Putty Knauf: a review of species and their characteristics

High-tech solutions for the repair and finishing of Knauf are familiar to almost every professional builder, and many home craftsmen prefer to deal with the products of this brand. A hit among dry building mixes was the Fugenfuller putty, which changed its name to Fugen, which, however, had no effect on its composition, working and quality characteristics, which, like all members of the huge Knauf family, are beyond praise. In our article we will talk about the possibilities of Knauf Fugen putty and its variations, types of gypsum mixes, the nuances of working with them and the rules for choosing finishing coatings for leveling surfaces of various building structures.

Special features

Any builder is aware that it is preferable to use plaster, putty and primer from the same manufacturer.Knauf with its extensive range of products eliminates the difficulty of solving this problem. All putty mixtures produced under this brand (starting, finishing, universal) - an essential part of the repair work. Finishing coatings are classified according to several criteria.

Mode of application

In accordance with the scope of use, the leveling coating is:

- Basic, characterized by coarse consistency and used for rough alignment of the base. The main component of the composition may be gypsum or cement. With the help of starter putty, potholes, large cracks and craters on the walls and ceilings are also sealed up. Their advantages are a good strength margin, the creation of additional noise insulation and an attractive price.

- Universal - has almost the same properties as the base, but it is already used not only as a putty, but also for filling the drywall seams. The advantage is the possibility of applying to any base.

- Finish - is a fine mixture for thin-layer puttying (the applied layer does not exceed 2 mm in thickness), the bases for decorative finishing.This material performs pre-finishing surfaces.

Astringents

Depending on the binder component in the composition, which largely determines the technical characteristics, putty mixture can be:

- Cement - Cement-based coatings perform façade finishing and finish wet rooms, as they are resistant to temperature changes and humidity.

- Gypsum - leveling coatings based on gypsum stone are relatively inexpensive, they are easily smoothed, making it pleasant to work with them.

- Polymer - these finishing materials are used when the repair goes to the finish line. Polymeric compositions are stored in finished form for more than a day and are easy to polish, which is especially appreciated by the dressers.

Willingness to work

All Knauf putties fall into two categories. The first is represented by dry mixes, and the second - by ready putty. Guided by the tasks and conditions of the premises, the masters select the necessary types of building mixtures.

Types and characteristics

Knauf bags are most often found on construction sites, regardless of the scale of finishing work.The leveling coatings of the German brand with the same success are used for finishing multifunctional complexes, apartments, offices and trading rooms.

The unsurpassed quality of finishing materials produced by the Knauf brand provides the possibility of implementing the most complex projects in private or industrial construction.

Consider some of them.

Fugenfuller Knauf Fugen

Fugen gypsum putty mixes are dry powdered conglomerates, the main component of which are gypsum binder and various modifying additives that improve the properties of mixtures. Their demand is due to high technical characteristics, ease of use and versatility of use.

With their help, you can perform the following types of work:

- Fill the joints after mounting the gypsum board with a semicircular edge. It uses serpyanka (reinforcing tape).

- Fill up cracks, slight drops and other local defects in plasterboard, repair damaged tongue-and-groove partition and concrete slabs.

- Fill joints between precast concrete elements.

- Install and fill the joints between gypsum-and-groove slabs.

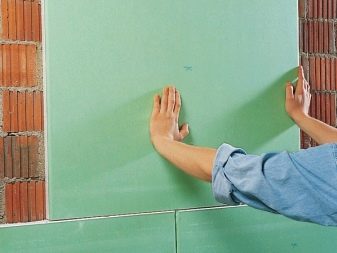

- Gluing plasterboard sheets on the bases with a permissible drop of 4 mm in order to align the vertical surfaces.

- To glue and putty various plaster elements.

- Mount metal reinforcement corners.

- To putty a continuous thin layer the plastered, plasterboard, concrete bases.

