Geyser Neva 4510: characteristics and subtleties of use

The use of gas columns has become quite widespread. Similar devices are being made on the territory of Russia. But in order to fully satisfy your interest and get a first-class product and not encounter problems, you need to study the specifics of technology.

Special features

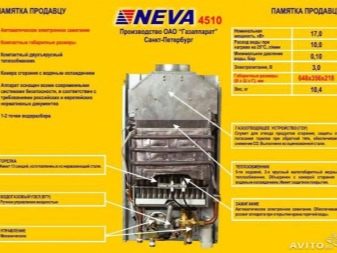

Geyser Neva 4510 causes conflicting feelings on the part of consumers. It is made by the concern Baltgaz, and there are no cheaper offers in the line of its gas-fueled water heaters for gas. But at the same time, components supplied from China are used in production.The name of the model briefly describes its technical characteristics corresponding to those entered in the product passport. Thus, the numbers "45" denote the series, "10" - the amount of water warmed in a minute, sometimes the letter "M" is sometimes present, showing deep modernization.

The specificity of the system in comparison with other products under the Neva brand is powered by a pair of batteries. There is no smooth modulation of the fire. That is, a change in the water pressure in the supply channel will affect its temperature after heating. To cope with this problem will have to manually. The front panel is equipped with a pair of adjusting knobs - the blue one is responsible for the intake of fluid, and the red one for the warming up achieved.

The gap between the handles is equipped with a digital screen that shows the already existing temperature. This minimizes the risk of error.

The column, like other Russian-made models, is equipped with:

- thrust sensor;

- indicator of the presence of fire;

- thermal sensor;

- gas control equipment.

The column has an efficiency of 88%, designed for natural gas pressure of 1274 Pa. For liquefied fuel, this figure is 2940 Pa, the nominal flow rate for 60 minutes is 1.95 and 0.77 cu. mFor the device to function normally, water must be supplied to it with a pressure of 300 kPa. If it heats up to 25 degrees, you can get more than 8 liters of liquid. With stronger heating (40 degrees) the flow rate drops to 5.3 liters.

The Neva 4510 is 0.65 m high, 0.36 m wide, and 0.21 m deep. The weight of the system does not exceed 10.4 kg. Provides prevention of excessive water heating. The control of the presence of flame in the burner is implemented due to the ionization effect. The design also provides a viewing window.

Benefits

Neva 4510 has several strengths:

- reasonable price;

- low cost of spare parts and repairs made with their help;

- small dimensions;

- Brand warranty for 24 months;

- the ability to act with a slight pressure of the liquid;

- wide availability of service departments.

disadvantages

We can not ignore the fact that customer feedback on the device is not always favorable.

There are such problems as:

- short operation of the heat exchanger;

- low quality of main components;

- the inability to smoothly adjust the intensity of the flame.

Principle of operation

The device is designed with the expectation of burning both natural and liquefied gas. The second function is implemented only after changing the nozzles. The maximum power in peak mode is 17000 watts. Ignition element at the initial start-up manually. To do this, press the keys that create a spark and let gas through.

As a result, the electronic control unit initiates the ignition. A small light will operate continuously, even at the moment when the valve is locked. If a fluid flow is directed through the water unit, the automation will start a common burner. Almost immediately, a stream of hot water is sent from the water intake.

The column is equipped with an electronic ignition system that receives current from a pair of R20 format batteries. The electronics are connected to the battery compartment via a microswitch that triggers the passage of water through the regulator. As a result, for the consumer, the launch of the column into operation is reduced to the opening of the valve itself, from which the hot liquid flows. The water circuit valve opens the flow of gas to the main burner only with the flow of water, while it also initiates the activation of the solenoid valve.

How to install and configure?

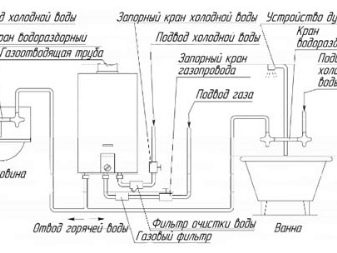

Getting 10 liters of hot water in 60 seconds means that only a single point of water can be served. The minimum requirement for starting is a liquid head of 0.15 atm. The diameter of the chimney provided by the scheme is 12 cm, the connection of the water and gas supply channels is made through ½ inch pipes with a cross section. Gas supply is allowed only on bellows type hoses. The recommended execution of the smoke channel - with aluminum corrugation.

Neva 4510 is equipped with a camera with a natural (gravitational) strain. Therefore, it is required to mount it strictly in rooms of at least 8 square meters. m. A prerequisite is carefully designed ventilation. In the composition of this ventilation should be used resistant to significant heat materials. Another prerequisite is the provision of devices that guarantee the safety of use.

Additional requirements:

- the obligatory presence of a window with a window, constantly open when the column is working;

- connection only to the chimney with a decent load and as close as possible to it;

- the inadmissibility of the installation close to the heat generators or to the equipment that gives open fire.

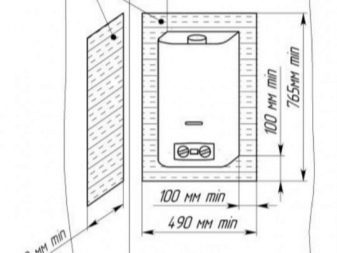

The geyser Neva 4510 is subject to obligatory registration in service of gas.Installation is allowed strictly on the walls of fireproof materials. Prohibited direct contact or approach to the tree, even covered with a protective layer. The wall is additionally insulated with a poorly flammable material 56x85 cm in size. The ideal insulator is galvanized steel on top of the basalt heat shield.

