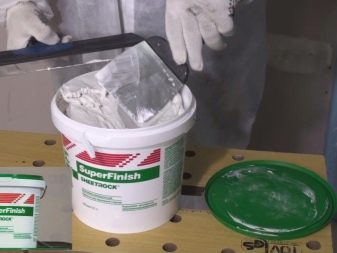

Sheetrock putty is popular not only among builders, but also among people who make repairs on their own. Sold the solution in plastic containers of different volume. You can buy a bucket with a volume of 17 liters and 3.5 liters, respectively, 28 kg and 5 kg.

The composition of the finishing solution includes:

- Dolomite or limestone.

- Ethyl vinyl acetate (vinyl acetate polymer).

- Attapulgite.

- Talc or pyrophyllite is a component containing silicon.

- Cellulosic microfiber is a complex and expensive component that allows applying the solution on glass surfaces.

- Antifungal components and other antiseptics.

General characteristics and features

Sheetrock solution has a number of positive characteristics, the main of which are listed below:

- After opening the package, the finishing putty is ready for use.

- It has a creamy color and a uniform oily mass, which is easy to apply and does not flow down the spatula and the surface.

- It has a high density.

- Very high adhesion, so the probability of delamination is small.

- It is easy to sand and rub up after it has completely dried.

- The drying process is rather short - 3-5 hours.

- Frost resistant. Maintains up to ten cycles of freezing / thawing.

- Despite the thickness of the solution, the consumption per 1 m2 is small.

- Designed for use in temperature from +13 degrees.

- Minimal shrinkage of the solution.

- Affordable price range.

- Universal leveling and corrective tool.

- Possibility of use in rooms with high humidity.

- As part of no asbestos.

There are a lot of countries producing this building material. - USA, Russia and several states in Europe. The composition of the solution for each manufacturer may differ slightly, but this does not affect the quality. The difference may be in the presence or absence of an antiseptic, for example. Regardless of the manufacturer, reviews of professional builders and people who used putty during repair work are only positive.

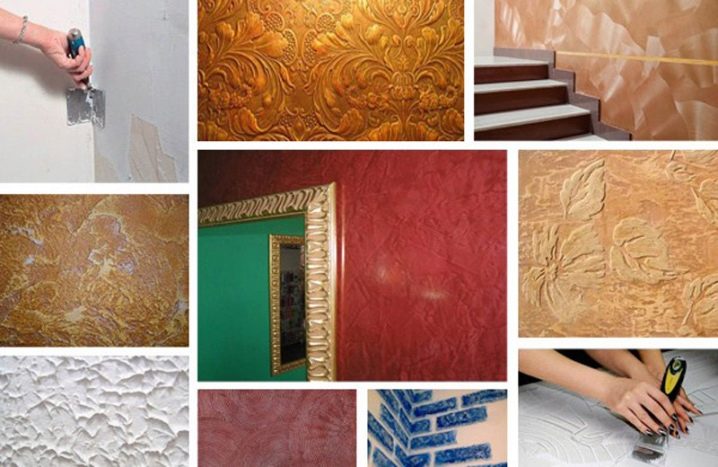

Application area

The scope of application of this type of putty is very large. It is used in the alignment of walls and ceilings. She perfectly removes any size cracks in the plaster. It can be a brick surface or concrete. Having applied a special construction corner, it is possible to level the external and internal corners in the room with the help of mortar.

The solution has good adhesion to metal surfaces, so it is used as the first layer on the metal. It is used as a finishing layer and in the process of high-quality decoration.

Kinds

American Sheetrock putty is available in three main types:

- Solution for restoration work. Its main purpose is to seal cracks in plastered surfaces and to use it on plasterboard.This type has super strength and is resistant to cracking even after a long time. It is also used in lamination.

- Superfinishing puttywhich, according to its characteristics, is ideal for the final layer. Also, due to its composition, it is ideally superimposed on other types of starting putty. Not suitable for leveling corners.

- Universal solution, which can be used for all types of finishing work, which are designed for the fillers of this brand.

Application rules

Before you start working with the material, you need to prepare the surface and buy a putty tool.

Tools you need:

- two spatulas - narrow (12.2 cm) and wide (25 cm);

- special tape Sheetrock Joint Tape or self-adhesive “Strobe” mesh;

- a piece of sandpaper;

- sponge.

The surface to be putty should be pre-cleaned of debris, dust, soot, grease, old paint, wallpaper. Next, open the container with the solution, it is necessary to slightly stir it. Sometimes due to excessive thickening, the solution is diluted with a small amount of purified water (maximum one glass of 250 ml).It is important to know that the more water in the solution, the greater the likelihood of shrinkage.

The average consumption of the solution is 1.4 kg per 1 m2. To putty was high quality, you need to properly smear the surface of the ceiling or walls. Putty putty only on a dry coating. Before each subsequent application we give time to dry.

Examples of using

Sheetrock putties are used in the following cases:

- Finishing the joints between sheets of drywall. Fill all seams with a solution using a narrow spatula. In the center we impose a special ribbon and press it well. Surpluses of solution appear, which are simply removed, and we put a thin layer of solution on the tape. Next, we putty the heads of the screws and let the solution dry, then the next layer begins to be applied.

It is made using a wide trowel. The application of the solution in contrast to the first layer will be 5 cm wider on each side. Again, the drying process. It's time to apply the third layer. The process is carried out by the widest spatula according to the principle of the second layer. If necessary, after complete drying, we grind with a wet sponge.

- Making interior corners. Apply the solution to the tape on both sides with a narrow spatula. Then we fold the ribbon along the middle and press it to the corner. Remove excess, and then apply the solution in a thin layer on the tape. Give time for drying.

Then we make the second layer on one side of the tape, dry it and perform the same procedure on the second side of the tape. If necessary, rub it with a damp sponge, but so that the water from it does not drip.

- Registration of external corners. Fix the metal corner profile. The application of the solution takes place in three stages with an interval for drying and a gradual increase in the width of each layer (finishing of the seams), using spatulas of different sizes. Finally, smooth the surface with a damp sponge.

Useful tips

So that work with this finishing material does not cause trouble and was successful, should remember the elementary rules:

- Any solution is dangerous in contact with mucous eyes.

- At the final stage, wet grinding should be necessary, since during dry grinding, talc and mica, which are harmful to the respiratory tract, may appear in the room air.

- Despite its versatility, the putty is not suitable for removing too large pits and cracks.For these purposes there are other materials.

- It is not recommended to primer the putty, which is applied to the gypsum base, as this will adversely affect the quality of the coating.

- The key to the perfect result of Sheetrock putty is a high-quality treated surface.

In the video below, see the testing of Sheetrock putty.