Sheetrock Putty: Pros and Cons

Sheetrock putty for interior wall decoration is the most popular, having features and advantages compared to other similar materials for leveling wall and ceiling surfaces. Back in 1953, USG began its triumphal march, and now the Sheetrock brand is known not only at home, but throughout the world.

Special features

Sheetrock putty is a ready-to-use building material used to decorate walls indoors. Also available for sale semi-finished putty material in the form of a dry mixture. This mixture will then need to be diluted with water in certain proportions. Ready-mix Sheetrock is easy to use, because you only need to open the container, and proceed to the finishing work.The ingredients of the mixture (vinyl) make it universal: it does not require special skills to use. In turn, polymer lightweight putty has its own varieties.

This type of putty has a cream consistency, thanks to which it falls perfectly on the surface. Sheetrock is suitable not only for applying to walls, but also for filling cracks, processing corners - all this thanks to the components that make up the product.

The putty does not need to be diluted and kneaded, as it is already sold as a ready-to-eat mixture. This feature saves time, avoids additional costs.

The mixture has a high density, which allows it to be applied to the surface in a uniform layer. The drying time of the material is only 3-5 hours, after which you can begin to grind the surface. Drying time depends on the temperature and layer thickness. Due to the high degree of adhesion, Sheetrock finishing material can be used at high humidity levels. This is a big plus compared with other varieties of putties.

Special Sheetrock mix withstands up to 10 cycles of defrosting and freezing, which has been proven experimentally. The defrosting process should proceed only at room temperature.It is forbidden to influence additional thermal loads. Therefore, you should not worry if you purchased a putty in frozen form.

Also, this type of finishing material is suitable for all types of wallpaper and paint coatings, does not cause chemical reactions. Due to the content of environmentally friendly materials, repair with a putty solution can be carried out in children's rooms and hospitals. The only disadvantage of the Sheetrock putty material is the high cost of production.

The areas of application are as follows:

- putty cracks in plaster and brick finish;

- putty plasterboard sheets;

- smearing of internal and external corners;

- decoration;

- texturing.

Specifications

Available finish coating in buckets of various sizes. Examples of packing:

- 17 liters - 28 kg of putty;

- 3.5 L - 5 kg;

- 11 liters - 18 kg.

Products are manufactured in white, and when applied to the surface, it becomes a beige tint. The density of the building mixture is 1.65 kg / l. The method of application can be both manual and mechanized. It is possible to work with such products at temperature indices from +13 degrees.The shelf life of this product ranges from several months to a year, but this condition is preserved when the product packaging is closed.

Ready putty consists of the following components:

- limestone;

- vinyl acetate polymer (PVA glue);

- attapulgitis;

- talc (powder with talc).

Kinds

Sheetrock finished products are manufactured in three varieties:

- Sheetrock Fill Finish Light. This type of putty is used to level minor flaws, it is possible to use for lamination. Part of the latex makes the finishing material moisture-resistant and resistant to defects during operation.

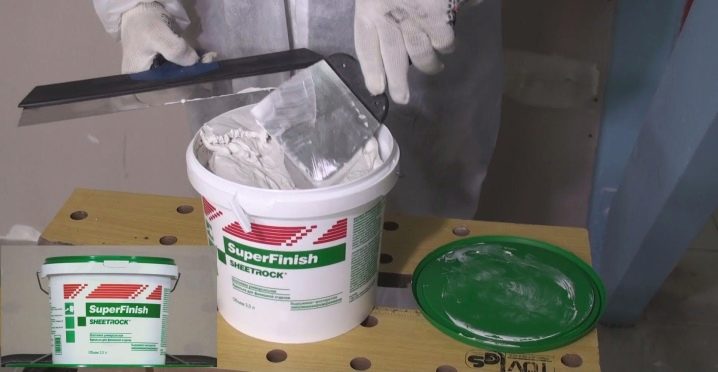

- Sheetrock Superfinish (Danogips) is a finishing putty. The finished polymer mixture has a high degree of adhesion, but this is not enough to seal large cracks and seams. Used for processing drywall, painted surfaces, fiberglass.

- Sheetrock All Purpose. This type of putty is considered multifunctional, because it is suitable for any kind of finish. It is widely used in texturing, sometimes used to fill the space in brickwork.

How to choose?

When asking about which putty is better, acrylic or latex, you should know that latex is the best option.This is due to the fact that acrylic does not have sufficient thickness, which would create a high strength material. Sheetrock ready-made polymer putty is a professional solution to any problems of interior decoration of walls and ceilings. She tested experimental experiments. There is a certificate of product quality. Its presence allows not to be mistaken in the choice of this material.

The choice of the type of putty material depends on the problem:

- SuperFinish solves the problem of finishing the surface;

- Fill & Finish Light is used for the finishing coating of gypsum boards;

- the purpose of ProSpray is mechanized processing.

