Disc filter features

Water purification can be done in various ways. Typically, such manipulation is associated with the use of cartridges or nets. However, a disk filter can be equally successfully used as a source element for a cleaning system.

Principle of operation

Disk-based main filters can effectively remove the following mechanical impurities:

- traces of rust;

- grains of sand;

- leaked silt.

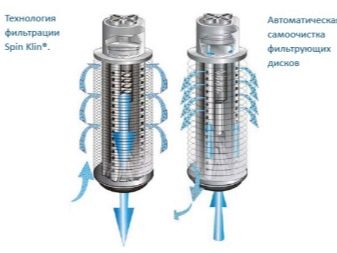

The main working parts are disc packs assembled from polymeric materials. Each block on both sides is covered with grooves similar in shape to the trapezoid. At the time of the free arrangement of the discs, the tracks form wide transverse grooves.If you squeeze the grooves, they change their configuration and taper, forming a tortuous, sophisticated structure. The selection of the number of disks, the level of compression and the geometry of the grooves is done in such a way as to ensure that solid inclusions are delayed and do not interfere with the flow of free water.

Specifications and variations

Disc filters trap particles as small as 20 to 800 microns. At the same time they are able to miss up to 3 m3 of water in 60 minutes. The maximum level of portable pressure reaches 6 atm. The total area of the filter section reaches 90 cm2. The mass of the filter ranges from 1.5 to 1.7 kg. Based on the described characteristics, we can conclude that such devices are quite acceptable for most objects.

To regenerate the discs, they need to unclench and remove. As a result, the grooves take the initial position and release the solid particles. You can wash them off very easily. But even this manipulation is not always necessary, since the number of models with the automatic flushing of filter discs is steadily increasing.

A package of such blocks is attached to the body and held by the casing, upon receipt of which either strong plastic or steel is used. The mount must be resistant to significant external pressure.

The advantages of coarse mechanical cleaning with disks are:

- ease of use;

- no need to regularly change the cartridge;

- ease of use;

- sufficient cleaning efficiency;

- long period of use;

- minimum sizes.

Both manual and self-cleaning disk-based filters can be used:

- as first line mud cleaners in industrial plants;

- for water treatment;

- for the purification of water supplied to the water supply and cooling systems;

- in order to protect heat exchangers and cooling towers from pollution arising from the operation of boilers and heating circuits.

The duration of cleaning is from 30 to 40 seconds. Automation turns on this mode as soon as it detects a specific pressure drop. The amount of water passed through the device is determined by its dimensions, since the area of the cleaning element is crucial. It is rational to put a disk filter if the water is relatively dirty, and the mesh design cannot cope with the work.

Also, the advantage of the disk device can be considered its extended functionality:

- for drinking water purification;

- for watering gardens;

- for various technical needs.

The absence of synthetic substances in the housing and the working parts of the filter significantly increases safety. Eliminates the use of corrosive elements. The use of disk mechanisms is allowed even in water supply systems with a pressure of 10 atm.

If the working unit is clogged with sediments, it will not lose its working capacity, but will only temporarily stop. Excellent results are achieved outdoors at high temperatures.

Additional details

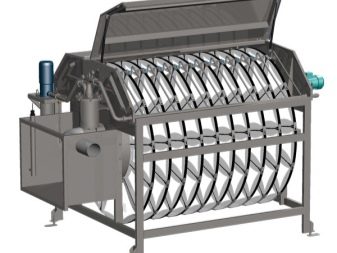

Liquid disk filters can be of different design depending on the dirt holding capacity. Their installation in concrete channels or in tanks from steel is possible. For example, In-Eko designs can clean a lot of liquid with a small footprint. Excellent cleaning is performed by filtering matter, the size of the holes in which starts from 5 microns. Disc filters of this brand are assembled from stainless steel, strong plastics and selected polyester.

