Putty: types and details of application

When it comes to major repairs in the apartment, of course, it is impossible to do without a serious approach to the preliminary preparation of the walls and ceiling. For this you need to use putty. The types and details of the application of this material should be known to every master who wants to repair the room with his own hands and carry out the work with the highest quality possible.

What it is?

Putty is a plastic mixture that is designed to eliminate or minimize even the largest defects on surfaces, of course, if good quality compounds are used. The main technical characteristics of the filler should be used for high-quality alignment of the surfaces of walls intended for painting or wallpaper.

Sometimes it is necessary to putty and ceilings for whitewashing or paintingif they have large cracks. A good putty will always help out the master and will ennoble even those surfaces that initially looked very unattractive. Modern materials provide many compositions completely white color when dried. This greatly facilitates the subsequent finishing work.

Produced putty in the form of powder or paste, which may include gypsum, lime, polymeric and fiberglass additives, as well as varnish and linseed oil (oily substance well known from previous times). The concept itself is derived from the German word "spatula", which in construction terminology means a spatula for applying a mixture on the surface.

Advantages and disadvantages

In order to choose the right putty, first of all you need to understand that it can be produced both in dry and in liquid form. Dry mixes are more common and need to be prepared immediately before starting work. Their main advantages are affordability, ease of storage and transportation. They can also be stored for some time at certain temperatures.However, a liquid mixture diluted with water is not subject to long storage, but in order to prepare it correctly, it is important not to be mistaken in the amount of water. It takes time, effort and skill to prepare.

Of course, it may seem that it is best to buy ready-made types of putty: they do not need to be diluted, and to storage conditions they are much more unpretentious. However, it is important to keep in mind that they are much more expensive and are not suitable for preliminary work related to the alignment of the walls: for this purpose it is necessary to use only dry mixtures.

Use the finished composition should be only when creating thin layers at the end of the filler work, then the surface will be so smooth that it does not require any additional grinding.

Kinds

Olive-based oil-adhesive putty is the cheapest of all. It is considered obsolete and even harmful, but it is not quite so. Of course, linseed oil tends to be absorbed deeply into any surface, including concrete, and later its stains may appear through a layer of finish. However, it is unfair to make the final “verdict” about harm: the oil-adhesive composition is perfectly suited as a waterproofing layer and can protect the plaster from premature destruction,especially in high humidity conditions. It is ideal for wet rooms, such as basements, bathrooms and kitchens. She can putty cracks in any parts of the bathroom, it is waterproof and never fails.

This specific type of material is ideal in combination with unpretentious oil paints, which are used for the subsequent lining of the walls; no stains will appear on them. It is perfect for working with wooden walls and OSB-plates lined with plaster, as well as in the event that it is planned to use fiberglass for cladding. Thanks to it, the crate lining and the lining of felt will be reliably protected from both rotting processes and the bark beetle, which often destroys wooden products and structures. Even the popular acrylic filler does not have such a degree of protection of plastered wood as oil-adhesive, therefore its use in some cases still remains irreplaceable.

Cement (or gypsum-cement) putty It is more expensive than oil and is suitable for all types of finishing work. This is a dry mix that needs to be kneaded in water.There are different types of cement putty: for residential areas and for areas with high humidity levels. First of all, such a composition is used to make the walls finish on the wallpaper: it does not leave stains like oil, so you can not be afraid to decorate the room with expensive and beautiful wallpaper.

Water dispersion filler also applies to cement varieties, but water-polymer materials are used as its basis. This is a ready-mix, which is sold in durable plastic buckets. Thanks to cooking in an industrial environment, such a composition is distinguished by a properly maintained level of viscosity, strength and smoothness.

This type of material is especially recommended for the novice master in preparing the walls for painting in the absence of serious defects.

Acrylic putty they are distinguished by high cost and good quality, but they cannot be called completely universal: they are not suitable as a basis for simple and cheap types of paints due to the too perfect surface that forms during leveling. If you use acrylic putty, then the paint for it should be of adequate quality and price,otherwise, it will not hold well and will quickly crumble.

