Improved plaster: what is it and what are the requirements for the composition?

Today, plaster is one of the most popular materials in the field of repair and construction works. Unlike many options, these formulations are affordable and easy to work with. Particular attention should be paid to such a form as improved plaster. The peculiarity of this option from the standard mixture is the presence of additional components that provide high performance properties of the material.

What it is?

Improved plaster - not a special type of finish with advanced substances that are part of this mixture. At the heart of the material there are standard components, without the presence of modifiers.It is only an intermediate option in the classification of putties: it occupies the standard position between a simple and high-quality mixture. The difference between all types of coverage is determined by regulatory documents - SNiP and GOST.

Simple - it is used most often for the decoration of non-residential premises, when there are no increased requirements for smoothness and leveling of the wall surface. It is envisaged to apply only 2 layers - spray, primer.

Improved - used as interior decoration of residential buildings, when the walls must be made extremely flat or on the treated surface a finishing coating or lining will be applied - tiles, mosaics, etc. The coating is carried out in three layers: spray, soil and covering.

High quality - plaster implies, in addition to three layers, the application of another additional primer. Thus, perfect surface smoothness of the walls is achieved.

And yet, in comparison with many other finishes, the putty has a high mechanical stability. On surfaces treated with improved plaster, microcracks rarely appear.In addition, the material provides high moisture resistance to the walls, which allows it to be used in different rooms.

In addition, PVC glue is often used as part of the improved plasters, which acts as an additional binding component. Versatility lies in fire resistance. Even with direct thermal exposure, the surface retains its original structure.

Features and requirements for composition

Before you get acquainted with the composition of the improved plaster, it is necessary to understand what are the differences of this option from other types of finishes.

In this case, you need to pay attention to the following features:

- after processing by the improved plaster, the covering becomes equal and smooth;

- to achieve the desired result requires a small layer of material - up to 1.5 cm;

- with improved plaster finishing work is much faster than with simple.

It should be noted that immediately after applying this putty, the surface can be painted or pasted over with wallpaper. Additional manipulations are not required, since plaster significantly improves the properties of the coating.

Please note that when working with these compositions can, but not necessarily, use beacons. In this case, the thickness of the elements must fully comply with the finish layer, otherwise the application technology will be broken.

It is worth paying attention to the fact that the thickness of the layers must comply with SNIP. According to its provisions:

Splashing:

- for brick and reinforced concrete - up to 0.5 cm;

- for wooden walls, taking into account shingles or metal mesh - 0.9 cm.

Designed to prepare the surface and increase adhesion before applying subsequent layers, so the wall is pre-cleaned, dust is removed. The mixture is prepared in the consistency of liquid sour cream. Then all cracks and depressions deeper than 5 mm are filled. Concrete-contact must be applied on concrete walls at this stage.

Soil for each layer:

- for heavy cement mortars (for rooms with high humidity levels) - 5 mm;

- for lightweight - gypsum, lime (for dry premises) - 7 mm;

- thickness of all layers (up to 3 is allowed) - no more than 10-15 mm.

This coating should complete surface leveling. Apply a rather thick solution - to the consistency of the test.Each subsequent layer of primer is applied after complete drying of the previous one.

Cover - no more than 2 mm:

Decorative plaster may be used for this layer. It is applied on the already dried, but not completely previous layer of soil. Dried soil moistened to increase grip.

The thickness of all layers of the improved plaster should not exceed the value - 20 mm. Particular attention should be paid to the quality requirements of these plasters. The composition used for spraying and priming should pass through a mesh with cells up to 3 mm in diameter. As for the coating solution, this refers to openings with a size of up to 1.5 mm.

In the sand, which is used for the preparation of the composition, must be present grains. The allowable size of each particle for splashing and ground is 2.5 mm. In the case of finishing, the indicator should not exceed 1.25 mm.

Application area

Improved plaster is used for both living rooms and public spaces, increasing the protective properties of surfaces. The composition provides a high degree of adhesion to various surfaces and finishing materials.

The advantage of improved plaster is that it fits:

- for brick, concrete, wooden and mixed bases, consisting of different materials;

- for decoration of walls, window openings, facing cornices and columns;

- as a leveling layer for ceilings in rooms for various purposes.

Application technology

The technological process is not particularly difficult if you follow the sequence of steps. First you need to do the preparation of the base. Dust and impurities are removed from the surface so that no further adhesion difficulties arise. After that, it is necessary to eliminate minor defects and cracks.

Many experts recommend the use of penetrating primer. The treatment of the wall should be carried out before plastering, which will increase the adhesion of the surface with different compositions. It should be noted that it is necessary to proceed to the next steps only after the surface has completely dried.

Then you need to do the blending of the lining components. As ingredients take hydrated lime and sand base. Their ratio with water should be 1: 1.5.

Professionals recommend using another common method. Sand, cement and water should be prepared for the mortar. PVA glue is used as a binding component. In this case, all the ingredients separately will cost much less than the ready-made solution.

For mixing, you need a container into which water is poured in - 20 liters. About 200 g of the adhesive component is used for such a volume of liquid; if necessary, the proportions can be changed. Then, all components are mixed, gradually pouring sand and cement into the container. The mixture must be thoroughly kneaded to obtain the composition of the desired consistency.

Thanks to the use of this method, it is possible to do a layer of plaster more. Allowable thickness - 80 mm. In this case, the application can be performed without the device frame, which greatly facilitates the work. Also, this will avoid the occurrence of irregularities.

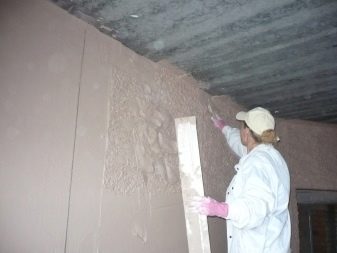

The next step is to spray with a weak solution. This period of work is one of the most important, because this is how the surface is prepared for priming.Due to the liquid consistency of the composition, it is possible to quickly and easily fill all defects on the wall. Processing ensures maximum flatness.

The next step is applying the primer. To work you need a trowel, which in the process have an angle of 150 degrees. Initially, the application is performed by lateral movements, and then - from the bottom up. The average thickness of the soil ranges from 12-20 mm. The rule is used to determine flatness. To eliminate defects, a solution is applied without fail.

The final stage - nakryvka. This layer is applied in accordance with a special technology. In the process it is necessary not only to level, but also to wipe the surface. Basically, a special pnevmokovsh is used to cover this layer.

The soil that has already dried out must be moistened with a small amount of water. Using a brush, a covering is performed in several layers. After drying, it is rubbed with a wooden trowel, tightly pressing the tool to the surface. First, perform circular movements, then - horizontal and vertical.

Such work is complex, especially if the processing of the plastered layer is done on the grid. Making a cover requires certain skills and a lot of experience.If you are using a ready-made solution, you should strictly follow the manufacturer’s instructions.

Tips and tricks

If you are working with improved plaster for the first time, it is advisable to take advantage of several helpful recommendations by professional craftsmen. For example, during the preparation of the solution, gypsum can be used instead of cement. Also, some PVA glue - 100 g is added to the composition. Due to this, the strength and quality of the finishing layer is improved.

When spraying, pay special attention to irregularities. After careful processing, you get a reliable coating without small cracks, which often complicate further processes.

To determine the evenness of the soil after application, the rule should be applied horizontally to the wall. Then the tool is used vertically and diagonally.

On the requirements for the composition of the improved plaster, see the following video.