Bosch geysers: types and features of operation

Bosch Concern can be called one of the recognized leaders in the production of high-quality water-heating equipment. The excellent reliability of this product is confirmed by its demand and only positive feedback from professionals and buyers from various countries of the world. A distinctive feature of products from Bosch has become a set of simplified functions.

The eminent brand produces only high-quality products and has been improving them for many decades. Concern all the time introduces all sorts of technical innovations in their columns to make them even more popular.

Device and principle of operation

Bosch company produces gas heaters of several types.

- Battery-powered design. The burner will need to be turned on using electric ignition, and a spark will be supplied by a special electrode.

- Bosch device with piezo igniter. It is necessary to light the igniter by simply pressing a button. The column will heat the water only after the owner of the house opens the tap, from which the hot water will have to go.

- A column that can work with a hydrogenerator. This unit works in the same way as on batteries, only a spark is obtained using the work of a hydrogenerator.

Gas devices have a rather complicated device. Before you start looking for the right model of this type of equipment, first you need to know its design features.

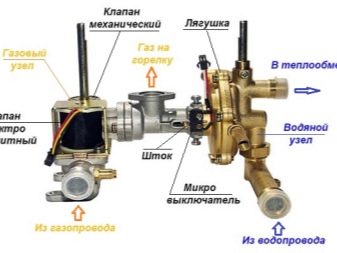

It is worth highlighting a few main working components of products.

- Housing It is produced by stamping from durable sheet steel. The case has an enamel layer of protection that helps the unit to withstand elevated temperatures for a long time, and also gives resistance to various damages. The heating elements and casing details are fixed behind the casing wall, which closes the “insides” of the column.And also on the body are the controls of the boiler.

- Viewing window. It looks like a normal hole, which is located on the front side of the product and is made in order to visually control the fire of the burner.

- Control system. This unit has two separate regulators - for pressure and for fluid temperature. The boilers are made with the regulation of water pressure, which is produced when you turn the knob - to increase the readings can be turned clockwise, and reduced - against it. The level of flame burning can be set using the slider.

- Highway entry and exit. Supply of water and fuel will be carried out with the help of fittings with a threaded connection.

- Chimney. The withdrawal of gas, which has already worked, goes through the pipe, which is located at the top of the product. The diameter of the nozzle will directly depend on the operability of the device and has parameters from 10 to 15 cm.

- Node for control over the pitch. This item looks like a sensor. He will monitor the level of available traction. In case of its decrease, the automatic will immediately shut down the unit.

- Gas node. This includes a burner and igniter, a special combustion chamber, a special gearbox and all the necessary elements for ignition.

- Water knot. Here there is a heat exchanger released from the pipe in the form of a coil, and durable pipes for transfer and release of liquid.

Products must have controls to control the pressure of fluid in the system. When it is lowered to critical parameters, the automatic switching off of the heating element should occur.

The principle of operation of the gas device is as follows:

- as soon as the taps with hot water open, the required heat transfer medium enters the heat exchanger;

- at the same time, the ignition of the heating torch from the igniter takes place;

- passing through the coil, the water is heated by heat, which is released in huge quantities during the combustion of fuel;

- rapid heating occurs through heat transfer at high speed due to the high level of thermal conductivity of the materials used;

- exhaust gases will be released under the influence of chimney draft.

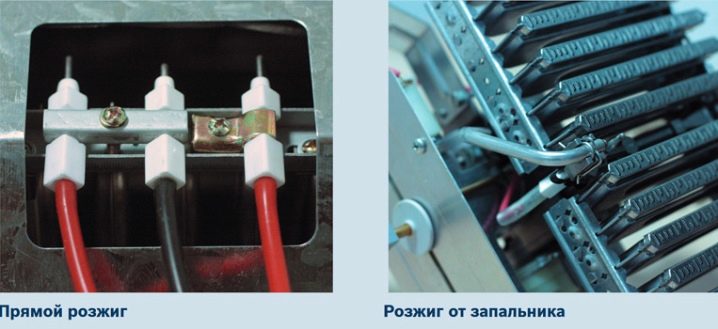

Bosch offers a choice of water heating products with different types of ignition.

That is why flow products are divided into 2 classes.

- Ignition machine. The combustion of fuel in the burner occurs at the same time as the hot liquid valve is opened.