Epoxy two-component putty replaced cement, lime and oil-based compositions. It contains epoxy, hardener and various fillers. It is also called polyester. Heavy solutions obtained from such compositions provide increased material strength. Recently, epoxy putty with fiberglass and aluminum chips has become popular. Separate types of such material are intended for metal works, in particular, in order to retouch scratches on automobiles and to prepare them for repainting.

The main feature of two-component epoxy-based materials is that it has an optimal curing rate, so it is not necessary to rush too much after preparing the mixture. The polymerization process begins some time after the putty is evenly distributed over the treated surface. It hardens completely after six to eight hours, after which you can safely deal with any lining or grinding.No extraneous solvents may be added to the mixture.

The scope of application of two-component compositions is very wide: from cosmetic "repair" of metal parts of cars to any puttying work, which have varying degrees of complexity.

Among the modern two-component fillers worth highlighting and polyurethane. It was developed to eliminate defects in polyurethane coatings (floors, walls, partitions), but due to its high adhesive qualities and durability it can also be used in work with metals, concrete, and ceramics. Its mechanical properties make it possible to seal serious potholes in sinks, bathrooms, transport bodies.

When applying such compounds, it is important to remember that they are produced in two packages (hence the notion of “two-component”): the very basis for puttying and hardening substance. When preparing the mixture should adhere to the observance of those proportions that are specified in the instructions.

By appointment, all materials are traditionally divided into four groups: starting putty (its main function is preliminary alignment of defects), finishing (material applied as the final layer after the main layer) and compositions of specialized use.

Starting types of material, or "putty of the first layer" are needed in order to eliminate deep surface defects: the ceiling, door openings and slopes. Such a putty is chosen depending on what the main material is in its composition.

When choosing, adhesive properties, wear resistance and strength, as well as the ability to apply a layer with variable thickness, which can vary up to 25 millimeters, are appreciated.

Finishing patches (“second layer”) should be applied after the first, immediately before the start of wallpapering or painting. They are used for a thin type of materials (flock coatings, textiles, paint) and are intended mainly for leveling minor defects. They are applied carefully and in stages, resulting in a white surface of increased smoothness and density without the need for subsequent grinding.

Universal types of putty, as a rule, have both finishing and leveling properties, and can also be used as materials for specialized purposes. Ideal for preliminary minor repairs of all surfaces and their leveling.In addition, putty- "wagon" is used for decorative finishes. Materials that will fully comply with the concept of universal, belong to a higher price category, besides their range is not very diverse.

As already noted, universal putty is significantly inferior in quality to dry mixes, which are designed to perform a specific purpose.

Materials of specialized purpose include special types of additives and are intended for work that has certain specific features, for example, for sealing joints on gypsum panels without using tape with reinforcing properties.

There are elastic and flexible mixtures to fill the "breathing" cracks in the walls and other similar options.

The composition of all filler mixtures are divided into three types: lime (cement), gypsum and modern, which are based on polymeric materials. Gypsum putty is non-shrinking and is well leveled, but does not have good moisture resistance, therefore it is suitable only for interior work in dry rooms. Calcareous varieties, on the contrary, tolerate moisture well, but at the same time have a strong shrinkage.As for all types of polymers, many of them are universal, but they are much more expensive, which often limits their use, especially in the processing of large areas.

Manufacturers

Semin Company, having a representative office in different cities of Russia, appeared in France, and has been on the domestic market since 1996. Its main specialization is the import of building materials and finishing mixtures from both France and other European countries. The company itself was founded in 1938 as a company producing professional finishing materials of good quality.

At the present stage, Semin is represented by a wide range of fillers, as well as mixtures for working with metal parts of cars. In France, the company has three plants, and in Russia - one. The total number of countries in which it organizes the supply of its products - more than 40.

