BaltGaz geysers: model overview and specifications

Many consumers, in addition to single-circuit boilers, choose gas columns as a means of obtaining hot water. This type of equipment has long been known and its production has been debugged, including in Russia. But it is important to take into account that specific models have their own characteristics, and this directly affects, among other things, possible problems.

Special features

Baltgaz constructions are produced at the Armavir Electrotechnical Plant JSC and therefore they fully take into account all the features of the operation of heating equipment in Russia. Branded warranty is 24 months, and in general, the company declares the service life of products at least 12 years without interruption.The hydraulic circuit is designed for uninterrupted action of the heater even when the pressure in the water line drops to 0.015 MPa. Columns belong to the economical price group. In their design requirements of modern design are taken into account.

Specific modifications

Model Comfort 11 is designed to work on liquefied gas. As the manufacturer claims, a copper heat exchanger is installed in the system that does not contain tin or lead alloys. Upon receipt of the heat exchanger, an advanced technology of soldering in an insulating medium was used.

Predefined 5 security tools that disable the column without human intervention:

- at a gas stop;

- in the absence of water;

- in the case of heating the fluid to more than 90 degrees.

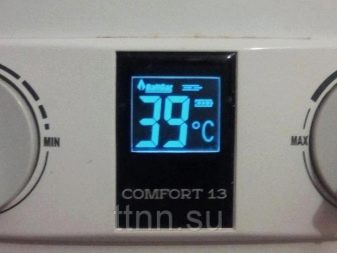

Keeping up with the times, the manufacturers used a digital display of the heating of the flowing water. But the adjustment of its consumption and fuel consumption is made purely mechanical. Gas combustion is strictly minimal, even with a continuously operating burner. The index "11" in the version name indicates the amount of water heated per minute.

The system starts immediately as soon as the hot water tap opens.

The efficiency of the device reaches 87%, it is able to supply hot water to two distribution points, if the need arises. The reviews on the Baltgaz 13 silver are quite favorable. A special built-in unit ensures the modulation error of the fire is not more than 2%. As in other versions of the Comfort line, the igniter, thermocouple, and gas distributing unit act simultaneously as safety features. When stopping the flow of gas or in case of stopping the combustion for some other reason, the flow of gas is automatically cut off.

The variation of Comfort 15 basically has the same parameters. The column allows to reduce the error of the set water temperature to 2 degrees. The size of the construction is 35x65x23.9 cm. When working, an efficiency of 85% is achieved. Of course, the chimney has its role in providing it, the internal cross section of which is 13.8 and the external one - 14 cm.

Model 4511 produces 11 liters of water per minute in the water circuit, automatically starting to warm it up when the faucet is opened. The working chamber is equipped with a water cooling system, and the brand warranty is 5 years. The dimensions of the device are 29x56.5x22.1 cm. The flame is ignited by an electronic automatic unit, 60 minutes is spent up to 2.22 cubic meters of gas.The system can supply hot water at 1 or 2 points, while its efficiency is 87%, and the inside and outside of the chimney section is 12.1 and 12.3 cm, respectively.

Version 4510 runs on liquefied gas, for 60 seconds 10 l of water is delivered to the water supply system, the column width does not exceed 290 mm. The firebox of "dry" execution is complemented by a multi-level safety line. The nominal heat output is 17.9 kW, and the hourly gas consumption reaches 1.89 cubic meters. The efficiency is relatively small compared to other models of this manufacturer and is 84%. The models of the Comfort line are supplied in silver, painted in white tone or with stainless steel lining. Baltgaz Comfort differs in principle from the piezoelectric launch, it is necessary to use 2 batteries (on the Neva collection, only 1 battery was enough).

The company completely refused to use components supplied from China. All parts of the newest line of geysers are manufactured in Russia. As the manufacturer claims, this will increase the attractiveness of products for customers and press even such famous competitors as Bosch, Ariston.In columns Comfort mounted steel (stainless) burner modification Ungar. Provides protection against overheating of the coolant and related problems.

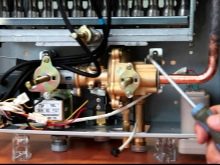

Probable failures

With all due respect to the engineers who designed these speakers, and their assemblers, it is not yet possible to create an extremely reliable design. And because consumers have to prepare for the elimination of various problems, failures.

If the water heater does not ignite and there is no spark, the reasons may be:

- too weak pressure in the water supply;

- loss of battery charge;

- contamination of the igniting electrode;

- scaling on the heat exchanger;

- water filter clogging;

- violation of the integrity of the supply chain;

- closed valve on the input from the plumbing.

There is also another kind of problem when a spark is present, but it cannot ignite a gas. First of all, it is worth examining the solenoid valve, when detecting its failures, the device is replaced. It is also required to check whether the distance from the end parts of the electrode of the candle to the head part in the burner is too large. Experienced owners of heating equipment also always have a pressure gauge at the entrance to the heater and above all, check its readings.Unauthorized termination of work every 7-10 seconds indicates faults in the membrane of the water node, which can only be replaced.

If the part is not changed, it will provoke an abnormal reaction of the draft meters in the chimney or the actual temperature. It is also worth checking whether the contact with the ionization recognizer is normal. When the column does not warm the water, first of all, you need to inspect the heat exchanger - perhaps there appeared scum.

It is also recommended to check the gas burner, which accumulates non-combustible dust during operation. When both these assumptions were not justified, the membrane should be changed.

It is important to remember that the system is not capable of heating the water to the desired level if the pressure in the gas pipeline does not meet its needs. It is also useful to check if cold liquid is invading the hot stream due to a failure in the mixer. When installing a completely new gas water heater, which does not warm the water, there is an error in connecting the inlet and outlet hoses. Sudden shutdowns at 2 or 3 minutes of operation, after which the unit does not light up until it cools completely, indicate that the source of the problem is a chimney or ventilation.

It so happens that the gas column is turned on with a kind of clap, the volume of which can be different, from barely noticeable to a “weak explosion”. Usually, the insulator of one of the spark plugs is covered with soot. A similar problem is associated with the transition of electricity to the body. The problem place is required to be isolated, the ionization electrode and the candle itself should be cleaned to a shine, and contact with the wire is also checked. It is also useful to check if the gas does not ignite outside the burner (the so-called near flame).

The last problem faced by people is the arbitrary self-switching of the gas column. For the most part, this problem is associated with a thermal regulator or temperature meter. After evaluating the condition of these components, it is necessary to replace the defective part. You also need to check if the reset valve is open all the time. If it has deteriorated, the heated water constantly flows into the sewage system, and the system recognizes this as a “warm up still” situation.

Video review of the gas Baltgaz Comfort 11 see below.