Mixer "Herringbone"

The “Yolochka” mixer is simple, from the point of view of the device, but rather demanded equipment, despite its relative reliability. Today there is a choice among a large range of double-lever models of different price categories and different designs, suitable for any interior of a bathroom or kitchen.

Types of faucets

A special feature of the “Yolochka” device is the presence of valves on both sides of the crane.

Depending on the type of spout, several sanitary fixtures are distinguished:

- High (arc-shaped) spout provides for a length of 160-250 mm. Such a mixer with a height of 350 mm is more suitable for washing in the kitchen: it allows comfortable use when washing pans, bulk containers. Usually the device is equipped with a swivel crane.

- Shortened spout assumes cranes 75-200 mm long and 90-280 mm high. With a large depth of the sink is better to use a curved spout tap.

- There are mixers direct spout with 2 flywheels and the possibility of turning. Basically they are designed for baths.

- Short spout have devices with a rotary aerator and a grid that protects against splashing water. Their length can vary from 90 to 115 mm, and height - from 70 to 120 mm. As a rule, this type is used for a bidet, and because of the impossibility of placing in standard bathrooms is not particularly popular.

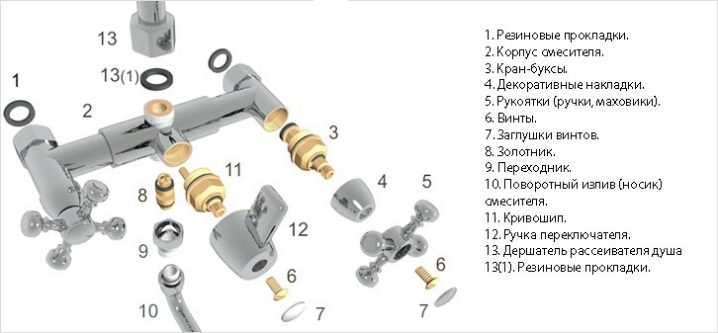

Despite the external difference and design features of some models, the construction of the “Yolochka” mixer remains the same: in the middle there is a faucet and on the sides of the handle (valves) with which the comfort temperature is adjusted.

Two-valve plumbing I and II groups

Modern mixer has two types of devices for mixing water, whose properties depend on the differences in the parameters of the handles. In this regard, the devices have different technical characteristics:

- For double-lever mixers with a worm crane, the locking mechanism is a special sealing gasket. from elastic material with silicone additives.The main principle of operation - reciprocating movement of the crane-axle box. When the valve is closed, this tight fitting part creates tightness conditions and prevents water from leaking out. However, the gasket remains the weak link of such mixers: it quickly wears out and becomes unusable. Foreign counterparts of the “Yolochka” significantly exceed Russian counterparts: the connection of the stem and the gaskets in them is not based on rotation, but on uniform displacement, therefore, the equipment needs to be repaired less often.

- Two-valve devices of group II are equipped with a ceramic shutterconsisting of two plates with holes, one of which is movable. When the handle opens, the water comes out by aligning the holes. This is the most reliable version of the device, so its cost is higher. The advantages include convenient temperature adjustment. In addition, the equipment has a tilt of 180 and 90 degrees, which allows you to quickly (almost instantly) adjust the required flow of water.

Of course, the second type of plumbing is more preferable in its technical and operational properties.However, these two models still lose single lever modifications.

Materials for the manufacture of machinery

When choosing a mixer, it is important to look at what material it is made of, since this directly affects its functionality, appearance, durability, and even safety:

- The most acceptable is brass. The product made of it is durable, reliable, it is not subject to wear, abrasion and erosion. At the same time, this technique belongs to the budget category (costs about 2.5 thousand rubles).

- Bronze plumbing equipment is in second place in terms of its technical characteristics and service life. By the way, the thread on such mixers is made of brass.

- Mixers made of silumin and other light alloys based on beryllium, aluminum, magnesium do not have high strength, so in this case it is not necessary to talk about durability.

- Plastic products are the most unreliable and can last for a very short time. Despite the fact that they are sufficiently resistant to water, many problems are always associated with their use.

- Today, the fashion trend is the purchase of ceramic models.Their main advantage is an attractive appearance. However, in reality this is a fragile technique that often breaks down and fails.

Equally important is the coating applied to metal elements. This is done not only for the aesthetics of model perception.

- Nickel coating provides corrosion protection. It is usually applied to the outer surfaces of the brass parts of the device.

- Chromium prevents the reproduction of pathogenic bacteria, salt deposition, however, the cost of chrome-plated parts is higher.

- Colored enamel gives the product a beautiful appearance, but the strength of this coating does not possess: very quickly cracks and other defects can appear on such a mixer. And all this, despite the fact that such a plumbing is more expensive than other types.

Considering these features of materials, it is possible to choose a truly reliable and durable device.

Pros and cons of the mixer "Elochka"

The device is widely demanded, is used in the kitchen and in the bathroom, if the requirements for the size of the sink. Of course, such popularity is due to certain advantages:

- the equipment is easily installed and dismantled;

- the cost of the product, excluding some models, is available for almost everyone;

- use differs in convenience and simplicity, and it is possible to correct temperature condition by means of one valve;

- such mixers have a rather long service life - at least 10 years;

- machinery is easy to repair, quick replacement of components;

- it is possible to use a ceramic crane box, if this element is from the same manufacturer;

- materials used for manufacturing, are of high strength and reliability;

- The device has a nice appearance and design.

The disadvantages of the product too. First of all, these are gaskets, although other low-quality parts can sometimes be found, but this should be attributed, rather, to defective products that have not been tested for compliance with GOST standards.

During operation, problems arise not only with gaskets, but also with valves, but they, like other elements, must be replaced. Successful and long service of the mixer depends on the following reason - water, or rather, on its quality.

When selecting a mixer, it is important to pay attention not only to the material, but also to the placement options, the type and parameters of washing. In the latter case, it is necessary for the device to be convenient for operation. In general, equipment is considered suitable if it is compact and equipped with a swivel function.

Rules for the installation of plumbing equipment

People who are not versed in the workflow mount, it is wiser to use the services of qualified professionals.

Installation is made in the perforation located in the sink.

The procedure is as follows:

- first you need to turn off the water;

- then the old mixer is disconnected from the water pipes by means of an adjustable wrench;

- install equipment through a collet - threaded sleeve;

- this segment is twisted with a nut, with the result that the device is fixed to the sink;

- further made fasteners to the water pipe.

Unfortunately, afterwards such fastening is loosened, so the nut will have to be tightened periodically.

True, professionals can carry out the installation directly to the conclusions of the water supply, usually after that they are closed with a partition or another structure for masking. As a result, only the faucet and valves are left outside, and the fixtures are hidden in the wall.The downside of this mount is the need to disassemble the wall if the mixer starts to flow.

Therefore, it is recommended to choose for such purposes the highest quality products.

For information on how to install the Yolochka mixer, see the next video.