One of the most popular ready-made mixtures of this company is Semin two in one putty, intended for both primary and finishing surface treatment. Differs in easy drawing and high adhesive properties. After drying, the wall becomes pure white.All properties of the material described in the instructions for use fully correspond to reality.

Polish company Novol in 1978 was widely known in Eastern Europe as a manufacturer of painting materials for cars. It was started by a small firm engaged only in this segment of the business, but soon the production expanded: universal and specialized filler compositions appeared along with additional materials. Since 1989, another large plant in Poznan has been operating, and Novol products have been supplied to the Russian market since the late nineties.

The line of putties of this company is very diverse. Each material has its own specific purpose, which greatly facilitates the choice. Basically, the compositions are focused on working with metal and plastic surfaces. Specialized compositions are available for sale, for example, only for plastics, as well as universal ones.

Materials can be applied either with a conventional trowel, or with the help of pneumatics, but only if major alignment and elimination of large defects are not required.

Among the car mixes of this company, the best reviews received Novol Fiber putty. It differs in ease of application on a metal surface, good adhesion and high wear resistance. Ideal for body repair of trucks. The strength and durability of this putty is due to the fact that it consists of polyester resins and fiberglass.

On the territory of Russia there are also several worthy companies for the production of putty materials for different purposes. For example, a company "Hercules", founded in 1997 in Siberia, initially took over most of the valuable experience from colleagues from Germany, which led to its further licensing from the Germans. "Hercules" is a deserved leader in the Russian market, specializing in dry putty mixtures, indispensable in cases of deep leveling and processing of large surfaces.

The company's products imply the use of exclusively high-quality raw materials and are the best in Siberia, and product prices are always available and humane, targeted at a wide range of consumers. In 2015, a new production hall was opened, equipped with modern types of equipment, which allowed the company to significantly increase the overall performance of the goods. The manufacturer is constantly engaged in expanding its business relations in the market.The product is successfully sold in more than twenty regions, as well as in Kazakhstan.

Among the fillers of the company "Hercules" non-shrink two-component mixture is in demand. It has a low cost, it can fill cracks of any size. Suitable for use in dry rooms. It consists of high-grade plaster material, as well as white inert filler and polymer additives, which provide the material with high adhesive properties.

The composition is easy to apply and is environmentally safe.

Another recognized leader in the Russian market for putty materials is trading brand "Tex" from St. Petersburg, better known as Tikkurila. In such cases, one should distinguish between the concepts of the company and the brand under which it manufactures its products. “Tex” has long been providing the Russian consumer with dry and universal mixtures for puttying, attracting by moderate prices and decent quality goods.

The products of the trade mark “Tex” are represented by a wide range of primers, adhesives and solvents, as well as various fillings: oil, acrylic, latex.Among them, among buyers, the universal composition “Lux” is most often in demand for work inside premises of any purpose. Putty "Lux" has a high level of moisture resistance, which allows its use in the bathroom, in the kitchen, saunas and swimming pools.

However, it is not recommended to use it in places where there is no heating, as the material in the cold can quickly become unusable.

Large German concern Knauf is a recognized leader in the market of building materials of all kinds. In the early 30s of the last century, the brothers Karl and Alphonse Knauf had the idea to use such wonderful natural material as gypsum in construction. It all started with the development of gypsum mines in Schengen, after which the first Knauf plant was opened in Germany. It is noteworthy that the Knauf brothers decided to start their activities with the production of dry plaster mixes on a plaster basis.

In the future, the company began to develop rapidly, releasing drywall, machine plaster and a liquid screed for floors. Putty dry mixes of cement and plaster appeared on the market in the 70s,and when the state system in Russia began to change dramatically, the German manufacturer was seriously interested in the prospect of international cooperation. In the 1990s, gypsum production plants in the former USSR almost stopped their work, and if any of the building mixtures were produced, their quality, unfortunately, left much to be desired. But since the representatives of Knauf saw a good potential in the development of the market in Russia, they soon decided to start production with us, the more the company's product line was subsequently expanded to the production of universal filler mixtures, most popular for simple repairs.

