Volma Plasters: Varieties and Characteristics

Before starting plastering walls, you must choose a finishing material. What is a cement plaster mix for the walls of Volma and what is its consumption per 1 m2 with a layer thickness of 1 cm, and also reviews of buyers and builders about this plaster in one article.

No major repairs in the apartment can not do without leveling the walls. Excellent and very popular today finishing material for these purposes is the Volma plaster.

The company "Volma" produces high-quality building finishing materials, among which a special place is occupied by plaster. Due to its characteristics and properties, plaster is superior to many materials.this category.

Special features

Stucco "Volma" is used to align the walls inside the premises. The main feature of the finishing material is its versatility.

Its composition and properties include application to many types of surfaces:

- Concrete walls.

- Plasterboard partitions.

- Cement-lime surface.

- Aerated concrete cover

- Foam concrete coatings.

- Chipboard surface.

- Brick walls.

As a basis, plaster is used for wallpaper, for ceramic tiles, for various types of wall decorations, as well as for painting and plastering.

This finishing material has its advantages:

- Simplicity of application due to increased plasticity of the material.

- Lack of shrinkage even at thick layer of drawing.

- High adhesion.

- When drying, the treated surface becomes glossy, so there is no need to use a finishing putty.

- The composition is natural and not harmful to health.

- It is applied to the walls without prior preparation, it is enough just to degrease the surface.

- Pass air, not allowing bacteria to accumulate, and controls the humidity of the room.

- Does not crack and does not exfoliate, even after a time.

There are drawbacks to the plaster, but insignificant:

- The price segment of the material is above average when compared with the goods of this category.

- Sometimes there are large elements in the mixture which, when applied, can spoil the appearance of the surface.

To choose the right finishing material, you need to know its technical characteristics:

- The drying time of Volma plaster is 5-7 days.

- The initial setting time is forty minutes after application.

- The final hardening of the applied solution occurs after three hours.

- The ideal thickness of the reservoir is 3 cm, if more is needed, the process is divided into several stages.

- The maximum thickness of the reservoir is 6 cm.

- On average, one kilogram of dry mix requires 0.6 liters of liquid.

- Plaster consumption with a minimum thickness of the layer is 1 kg per 1 m2, that is, if the layer thickness is 1 mm, then 1 kg per m2 is needed, if it is 5 mm thick, then 5 kg per m2.

As part of all Volma plasters, there are only environmentally friendly ingredients, including mineral components, chemicals and binding elements.The plaster is white and gray.

The assortment of Volma mixtures contains solutions for mechanized plaster, machine plaster, as well as solutions for hand plastering walls.

When buying mixtures for plastering of walls, one should pay attention to the shelf life of the material, get feedback from experts. And before you start working with the mixture, you must read the description on the package.

Kinds

Volma plaster is popular both among builders and among people who make repairs themselves. Mix for plastering surfaces is represented by different types and different packaging.

First of all, it is divided into two types:

- Gypsum mix.

- A mixture of cement.

For convenience and in order to avoid extra costs during repair work on finishing materials, the manufacturer produces mixtures in packages of 5, 15, 25, and 30 kg each. The mixture is designed for walls and ceilings.

The line of finishing materials includes mixtures for hand and machine application. It is necessary to use a finishing material at a given temperature regime (from +5 to +30 degrees) and at a humidity level not lower than 5%.

In the arsenal of manufacturers there are different types of mixtures, differing by purpose and method of use:

