Rules for connecting storage water heaters

Accumulative (accumulative) heater - overall, durable, efficient and convenient device. It has a large supply of hot water, which makes it possible to work with several sampling points, even when several people use it at the same time. It can work with a cheaper electricity tariff (the second tariff is night), which significantly reduces the cost of heating water.

Special features

The advantage of electrical systems used to heat hot water is the low installation cost associated with their installation. It is also true that they may be more expensive to operate (although this is not always the case).But in general, can be an interesting alternative to ensure the comfort of bathing in the bathroom in streams of hot water. There is no need to light a fire, and then carry away the ashes from the hearth of wood-burning stoves.

In these devices, water is heated in the tank to a certain temperature and remains in it until it is used. When the water has cooled, the heater will turn on and the set water temperature will be the same. This allows you to effectively use hot water at the right temperature and with the proper pressure of the jet. Due to thermal insulation, tanks maintain the highest temperature for several hours after heating. There are two types of storage heaters.

- Working under pressureThey have a large stainless steel tank up to 200 liters. All the cranes in the house can be connected to them.

- Working without pressureThey are characterized by a small reservoir up to 10-15 liters. Only one point can be connected to them.

Low-power single-point devices have low efficiency, so they can only heat a small amount of water in them. They are installed next to the faucet, which serves hot water.Often these are very small devices that can be installed directly above or below the sink.

On sale is equipment equipped with its own battery and even a shower. Such a heater may be, for example, an ideal solution in a toilet that is far from other sanitary facilities. Those that have a capacity below 6 kW, serves no more than 3 liters of water per minute at 40 ° C.

Space must be provided for the heater. The longer the water heats up, the greater the volume that the heater must have. If you connect one capacitive heater, from which hot water will flow to all inlet points, it is necessary to provide circulation to ensure the movement of water in the pipes and prevent it from stopping. Due to the circulation at the time when water is not used, it does not cool in the pipes.

After unscrewing the tap, the water in the pipes first flows out of it, and not from the heater. If there is no circulation in the installation, the water is usually cooled. Hot water pipes must be thermally insulated.

The second, less popular, but recommended method of preventing water cooling in pipes is to install special cables around them that will heat the water from the inside.

Connecting the heating element with a top connection to a double-circuit boiler and electricity in an apartment or a private house with your own hands is a simple matter if you follow all our recommendations. The height of the device and its appearance is selected individually in each case. This can be considered in the estimate.

Power selection

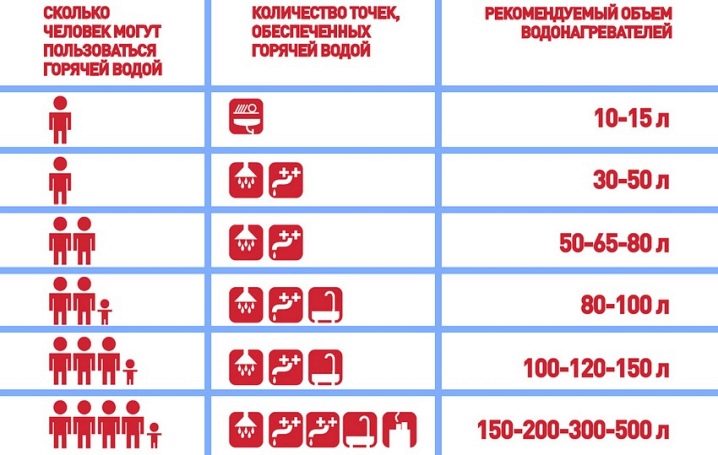

The criterion for selecting a capacitive water heater is how long the tank is filled with water. Depending on the requirements of the household members, one of the possibilities of the heater must have enough water for one or two baths. For a family of four, it is worth buying a heater with a capacity of 180-200 liters.

Capacity required

The capacity of the tank must be adjusted to the amount of water used in the house, and depends on the number of people. It is assumed that with economical use a person uses up to 30 liters of hot water. In homes where no attention is paid to water consumption, a boiler is needed that can hold up to 60 liters per person. A family of four may plan to purchase a heater with a capacity of up to 240 liters.

