Secrets of making a bath frame

To install the bath is often required to prepare a reliable and durable frame. With such strong supports plumbing will last for years and maintain its stability. However, not all owners know how to make the basis for such items.

Special features

Many people are confident that to install the bath does not need unnecessary manipulation, it is quite possible to do with the legs holding the bowl. Of course, in many cases this is true, and the installation of additional frame structures is simply not required.

However, it should be borne in mind that only a heavy and expensive model of cast iron will stand securely and firmly on its legs, because it really does not need a frame.

The stability of such plumbing is ensured by its massiveness and impressive weight.The lighter and more affordable models of steel and acrylic cannot boast with such stability, therefore it is necessary to prepare a frame for their installation.

Very often, frame designs come complete with baths. If there are no such items in the kit, then all the parts must be purchased separately.

For the manufacture of the frame is recommended to use the strongest and durable components of the metal. Do not do without the frame and in the event that there is a desire to tile the bath.

Such design solutions look original and stylish. In this case, the configuration of the plumbing itself does not play any role. With this design, the framework will also need a cast-iron construction.

Not all baths have simple symmetrical shapes. Today in stores sold many original options for non-standard forms. Included with these options are unusual frames, and entire platforms suitable structure. In addition, in such plumbing most often there are wide sides, with which the installation of the model is faster and more convenient.

Without a high-quality and reliable frame, a light and unstable bath will undergo deformation.Because of this, the enamel on the plumbing may begin to crack and exfoliate.

To the product has lost its original appearance, it is necessary to put it on a frame basis. With the installation of the frame under the bath can cope on their own. Such work can not be called difficult. Moreover, the frame can not only be installed, but also made by hand. To do this, you must use only high-quality and durable materials - the platform must be as strong and durable as possible.

Materials

To prepare the frame can be used different materials. The main requirement they must meet is increased durability and wear resistance.

Wooden

For the manufacture of the frame is often used wooden beams. This material is environmentally friendly, lightweight and fairly durable. To work with such raw materials do not need to use expensive professional tools.

Wooden structures are considered the most economical, but no less reliable. However, such options frames have their weaknesses. For example, wood does not tolerate high humidity. In the conditions of a bathroom it cannot be avoided.For this reason, over time, the frame may begin to rot and deteriorate. In addition, mold and fungus can appear on a similar basis. It will be very difficult to get rid of them. So that the base does not become a “dust”, it must be regularly treated with special protective solutions.

Metal

No less popular are the frames of the metal profile. According to experts, the wear resistance of such foundations leaves much to be desired, since iron and aluminum elements are not designed for impressive loads. For this reason, they are recommended to be used only to create auxiliary supports and to further mount a decorative plasterboard with legs.

Profiled pipe, corners

Experts say that the frame structure of the profiled pipe and metal corners - is the most reliable and durable. They can withstand impressive loads, especially if they are of sufficient thickness.

When choosing a material for the manufacture of a frame under the bath, it is necessary to take into account that welding will be required to assemble the metal elements.

All-welded base will make the whole structure more reliable and durable,but it will be much easier for any master to work with a wooden block that does not need to be boiled.

Dimensions

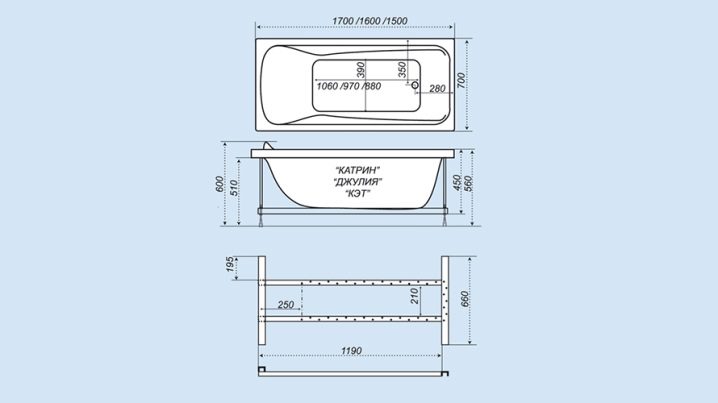

The dimensions of the frame construction are largely dependent on the dimensions of the plumbing. For example, models with dimensions of 170x80, 170x70, 100x70 cm should be installed on the bases with the same dimensional parameters. The dimensions of the bath depend on its shape. For example, the parameters of 170x80 cm are typical for simple rectangular products, 194x100 cm for oval, 130x130 cm for corner ones.

