Types and installation of siphons for shower

In the design of the shower siphon plays a kind of intermediate role. It provides the redirection of used water from the pan to the sewer. And also its function is to provide a hydraulic shutter (better known as a water block), which cannot always be detected due to the presence of membrane analogues protecting the apartment from the penetration of air with a fetid odor from the sewer system. The air from the effluent can be dangerous to the respiratory system and human health, as it has toxicity.

Standard siphon construction consists of two elements - it is a drain and overflow, which is also not always present. The modern market offers consumers a wide variety and choice of the most different siphons, different in design, method of operation and size.

Species

Based on the mechanism of action, all siphons are classified into three main groups.

- Ordinary - The standard and most common option with which most consumers are familiar. The scheme of an ordinary siphon is as follows: when the plug is closed, water collects in the tank; when you open the stub water goes into the drain sewer. Accordingly, it is necessary to manage such units completely manually. These siphons are considered completely outdated, although the cheapest, budget. Therefore, more often they prefer the more modern models with an improved mechanism.

- Automatic - such models are mainly designed for high pallets. In this design there is a special handle for control, thanks to which the user independently opens and closes the drain hole.

- With Click & Clack design - is the most modern and convenient option. Instead of a pen, here is a button that is located at the foot level. Therefore, if necessary, the owner can open or close the drain by pressing.

When choosing a siphon, first of all it is necessary to focus on the space under the pallet, because it is there that the structure will be installed later.

Models reaching 8–20 cm are more common, so a low siphon is required for low containers.

Designs and sizes

In addition to the fact that they differ in the mechanism of action, siphons are also subdivided by constructional execution.

- Bottle - almost anybody met such a design in their home in the bathroom or in the kitchen. Proceeding from the name, it is clear that such a design is similar in appearance to a bottle or flask. One end is connected to the drain with a filter grate in the pan, the other - to the sewer pipe. In this bottle, all the garbage falling into the drainage accumulates and accumulates before it is disposed of in the sewer system. But also its function includes provision of a water seal system. It is created due to the fact that the siphon goes somewhat higher than the edge of the inlet pipe.

In total there are two types: the first is with a tube submerged in water, the second is with two interconnected chambers divided by a partition. Despite the slight structural difference, both types are equally effective. In general, this type of construction is impressive in size, which makes it practically impossible to use them together with shower cabins with a low basement (a special podium will help here).They are convenient only in that it is very easy to clean them from the dirt that has accumulated inside; to do this, simply unscrew the side cover or through a special hole from the bottom.

- Classic Trumpet - are also quite common models that visually look like a tube bent in the shape of the letter “U” or “S”. The hydraulic lock is located in the natural tube bend segment. The design is reliable and highly resistant due to its rigidity. This type, due to the smooth walls, badly incandescent dirt and therefore does not need frequent cleaning. You can buy models of different sizes that are difficult to use with low pallets.

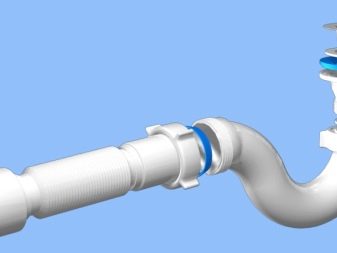

- Corrugated - this option is the most convenient if the space in the room is limited, since the corrugation can be given any desired position, which also simplifies the installation process. Accordingly, the hydraulic valve is formed at the bend, but the water must cover the opening of the pipe completely for the hydraulic lock to function properly. The disadvantage of a corrugated pipe is its fragility and the rapid accumulation of dirt in the folds, which requires frequent preventive cleaning.

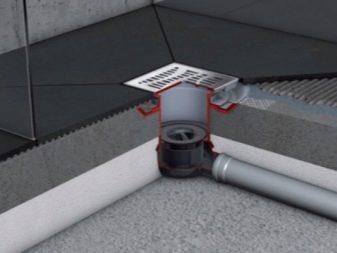

- Ladder drain - characterized by simplicity of design and installation. Designed for cabins with low pallet, no plugs and inputs for overflow. The height of the drain reaches 80 mm.

- "Dry" - this design was developed with the lowest possible height, while the manufacturers abandoned the classic hydraulic lock and replaced it with a silicone membrane, which, when straightened, allows water to pass through, and then takes its original state and does not release harmful sewage gases. Visually, it looks like a tightly folded polymer tube. The advantage of a dry siphon is that it functions perfectly at low temperatures and underfloor heating system (it causes drying of the water seal). It will fit in size even for the lowest pallet. However, such fittings are the most expensive, and in case of clogging or breakage of the membrane, the repair will be expensive.

- With overflow - its installation is carried out only if it is provided for in the construction of the pallet, in this case, an appropriate siphon will be needed. It differs in that an additional pipe passes between the siphon and the overflow, however, the reinforcement can be any of the above.Usually made of corrugated pipe, to change if necessary, the location of the overflow. The presence of overflow allows you to use the tray at the appropriate depth for washing things or as a bath for a small child.