Carefully thought out profile and overall configuration minimize the load that occurs. The developers managed to figure out how to reduce the wear of the main components, as well as increase the period of their work. But disk filters have certain drawbacks.They are less well sealed than usual when it comes to industrial vacuum systems. Therefore, the main area of their use is production where the precipitate does not need to be washed.

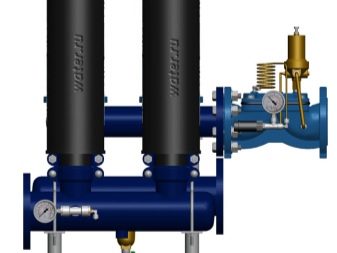

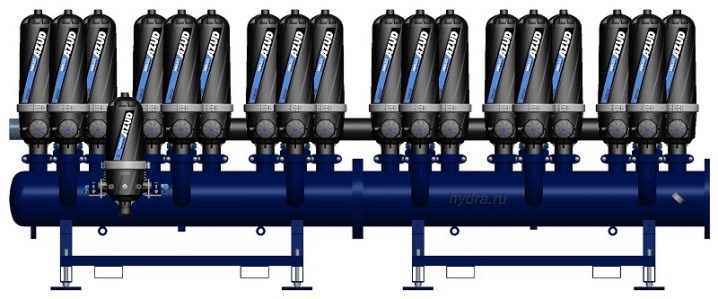

In the industrial sector are actively used station mechanized purification. According to the signals from the sensors, the valves alternately unclench and compress the discs. Large installations for industrial use can be fitted with hardened polypropylene discs. Their total hourly output ranges from 3 to 20 cubic meters. m of water per hour. Typical mounting dimensions are from ¾ to 2 inches.

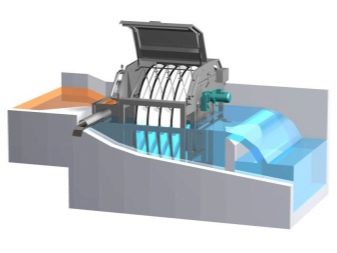

By means of the disk filter, effective water purification is ensured before its passage into the sand septic tanks. In addition, such systems help to further improve the quality of rainwater wastewater. They can be a substitute for secondary settling tanks on biological treatment plants. There is considerable benefit in the use of such equipment on fish farms. There, they effectively purify water polluted by the waste of organisms, and they are capable of doing so with continuous recycling.

When a disk filter is mounted on a biological treatment plant,immediately after it is placed disinfectant unit. The water that has undergone such treatment can be immediately dumped into the water inlets. If such equipment is installed to protect the cooling towers and other components of heating systems, the required design capacity is 5% of the hourly bypass water flow.

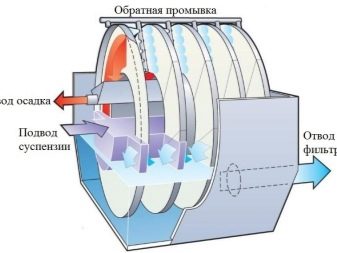

There are two main subtypes of disk filters. In the first version there is a built-in bath for clean water. Dirty liquid is introduced through a pipe connected to the flange, and purified water is discharged through a different pipe.

The second scheme involves the organization of an open channel through which water should move by gravity. From the channel through the rectangular flange it passes into the receiving chamber of the filter. After filtration, the liquid immediately rushes to another chamber, after which the draining devices are mounted. Sets a certain depth of immersion of disks in a layer of water. Modern cleaning systems are equipped with several working circuits. While one is being washed, the others calmly work, providing an impeccably clean and fresh stream of water.

Azud Corporation offers two main disk geometries: MG, W.In the first case, the grooves are made triangular. They are directed at an angle to the radius and have varying depth along the way. The total area of the cleaning element is 224 square meters. see. A more complex configuration option implies an increase in the filtering surface up to 399 square meters. see. But for advanced features, of course, you have to pay.

In the next video you will find the principle of operation of the disk filter Azud.