Throughout its existence, the mixes of this company have not changed in terms of quality and production technologies. Knauf is distinguished by customer focus and humanity in terms of pricing policy for its goods. Now in Russia, production is carried out on German equipment, and raw materials are mined in our territory. In the 2000s, the company entered the investment market of Ukraine and Kazakhstan. In Russia, the company attracts and trains our specialists,providing people with decent jobs and excellent products.

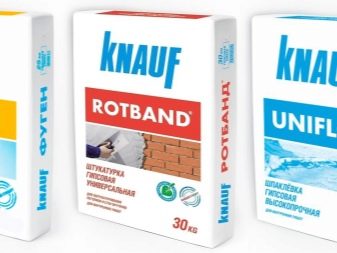

The most popular among consumers can be called Fugen putty, which is a highly effective mixture with gypsum powder and polymer additives in the composition. It is designed to level the walls and ceilings in rooms with optimal humidity indicators. Suitable for work with concrete and plastered surfaces in order to eliminate large and small defects, ideally in contact with drywall.

Due to plasticity and high adhesion, this particular composition received the best reviews among construction professionals.

Many, of course, are familiar with the other. German company Henkel. She is known as a manufacturer of household chemicals and personal care products, but her branch called Henkel Bautechnik deals specifically with the construction segment. Among a wide range of building materials, especially filler mixtures are distinguished, and both dry and ready-made. The choice of putty, unlike Knauf, is not so wide, but the advantage of this manufacturer is that just a specialized mixture can be found much easier.Each putty is designed strictly for a specific task, which is very popular with many craftsmen. In the Russian market, Henkel is represented by Ceresit.

Filling mix Ceresit CT 225 - A great option for facade work. Masters point out that it is cement types of mixtures that are the best among all the fillers of this brand. Its main advantage is the content of a large number of reinforcing additives necessary for carrying out external finishing works, but in order to evenly distribute them over the entire surface, one should not forget to stir the already prepared composition as often as possible.

Tips for choosing

The best results can be obtained only when the compositions produced by one company are used, as a rule, in this case they best complement each other. When applying the first layer of putty, a mixture of coarse-grained fraction with a thickness of up to one and a half millimeters is ideal.

The final stage of puttying should be carried out with a smaller fraction of the material - not more than 0.3 mm.

When choosing a mixture, the question always arises as to which is better: finished or dry. Of course, dry mixes are much cheaper, but they allow you to get the best quality results, and all efforts to prepare a homogeneous mass will be justified. It should always be borne in mind that no matter how attractive this or that ready-made mixture from the universal discharge seemed, the base layer should be applied with a dry mixture properly diluted with water. Especially since ready putty always costs much more.

On each package there is an indication of the scope of the material, which you should definitely adhere to. Also, when buying you need to pay attention to the conditions in which the use of the composition is acceptable or the most optimal. This is an indicator of temperature, place of application (room or open air), humidity.

It is necessary to carefully read the material to be used. It can be used for deep leveling of the surface in order to smooth the upper layers of even places. It is also necessary to get acquainted with how this or that kind of putty is combined with other additional materials in order to avoid problems in the process of work.

If concrete walls are prepared for painting and have no serious defects, the universal ready-made putty “for concrete” is best suited because it will provide an impeccable level of quality in the final layer. Inexpensive, but reliable dry mix will be an excellent basis for any type of wallpaper. When it is intended to stick thin and light wallpaper, the finishing layer of the material should be chosen as whiter as possible so that the color of the decorative coating does not change or deteriorate.

When planning work only indoors, you should buy a putty that does not contain sand.

Before buying a ready-made putty mix, it will not hurt to check the quality of the goods "by eye"by asking the seller to open the lid of the can. If the product is of poor quality, its surface may contain dark streaks or dried blots. If it is not easy to make a choice, it is recommended to stop at one of the mixes of the universal plan, thus reducing the risk of buying that material that may not be suitable at all. Among professionals there is an opinion that for leveling the walls it is best to take acrylic putty.