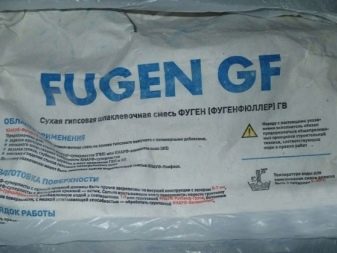

Fugenfuller Knauf Fugen is a versatile plaster mix and its two varieties: GF topcoat for gypsum fiber (GVL) surface treatment or Knauf-superlist, and Hydro for moisture-resistant gypsum board (GCBB) and moisture-proof and fire-resistant sheet material (GLCVO) ).

Performance characteristics and nuances of using this mixture:

- The structure of the material is fine-grained, the average size of the fractions is 0.15 mm.

- Limit values of layer thickness - 1-5 mm.

- Temperature conditions of work - at least + 10 ° C.

- The viability of the finished solution - half an hour.

- The shelf life is limited to half a year.

Mechanical properties:

- Compressive strength is from 30.59 kg / cm2.

- Flexural strength - 15.29 kg / cm2.

- Indicators of adhesion to the base - from 5.09 kgf / cm2.

Gypsum mixture is Packed in sealed multi-layer paper bags with a volume of 5/10/25 kg. The reverse side of the package contains detailed instructions for use. For storage, the manufacturer recommends using wooden pallets.

Pros:

- This is an eco-friendly composition that does not harm human health, which is confirmed by a certificate of environmental safety.

- Easy operation. For preparation of working solution only water and the construction mixer is necessary. Guided by the instruction, water is added to the powder taking into account the indicated proportions and mixed thoroughly, after which the composition can be used.

- High curing speed. This is not so obvious with a continuous putty of surfaces, although the probability that the putty will peel off from the walls is zero. In cases with the restoration of local damage or installation of reinforced corners, the use of high-strength mixture provides significant advantages.

- Low coefficient of consumption of the mixture: provided that all the walls of a typical 2-room apartment with an area of 30-46 square meters are correctly aligned. m using beacons putty a relatively flat surface can be a single 25-kilogram bag "Fugen".

- Ideal surface quality for pasting or painting. The plastered base is absolutely smooth, like a mirror.

- Acceptable cost. A bag of plaster mix universal packing 25 kg costs about 500 rubles.

Minuses:

- The intensity of the setting of the working solution.

- The heavy grinding demanding considerable efforts. Moreover, to solve this problem quickly and without the use of quite serious physical strength is impossible even with the help of an abrasive sandpaper mesh with a grain of 100.

- The inability to apply a layer of more than 5 mm.

- High probability of getting spotty walls with dark gaps, if you stick a thin wallpaper of light colors.

The difference between the Fugen GF (GW) and the standard product is the higher flow rate. Otherwise they are identical.

As for Fugen Hydro, this mixture has moisture-resistant properties due to its composition containing water-repellent agents - binder impregnations based on organosilicon components.

What works are best performed hydrophobic dry mixture:

- Fill the seams of moisture-resistant (GKLV) or moisture-resistant (GKLVO) sheets.

- Stick moisture resistant plasterboard to a pre-leveled base.

- Fill cracks, grooves and other local defects of concrete floors.

- Install and putty moisture-proof partition wall tongue-and-groove plates.

In the sale of moisture-resistant mixture comes exclusively in 25-kilogram packages, its purchase costs twice as much as regular putty.

Uniflot

It is a specialized high-strength, water-resistant compound with gypsum binder and polymer additives, whose unsurpassed mechanical properties make it the absolute leader among existing analogues.

It is designed to work with sheet materials, namely:

- Plasterboard sheets (gypsum board) with rounded thinned edges. In this case, there is no need to use a reinforcing tape.

- Knauf-gypsum superlists (GFL).

- Knauf-superfield of PVT-elements.

- Perforated plates.

The scope of Uniflot is limited exclusively to the filling of the seams of the listed materials.

Benefits:

- Increased strength properties in combination with high ductility.

- Excellent adhesion.

- Guaranteed to exclude shrinkage after drying and the formation of cracks at the joints, including the most problematic transverse joints of drywall sheets.

- It is possible to use in rooms with any humidity conditions. Uniflot has the ability to resist moisture due to its hydrophobic properties.

