Plastering bucket: types of structures and their advantages

Almost all the finishing work involves the alignment of the walls using different types of plaster. It is not always convenient to apply the solution with a conventional trowel, as it is difficult for it to evenly distribute the composition over the surface. A universal solution here is the use of a plastering bucket.

Basic concepts

Plastering bucket is an auxiliary device that is intended for applying a liquid solution to the surface of a wall or floor. They are often used when plastering vertical surfaces.

Such a construction consists of several main parts:

- Metal bowl. Capacity can vary in different sizes.Make a bowl of durable steel sheet, which give a different shape.

- A pen. Attach it directly to the frame in order to simplify the work. Many simple handles are made on the basis of wood, as it has a small weight.

It should be noted the shape of the bucket, which may vary depending on the environment of application and method of applying the solution.

It is much easier to work with such a tool than with a trowel, on the surface of which the solution can part.

Kinds

Construction buckets appeared a long time ago, and were simple and practical. After the time, the products remained virtually unchanged: manufacturers only slightly improved the shape of the bowl.

Depending on the method of application, these products can be divided into 2 main types:

- Hand held These are the usual homemade bowls with a wooden handle. You can make them yourself from a thin sheet of metal. Tools are used by craftsmen for small amounts of work, where there is no need to achieve high accuracy of application.

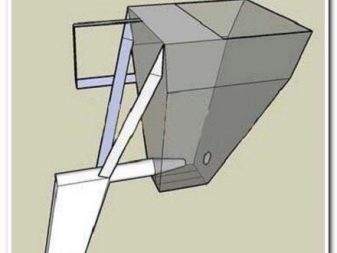

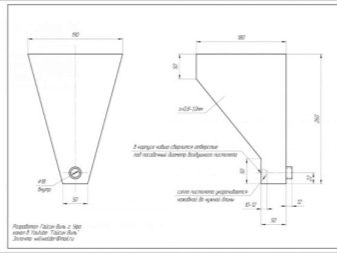

- Hopper. This is a pneumatic bucket that allows the solution to be applied at a higher speed. Outwardly, it resembles a bowl with high sides.At the bottom of the tank there are openings through which the mixture is brought out. There may be several of them, and they are complemented by special guide tubes.

The solution is supplied by compressed air.

To simplify the work of designers can change the location of the handle. This allows you to work with surfaces located in different planes. Some modifications can be equipped with rotating heads. This allows you to change the direction of work depending on the location of the wall.

Hopper principle

On this type of pnevmokovsha should stay in more detail. Its use allows you to speed up the plastering several times.

The principle of operation of pneumatic tillers for the application of the solution can be described by the following algorithm:

- A certain amount of the prepared mixture is poured into the bowl. It should be noted that the quality of the application depends on the consistency of the solution. It should not be too thick or too liquid. The density of the mixture is determined visually.

- After filling with the solution, the compressor is connected to the bucket. Management is carried out using a special lever.The air at the exit enters the solution and pushes it through the lower opening, after which the mixture sticks to the wall.

Drawing is carried out consistently thin layers. It is better to implement several approaches, as this will allow you to get the desired bundle of mixture with a base. It should be noted that modern automatic buckets are versatile.

In addition to plaster with their help you can apply the following compounds:

- sandy solutions;

- embossed paint;

- cork solutions.

One of the technical parameters of the hopper is the angle at which the system can distribute the plaster. This value in most devices varies from 30 to 90 degrees. The smaller the angle, the smaller the area covered by the mixture at the exit.

Therefore, when choosing a device, you should take into account how much work is needed at the moment.

Advantages and disadvantages

Plastering buckets today are quite common and are used by many professional builders.

These universal devices have a number of undeniable advantages:

- Easy operation. Everyone can use a manual or pneumatic bucket, even without a construction experience.

- Increase productivity.Achieved by the possibility of quickly applying the desired volume of the mixture on the wall. It should be noted that hand buckets do not give such a large increase as automated systems.

- Uniform distribution. With the help of such shovels can be applied a relatively even layer of plaster, which will only need to trim the rule. But this does not mean that using a bucket it is impossible to get a flat plane.

- The formation of thin layers. This advantage applies to pneumatic buckets. With their help, the solution adheres very well to the surface. This allows you to more evenly distribute it, causing the mixture to a thickness of 1 cm.

- Low cost. Models are available to almost everyone. But if you plan to use a pneumatic bucket, then you will need to additionally stock up on a compressor of a certain capacity.

- Durability. This is due to the fact that the shovel does not contain moving parts and mechanisms. If you properly care for her, then you can use it for several years.

The bucket has almost no drawbacks - it copes well with the task.One of the drawbacks can be considered the use of low-quality metal for its production, which will quickly corrode and lose strength.

We make by ourselves

Construction ladles have a relatively simple form that allows you to recreate it at home.

Manufacturing technology of this device consists of several successive operations:

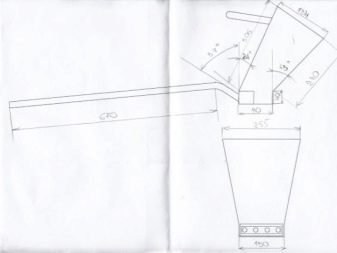

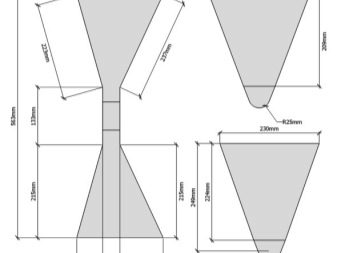

- Initially, you should find a suitable drawing or an approximate drawing with a sketch of the desired shape. If the design involves the use of a compressor, then it is necessary to make it look like a rectangular bowl without a top lid.

- From two sheets cut blanks for the bowl. One part will act as the bottom, and the other should be formed bumpers. To do this, bend the sheet at a right angle or roll it up in the shape of a cylinder.

- The connection of elements. The simplest way to make a bowl is to weld the obtained blanks. But this option is not always suitable for steel. Therefore, the use of bolted joints is a universal method.

- Cutting holes. At the end you need to drill two holes,which will be used to connect the compressor and exit the solution. Small guide tubes should be welded to them.

Technology use

Applying plaster with a ladle is not a difficult process.

Carrying out this procedure, you should follow a few simple rules:

- Before plastering the surface of the walls should be carefully prepared. Depending on the solution used, the base is primed with a certain composition. If the walls are severely curved or have many cracks, they must be leveled or reinforced.

- Apply the solution with a hopper at a distance not exceeding 15 cm from the wall. If you need to control the thickness of the layer, then this value is reduced to 2-5 cm. Note that the farther the pneumatic head is, the more bubbles will form in the structure. In order to remove voids, the surface will need to be leveled more carefully.

- If a regular bucket is used, then the mortar must be thrown over the walls. At the same time, one should try to make the movement of the hand resemble a fan. This will distribute the solution more evenly.

- Put the solution in several layers until it protrudes over the previously installed beacons. Use only high-quality plaster, which, according to experts, is well kept on a certain material.

Plastering buckets are simple fixtures that can make wall decoration much easier and of higher quality. The simplicity of the application lies in performing simple and smooth movements, allowing the mixture to be evenly distributed over the surface. This greatly simplifies the finishing work and allows you to make repairs yourself.

See below for a video review on plastering bucket.