It is imperative to measure all necessary surfaces before designing the framework.

You should try not to be mistaken with the size, if you make the foundation yourself. Otherwise, plumbing will be unstable.

How to do it yourself?

Making the frame - this is an easy job. For the manufacture of wooden construction will need pine bars 40x40 cm, moisture-resistant plywood, edged board with a thickness of 28 mm. Frames of these components are created with a saw on wood, hammer, planer, screwdriver and chisel.

This process involves several steps:

- First you need to make the top trim of the wooden frame. It is necessary that the structure in the future does not stagger and “play” under the weight of the bath.

- It is necessary to set the rack in a vertical position.On the shorter part of the structure there should be at least one support detail, and on the long side - 3–6 racks (it all depends on the dimensions of the bath itself). Fastening the bars between each other should be done with nails and screws.

- You can proceed to the assembly of the upper strapping. It must be fixed to the wall with dowels. It is necessary to arrange the bars so that the sides of the bath rest on it. Structures in which steel fonts are simultaneously supported on 3 wall ceilings are considered the most reliable.

- After that, you can proceed to install the bath.

- To make the frame of metal profiles, you need to put the bath in its main place, remove all measurements, cut off the extra details of the profiles and fasten them together.

- It is necessary to fit the frame under the bath in order to achieve the most snug fit of all the constituent elements. Then you need to weld profiles with each other.

- The metal frame should be made taking into account that the drywall and tile are then located in a single plane.

- At the end of all work it is necessary to close all the joints between the bathroom and the floors with a special sealant or rubber.

Lined bricks can also act as a frame for a bath. They do not need to cook or make complex boxes, as is the case with metal or wooden versions.

- It is necessary to build two pillars of brick. They should be at a distance of 50–60 cm.

- As for the width of the support, it should not exceed the dimensions of the font itself.

- It is advisable to make supports such that they repeat the shape of the bottom of the bath bowl.

- In the place where the drain is located, the support should be lower by a couple of centimeters in order to improve the outflow of water.

- It is necessary to ensure that the sides of the bath are horizontal. No need to achieve bias, because such elements are usually used at the stage of manufacturing plumbing.

- At the end of the bathroom you need to put on the brick foundations as on the legs. To make the construction more reliable, it can be additionally attached to the walls.

- If gaps appear between the brick structures and the bottom of the bath, they should be filled with tile glue or regular foam.

Useful tips

Experts recommend in the manufacture of bath frame to follow a few tips.

- If a metal profile is used for the manufacture of a frame, then it should be further strengthened.To do this, you can use wooden bars, impregnated with antiseptics.

- The support for sanitary ware from a profile pipe also demands welding. This is perhaps the only difficulty that a home wizard may face.

- It is very important to fix the steel frame on the outside. In such cases, the frame is constructed under the screen. This design is simple and can be made without dismantling the font.

- So that the weight from the bath is evenly distributed, you can use not only the legs. A simple brick and plank substrate will also cope with such a task.

- After connecting all communications, it is recommended to hide them behind decorative plinths.

- It should be borne in mind that all-welded structures (both improvised and factory-made) are less reliable than prefabricated ones, since assembling the basis on the bolts with your own hands is the same as making connections that are not inferior in strength to solid metal.

- It is recommended to equip a separate door for access to the drain equipment so that it can be checked and repaired.

- For fasteners it is necessary to use screws, treated with anti-corrosion compound.

- For facing the frame in the bathroom it is necessary to use only moisture-resistant drywall. Ordinary material in such an environment very quickly breaks down.

Successful examples

When facing a bath with a tile, a frame construction is indispensable. Interiors with such elements look very interesting and stylish. For example, a bowl surrounded by a small square tile in blue will look impressive in an ensemble with a blue tiled floor and an adjacent white wall.

It will be interesting and elegant to look at a room in which the bath itself and the walls around it are decorated with a glossy mosaic in sandy brown tones.

You can add a box of tiles not only to the rectangular and square, but also to the rounded model of the font. So, in a cozy bathroom in pale beige tones it will look amazing a large round or oval bathtub, decorated with a small mosaic of green. Such plumbing lining can be backed up with mosaic inserts of the same color on the floors.

On the installation of a reinforced frame for the bath, see the video below.