Industrial water filters: how is water treatment for businesses?

Water, and pure, is necessary not only to people and animals. Industry, transport and agriculture, energy and various infrastructural facilities make their own demands on it. Let sometimes the rigidity of the requirements is small, but the corresponding purified liquid corresponding to them is demanded in huge quantities.

Special features

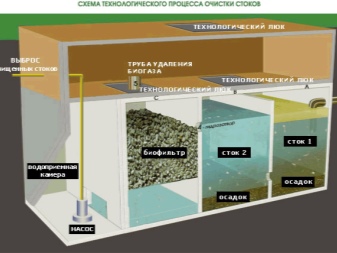

Federal and international wastewater regulations are becoming more stringent from year to year. In addition, ultimately, environmental safety is fully in the interests of each enterprise and its owner. In order to neutralize sewage, without shifting the matter of cleaning to the regenerative forces of nature, it is just that industrial water filters are used.Professional cleaning effectively copes with pollution by phosphorus and nitrogen, microbiological agents and organic matter.

Who needs?

Water purification is needed in almost all existing enterprises. Many of them consume a huge amount of liquid or even use it as a basic reagent. Water treatment should not be confused with water treatment. In the first case, the liquid is simply brought into compliance with the standards describing the basic parameters of drinking or process water. In the second, their compliance with the requirements of a specific production is sought.

So, for CHP and boiler rooms, the rigidity of the incoming water is critical.

The list of requirements in other places is wider, it is especially large in:

- pharmacology;

- chemical synthesis industries;

- especially clean industrial complexes.

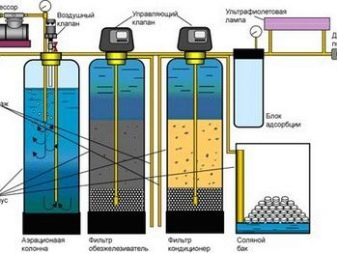

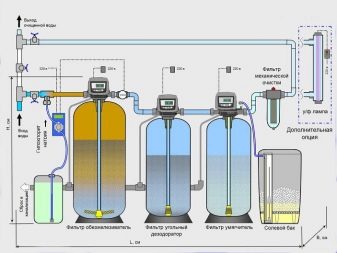

Water passed through the purifiers can be submitted to any installation, subject to strict selection of cleaning methods and the full implementation of all planned processes. Key technologies are aimed at the removal of chlorine, iron, mechanical impurities. In some cases, the liquid is disinfected, lightened, soften, condition,change the saturation of oxygen and carbon dioxide. There are other methods of preparing water for industrial use.

Discharge of wastewater into storm sewer is allowed only after removal of:

- heavy metals;

- toxic organic matter;

- organic residues;

- excessive mechanical suspensions;

- flammable, explosive and highly flammable substances.

Process description

Water treatment and water treatment on the scale of modern industry imply the use of various technologies, the selection of which is dictated by the needs of customers.

Most industrial enterprises have three goals:

- correct and uninterrupted action of equipment in contact with water;

- corrosion prevention;

- elimination of scaling and other foreign deposits.

But the food industry requires further harsh disinfection of water, and pharmaceuticals are making a similar request. Water treatment is divided into a number of stages, some of which are strictly prescribed in the regulatory documentation. Other stages appear or are absent depending on the initial quality of the liquid.Traditionally, clarifiers and mechanical filters have been used to clarify water. A more modern option is deep cleaning with the addition of reagents that chemically bind colloidal inclusions.

In the process of deodorization and bleaching it is possible to remove organic components and salts from water.affecting its taste and color. There are many options for achieving this goal, which depend on the capabilities of the equipment and the task. Iron removal is very important for technical and drinking water supplied to water pipes. The latest techniques provide a total release of the liquid from the corrosive iron and manganese ions.

So that pumping of hot and cold water does not cause deposits of plaque, calcium and magnesium are removed from it, for the most part this is done by lime-soda method, and if it is heavily polluted, phosphate treatment is also carried out.

Gases from water are scrubbed by desorption. In this case, the partial pressure of a particular gas should be reduced to zero after special treatment with steam. Using hydrated lime in the form of a suspension, it is possible to lower the concentration of bicarbonates.The precipitate is eliminated by filtration. But all these approaches cannot guarantee sufficient microbiological safety. Meanwhile, disinfection is an obligatory stage in water treatment for domestic and industrial purposes.

Radically improve the quality of water for microbiological indicators can, if subjected to purification in several stages. Laboratory tests are carried out to check whether the applied processes have reached their goal.