Application Tools

The spackling workflow is not so complicated, but often requires basic skills and a certain amount of experience. For a beginner, the main thing is to focus on ensuring that all actions are performed in the right order, plus learning how to properly handle the tool.

The first thing you need is a screwdriver or drillhaving a special nozzle, because the dry mixture requires dilution with water. High-quality mixing is possible only with the use of drills and nozzles. If there is no such tool at hand, you can try “in the old fashioned way” to use an ordinary kitchen mixer.

Material is applied with a spatula, but for the full and high-quality work of one tool will not be enough. It is recommended to buy a set that includes blades, each of which has an individual size.

The main space is treated with a spatula with a wide working surface, and for the corners you need to use a small spatula.

You will also have to work with a roller and, most likely, also not one, in order to work well in several stages in hard-to-reach places. The optimal length of the pile roller is two to three millimeters.Primer brushes should also not be overlooked, because pre-priming the surface, no matter how troublesome it may seem, will provide better adhesion of putty and other materials. A building or laser level will be needed to assess the flatness of the walls, and sanding paper, both large and small, will be needed to clean the surfaces.

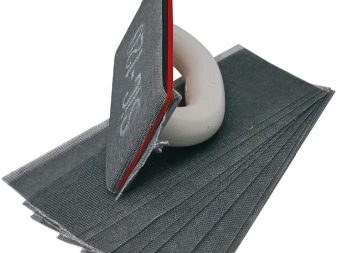

If the work area is large, the so-called hand skinner will become an indispensable assistant. It will be possible to fix sandpaper or mesh on it with the help of clips - this is how a wider surface area is captured and the process goes much faster. Large sandpaper is required for starting work, and fine sanding is useful for finishing layers.

Since the main tool when working is a spatula, it is important to keep in mind when buying it that they are different. There are blades for carrying out external work on the facades of buildings and tools that have a paint purpose. The thickness of the blade of the painting spatula is much less than that of the front one, and the width of the front blade is much more, because it is designed to work with a much larger surface area.

A good paddle should be made of a good material and have a comfortable and strong handle. It is better if it is rubberized and tightly attached to the working part. The width of the working part of the tool can be from 40 to 60 centimeters (when carrying out the main work), and for filling with difficult accessibility the width will be from six to fifteen centimeters. If the room is small, a 40 cm wide work surface will be quite enough.

Corners are usually puttied with an angled spatula, but in order to properly handle it, certain skills are required.

The task of the angular spatula - the creation of clear angles of 90 degrees.

How to apply?

Before applying the wall material must be thoroughly cleaned of old paint or wallpaper. To alleviate this unpleasant activity is possible by applying special means for flushing, which are sold in stores along with other building materials. After washing the walls, the room is left to dry for at least a day, after which a thorough inspection of the walls is carried out for small residues, which are best removed with a special mounting knife.Instead of a knife, it is allowed to use a flexible thin spatula, the main thing is that it should not be putty, because it can easily get scratched or broken during such work.

After a preliminary inspection of the prepared walls you need to check their relief. To do this, you will need tools such as plaster rule and a flashlight. The rule is applied to the wall, and the light of the lamp is directed casually towards it. This will help to identify the smallest holes and bumps, which can later adversely affect the aesthetic appearance of the walls after the final finishing. The light will help to see all the small defects that are immediately brought down by a plane or spatula having a plastering purpose. The wells are preliminarily contoured with a pencil along the contour of light.

Before starting work all the tools are carefully prepared. It should be washed, dried and wiped dry with a cotton rag. Disposable dry wipes may be used. Before using special attachments or a mixer for mixing, they are carefully checked for traces of previous work.

Even the smallest pieces of old putty mixtures must be removed.