The finished mixture retains working properties for 45 minutes, after which it begins to thicken. Since the composition does not shrink, it is necessary to fill the joints with them flush, so as not to waste time and effort on grinding the projections and surges. Since gypsum is mined in various places, the color of the powder is pure white, pinkish or gray, which does not affect the quality indicators.

For finishing

At the final stage of finishing work, it remains only to eliminate minor irregularities in order to obtain smooth, durable, smooth walls for decorative decoration.

Just for these purposes, two solutions of final coatings in the form of:

- Dry gypsum putty mix containing Knauf Rotband Finish polymer additives.

- Ready-to-use pasty vinyl putty Knauf Rotband Pasta Profi.

Both mixtures for interior decoration have high plasticity, ease of operation, exclude shrinkage and cracking of the filled surfaces.Their field of application is continuous thin-layer puttying of concrete, plastered compositions based on cement and gypsum, finished with glass fiber surfaces of building structures.

When leveling walls or ceilings with a finished “Knauf Rotband Pasta Profi” finishing coating, the allowable values of the applied layer thickness vary within 0.08-2 mm. Treat the surface of the paste can be manual or machine. A mixture of "Knauf Rotband Finish" perform finishing puttying and applied only by hand. The maximum thickness of the applied layer is 5 mm. Close up the seams GKL this material is impossible.

If you are looking for a budget product, then Knauf HP Finish exists for this case.

This gypsum plaster putty walls or ceilings with a solid foundation. The mixture performs internal finishing work in rooms with normal humidity conditions. Acceptable values of the thickness of the applied layer - 0.2-3 mm. The compressive strength is ≤ 20.4 kgf / cm2, while bending is 10.2 kgf / cm2.

Also noteworthy is Knauf Polymer Finish - the first powdery finish coating, in which the manufacturer used a polymeric binder as the basis. Those who want to achieve the ideal surface of the walls for wallpaper, paint or other decorative coatings should definitely choose this mixture.Knauf Polymer Finish can work after using other Knauf products, including the legendary Rotband plaster.

Pros:

- It gives minimal shrinkage due to microfibers in the composition.

- It is very easy to grind and eliminates fragmentary shedding of the coating during the grinding process, since it is characterized by the small size of the grains.

- Differs in extreme viability - mortar mix does not lose working properties during three days.

- It has a high adhesive ability.

- Crack resistant and plastic.

Bonus for customers - a convenient amount of bags of 20 kg.

Starting for facades

Basic putty mixtures, in which cement with the addition of aggregate and polymer additives is used as the main component, are represented by two variants of the coating - Knauf Multi-finish, gray and white.

With their help, you can:

- Partially or completely level the concrete and cement surfaces treated with plaster mixes.

- Perform interior decoration of rooms with high humidity conditions.

- Seal the cracks and fill the holes in order to restore the integrity of the walls.

In the case of a continuous alignment, the allowable values of the thickness of the deposition are from 1 to 3 mm, and partial - up to 5 mm.The advantage of using a mixture of white is the ability to get an ideal base for decorating interior paints.

Both mixtures have the same performance properties:

- Compressive strength - 40.8 kgf / cm2.

- Adhesive ability - 5,098 kgf / cm2.

- The pot life is a minimum of 3 hours.

- Frost resistance - 25 cycles.

Consumption

When calculating the consumption of leveling coatings per 1 m2 of surface it is necessary to consider:

- The permissible values of the thickness of the mixture, which can vary from 0.2 to 5 mm for different leveling coatings.

- Type of base to be processed.

- The presence and degree of uneven ground.

The rate of consumption is also influenced by the type of finishing works.

Consider the example of Fugen, how much of the mixture is consumed:

- If you close up the joints of the gypsum board, then the output rate is 0.25 kg / 1 m2.

- When puttying in a continuous layer of millimeter thickness - from 0.8 to 1 kg / 1 m2.

- If you mount tongue-and-groove slabs, then the rate of use of the finishing coating increases almost twice, that is, it will already be 1.5 kg / 1 m2.

