The principle of operation of indirect heating boilers

Heating of a liquid at a combined heat and power plant with wiring to homes is not available everywhere. And even where it is, there are still technological breaks and the risks of failures on the highway. Various devices, including indirectly heated boilers, help to cope with these problems.

Special features

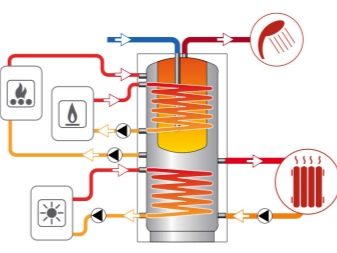

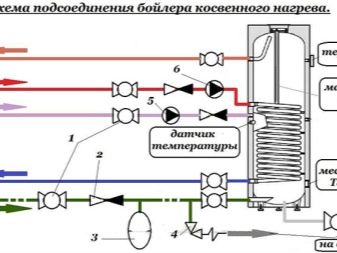

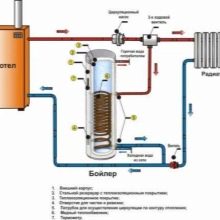

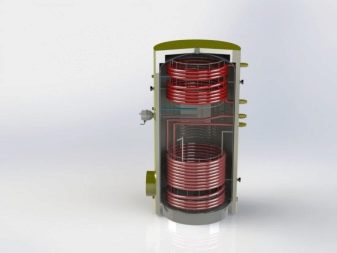

Indirect heating boiler is so named not by chance: unlike all other existing options for obtaining heat, it is not equipped with its own heating unit - heat is generated from external sources. In some devices use boilers, others are connected to the central heating mains, taking heat from the surface of the pipes.In remote areas, even solar panels can act as a primary water heater. Regardless of the specific performance, thermal energy goes through the coil passing through the boiler.

The pump circulates, and upon contact between the two surfaces, the pipe heated in the boiler itself is heated. For maximum reduction of heat losses, polystyrene and polyurethane are used, which reduce heat leakage to the outside. In such a heating device cold water penetrates with the help of general water supply.

To connect the boiler to the source of coolant, special nozzles are used. When the circulation cycle through the coil is completed, the coolant enters the heating system again - this is done through the outlet pipe.

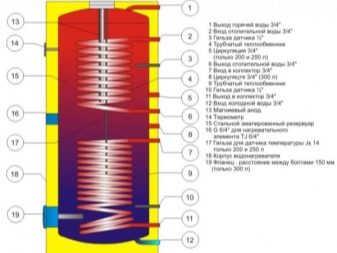

Anyway, the power of the heat source is of primary importance. If it is too weak, the water simply does not have time to warm up to the desired value. There are almost no external differences from a gas or electric boiler. Only additional holes for the input of fluid and output can recognize such a device. To suppress galvanic corrosion, magnesium anodes are used.

Device

The principle of operation of the indirect heating boiler in most cases involves placing the inlet in the lower part of the apparatus. But there are models in which such a block is located at the top, and then the liquid moves in the direction of the lowest point. The pump, developing the pushing force, drives the coolant along the contour. At the same time, being among the colder water, he gives off heat. Usually the coil operates with one portion of liquid in several steps.

Having found that the temperature of the coil coincides with the temperature inside the heating unit, the relay disconnects the electrical circuit supplying the pump. At the moment when the sensor registers water cooling to a predetermined value, the flow of current is restored, and this allows the pump to pump hot water from the boiler to the tank. The upper connection of the coil to the source of the coolant is considered the most advantageous in terms of energy.

The advantage of indirect heating boilers over other models are:

- markedly lower energy costs;

- increased generated power;

- the opportunity to supply warm water to several consumers at once;

- ease of installation and the rate of heating of the fluid.

The main disadvantage is also related to the principle of operation of the device: it is firmly tied to a real source of heat. If such a source made heating, then in the summer months the system will be inoperative. To compensate for this flaw can built-in heaters, which are present in almost every boiler. Devices with indirect heating are a bit more expensive than their simple electrical counterparts. In addition, increasing the length of the line and adding an additional link entails increased power consumption.

Some layouts even allow the installation of KN boilers and conventional gas or electric boilers, side by side, to reduce the space occupied. The heat exchanger in the apparatus is made of steel or brass, the designers are trying to maximize its surface. In addition to thermal insulation, insulating materials are sometimes placed on the housing. There are models with a pair of heat exchangers that heat the fluid noticeably faster than conventional designs.