The mixing process itself is fairly simple, but requires care and accuracy. If a construction bucket is used as a tank, water is poured into it for one fourth, and if it is usual, one third of water will be enough for economic purposes. Only after that in a bucket gently, in a trickle, dry mixture is poured until the top of the resulting slide appears from under the water. After 20-25 seconds, the slide should be saturated with water and sag, after which it should be thoroughly mixed. After mixing, you need to wait another minute and mix everything again, after which the putty will be completely ready for application.

Important point: in no case can not add water or add dry powder in the event that the mixture is already ready. Before you knead, it is important to pay attention to how long after cooking the mixture will be suitable for work and will not dry out. The best thing to do batch batch.

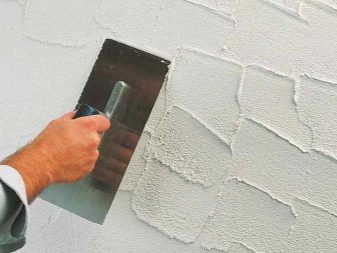

One portion of the application should not be very large to save material and maximum accuracy of work. On the spatula you need to take the amount of the composition in such a way that it could be applied with one stroke.Minor defects are overwritten by a small or medium spatula. When grouting, the arm movements should be wide and the pressure should be uniform, until the layer of the mixture becomes equal to the wall.

Drying puttied surfaces should be using drafts and, if possible, direct sunlight. “Accelerated methods” of drying with heaters and fans are not allowed. If the composition does not dry out naturally, it will warp or crack, and this is usually manifested during decorative decoration, which should be avoided. During the ventilation of the room also do not open the balcony door to avoid exposure to temperature changes.

Room doors, kitchen doors, a corridor, and a bathroom should be open.

The maximum time for complete drying of the filler is 10-12 hours, however, the surface should be ground no earlier than after 24 hours. During this time, the mixture will become more durable, which will provide ease of work in the future, and optimally smooth surface.

If the walls are processed for the purpose of wallpapering, the work is first carried out with a wide spatula with the mixture applied in the form of strips and slightly overlapping (from 10 to 25%).You need to hold the tool at a 20-30-degree angle, with constant pressure, to get a layer of constant thickness - from two to four millimeters. It should be borne in mind that if the angle of inclination of the blade is smaller, then the layer will be thicker.

After drying the walls, the sags are removed using an abrasive tool. - jointer, and the wall is tested again for evenness with the light from the flashlight. Hillocks are also removed by abrasive, and the holes are closed with a small spatula or manually. Beginners usually cope with the work in several approaches, the purpose of which is to bring the wall into a plane or to “zero”, if you use the terminology of professional craftsmen.

After the wall is “nullified” and dried, you need a grid jointer for mashing the surfaces (grid size is from 80 to 120). The more sandpaper numbering, the smaller its grit. The first passage along the wall is made in a uniform motion in a circle, after which the strokes are carried out in a cross direction in order to remove the circles. The wall is again tested for evenness, and if the light from the lamp does not go far, we can assume that the process was a success.After checking the wall is dried for another day, and then it is already being taped.

If you need to putty the walls for painting, after the main stages of puttying and removing the walls to “zero” with grout, you must apply the last plaster layer, which is also called finishing.

When working with corners there is the simplest method: at first, a small surplus of material is left there, which after drying is corrected by abrasive. The corners on the slopes are worked out using an angled spatula, after which the abrasive is removed again and the walls are tested for evenness.

If you need to putty the plasterboard surface after the primer, you first need to glue the fiberglass mesh, and make it so that it covers the corners and joints. The seams should fall exactly in the middle of the mesh. The joints between the cardboard sheets are puttied successively with two vanes: medium and wide. As with the processing of the usual wall, you should remove all the formed bumps and irregularities, so that there is less hassle during sanding. A layer of the mixture is uniformly applied across the seam and leveled with a middle spatula.

Screws putty crosswise to completely disappear their caps.

The corners in this case will be more difficult to handle. The first thing you need to handle a mixture of one side of the corner, as usual, and when half of the seam dries, is the second side. Thus, the seam is neat and smooth. Next you need to fix the building corners all the slopes of doors and windows on top of the putty layer. Press the mixture into the profile holes with a small spatula so that all the gaps are filled. The surface is leveled with a large and wide trowel.