- With a special basketwhich can be extracted. Cells in such a grid are larger than those in self-cleaning siphons.

- Ladders, equipped with grill and plug, locking the drain hole.

Paying attention to the most common type of pallets, namely low, corrugation is perfect for it, and even better - a drain.

The drain ladder is inserted as an ordinary siphon into the drain hole or poured directly into the base of concrete (in the concrete screed), which performs the function of a pallet. It is worth considering that the lower the height of the ladder, the more effectively it performs its function.

Criterias of choice

The principle of operation and design are not the only criteria for selecting a siphon. Its technical characteristics are important, and especially its diameter.

To plumbing served for a long time and efficiently perform all their work, the choice should take into account the necessary characteristics.

- The first thing to consider is the space between the pallet and the floor. This is the main and decisive criterion, all subsequent features are taken into account in the next turn.

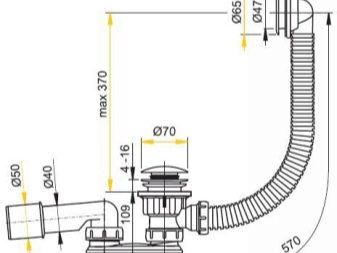

- The diameter value of the drain hole. Standardly pallets have indicators of diameter of 5.2 cm, 6.2 cm and 9 cm. Therefore, before buying, it is necessary to know for sure the diameter of the drain hole, measuring it. If the siphon for connecting to the sewage system already goes along with the shower cabin and is fully suitable in all respects, then it is better to use it.

- Bandwidth. This will determine the speed at which the tank will be emptied of used water, how quickly the structure will clog, and how often it will have to be cleaned. The average throughput at the shower stalls is 30 l / min, a greater flow of water can only be if there are additional functions, for example, hydromassage. The throughput rate is determined by measuring the water layer above the drain surface. In order to fully remove water, the level of the water layer should be: for a diameter of 5.2 and 6.2 cm - 12 cm, for a diameter of 9 cm - 15 cm.Therefore, for low pallets, siphons of smaller diameters (50 mm) are used, and for high, respectively, larger sizes. In any case, the instructions for the shower should indicate the recommended throughput, which must be considered when choosing a siphon.

- The presence of additional elements. Even the highest quality and functional siphons clog from time to time. In order not to have to completely disassemble and dismantle the system in the future, the protection of the drain must be considered in advance. From the moment of purchase, it is better to give preference to self-cleaning models or products with a grid to stop small-sized garbage, which will not allow the drain to clog quickly. Important: in no case can not clean the clogging with compressed air, this can lead to depressurization of connections and the occurrence of leaks. An interesting fact is that the fewer connections a structure has, the stronger it is, and less chance of its depressurization.

Installation

Despite some differences, all shower siphons have the same installation order. Only additional elements join in different ways, for example, handles for “dry” siphons, a button for Click & Clack, and so on.However, it is best to clarify in advance the order in which the installation is carried out directly from the manufacturer, since different brands may have their own characteristics.

Before we begin, let us familiarize with the siphon construction components.

- Housing Fastened with threaded studs of a resistant corrosion-resistant alloy, they can be from two to four pieces. The case itself is made mostly of polymers, and the rest of the stuffing is placed inside it.

- Sealing gum. The first set between the surface of the pallet and the housing, the second - between the grill and the pallet. When buying it is important to look at the surface of the gum. Foreign manufacturers produce ribbed gaskets, and this significantly increases the level of reliability of sealing, with a decrease in the tightening force. The latter provides a longer service life. In contrast to this, domestic manufacturers produce absolutely flat gaskets, which, on the contrary, adversely affects the service life.

- Nozzle This is a short tube that serves to connect the siphon to the external sewer pipe. It can be both straight and angled, with an additional release (fit in length).

- Self-sealing gasket, nuts with washer. They are mounted on the pipe, and the nut is screwed on the outlet threads in the housing.

- Glass of water seal. It is inserted into the housing to stop the sewage air from entering the room and holding large debris. Fixed with metal bolts.

- Safety valve. Protects siphon during work. The valve can be cardboard and plastic.

- Water lock. Equipped with rubber sealing rings, located in a glass.

- Drain grate. It is made from a corrosion-resistant alloy. It is equipped with hooks and fastens on the top surface of a glass. These locks protect the grill from spontaneous detachment during a shower.

Installation is more practical after installation of the pallet on the base.

- We clean the old glue, which was attached facing tiles. At the time of facing works, the bottom row is never completed until the end; it must be installed only after finishing work with the pallet. We carry out the cleaning of the room and remove all the resulting debris.

- The wall next to the pallet is treated with waterproofing material.The treated area in height will be approximately 15 - 20 cm. As a waterproofing, you can use mastic, following all the recommendations of manufacturers. The number of layers depends on the state of the wall.

