Mora Top geysers: product overview and operating tips

The Czech company Mora Top for many decades present in the market of geysers. All this time, she tries to produce flawless, satisfying all consumer needs products. At the same time, the company does not lag behind the requirements of technical progress. Consider the most popular models of geysers of this brand, their features, as well as give valuable advice on operation.

Vega max

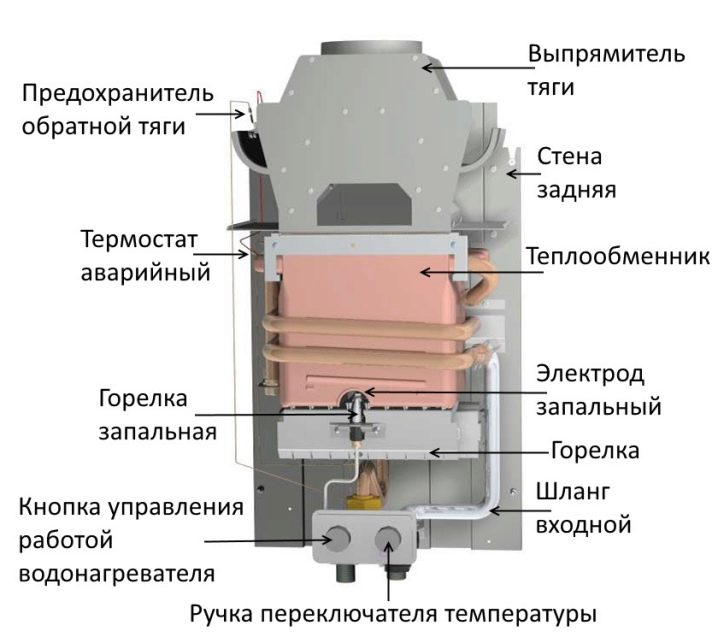

This modification was designed to replace models 5502, 5505, 370, 371. All four versions have been discontinued several years ago, but instead of them, as the previously installed equipment wears out, you can install a new column without changing the connecting dimensions.Thanks to this, updating water heaters will be easy and simple. The geyser is mounted on the wall, capable of developing a heat output of 17.3 kW, providing up to 10 liters of heated water in 60 seconds. In the construction of this model are applied:

- German fittings for water and gas Mertik;

- main and pilot burners, Czech heat exchanger;

- pipes with a wall of 0.1 cm.

The system automatically maintains the set fluid temperature. There are two options - with piezoelectric ignition and with battery power. Installed a full range of safety devices.

The transfer of the gas valve to the open position with the water supply turned off is excluded. Gaseous products will not get out.

Vega 10 model

This is another promising model from the Czech company. Its characteristic advantages are, in addition to the brilliant design, compact dimensions and technological excellence. The thermal generation rating is 17.3 kW, and the variation in the amount of water produced (when heated to 25 degrees) is from 5 to 10 liters. The device is able to operate in an automated mode and spend 10% less gas than other products of comparable power. Positive customer reviews and causes up to 92% efficiency, as well as the smoothness of power control.

Combined valves from Germany are able to turn on a column, even with a pressure of 2.5 liters in 1 minute. Other designs of the same kind do not provide this feature. Importantly, the German developers have taken care to maintain a strictly set temperature. This allows you to extinguish the negative effect associated with pressure jerks. The failure of moving parts to work in water prevents the lack of most columns - a high risk of leakage at the intersection of the water and gas fittings.

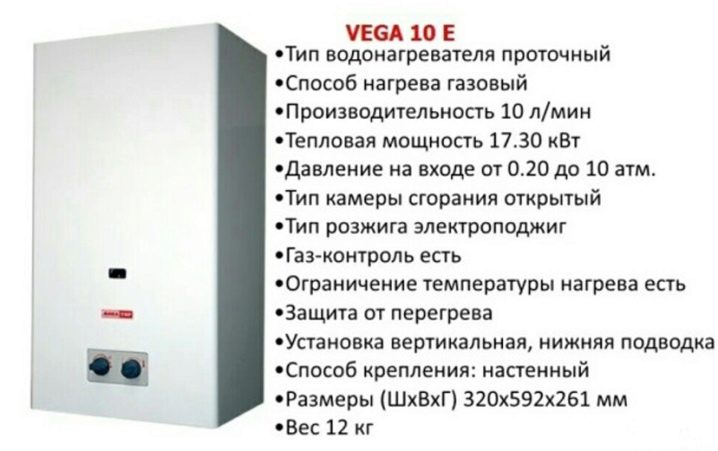

Vega 10E

This model is equipped with a 1.5V ignition battery. For normal operation, 2 batteries must be used. Like other versions in the Vega lineup, the design attracts attention with external performance and at the same time technical leadership. A protective thermostat is provided to prevent overheating of the liquid inside the heat exchanger. The automatics will block the action of the main burner, if there is no water, a high-class ionization electrode is installed.