- Ignition semiautomatic. The ignition of the fuel in the combustion chamber comes from the igniter, which must first be ignited.

In the markings of the Bosch brand units there are letter indices that indicate a kind of ignition system, namely:

- “P” - piezo ignition;

- “B” - electric ignition;

- "H" or "G" - ignition from the hydrogenerator.

Advantages and disadvantages

Gas devices from the Bosch concern have the following advantages:

- long service life - devices of this manufacturer work without fail for many years;

- excellent simplified functionality that pleases consumers;

- a huge model range - among the range you can find both simple and advanced models; A considerable number of options and subspecies of Bosch devices allows you to choose the most suitable model for home use, installation in the office or installation indoors in production;

- excellent security system, in addition, competent control over the removal of products of combustion of fuel;

- temperature control, as well as the auto system functioning of the entire device.

Bosch units have such disadvantages as:

- a small number of domestic service workshops;

- high cost of production;

- high prices for spare parts.

Lineup and customer reviews

Therm 2000 series

This model is considered the most budget. It can heat a liquid in a volume of 10 liters in one minute. It has a built-in electrical ignition (battery-operated), a burner that is made of stainless steel, a heat exchanger made of copper, and an original design. The device is protected from accidents by special sensors measuring the temperature of the heat carrier and the level of thrust, and there is also a system that controls the flow of fuel.

The Bosch W10 KB model relating to this series has the small sizes, low cost therefore it is in special demand among buyers.

Termo 4000 series

Bosch products of this modification are presented in two models - Termo 4000 and Termo 4000 S. They can be with electric ignition and piezo ignition. They can produce 10–15 liters in 1 minute. The heat exchanger has a rather long use period - up to 15 years. In the models there is a system that guarantees a smooth adjustment of the flame and provides the desired temperature of the liquid with an increase or decrease in the level of pressure in the water circuit.

A distinctive feature of the Termo 4000 S model is an installed fan,which produces the exhaust gases from the combustion chamber forcibly and injects air into this chamber.

In addition, you can buy a coaxial-type chimney in order to easily remove the products of combustion from the house. This kind of opportunity helps to install these products in those rooms where there is no ventilation system or there is no chimney at all. There are three types of products of different capacity and performance from 10 to 15 liters per minute.

Flowing water heaters of this series have such designations as:

- Bosch device with auto ignition (article “B”): WR 10-2B and WR 13-2B, as well as WR 15-2B;

- Bosch semi-automatic unit with piezoelectric ignition (symbol “P”): WR 10-2P and WR 13-2P, besides this - WR 15-2P.

Termo 6000 series

Products of this series are equipped with hydrogenerators to automatically ignite the burner. On the front panel is the LCD monitor, which displays the values of the set temperature. The heater can be controlled mechanically, and the support of the existing settings is done in auto mode. The model is presented by three options of power, with working capacity from 12 l to 18 l per minute. True, it is worth remembering that this series of devices is energy dependent. There is a fan that needs to be connected to the electrical network.Products are marked according to the specific power of the device - WTD 12 AM E23, WTD 15 AM E23 and WTD 18 AM E23.

Thermo 6000 S and 8000 S series

These are mostly industrial-type units from a famous German brand. The performance of these products will be 24 and 27 liters per minute. These products can provide heated water from 4 to 5 points. Bosch water heaters have an electrical ignition and a display with an LCD screen on the front of the product. In the 6000 S model there are 2 fans that remove the combustion products necessary to draw in oxygen. The Bosch 8000 S product has a special condensation technology, it is designed for more efficient heating of water. In addition, the water valve of this model is supplemented by an electric drive.

Important: all models of gas devices are produced in Portugal, but there is an exception - this is an inexpensive series Termo 2000, which is assembled in China.

Installation and connection

The choice of this kind of appliance should be taken very seriously, since the placement of such a device in a dwelling, in the kitchen of which there is no chimney channel (should not be confused with the ventilation channel), according to the norms is not allowed. The best way out of this situation is the purchase of a product with a closed-type combustion chamber.In a similar device, a coaxial pipe is used as a chimney, which will be led through the wall directly into the street. A specialist designing a scheme should warn about a similar solution to the problem. The place of installation of the product is usually determined by the existing and approved project, so those who want to have a high-quality water heater in their kitchen should be clearly acquainted with the rules of the location of the unit in a residential building.