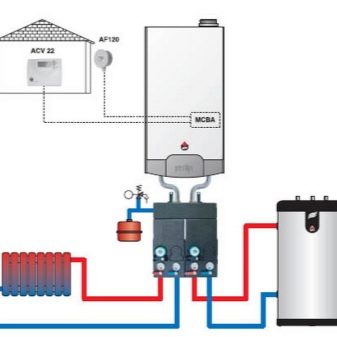

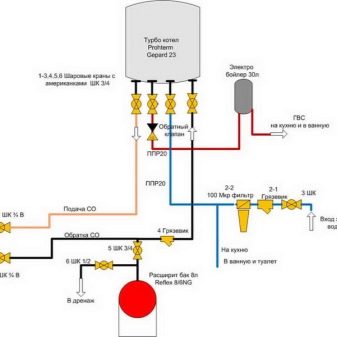

Mounting scheme

The heater can be installed in any room protected from a temperature drop below 0 ° C, so that future maintenance work is possible. The assembly site must be rationally chosen so that household appliances, hot water pipes and electrical wires do not interfere with the installation.

To avoid energy loss, all hot hydraulics must be carefully insulated.

When choosing an installation site, you need to take into account the space required for operation and replacement of the protective magnesium anode, as well as the weight of the filled heater. Due to the significant weight of the device, filled with water, its suspension is possible only on the load-bearing walls with sufficient carrying capacity. The heater can be installed in a vertical (recommended) or horizontal position. Heater accessories:

- hot water pipe;

- magnesium anode;

- a heating element;

- thermal insulation (polyurethane foam);

- enamel tank;

- Control Panel;

- connection for the selection of hot water;

- connector for cold water;

- bottom case cover.

How to install?

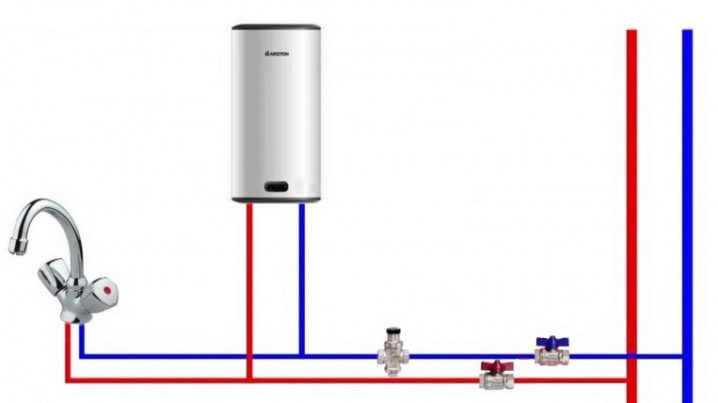

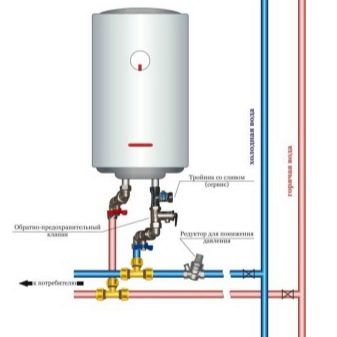

The heater must be connected to the water supply network with a pressure of not more than 0.6 MPa, and the minimum pressure cannot be lower than 0.1 MPa (about 1 bar). A safety check valve should be installed on the cold water supply pipe. The valve should not be mounted directly above the heater. The outlet of the safety valve must remain open, that is, connected to the atmosphere.

There should be no device (for example, a safety device) between the safety valve and the heater. At the same time, a tee is allowed, on which a drain valve is located, allowing the tank to be emptied. If the pressure in the water supply network exceeds the value of 0.6 MPa, it is necessary to reduce it by adjusting the valve.

Heater Installation

The heater must be installed by qualified personnel, who must take care of the free access to the device in case of further maintenance or quick replacement. Depending on the design, the unit is attached with screws to the holes on its rear wall. Installation must be carried out on the bearing wall of the building.This is caused by the significant weight of the water filled heater.

An apparatus with a large tank capacity can provide multiple water takeoff points. Do not bend the connecting pipes on the housing. This may damage the anti-corrosion protection of the enamelled tank.

Connection to the AC mains is made only with a type P outlet. -0 / 230V / 16 A (outlet with a grounding terminal).

First start

After installing the water heater it is necessary to fill it with water. After filling, the tightness and quality of attachment is checked. If necessary, tighten all screws well. If there are no leaks, the heater can be plugged in by plugging it into a power outlet. Use the thermostat knob to set the desired water temperature. A red light indicates power consumption and the start of heating.