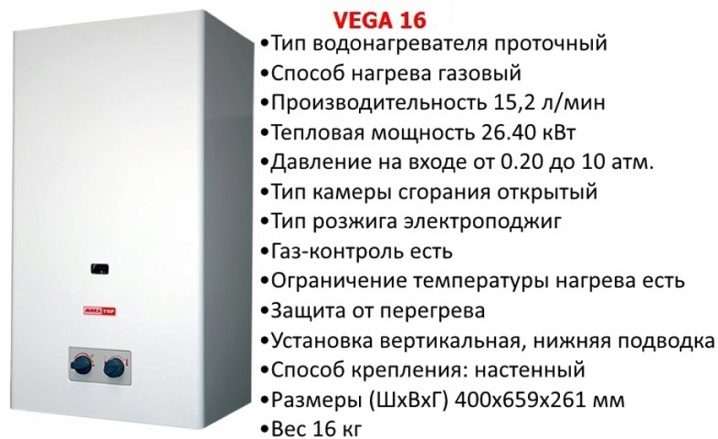

Vega 16

Such a geyser far surpasses all the versions listed above. It develops thermal power up to 26.4 kW, while the minute flow rate of warm water ranges from 8 to 15.2 liters.The operation of the device involves the consumption of natural gas. The special design of the valve ensures that the column starts already when 4 liters of water are received per minute. The rate of heating due to an improved heat exchanger is raised by 15% compared with similar designs.

Additional turbulators slow down the deposition of scale particles and accelerate the heating of the liquid. The carefully selected diameter of the tubes of the heat exchanger ensures a balance between the delayed accumulation of salts and the effective cooling of the walls. This cooling takes place without simultaneous overheating of the casing and casing. The design includes protection against leakage into the room of flue gases. There is also a fire fuse, stabilizing the action of the main burner and fuse.

Probable problems

No matter how well the Czech and German developers treat their duties, nevertheless the geysers can cause various failures. Malfunctions in the water and gas blocks can be associated with mechanical defects of the water heaters themselves or with deformation of the supply cables. In addition, as in other columns, problems are often created:

- heat exchanger blockages;

- scale deposits on pipes;

- weak liquid pressure.

At the input to the column is a filter in the form of a grid. It is designed to trap shallow debris moving with a stream of water. But since the net itself is inevitably clogged with this dirt, it needs to be periodically cleaned. When the column does not ignite or goes out too quickly after the start of work, the reason for such a development of events is almost certainly related to the wear of the membrane. An element continuously stretching under pressure eventually fails, is stretched beyond measure, or breaks altogether.

If, during ignition, cotton is heard and the wick is immediately extinguished, the contamination of the fuse is evident. It is cleaned by removing the casing and unscrewing the thrust indicator tubes of the gas feed channel. In addition to the fuse itself, it is better to immediately release the wick and nozzles from dirt. In a situation when these measures do not give results, it is necessary to change the solenoid valve. If there is a spark that does not ignite the burner, it is required to examine and tighten the wiring of the ionization controller, to clean its contacts.

How to cope with other problems

It is often possible to hear that a gas column heats the water badly.The main reason is the failure of the heat exchanger clogged with soot and soot. An accurate diagnosis can be made by the color of the fire - in the case of a real blockage, it turns yellow and may even deviate to the side. Such a state threatens to seriously overheat the casing and requires immediate cleaning.

To reduce the risk of scaling, you need not to warm the water without the need to 55 degrees and install protective filters. If a blockage does occur, it is necessary to close the pipeline and the water supply circuit. Drain the remaining liquid in the radiator, remove the casing and open the way to the main plates. If necessary, they are not just cleaned with a brush, but also removed and washed problem parts.

Water leakage does not appear suddenly, because the corrosion process develops gradually. Small holes can be seen on the spots on the surface of the heat exchanger. It is best to inspect the structure after locking the valve, then the pressure will be higher, and the problem will become clearer. Instead of brazing the radiator, you can use rubber pad or cold welding.

In the latter case, you will have to pick up the material, the melting point of which is higher than the expected heating during operation.

Additional recommendations for use

A system that has been in a cold environment for a long time can be connected in at least 2 hours in a warm room. You can not use the gas column, located closer than 0.1 m from the walls and any other objects. Above it must remain at least 0.4 m. If a thermostat is mounted, it must be chosen with an output without electric potential, since any discharge threatens to explode.

Strongly unacceptable:

- accumulation of explosive and flammable substances nearby;

- connection of equipment without the involvement of specialists;

- operation of the water heater, on the water inlet of which the screen filter is not worth;

- the inclusion of both hot and cold water at the included column;

- use for cleaning the heat exchanger and other parts of the water heater acids, even their weak solutions.

In case of unsuccessful actions to configure or troubleshoot the problems recommended by the instruction, you should immediately stop all such attempts and contact the professionals. Any maintenance or even limited repair of Mora Top water heaters is possible only after switching off the equipment. In the cold season of the year, it is necessary to do everything to prevent the heater from freezing.Wall structures should be fastened as firmly as possible and only on solid walls. On most of the columns, smoke exhaust is installed, compatible with chimneys with a cross section of 110 mm (single models are calculated for 130 mm, and this is discussed especially in the documentation).

Review the gas column Mora Top Vega 10E, see the video below.