To avoid the harmful effects of high pressure, use safety valves and thermostats.

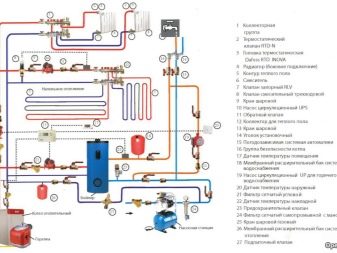

Systems with recycling have a more complex structure. They allow you to get hot water immediately when you open the faucets, and not a few minutes after that. In addition to the standard set of components, you will need:

- expansion tank;

- a discharge valve;

- backstop valve;

- safety device.

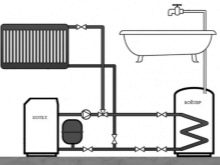

It is necessary to carefully consider where the recycling point will be located. To bring cold water will need to be in the bottom hole, and the release of hot will be made from above. There is also connected leading down the coolant pipe. Connecting all the pipes to each other is achieved through adapters, as well as taps and valves. Important: it is necessary to immediately think through the entire heating system. Only under this condition will it be possible to ensure high-quality recycling.

The use of recycling provides increased efficiency of heating at home, the efficiency of the boiler immediately grows by 30-35%. For strapping it is recommended to use high-quality products made from the strongest materials. Experts believe that the use of corrugated rubber hoses and any materials obtained by powder metallurgy methods is unacceptable.You should not be afraid of noise: the system uses pumps of small size, which work without unnecessary sounds. The most common organization scheme is with separated circuits for heating and hot water.

The servo drive in such a system automatically turns off the heating circuit when the water tap is open. As soon as there the water reaches the set temperature, the heating water begins to warm up again. In another version, two pumps are installed: one provides recirculation in the heating circuit, and the other around the boiler perimeter. Thus, priority is given to the normalization of temperature in the heater, and only then the automation is engaged in heating radiators. Normal operation of such a system is ensured only with a thermostat and a device that switches modes.

Kinds

In addition to the strapping scheme, there are many other nuances that allow you to more fully take into account your needs. And the thing is not only whether to install the boiler on 100 or 200 liters. It is also important how to install it. Quite great popularity was gained by wall models. Some of them work from a gas boiler, and some from an electric heater.

One of the latest innovations is a combination of electrical and indirect circuits.Such boilers are just called combined. An impermeable housing with an integrated tank is attached to the wall. A heat exchanger is carried out along the tank, supplemented with tubular heating elements. The water in the tank that has passed through the pipe is additionally heated. The undoubted advantage of such a scheme can be considered suitability to work in any season of the year.

In order for the wall unit to work stably and not fail, you should give preference to products of well-known companies that have been produced for a long time.

The advantage of the combined subtype is the ability to save increasingly expensive electricity. It becomes possible to simultaneously use two or even three points of water pumping. In this case, no one will feel either the weakening of the pressure, or lowering the temperature.

Important: as with any indirect heating boiler, the combined apparatus itself is more expensive than similar products of direct heating and will take up more space.

High thermal inertia can also be a problem, especially with a large tank size. The vast majority of boilers are now made of stainless steel.This material is both light and durable, with minimal risk of corrosion. In addition to the main substance of the body, an additional coating applied to it also plays its role. A one-piece stainless block will last much longer than a ferrous metal under a glass porcelain film.

This is noticeable even by the guarantees that manufacturers give to their goods: they are 5 years and 1 year, respectively. The high cost of stainless steel seriously limits its demand. A partial solution to the problem is the choice of models with an anode based on magnesium. In steklofarforovye boilers certainly need to put coarse filters. At least, all sorts of garbage will not scratch the inside surface.

As is already clear, the indirect heating device only takes energy from other systems, which generate heat by itself. Most often for this purpose use a gas boiler or heater with electric heating elements. Because the choice between two similar options is worth considering separately. The natural gas hot water storage unit is perfectly compatible with the heating boiler.It is no wonder that such constructions became frequent guests in the boiler houses of various cottages and simply private houses.

The system working on electricity brings the liquid to the desired temperature in 1-3 hours. After reaching the required level, it is able to instantly supply water to a number of consumers in a large volume. The pressure in the water supply system and the initial temperature of moisture affect only the waiting time, but not the operation of the device. The time of simultaneous strong consumption is limited only by the tank capacity. Installation of an electrical apparatus does not require special permits and installation of complex chimneys.