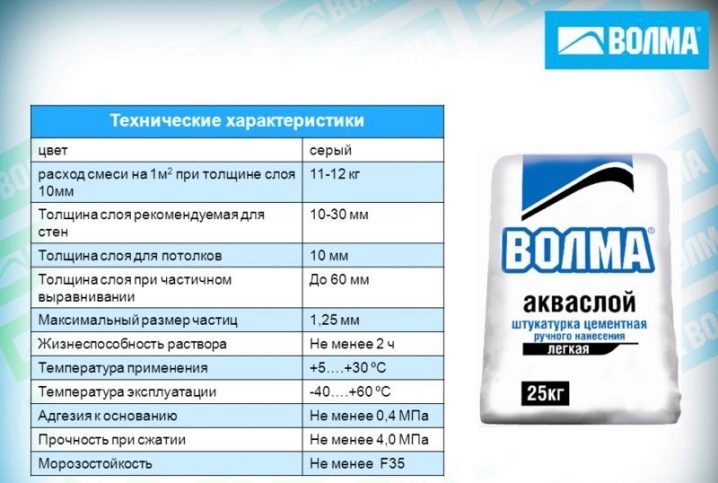

- Volma-Aquasloy. This is a plaster mixture that is applied to the surface only by machine. Its composition contains light modified aggregates, mineral and synthetic additives, as well as portland cement - this gives the mixture good physical characteristics. It is used to align the walls inside and outside the premises. Suitable for plastering surfaces in rooms with high humidity.

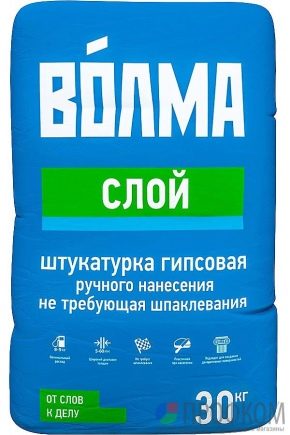

- Volma-Layer. Suitable for manual plastering of walls and ceilings. There is a variation of this mixture - Volma-Layer MN, which is used for machine plaster, and can also be found in stores Volma-Layer Ultra, Volma-Layer Titan.

- Volma Plast. The basis of the mixture - gypsum. It is used as a base when there is a finishing covering of the walls, i.e. finishing plaster, and it can also be a finishing material (decorative finish). Due to its composition, this mixture has a high plasticity and a long setting period. Most often used before sticking wallpaper or laying tiles.The mixture is white, rarely found in pink and green tones.

- Volma-Decor. It has a characteristic distinctive feature - with a certain method of application it can take various forms. Forms an excellent decorative layer.

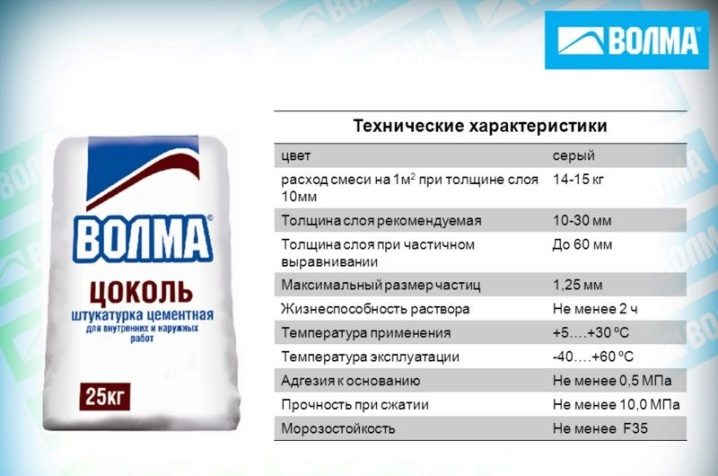

- Volma-Plinth. This is a dry mix based on cement. It has a unique composition that allows widespread use: it aligns the foundation, eliminates all surface errors, is used as a decor for walls. It has an increased level of strength, high protective degree, as well as it is moisture resistant and very durable. There is a form used for outdoor work.

In addition to all the above types, there is a “Volma-Gross” on the basis of gypsum, “Volma-Lux” - a gypsum for aerated concrete surfaces, “Volma-Akvaluks” on the basis of cement, universal.

Consumption

The consumption of this finishing material depends on some factors:

- From the degree of curvature of the surface.

- From the thickness of the layer to be applied.

- From the type of plaster.

If we talk about each separately taken form of Volma plaster, in order to understand the consumption of material, you need to look at the instructions for use.

More accurate calculations will help make a construction online calculator, which can be found on the Internet. In order for the calculations to be accurate, it is necessary to know the area of the room in which the plastering will be done, to understand what thickness the plaster will be applied to, what mixture (cement or plaster) will be used, and packaging the mixture.

For example, the length of the wall is 5 meters, the height is 3 meters, the layer thickness is assumed to be 30 mm, the gypsum mix will be used, which is realized in bags of 30 kg each. Enter all the data in the table of the calculator and get the result. So, for plastering you need 13.5 bags of the mixture.

