"Bark-eared" plaster: characteristics and features of use

The modern look of plaster called "Bark beetle" is one of the most sought-after finishing materials. The original coating is famous for its aesthetic and protective properties. Simplicity, ease of use makes it a versatile material in all respects.

Features of the composition

The main components of the plaster are granules and powder. The size of the grains varies from 1 to 5 mm. It affects the amount of material required. The larger the grain, the more mixture is required.. It also affects the expressiveness of the picture.

The mixture may consist of gypsum, cement or acrylic. Marble or mineral grains of sand are used as granules. The disadvantage of gypsum or cement mixture is that they, unlike the acrylic composition, must be diluted before applying. Here it is important to comply with the technology of preparation and proportions.

The advantages of plaster can be attributed to the presence of a huge selection of compositions. Each manufacturer cares about improving the quality, increasing the versatility of its products. Therefore, despite the presence of the main components of the mixture, additional substances are added there. Depending on the desired result, you can always choose the most optimal characteristics.

Do not neglect the advice of professionals. Competent consultation will allow to sort out all the variety of components and their combination with the initial data.

Types and characteristics

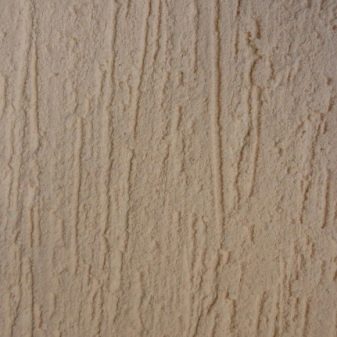

The name of the bark beetle comes from the name of the insect - the bark beetle, which leaves a kind of indentation on the tree.

The unique appearance of the outer surface is formed by small or large depressions imitating the trail of a beetle. The pattern is formed by marble, mineral chips or titanium dioxide.The effect of a tree eaten by a bark beetle is created.

It should be noted that the technical characteristics of the compositions of decorative plaster may vary depending on the quality, type of components.

The compositions differ in purpose:

- for decoration of walls indoors;

- for exterior decoration of houses;

- universal formulations.

Differences in structure:

- with large grains;

- with an average grain size;

- with fine grain.

The difference in the type of the main component:

- Mineral mixtures based on cement or gypsum, they have a service life of at least 7 years. Due to their resistance to low temperatures and high humidity, they are used to finish the exterior surfaces of houses.

- Polymer blends Acrylic based is very plastic. This property eliminates the risk of cracking. Under favorable conditions, the composition can maintain its quality for 20 years. Acrylic mixtures are often used for interior walls and ceilings.

- Also exist silicone resin blendswhich have plasticity, moisture permeability. Under favorable conditions, their service life is 10-15 years.

Differences in readiness for use:

- ready solutions;

- dry mixtures requiring dilution.

The advantages of the textured bark beetle plaster also include:

- Strength. Plasterer withstands mechanical impact, vibration. Possesses long service life.

- Ease of care. Dust, dirt is easily cleaned with water or any detergent.

- Resistance to temperature extremes. The material easily transfers temperature to minus 50 degrees.

- The absence of harmful substances in the composition prevents toxic particles in the air. This allows you to use the material inside the premises, children's rooms.

- Fire resistance. The material does not apply to flammable, which makes it possible to use it in the kitchen, next to the fireplace.

- Easy to apply. Compliance with the correct technology allows you to make repairs in the room with their own hands.

- Original texture. Unusual design is harmoniously combined with almost any type of interior design.

- Relatively low cost. The presence of a huge number of manufacturers allows you to choose the best option for any budget.

- Ease of composition. The material does not create an additional load for the supporting structures, which significantly reduces the risk of its damage or wear.

Knowledge of the features of the compositions allows you to easily navigate in all the variety of offers on the market.

Colors and design

Unique drawings of plaster serve as decoration of any room. As a decor, the finish can be made on the ceiling, on several or only on one wall.

If the mixture is initially white, then during the preparation of the solution or subsequent staining, you can create different colors. Monophonic shades of pastel, beige tones are relevant. You can also create contrasting reliefs. The color palette can be represented in bright red, brown, yellow, silver, blue tones.

It should be noted that when adding the coloring matter to the finished solution, the colors look more natural. If dry powder is used, it is recommended to paint it only after the plaster dries.