A plasterboard finish is also required.so that the wall was as smooth as possible. All minor defects are sanded to ensure the best adhesion of the “final” mixture. As a finishing putty, it is recommended to use a mixture that includes fiberglass, you can also use the same solution that was used at the start, but with the condition that the manufacturer is the same, in order to avoid problems with adhesion. The final puttying is carried out with a wide spatula, and the composition is diluted to obtain a mass that looks like sour cream in appearance.This will result in a uniform application of the composition to drywall.

Useful recommendations

When using dry mixes, it is important to take care of acquiring a convenient container in advance. With a large amount of work, you should never use the entire mixture in one sitting, because it will simply dry for several hours and the master may not have time to use it for its intended purpose. For optimal and economical consumption of the mixture is better to prepare in several stages and always pay attention to how much time you can use one or the other version of putty. Depending on its composition, the time may be different.

It would seem that it is very easy to prepare the container for mixing the putty mixture., but it is not so. The use of too old buckets with a large number of residues of different mixtures adhering to the inner surface of the container is not recommended. In the process of fast mixing with a mixer or a nozzle on a drill, solid remnants of the old can get into the fresh mass, which will cause great inconvenience when working. Pulling out the hardened pieces of old from freshly mixed putty is unnecessary and useless, so it is better to take care of that the container was clean from the beginning, without any traces of paint or rust.

When all the work will be completed, you need not forget about thorough washing of the entire toolkit. If you do not do it right away, dried pieces of putty will have to be “torn off” with a knife, which can damage the blade. The mixture should be cleaned while it is wet, and the cleaned tools should be wiped dry - both the handle and the blade. If you still have to deal with untreated tools, then in order to soften the adhered composition, you can try to use a solvent, although this does not always work. In the worst case, you will have to either use a knife or buy a new device.

You should never take a spatula with too much mixture. It is a mistake to assume that the bigger the putty, the faster all the assigned tasks will be completed. With an excess of the mixture, the quality of the coating will significantly deteriorate, the surface will become uneven and uneven, which will certainly create many problems with further painting or pasting walls. Some advise “not to bother” with such subtleties, explaining that after applying a thick layer of the mixture, you still have to “sand” sandpaper, but such an opinion is wrong.Prolonged sanding not only delays the workflow, but also leaves on the walls those defects that will have to be aligned again and again, which, of course, is completely unnecessary.

Work on each wall is best done in one day to ensure that the surface is evenly dried. In the case of forced breaks, that part of the wall that has dried out must be wetted with water using a spray bottle, and the transition should be smoothed with the capture of the previously wetted layer. If the surface is dry for a long time, it should be wetted abundantly, previously rolled out with a roller.

If nails are found in the walls, one may unwittingly be tempted to hammer them back as quickly as possible, or, conversely, pull them out with a spatula. In no case should this be done, because any paint spatula is a flexible tool and quite fragile. If the blade is damaged, further work will be simply impossible. When working with “problem” walls, it is better to always carry with you an additional “arsenal” of tools - like a hammer or a nail puller. If the nail is not pulled out, or the master decided that it would be better to hammer it into the wall,one should not forget about thoroughly filling the caps with the help of a small spatula.

It is not recommended to purchase too cheap tool kits., even if they will be rarely used in the future. The blades of the so-called "disposable" often break or their working surface is covered with scratches in the first hours of the process, which will adversely affect the quality of the surface. It is best to buy a set in a proven hardware store or buy everything you need separately, without being led to a cheap price.

It is troublesome, but interesting, for the first time to do spackling work with your own hands, especially if you have the opportunity to consult with a more experienced master who can give valuable practical advice in the process. If the beginner master has enough patience and perseverance in achieving his goal - everything will definitely work out.

About what are the ways of applying putty on the walls, see the next video.