According to common practice, the targets are:

- cold water hardness of up to 3 mEq / l;

- the hardness of warm and hot water is 50% less;

- up to 2.6 units of suspension (this is already the limit, the complete elimination of it is recommended);

- presence of 2–5 mg / l of various salts.

The presence of solids, oxygen, nitrates and sulfates was normalized. Water used in industry must have an acidity of 4 to 8 units on a universal scale (unless a different value is specified in the process requirements). For most industries, disinfection is done in the minimum version. But at any technological facility, water,arriving in emergency spraying systems, in air-conditioning installations and in swimming pools must have the same quality as that supplied to the water supply system. Separate industries, including chemical, require pre-distillation and softening, so that the resulting reagents and other products do not cause problems.

What equipment is needed?

The solution of the tasks leads to the use of a wide range of equipment. So, clarification is performed in sumps and filters. Initially, water is passed through grids stopping large impurities, and then through granular layers. Centrifuges help maximize productivity. Although such devices are considered obsolete, their effectiveness has been proven to be used for many decades.

Long-term work of aerobic columns, extracting iron due to its reaction with oxygen, fully justifies the significant cost of such systems. Active resins help reduce stiffness and get rid of mineral salts. But along with this filler apply activated carbon and other substances to filters.If the company has an internal plumbing for workers, for the kitchen, for various animals - it must be equipped with household filters of maximum power.

When the water is very dirty, or it is not possible to install several types of systems at once, reverse osmosis and radical filtration systems are used, which alone can solve almost all probable tasks.

Choosing specific options, you should focus on indicators such as:

- the cost of the filters themselves and replaceable reagents;

- the duration of their operation;

- compliance with the cleanings and the list of threats;

- stability of action in various conditions;

- extending the life of the main production equipment;

- reputation of the manufacturer and compliance of its products with standard requirements.

Types of systems used

Self-cleaning filters with membrane working structures allow water to be cleaned deeply, reducing the concentration of suspended solids to 0–20%. They can be used both offline and as a means of complex cleaning. Modern installations of this kind can easily integrate into any pipeline network of domestic or industrial use, filter the liquid fully and work for a very long time.The extension of the working resource is provided with a powerful ability to regenerate the main circuit without opening the case with the replacement of the working part. It is self-cleaning filters that are widely used in socially significant facilities in the metallurgical, pharmacological, transport industries, and the fuel and energy complex.

A more traditional solution that has not yet lost its relevance is mesh filters. The design of such a system is extremely simple, and even non-specialists can serve it. To restore the equipment to work, you only need to rinse it and occasionally change the mesh as it wears out. The absence of synthetic materials and special cleaning reagents completely eliminates the danger of toxic substances entering the water.

But it is worth considering that the mesh cleaner will cope only with mechanical clogging, and then to a certain size; foreign substances and microbes are completely ignored.

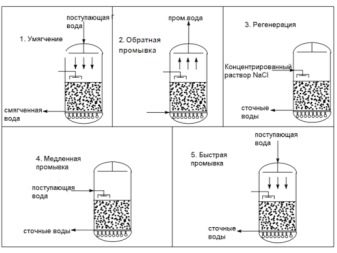

The undoubted advantage of coarse filtering is that it protects costly and more efficient filters of a modern design. Washing can occur either from above or from the inside, which is much more practical.The strainer can be self-cleaning, it lasts much longer than other varieties. But such a device takes up a lot of space and requires connection to the power supply. In addition, washable dirt should immediately go to the sewer, to which the filter is connected in constant mode. One of the most modern solutions is ion-exchange installations.

For the most part, such systems are designed to clean hardness salts from water. Since the workflow implies a reversible substitution reaction, it is very important to maintain stable temperatures and pressures. In some cases, additional reagents are added to the ion exchange resins, which expand the spectrum of the substances to be collected. But the general principle remains the same: devices convert ions of certain types into insoluble modifications. Such systems do not emit noise, but regenerating tanks, concentrated salt solutions and constant utilization of regenerable substances are required.

Recommendations

In the selection of equipment for water treatment and water treatment should be guided by technological maps, standards, specifications for certain types of process technology.Differences are manifested in continuous and periodic modes of operation of specific equipment primarily.

Attention should be paid to the temperature of suspensions and washings. You should also carefully read the performance level of a particular system and how well it cleans the liquid. For example, some of the filters that protect against iron can also remove manganese from the water, but this should be clarified separately.

About filters and filtration systems for water purification, see the following video.