To obtain a saturated color, color is produced in two stages:

- The first coat of paint is applied with a brush.At this stage, the emphasis can be made only on the grooves.

- After the paint dries, apply a second layer of paint with a roller. So that the paint does not smear the plaster drawing, the work is carried out at a fast pace. You can use lighter shades.

Subsequent lacquering of the surface will give it durability, will increase the brightness of the color.

You can also choose a color mixture. In this case, there is no need to add a coloring matter.

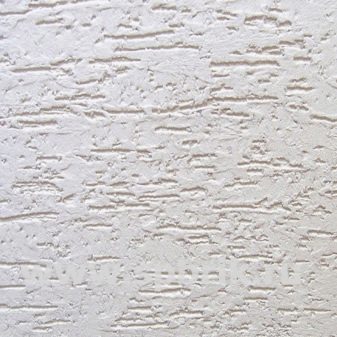

Depending on the applied technique of applying the material, the type of pattern is formed.. If the mixture was applied in circles, the drawing will have oval grooves. If the movements were smooth in the direction of up, down or to the right, to the left, then filamentary straight grooves are obtained. You can make movements diagonally, then the grooves will be directed to the sides of opposite corners.

The saturation of the pattern depends on the selected grain size.. If a small fraction was used, the pattern will be more subtle, less noticeable. This design is more suitable for decoration of small areas, interior walls or ceilings in the bedroom, children's room.

If a large fraction of grains was used, the pattern will be more noticeable, coarse. This design is often used in the decoration of external surfaces. Inside the room a deep pattern will be relevant if there is a large area, for example, in the living room, hall. In modern design styles, for example, industrial, minimalism, hi-tech such decor will also look appropriate and harmonious.

The presence of different grain sizes, as well as the ability to use any type of color allows you to create modern original surface models.

How to choose?

Ready-made examples of finishing, as well as expert advice that should not be neglected, will help determine the design and color of the plaster.

First of all, you should decide on the characteristics of the composition. Different types of mixes are suitable for finishing outside and inside. The calculation takes the thickness of the required layer of plaster, which depends on the grain size, operating conditions, mechanical, chemical or temperature effects. The expiration date, and also the price is important.

You need to think in advance about the colors, drawing. To form the desired result, a specific grain size is selected.It is better to buy the right amount of consumables at once, as often the parties may have slight differences in tones from the same manufacturer.

Preferring ready-made formulations that are more convenient to use and plastic, it should be remembered that they can not be stored. Unused mixture dries quickly, becomes unsuitable for use. It is also important to note that such solutions usually cost more.

In this plan the consumption of dry mixtures is more economical, and they are cheaper.

However, when cooking it is necessary to observe the correct proportions.

Depending on whether the repair will be carried out by a professional or a beginner, a certain type of tool and material application technology is chosen.

Before purchasing a finishing material, it is necessary to study the instructions indicated on the package, as well as the date of issue. It is not recommended to use the mixture, the shelf life of which is more than one year.

For interior work

Walls finishing inside a room or a corridor should be made taking into account the use of environmentally friendly components, resistant dyes, moisture-resistant materials.For the formation of an exquisite beautiful pattern, usually the size of the granules is chosen less than 2.5 mm. Fans of extravagant reliefs may prefer large sizes.

When choosing plaster to finish the balcony, especially if it is not heated, you should choose a mixture with more reliable characteristics. They must be resistant to high humidity, temperature extremes.

Regardless of whether a ready-made solution or a dry mixture is being selected for dilution, it is important to think in advance about the color palette, which will be harmoniously combined with interior items.

For exterior finish

Mixes are chosen with a large granule size - not less than 2.5 mm. Since the plaster will be exposed to various adverse effects of the environment, it is necessary to choose compositions with the greatest strength, resistance to temperature changes, moisture, and mechanical stress. As a rule, such compositions require preliminary preparation, so it is important to make the correct calculation of the required amount of material.

You should take care in advance about the choice of colors, which should be combined with the surrounding external design.

Application area

Plaster material is used to finish both the interior walls of the apartment and the external facades of private houses. It is also used for decoration of public spaces. However, this happens much less frequently. Due to its universal properties, it can be applied to the base of concrete, brick, drywall, panel, and also on the walls of cinder block.