Besides, Heaters on the current serve for a long time. Modern models are almost always covered with a ceramic layer and can not burn out during the formation of scale (as it is shown in advertising). It is very important to choose the right volume of the boiler: too small will be impractical, and very large ones will have to be heated for a long time. A gas appliance is valuable in that it does not depend on electricity (in the case of installing a boiler with an open combustion chamber).

The problem is that the installation of an apparatus burning natural gas must be carried out strictly according to a specially designed project.The project is created by a specialized organization, it is approved by the regulatory authorities.

In case of violation of these requirements, they can issue an order to dismantle the equipment and even insist on it in court. Gaseous fuel inevitably generates and very harmful products of combustion, which will have to divert to the chimney or by means of a coaxial pipe.

Installing an electric boiler in conjunction with a boiler can even be done with your own hands. This combination will be more reliable, since the only requirement for caring for it is a systematic cleaning of the tanks from the inside and a change of anodes. Having dealt with the preferred type of fuel, it is useful to find out what a horizontal boiler is. The advantages of such a device are deservedly considered:

- simplified installation;

- accelerated heating of the fluid;

- total work period of 8-10 years;

- increased strength and wear resistance;

- optimum quality of thermal insulation;

- compactness;

- relatively small power.

But the location of the heating unit in the supine position can deliver certain inconveniences.So, due to the specificity of the placement of the nozzle under the hot and cold water, it can be mixed. As a result, the hot liquid will be just warm. In addition, this technique is expensive. A flat tank (placed in a horizontal hopper) does not hold heat as well as a classic one, made in the shape of a cylinder.

Along with wall indirect boilers, floor-standing analogues of them are in demand now. The undoubted advantage of this design is the low demands on the mass of the product. A heavy heating apparatus will either not be able to be attached to the wall at all, or it will have to be done at your own peril and risk. As in the previous case, the external heat source is gas or electrical energy. Leading manufacturers equip their products invariably with special legs, performed in an embedded or dismountable format.

Many outdoor devices expose under sinks, which allows you to get hot water almost immediately.

It is important: to distinguish between floor and wall model solely in appearance is quite difficult - you need to either focus on the descriptions in the technical documentation, or use the help of specialists.

The indirect water heater placed on the floor surpasses the suspended samples in design (decoration) quality: it easily fits into the most different interiors.

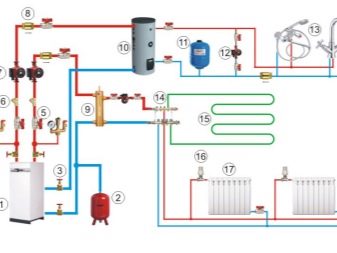

The three-way valve option is preferred if the system prepares and supplies a significant amount of water. Coordination of the valve takes over a common thermal sensor. The three-way system is recommended for areas with extremely hard water, because another option - with a double-circuit boiler - is not reliable enough in this situation.

In order for the valve to work properly, attention will need to be paid to adjusting the thermostat. It is impossible to heat the fluid in the tank more than in the boiler, because then the automation will give a command for continuous operation, and it will not be possible to warm the heating circuit.

It remains to answer one more question: “Which boiler is better to choose: single or double? ". Of course, in this case (in close connection with the indirect heating boiler), it is worthwhile to choose a single-loop device. If there are already two outlines, there is not much point in using additional equipment.In most cases, switching is performed when the temperature reaches from 50 to 55 degrees. Expansion tanks are usually selected in the amount of 10% of the drives.

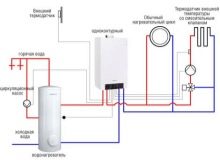

Wiring diagram

A water heater, even the most reliable and well-made, may not give a good result. The main reason for this development of events is an illiterate connection scheme or a violation of the optimal principles for building a system. Maximum attention should be paid to the security group. This kit is often mounted on a cold fluid inlet and replaces a simple valve. The reason is simple: if the thermostat breaks down, the rise in temperature and pressure can be very rapid.

Only an immediate discharge of fluid to the outside can prevent an explosion. The bandwidth safety group is far ahead of simple valves and efficiently copes with this task. It contains a built-in non-return valve, moreover, some models also contain draining or cutting ball valves. Armature for water supply is available in a wide range, and there is no unified architecture of it.A block with ½ or ¾ inch thread is used to inject cold liquid.

In addition to this part and the check valve, a ball valve is installed to help cut off the water. By default, the socket for the pressure gauge is closed. But if the owners are interested in the fluid inlet pressure, they can dismantle the plug themselves and install a meter.