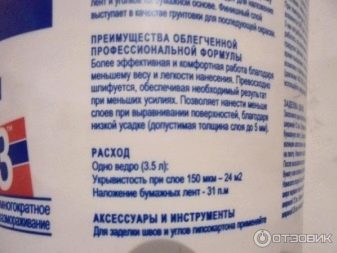

Consumption

Sheetrock polymer putty, unlike conventional putty, weighs 35% less. With low shrinkage of the material, the cost of it is about 10%. Only 1 kg of putty is spent on 1 m2, because the dried putty does not shrink the finishing material. Also, the cream texture of the special mixture prevents unnecessary costs (slipping from the spatula or from the surface of the wall). Material consumption at the joint of sheets of drywall is 28 kg per 55 pog. m of the seam, and for texturing - 28 kg per 20 m2.

Application details

Tools for applying Sheetrock putty:

- spatulas (width - 12.20-25 cm);

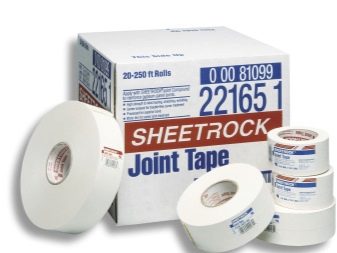

- Sheetrock Joint Tape;

- sponge;

- sandpaper.

It is necessary to apply a finishing coating on the prepared surface, which was previously treated with a putty for leveling, plastered or sanded. The surface should not have irregularities and cracks. Apply the first layer of putty necessary to completely dried plaster, otherwise, over time, mold will form. A small amount of putty is collected on a wide spatula, then evenly stretches over the entire area of the wall or ceiling.

It is recommended to achieve the application of the mixture as thin as possible so that the surface is even and smooth.

Next, you need to give the first layer to dry. The next layer is applied only to the completely dried previous layer. To obtain an ideal surface condition, experts recommend sanding each layer of putty with an abrasive mesh of 180-240 grit. The maximum number of layers is 3-4. After all the work, the treated area is cleared of dirt and dust.

If necessary, you can dilute the composition with water, but you need to add it in portions of 50 ml, followed by stirring.A large amount of water will only worsen the adhesion of the solution to the surface, but the result will not give the desired effect. It is forbidden to mix putty mixture with other materials. Frozen putty mixture should be stirred to a uniform consistency without lumps and air bubbles.

To prevent the applied decoration material on the walls from freezing, it is recommended to cover it with a heat-insulating coating (foam). At the end of the finish, the putty remaining in the container must be tightly closed with a lid. Store at room temperature.

Seaming with Sheetrock putty:

- seal the seams (trowel width - 12 cm);

- center the tape to be pressed into the wall;

- excess putty mixture must be removed, apply a thin layer on the tape;

- putty of screw heads;

- after one hundred percent solidification of the first layer, you can proceed to the second. For this, a trowel is used with a width of 20 centimeters;

- give time for drying the second layer of putty;

- apply a thin layer of finishing putty (spatula 25 cm wide). The same layer is applied to the screws;

- If necessary, smooth the seams with a sponge dipped in water.

Interior corners:

- cover all sides of tape material with putty;

- the tape is folded along the middle, pressed against the corner;

- get rid of excess mixture and apply a thin layer on the tape;

- give time for freezing;

- drawing the second layer on one side;

- drying;

- drawing 3 layers on the second side;

- give time for drying.

Finishing outer corners:

- fixing the metal corner profile;

- applying three layers of putty with pre-drying. The width of the second layer should be greater than the previous one by 10-15 cm (trowel width - 25 cm), the third layer should slightly exceed the previous one.

Texturing:

- apply Sheetrck putty to the required area with a paint brush;

- texturing technology using special tools (paint roller, sponge and paper);

- drying time is about 24 hours at a humidity of 50% and a temperature of + 18 degrees.

Grinding of putty:

- To carry out the grinding work will need a sponge and sandpaper.

- The sponge moistened with water turns into paper. This is necessary so that less dust is generated.

- Grinding is performed with light movements on the resulting irregularities.

The smaller the number of movements, the more ideal the surface will be. At the end it is necessary to rinse the sponge with water.

Precautionary measures

It is necessary to remember the safety rules that must be observed during construction work with Sheetrock material:

- If the putty solution gets into the eyes, it is necessary to immediately rinse them with clean water;

- When performing dry grinding of materials it is recommended to use protective equipment for the respiratory tract and eyes. Finish with gloves;

- take the putty mixture inside is strictly prohibited;

- keep away from small children.

If the use of putty occurs for the first time, then it is better to give preference to branded manufacturers with positive reviews. Putty Sheetrock has established itself only on the good side. According to the description of the technical characteristics and the technique of applying the material, it is clear that carrying out the finishing works is not particularly difficult.

Review Sheetrock finishing putty, see below.