The structure does not use for finishing of the bases from a tree, metal, glass, and also plastic.

Properly chosen parameters of plaster can be used as a finishing material for walls or ceilings of any room.

Application technology

If you wish to finish the walls with your own hands, you must carefully study the process of applying plaster. Compliance with the sequence and rules of use of the material will allow you to get the desired result, which will please for many years.

Before you apply the composition to the finished surface, it is necessary to prepare in advance the necessary devices, containers. The mixture can be applied immediately.. It does not require additional training.

If for receiving plaster material it is required to dissolve it, then it is necessary to be guided by the instruction indicated on the package. It should be carefully studied.Any composition has its own characteristics, given that, you can avoid many troubles.

The sequence of preparation of the solution:

- Prepare a container with the required amount of water. The exact proportion is indicated on the packaging. Water temperature should be at room temperature.

- The dry powder is slowly poured into a container with water. The mixture is thoroughly stirred until a homogeneous mass. It is important to prevent the appearance of lumps.

- Homogeneous pulp is allowed to brew for 5-10 minutes.

- Stir again. You can use a special mixer.

The amount of the mixture is determined on the basis of the area of the surface to be coated, the grain size, and the specific composition. On 1 square. m can take from 2 to 5 kg of the mixture. Exact proportions are indicated on the packaging.

Tools are used for applying the solution, for example:

- Trowel, trowel, spatula. Level the surface, remove excess.

- Grater. This tool is used to form an absolutely masonry surface. The most reliable material from which the grater is made is metal. It is characterized by a long shelf life. Beginners are advised to choose a tool from polyurethane.But professionals often choose foam, which is characterized by excessive brittleness.

For one-time work fit plastic grater. The tree-based tool also has a relatively short duration. There are graters based on rubber, latex.

The tool is chosen depending on the destination, ease of use, cost.

Regarding the facade finish, it should be produced in spring or autumn to get the best quality. The air temperature should be in the range from 5 to 30 degrees above zero. Humidity should not exceed 60%. It is better if the weather is calm.

The surface on which the plaster will be applied should be smooth and clean. The presence of cracks, irregularities more than 2 mm.

The day before the repair of the wall or ceiling primed to match the finish. This is done so that the applied material is in close contact with the base. As a rule, use mixtures with the content of quartz sand. It is allowed not to prime the concrete base, but only wet it with water.

When carrying out repairs it is important to observe the sequence of actions:

- The mixture is evenly applied to the surface, spreading over the entire area. The tool is held at an angle of 30 degrees.Each subsequent furrow is applied in such a way as to cover part of the previous furrow by 4-6 mm.

- To form a picture using a grater. Uniform pressure on the composition in different directions allows to obtain the desired image. Pressing is performed in areas of 1-1.5 meters.

- So that the solution does not freeze quickly, it is periodically stirred in the process.

- After about 2 days, the walls or ceiling are polished, removing excess material, and then primed.

- If the paint has not been added to the composition of the plaster, then after drying the surface, you can proceed to painting.

- After the paint dries, the base is leveled, then varnished.

It should be noted that the mixture should be applied very carefully. At the slightest wrong movement, the drawing will be blurred.

The special attention is deserved by furnish of external facades. It is not allowed to take breaks in work for more than 4-5 hours.. Otherwise, the appearance of the surface will be uneven. Therefore, repairs are made with the involvement of the brigade. Also used mechanized means of applying the mixture, which significantly reduces the repair time.

The end result depends largely on the technique of applying the plaster. It can be direct movements in horizontal, vertical, circular rubbing. The more perfect the technique, the better the result will be.

For how to apply bark beetle, see the video below.

Care Tips

Walls, finished with plaster "Bark-eater", do not require special care. They are sufficient to keep clean, doing wet cleaning. However, to get the desired result, resistant to various influences, it is necessary to follow the rules for applying the material.

The coloring process deserves special attention. Any flaws in the future will lead to loss of quality or appearance of the surface.

Before you start applying paint, you need to make sure that the walls are dry, smooth, clean. If necessary, they are leveled with grouting tools. If staining is carried out on the street, then it is better to choose dry, calm weather.. You also need to ensure that the direct rays do not fall on the drying paint. If the staining is carried out in several stages, it is necessary to withstand the time between stages.