It is recommended to remove the insulation over the edges of the case by at least 10 cm on all sides. Before installation and attachment to the hot water supply system, the lining is removed from the column. Provide a full service can be, leaving 15 cm between the side of the unit and the nearest wall, as well as providing a space in front of the front part of 60 cm or more. The canopy is made on the brackets inserted into the wall.

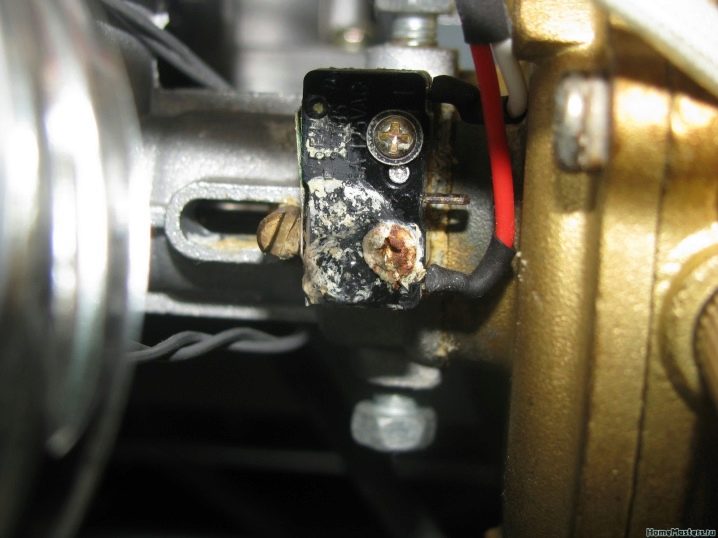

Possible faults and remedies

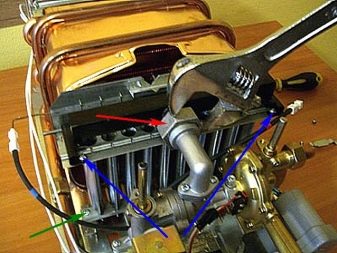

If the geyser does not turn on, the reason may be related to the discharge of the batteries. Also it is worth suspecting a low pressure of the fluid, contamination of the inlet filter, damage to control devices or membranes. First, check the serviceability of the filter and the battery charge, put the device regulating the flow of water to a maximum. Sometimes these parts have to be changed.Before such a replacement, you need to look again if the heat exchanger is not clogged with scale.

When the column does not ignite, but there is a spark, there is either a defect in the solenoid valve or air clogging of the gas circuit. The problem valve can only be replaced. The air mass can be eliminated by adjusting the gap from the nozzle on the burner to the ignition plug. Sometimes the fire does not light up due to the weakness of the spark. The defect is eliminated by improving contacts in the battery compartment or replacing them completely.

Some users are faced with such a problem: the column seems to be working, but at the same time the water heating is too weak or takes a long time. The reason is a malfunction of the water-gas part, the occurrence of scale on the heat exchanger or the dusting of the burner. In some cases, simple cleaning helps, but if it does not give results, it will be necessary to change the corresponding nodes. Some people complain about the unauthorized shutdown of the device.

They can be provoked by:

- loosening of traction;

- failure in the fire indicator;

- problems with the membrane on the water node;

- heating the fluid to more than 77 degrees.

Reduce excessive heat is obtained by reducing the flow of gas.It is also useful to free the chimney from the soot accumulated in it, change the membrane and the fire indicator. When an error occurs, the EE will have to change the sensor that controls the heating of the water. Strong noise, if it is not caused by overheating, is caused by a malfunction of the gaskets on the water assembly. As you can see, almost all the problems are manually eliminated manually, albeit with the help of interchangeable structures.

A serious and, alas, frequent problem is that water is dripping from the column. First of all, we can assume the wear of connecting elements placed in the interval from the hose to the pipe. Another source of trouble is with a heat exchanger breakthrough. Pipes that constantly supply hot and cold water are connected to this device. Another cause of failure is often neglect of regular prevention.

Cracks in the radiator can be fixed only after draining all the water. The last of its remnants are removed from the coil with a pump or vacuum cleaner for wet cleaning. Next, clean the metal surface with sandpaper. And only after that take a soldering iron, designed for at least 100 watts and warming up to 180 degrees. It is necessary to build up solder on defective places to a thickness of 2 mm.

Recommendations for use

A lot depends on how well the system is used. With proper observance of technical standards, the display, microswitch and other parts will not be subject to failures or will be exposed to them less frequently. Neva 4510 is very susceptible to the characteristics of heated water. The supply of rusty fluid significantly accelerates the pollution of the internal ducts and leads to a pressure drop. It is important to remember that, despite instructions from the manufacturer about 15 regulatory provisions, usually gas injectors are placed in one of three positions.

It is not necessary at the same time to open the hot and cold taps at the same time. In such a situation, automation often gives a false alarm and mistakenly stops the device. It is imperative to maintain a limited water temperature on the outlet circuit. Otherwise, accumulation of a very large amount of mineral salts and scale is likely.

Cleaning the burners and the heat exchanger, although it does not represent a particularly pleasant procedure, is the only guarantee against premature failure.

At least once a year, you should invite a gas mechanic or other specialized organization.It is recommended to air the room before each use and after shutdown. It is impossible to light the column if the draft is not checked in the chimney or the reason for its absence remains. The use of input magnetic filters on the plumbing system dramatically reduces the risk of scaling. You can reduce this risk if you never warm the water to more than 40 degrees.

In general, the system meets the same requirements as developed Western European structures. If water freezing is detected, it needs to be drained.

Normal operation of the column when the gas pipeline is in good condition is not accompanied by the appearance of mercaptan odor in the room. Having found it, you should immediately turn off the device, do not use any electrical appliances. Further actions should be taken by gas service employees.

On the repair and replacement of the membrane in the gas column Neva 4510-4511, see the following video.