- We fix on the pallet legs. First, we lay out the cardboard sheets so that the surface is not scratched, and lay the pallet upside down on them. Choose the most suitable location of the legs, given its size and features of the bearing surface. In any case, the legs should not come into contact with the sewer pipe. The legs need to be fixed with self-tapping screws, which should be bundled with the pallet itself. They are already thought out on the calculation of the safety factor. It is not necessary to mount reinforced screws, as they can damage the front side of the pallet.

- We put the pallet with fixed racks on the intended place and adjust the position of the screws located on the legs. Verification of the horizontal line occurs in both directions. Initially, we put the level on a pallet near the wall and adjust the horizontal position. Then set the level perpendicular and re-set the horizontal position. At the end, we return to the pallet and align it.After tightening the lock nuts to prevent self-unscrewing of the thread.

- Insert a simple pencil into the drain hole and draw a circle under it on the floor below it. Draw the lines along the bottom edge of the shelves. We clean the pallet.

- We put a ruler and select the clearer lines. There will be fixed side support elements.

- We attach fixing elements to the marks and mark the location of the dowels. The upper part of the device is located clearly on the line.

- Now we drill fixing compartments for dowels approximately 1 - 2 cm deeper than the length of the plastic nozzle. A spare place is needed so that the settling dust does not prevent the nozzles from entering tightly. Fix the entire structure with dowels.

- We glue waterproofing tape to the corner parts of the pallet, put it on a double-sided tape.

After preparing the base and fixing the pallet, you can install the siphon. Step-by-step instructions for attaching a siphon with your own hands includes a series of sequential operations.

- We unpack the siphon and check the integrity of the configuration, the reliability of the threaded connection.

- We put on the pipe (short pipe) nut and sealing rubber.The resulting insert into the body outlet. In order to avoid damage to the gum, it can be lubricated with technical oil or ordinary soapy water.

- We put the siphon on the circle outlined earlier, measure the length of the tube being connected and cut it. If the pipe and the pipe are angled, then you need to use the knee. Connect the knee. It should be fixed in the direction of the sewer entrance. It is necessary to attach it before checking the leakproofness of the shower stall. We must not forget that every joint must have a rubber seal. Check the slope of the drain pipe, which should not be less than two centimeters per meter.

- Close the pallet to the wall as close as possible and check the stability, the legs should not be loose. Fix the lower edge of the board to the wall. Recheck and level everything up by level.

- We disassemble the siphon and withdraw the drain valve.

- Unscrew the sleeve from the case, take out the cover with the gasket.

- Apply sealant on the edge of the drain.

- We lay the previously removed gasket into the groove, on which the hermetic compound was applied.

- Now apply sealant on the gasket itself.

- The removed cover is attached to the drain hole of the pallet; the thread on the cover should be completely identical to the hole thread. Immediately make a connection and scroll the sleeve on the cover.

- Next, you need to fix the drain. To do this, tighten the connection with an end wrench, and then insert the valve.

- Go to the installation of overflow. As with the installation of the drain, then you need to bookmark the gasket with sealant. Loosen the fastening screw and detach the cover. Combine the overflow cover with the drain hole in the pan. After connection by tightening with a wrench.

- Finally, connect the knee. This is mainly done with the help of corrugations and, if necessary, use the appropriate adapters.

- We check the connection for tightness with water. At this stage it is impossible to hurry, and it is important to check everything carefully for small leaks. Otherwise, minor leaks that are imperceptible to the eye during the operation may cause the fungus to multiply and destroy the facing material.

- Apply another waterproofing material on the wall with an average brush or a small roller; we especially carefully process the joints.

- Without waiting for the complete drying of the mastic, glue the water-repellent film and coat the second layer of mastic. We are waiting for the complete drying of the material, which is on average a day, we specify it on the package.

- We install a decorative lattice on the siphon and check the reliability of fastening.

Siphon is installed and now you can begin to finish the wall tiles, connect faucets, shower, shower and so on.

Cleaning and replacing

No equipment serves forever, and siphons including, no matter how high quality they are. Therefore, you need to know how to change them. First of all, we remove the decorative panel on the bottom of the shower tray, which is most often attached by snap-on clips. We press on the periphery of the panel with a little effort, and they will open.

Now we analyze the old siphon in the reverse order of installation:

- detach the knee from the external sewer pipe;

- unscrew the knee from the pallet with a wrench or washer;

- if overflow is provided, then disconnect it;

- and at the end you need to disassemble the drain in the reverse order of its collection.

For all discharges, except 9 cm, it is necessary to leave a so-called opening for revision, thanks to which it will be possible to clean up the garbage.In 90 mm garbage is disposed of through the drain. Once every six months it is necessary to carry out preventive cleaning, they can be cleaned with the help of special chemicals for pipes.

How to replace the siphon in the shower, see the following video.