The surface is coated with varnish after the paint has dried.Moreover, if the process is performed on the street, it is necessary to choose the appropriate weather, also to provide maximum protection from negative external influences.

The process of staining is started no earlier than 2-3 days after applying the plaster. The exact dates are specified in the instructions on the packaging of the textured mixture. It also indicates the types of paint that will be ideally combined with the composition of the mixture.

Compliance with the rules of applying the material will save time, money, and get the desired quality for many years.

Manufacturers and reviews

On the market there is a huge number of foreign, domestic producers, producing a variety of composition and characteristics of the mixture.

The most common marks used for exterior finishes include:

- Ceresit CT 175 . Silicone resin based mortar. According to reviews, it looks very beautiful on the wall, but requires special skills when applied. Possesses good adhesion, resistance to frosts, durability.

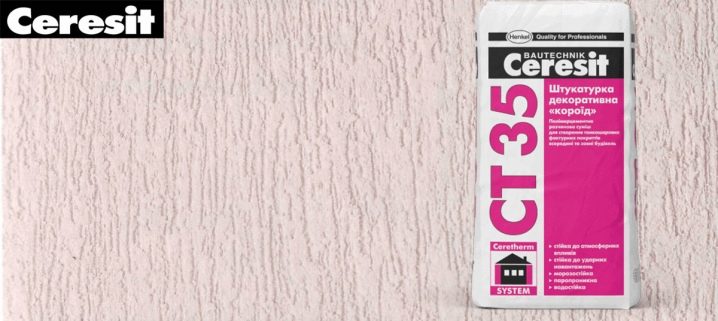

- Ceresit CT 35. Mix on the basis of cement, minerals are used as additional substances. Plaster is easy to apply, has wear resistance.It has a relatively low cost.

- Unis “Coarse-grained“ Bark Beetle ”. Mix on the basis of cement, flour with a marble filler. The material is quite durable, does not scratch, is resistant to temperature changes, moisture-proof, but does not tolerate exposure to sunlight during drying.

- "Bergauf Dekor". Dry mix based on cement, marble flour, mineral filler, additional modifying components. According to the reviews, this finishing material tolerates frost well, humidity, easy to apply.

The brands for interior finish include:

- Ceresit CT 64. Ready solution based on acrylic with mineral fillers, pigments. Requires special skills when applied. Possesses good adhesion, pleasant appearance. The base must be perfectly level. It has poor thermal insulation, is quickly consumed, it is not cheap.

- Knauf "Diamond Bark Bark of 1,5 mm". Dry mix based on cement with the addition of mineral granules. According to reviews, the material is easy to apply, has durability, plasticity, good quality. However, there are reviews that the material crumbles after drying.

- Osnovit Exterwell "Bark Beetle 2 mm". Mix on the basis of cement with addition of mineral grains. According to reviews, has durability, is inexpensive, is applied easily. There are also reviews that the material crumbles after drying.

- "Miners" - dry mix based on gypsum. Easy to apply, inexpensive. The surface with him "breathes." After application requires putty. Among the negative points distinguish quick drying of the composition. In general, among the advantages of “Bark-eating” plaster, users distinguish beautiful appearance, resistance to moisture, temperature extremes, long service life, ease of operation, the ability to apply paint several times.

Among the negative aspects are the accumulation of dust, dirt particles in the grooves, cracking, crumbling of the material, the complexity of the application, cost. Many people associate negative consequences with the use of incorrect technology during application, a combination of materials from different manufacturers.

Thus, when choosing a plaster you should not be guided by the brand’s fame, advertising or price. An important criterion is the constituent components that will best match the desired result.

Beautiful examples in the interior

Original ideas allow you to create in the room a unique image, comfort, beauty. The photo shows examples of creating a warm cozy homely atmosphere with the help of plaster "Bark".

- Interesting design of the kitchen with the use of textured finishes.

- The harmonious combination of different colors with openwork ornament creates an atmosphere of warmth and mystery.

- Making a bedroom in a modern style with the use of decorative plaster creates an atmosphere of mystery and tranquility.

- The possibility of applying plaster to finish one wall.

- The unusual pattern is striking in its originality, scale. Making facades with textured plaster transforms the building, making it neat, modern.