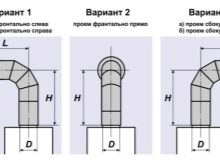

Such products can be placed only in the kitchen or in any other non-residential space, with the exception of the bathroom, since, according to updated standards, the presence of such a device is not allowed in it. In order to connect the outlet needed to remove the burned fuel residues from the appliance and to enter the chimney that is in the wall, you can choose a steel pipe with a wall thickness of 1 mm. Its diameter is from 1.2 cm. The use of pipes made of aluminum sheet or corrugated type is not recommended. The section of such a pipe at the exit of the product must have parameters of about 30–50 cm.

Installation of the device is carried out at such a height that children do not reach it, but at the same time adults should easily reach all available regulators.The distance from the wall closest to the appliance is not less than 0.15 m. There should not be any obstacles in front of the product itself at a distance of 0.6 m. The pipe that is intended for the removal of products of combustion of fuel must go only to the chimney, if it is a separate building, or to a special chimney channel, which is usually built into the walls. Connecting the product to the ventilation is strictly prohibited, since the products of combustion can get into the house to the neighbors, which is not very good.

Good chimney draft is the main condition, which is confirmed by documents. It is prescribed in them that the thrust force has full compliance with the necessary norms. The room where the device is placed should be well ventilated, for example, you can equip a window with an opening window.

A good way out is to install the purchased device on the wall according to the existing special project and to connect only the water supply hose to the unit pipe. Only an experienced specialist can connect the product to the gas hose and carry out other work with combustible fuel.

The order of installation of the device is unoriginal. Where the apparatus is attached to the wall, it is necessary to make markup for future fasteners. The entire height of the fixings is calculated so that the chimney that comes out of the device vertically has parameters of at least 30 cm. The pipe to the chimney is set at a predetermined angle. Its parameters can be calculated by applying the wiring diagram.

After determining the height of the suspension device, you need to do the following steps:

- measure how many centimeters between fixtures on the product, transfer these parameters to the wall using a level and a ruler;

- make small holes in the wall under the dowels or hooks;

- after mounting the hooks, you need to hang the device on them;

- Further, the installation of water hoses is made, they are screwed to the water inlet and to the drain pipe;

- to check the tightness of the connection, you need to open the taps with cold and hot water;

- the chimney pipe is fixed on the placed unit with the help of a diagram; the use of corrugations is permitted;

- to connect the gas pipe, you will have to invite a professional who will do this as faithfully as possible and will hand in documents on the registration of the device; at this stage the water connectionthe device can be considered complete, the boiler can be run for operation.

Common Malfunctions

Despite the fairly high level of reliable operation of these units, it is worth remembering that it is quite common for technology to become unusable from time to time. But nevertheless German geysers can function very long without any serious failures. In modern operating conditions, such a device will last from 5 to 10 years. A characteristic feature of the speakers from the Bosch brand can be considered a digital control panel, on the screen of which various errors will appear in the event of device failures.

It is worth considering the most common faults, the origins of their occurrence and the quick repair of failures of a gas device from Bosch.

- The flame of the wick goes out at the igniter or the product simply does not ignite from the very first time. You just need to thoroughly clean the burner. To do this, it must be removed, carefully disassembled and also cleaned carefully.

- Igniter like and lights up, but immediately goes out or for no apparent reason the wick goes out if you open the faucet valve. It is well to check the gearbox, if the unit runs on gas from a cylinder.

- The water from the taps goes completely hot or generally cold. It is necessary to check whether the parameters are correctly set on the temperature controller on the instrument.

- From time to time the igniter does not burn. It is likely that the reaction of the traction sensor or the sensor measuring the temperature of the liquid. Just call an experienced master to troubleshoot these problems.

- There is a weak pressure fluid. Most likely, it is clogged either the heat exchanger itself, or the mixer, or the water unit. It will only be necessary to reveal the source of this blockage and make its complete cleansing.

- The column simply does not turn on (does not light up under any efforts). You should carefully check the batteries, if necessary, change them to new ones.

Important: spare parts for Bosch units need to be purchased only in specialized stores.

In the next video you will find a review and adjustment of the gas column Bosch Therm 4000 O.