Be sure to install a tool for manual drain: it helps to flush the liquid in cases where the automatic for some reason does not work, or even get ahead of it.

Strictly speaking, the drain key does not work by itself, but in close connection with a safety valve (opening it and freeing water to the sewage system). The connection to the siphon is equipped with a 1 inch thread. An additional air inlet is provided. For your information: it is recommended to form the most elegant drain into the sewer pipe. Even such a utilitarian part will benefit from high-quality design.

Security groups for boilers produced by many companies: both Russian and foreign. The differences between them are due primarily to the capacity of the tank, with which they can cope.So, the product Stiebel Eltron ZH 1, despite its strange appearance, is quite functional and capable of working with tanks of 200-1000 l. The system is equipped with a shut-off valve, check and security valves (the latter is complemented by a drain pipe). There is a pressure reducer. True German quality turns into a very substantial price of the product.

More simple modifications are essentially only an improved version of the valve. The right choice, in addition to the purely financial component and the total capacity, always takes into account the diameter of the thread. The overwhelming majority of security groups are connected to drains with threads for corrugations or have a siphon in the delivery set. As for the availability of additional details, they expand the capabilities of the consumer ... but also increase the bill payable.

A quality safety group is made only of brass - other metals and polymer structures are not even worth considering.

As for the manufacturer, it is not so much the name of the company that is important here as its good faith. Even in Asian countries much is being done properly, but European brands are no longer a 100% guarantee of reliability.But, in addition to protective equipment, attention should be paid to the main working part, namely the connection of indirect heating boiler with built-in heating elements. This work is not significantly different from the connection of the device of the classical electric type.

The mains voltage through zero and the phase is supplied to the input terminals on the thermostat. Zero is mounted on the screw to the drive body. Next, zero is connected to the first contact of the heating element, the second is fixed to the output of the regulator, and the phase is introduced to the input of the regulating unit.

Note: before the first connection of the device to the network it is required to fill the tank with water. This will help avoid overheating and damage to the device.

The degree of heating is also regulated before switching on, but after filling. Important: start should be made with the included protective device. This will prevent unpleasant surprises. The thermostat in the described circuit actually replaces the fuse. Separate models differ in constructive fusion of a thermostat and thermostat, but this will not affect the essence of the work in any way. It is worth paying special attention to the selection of the protective shutdown device: the safety of both the equipment itself and the people who will use it depends on it.

Connection directly to the boiler terminals (without mediation by an additional socket) is recognized by all specialists as the most correct and rational solution. If, however, an additional connection point is needed, it should be placed only after the differentiating automaton. In case of urgent need, it is recommended to consult an experienced electrician.

With regard to connecting the boiler to the supply line, it suffices to choose hoses and connecting elements of a suitable section. More information can be found in the manufacturer's instructions.

How to choose?

But before connecting the boiler, it is necessary to take into account how it should be. For domestic needs enough capacity from 100 to 300 liters; if it is planned to supply water to a hotel, dormitory, car repair shop, and so on, then a tank of 1000 liters at a minimum is already required.

When using an indirect boiler, the total and useful power should be distinguished. So, if the total heating force according to the documents is 24 kW, then the real effect of heating will be only 15 kW, the rest of the heat will be spent on the water heater itself.This circumstance should not be forgotten when planning an deployable system.

100 liters are considered sufficient indicator for three people to be able to calmly meet their needs, including not too active washing in the shower. For rarely used cottages, even 80 l is considered a sufficient indicator. But if the country house at least in the future may become the main one, there is no need to skimp. Since an indirect heating boiler cannot provide heat by itself, you need to think about the mechanism that will perform this function. Some people find it more convenient to use solid fuels, others prefer to burn natural gas; electric boilers can work year-round.

Other things being equal, the larger the heat exchanger (coil), the sooner the water will be heated. If its area reaches 1 square. m., warm 120 liters of water at room temperature to 75 degrees will get just ½ hour. Copper and brass coils are better than steel coils in terms of heat transfer. Such an indicator as strength, which determines the dominance of steel products, is practically irrelevant here. As for the tank itself, engineers consider stainless steel products, additionally reinforced with ceramic or glass-ceramic corrosion protection, as the best choice.

When it is known exactly how to connect the boiler to additional sources of energy, it is better to choose designs with a pair of coils, and not with one.

Most quality versions of indirect water heaters are equipped with thermal protection based on foam rubber. If polyurethane is used for this purpose, it means that the model is really new and high-tech.