It should be borne in mind that only starting putties have an increased consumption rate, so in some cases 30 kg of the mixture is only enough for 15-20 squares.

Whereas a 20-kilogram bag of universal composition can cover an area of 25 squares.

How to choose?

You already know that the putty is dry or ready.

Before making a choice in favor of a powder or paste, you need to consider the following factors:

- The cost of the finished leveling coating is higher, although the quality of the finished surface will be the same as when using a dry mixture.

- The shelf life of powdered formulations is longer, and they do not require special conditions for storage.

- Proper preparation of a dry mixture involves obtaining a homogeneous mass of a certain viscosity and without lumps, which beginners can not always do.

- Dry putty, based on the task, you can easily give the desired consistency, making the thicker to fill the joints of drywall and basic puttying or thinner for thin layer puttying at the stage of finishing.

High-quality surface finish involves the use of several types of mixtures:

- The seams are filled with specialized compounds. This may be Uniflot or Fugen. In extreme cases, use Knauf Multi-finish.

- The entire surface is filled with a starting mixture, followed by a finishing or universal, replacing both of these varieties.

Thus, when planning work with drywall, it is most advantageous to purchase a wagon mix and a special compound for the joints.

Recently, the use of aquapanels — cement slabs, which are universal, for interior or facade works — has been increasingly practiced in private construction. They are used in wet rooms or on facades as the basis of various building structures for finishing coatings.

In this case, the best solution would be to buy a special dry mix Aquapanel, high strength Uniflot or Fugen Hydro, in order to seal the joints and process curved surfaces.

Reviews

Based on the fact that user reviews of Knauf spackling mixtures are positive in 95% of cases, only one conclusion can be made: the products of the German brand are loved, appreciated and recommended to friends, as evidenced by high marks - from 4.6 to 5 points. Most often you can find reviews on the compositions of Fugen and HP Finish.

Of the benefits of the Fugen Universal, customers note:

- Uniform application;

- Good adhesion;

- The possibility of high-quality and inexpensive to finish the surface for painting;

- Very convenient use;

- Multifunctional application.

Interestingly, some consider the high setting speed of Fugen to be an advantage, while others are a disadvantage and complain about the need to work at a high pace.

The disadvantages of the mixture include:

- Grey colour;

- The impossibility of applying a thick layer;

- "Sophisticated" technology of preparation of the working solution.

Knauf HP Finish is chosen for the opportunity to create a high-quality, smooth surface, excellent adhesive ability, convenient operation, no unpleasant odor, harmless composition, crack resistance and, of course, low price. Those who have been using Knauf products for a long time are fascinated by the fact that their quality has remained consistently high for many years.

Application tips

Despite the fact that Knauf blends are easy to operate, there are a few rules that you should follow when working with them.

What you need to know:

- For dilution of dry mixtures take only clean running water with a temperature of 20-25 ° C. Hot, rusty water or garbage with liquid should not be used.

- The powder is poured into a container with water, and not vice versa. If kneading is done with a power tool, then it must be done at low speed. At high speeds, the composition is actively saturated with air and begins to bubble in the process.

- It is recommended to work with putties for interior decoration in conditions of temperature not lower than + 10 ° C.

- Any base must be primed to increase adhesion and, as a consequence, the quality of finish. While the soil is drying, it is impossible to process the surface with a leveling compound.

- To prepare a new batch of gypsum mix, always use clean tools and container. If they are not rinsed, then due to the frozen fragments, the rate of hardening of the working solution will automatically increase.

- When the joints are filled with a gypsum-based compound, a serpyanka is used, pressing it with a spatula into the coating. The second layer of the mixture can be applied when the first is completely dry.

When buying material do not forget to be interested in the date of manufacture and shelf life.

For stale mixes, setting too fast is characteristic, so it becomes inconvenient to work with them, and the viability of such compounds can be questioned. The recommendation here is one: to bypass the markets and acquire putty in large construction markets.

To find out how to properly level the walls with Knauf putty, see the video below.