Examples of consumption for some grades of Volma plaster mix:

- A mixture of "Volma-Layer". 1 m2 will need from 8 to 9 kg of dry material. The recommended layer of application is from 0.5 cm to 3 cm. Each kilogram of dry material is diluted with 0.6 l of liquid.

- A mixture of "Volma-Plast". One square meter will require 10 kg of dry mix with a thickness of 1 cm. The ideal layer thickness is from 0.5 cm to 3 cm. 0.4 l of water will be required per kilogram of dry solution.

- A mixture of "Volma-Canvas". For plaster 1 m2, you will need from 9 to 10 kg of dry solution with a coating of 1 cm. The recommended layer of plaster is 0.5 cm - 3 cm. To prepare a solution for each kilogram you need 0.65 l of liquid.

- A mixture of "Volma-Standard." Per kilogram of dry mix you need to take 0.45 liters of liquid. The recommended layer of plaster application is from 1 mm to 3 mm. Material consumption at a layer thickness of 1 mm is 1 kg.

- A mixture of "Volma-Plinth". 1 kg of dry solution is diluted with 200 g of water. When the thickness of the plaster is 1 cm, 15 kg of the dry mixture per 1 m2 will be needed. The recommended thickness of the layer is a maximum of 3 cm.

- Mix "Volma-Decor". To prepare 1 kg of finished plaster, you need half a liter of water + 1 kg of dry mix. With a thickness of 2 mm, 2 kg of plaster per square meter will be needed.

How to apply?

Apply plaster to the right, otherwise all efforts can be spoiled, and therefore time and money.

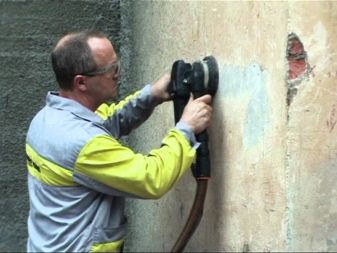

Before plastering all surfaces must first prepare:

- Clean up from any kind of blockages and greasy, oily stains.

- Remove peeling surface areas, cleaned with a construction tool.

- Dry the surface.

- If metal parts are present on the wall, they should be treated with anti-corrosion substances.

- To prevent the appearance of fungus and mold, you need to pre-treat the walls with an antiseptic.

- Walls should not be frozen.

- If the surface and the appearance of the plaster require it, then the walls need to be primed before plastering.

To prepare the solution, the right amount of water is poured into the plastic container, preferably at room temperature, or even slightly warmer, then the dry mixture is added. Everything is thoroughly mixed using a construction mixer or other device. The solution should have a homogeneous mass without lumps, resembling thick sour cream.

A few minutes the solution should stand. Then again whipped until complete elimination of small lumps. If the prepared mixture spreads, it means it is not prepared according to the rules.

You need to dilute exactly the amount of solution that will be used at a time, otherwise the residue will have to be thrown away.

Apply plaster to the surface with a trowel taking into account the required thickness of the reservoir. Then the surface is smoothed by the rule.After the final drying of the first layer of plaster, you can begin to apply another layer. When he grabbed and dried, he pruned the rule. After 20-25 minutes after pruning, the plastered surface is moistened with water and finally smoothed with a wide trowel. Thus, the walls are ready for wallpapering.

If we are talking about further painting the walls, then another manipulation is needed - in three hours the plastered walls are again sprayed with abundant liquid and smoothed down with the same spatula or tough float. The result is a perfectly smooth and glossy wall. The drying time of each solution is different. Some solution dries faster, and some slower. All detailed information can be found on the packaging. The time for complete drying of surfaces is one week.

If there is decoration on the plaster, then additional construction tools (roller, trowel, brush, sponge grater) will be needed for the pattern or pattern.

Recommendations for use

To plastering the walls was successful, you must not only follow all the rules, but also listen to the advice and recommendations of the masters:

- The finished solution dries out within 20 minutes, so you need to prepare it in small portions.

- Do not use gypsum plaster in rooms with high humidity; this may cause swelling or peeling of the mortar.

- A poorly cleaned surface significantly reduces the degree of adhesion of the solution.

- Before you glue the wallpaper or paint plastered walls, make sure that they are completely dry.

In the next video you will see a master class on the application of gypsum plaster "Volma-Layer".