There is no point in acquiring a storage device that is not equipped with a magnesium anode: a “saving” of this kind will invariably lead to the appearance of scale and even to the imminent destruction of the apparatus. Do not neglect the additional sensors, indicators.

Before buying it is recommended to clarify not only the warranty period, but also those moments when it is canceled. It is useful to find out exactly where the service centers are located and whether it will be convenient to get to them. Advance consultation with electricians and plumbers about the systems installed in the house will be useful. Or, at least, self-accounting of the connecting dimensions of the required voltage. We must not forget also that a certain place should be reserved for the water heater, and this should not cause inconvenience to the user.

Manufacturers and reviews

One of the best options in 2018 is considered Baxi Combi 80. The stainless casing of this boiler is really made of high-quality metal, which allows it to be listed in the most authoritative ratings of heating equipment. The design is designed in such a way that you can easily put it in a small room. The compact size and thoughtfulness of the controls are highly appreciated by consumers.

Another demanded model, this time a wall one, - Protherm FE 120/6 BM. The developers have equipped the heater with a 490 l tank, inside there is an excellent enamel coating and protection against microbial aggression. Warning: water can be heated to a maximum of 85 degrees. The system uses reliable thermal insulation based on carefully selected polyurethane. In 60 seconds it warms up to 59.1 kg of water. The product is ideally compatible with cast iron floor boilers of the same brand.

This model is also suitable for recirculating the flow of hot liquid, and there is no expansion tank. Consumers say that the device can maintain the set temperature, but there are some indicators of operating modes for it.Against the background of the practical advantages of this version, however, it is difficult to consider such a product to be somewhat flawed or not of sufficient quality as compared to others. The boiler is connected to the heating and plumbing circuits via inch connections.

Such a solid company as Buderus, also did not overlook the issue of indirect heating boilers. A special place in its lineup is taken by the floor-mounted hot water storage unit of the Logalux SU120-SU1000. Vertical execution is typical for this manufacturer, and in different versions the tank capacity varies from 120 to 987 liters. In different versions of the model being disassembled, tanks of 120 and 160 liters can be found. The water is heated there the same way: up to 95 degrees at pressures up to 10 bar.

But the differences in the area of the heat exchanger (0.7 and 0.9 sq. M.) Allow, with a fairly significant difference in the amount of liquid, it is heated up equally quickly (the difference does not exceed 1 minute). Connector under the heating element in the design is not provided. In the LT 135 model, it is possible to mount the boiler on top of a boiler, which drastically reduces the need for installation space. The intensity of cooling water after the shutdown is 20% less than that provided by the official standards.Consumers most of all appreciate the convenience of servicing such equipment.

Russian indirect boilers are not much inferior in their capabilities to products made in Europe. But there is no reason to trust Chinese models yet. It is better to wait until their quality is tightened after the rest of the equipment collected on the banks of the Yangtze and the Yellow River. Czech brand goods Drazice make a strong competition to the “grandees” of the international market Vaillant - a reliable German company, supplying indirect floor boilers with tanks, designed for a volume of 115-200 liters.

Tips and tricks

- If you need an indirect boiler for receiving and storing hot water, it is worth considering a few more subtleties. Thus, the average power drive, reaching a maximum of 50 liters, is capable of providing heated liquid up to 300 liters within an hour. The system can be connected to a rural stove or a security camera. Due to the use of additional pumps that provide circulation, it is easy to supply liquid even to the upper floor. In some cases, recycling is done through a heated towel rail, and if not, a blunt recirculation circuit is formed.

- A point for recycling hot water should be provided in the middle of the tank in height. In some cases, it is put somewhat higher, but such a decision should not be made without consulting with specialists. The spiral pipe (heating circuit of the boiler) should provide the movement of the liquid from top to bottom. The opposite move contradicts the laws of thermodynamics and therefore causes a decrease in efficiency. Most experts believe that indirectly water heaters should be equipped not with a simple thermal relay, but with one that switches power from one circuit to another.

If the creators use just such a detail, there is no special need for a three-way valve. It is recommended to pay attention to acquaintance with electrical circuits and the operation of servos. Do not be shy - be sure to ask about all the details and nuances.

It is also advisable to avoid six typical errors during installation of equipment, such as:

- lack of pipe insulation;

- lack of expansion tank;

- the use of additional materials and strapping of dubious origin;

- use of water heater, not protected from germs;

- poor preparation for circulation;

- exclusion from the scheme of thermostatic valves.

About indirect heating boiler: device, principle of operation and wiring diagrams, see the following video.