Heater off

To turn off the water heater, you must unplug the power cord. If the shutdown occurs in winter, the water in the heater may freeze and must be drained.

Heater health

To maintain the heater in good condition, it is necessary to remove scale in the tank at least twice a year.If there are no relevant chemicals or acids for this activity, you can try to crush the layer of limescale manually (care should be taken not to damage the inner surface of the tank).

Tips and tricks

The safety valve is a very important part. When the pressure in the tank exceeds the allowable value, the valve will automatically open to prevent an explosion. If the safety valve does not work properly, for example, it flows, it must be replaced.

Safety valve replacement

The valve protects the installation from damage and protects users. If there are any disturbing symptoms, it is necessary to make a decision about the replacement. Currently, the old valves are not repaired. If signs of malfunction are noticed, you need to buy a new part.

The function of the safety valve should be checked every six months. Many manufacturers offer siphon valves that force the valve to discharge. After opening it, a small amount of water should flow out. But if the flow continues uninterruptedly, it’s time to replace it. Replacing an old valve with a new one is a simple operation, and you can do it yourself.

Replacement tools

First of all, we need a new part. It is best to unscrew the old valve and buy the same one. A good solution is to go with a defective item to the store. Customer support will help you make the right choice. In addition, you will need a wrench.

Sequencing

You need to start by disconnecting the power source and closing the main water valve. Then it is necessary to empty the tank. To do this, open the cold water tap and wait until it all goes away. When the tank is empty, you can prepare the valve for assembly. Wrap the thread with sealing tape, observing the correct direction of the thread. Under the tank, place the water tank so as not to fill the floor. If it is a siphon valve model, it must first be unscrewed.

Then the key turns off the water supply. During this operation water may leak out, therefore it is necessary to work very slowly with the tool. Removing the old valve is fast. It is simply unscrewed, and after its removal, the thread is covered with sealing tape.

Of course, when installing a new safety valve, you need to tighten it with an adjustable wrench with sealing tape.

After installation of the valve, all elements of the installation must be connected. Lay the gasket on the supply hose. It is worth replacing it with a new one and screwing the hose onto the valve. You can now open the main water valve by letting fluid flow into the valve. Finally, let the air out of the tank by unscrewing the tap of warm water. If the water flows smoothly, you can turn on the power supply. The unit should work correctly.

Errors and solutions

In order for the newly installed hot water devices to work properly, you need to follow the rules for their installation. Equally important is the systematic testing and programming of the operation of the device.

Non-insulated hot water pipes

Many users do not know how much heating costs are due to the fact that pipes with warm water are not insulated. The water in them is very quickly cooled.

Solution: When deciding on the installation of a new heater, it is necessary to insulate the pipes. In order for the heat loss to be effectively reduced, according to the new rules, the heat protection must have an appropriate thickness.For example, for pipes with a diameter of up to 22 mm, an insulation thickness of 20 mm should be used, provided that its thermal conductivity is 0.035 W / mK. With an increased diameter of 22-35 mm, this thickness increases to 30 mm.

Heating is not supported

Sometimes users complain that after several years of operation of the water heater, rusty water flows from it.

Solution: Most tanks are made of steel coated with several layers of enamel. In addition, they are protected by a magnesium anode placed inside. It creates a low voltage that counteracts the corrosion of the tank. After a while it works, therefore every 2-3 years it needs to be changed. For this reason, regular maintenance of the tank is very important. According to the rules, it should be held at least once a year.

There are heaters on the market that are protected by anodes to increase service life (magnesium-titanium or titanium). However, the most expensive boilers are made of stainless steel.

Attention! Electrical flow meters should also be checked regularly.

Heater not programmed

It happens that users who use the second, cheaper rate every day at a certain time,The electric storage heater is turned on and off to reduce the cost of preparing hot water for washing. Such service is very cumbersome.

Solution: This can be avoided by installing a programmer (this is easy). It is equipped with a timer, so you can choose the hours of operation of the device. At the right time, the programmer will automatically shut off the power supply. It is important to sometimes check the time at which the timer is set. This is due to the fact that in the absence of power, most controllers stop working, and the clock starts only after power is restored, which causes the correct time to go astray. As a result, the programmer turns on the heating at a different time than during the hours when cheaper electricity can be used.

When using electric water, it must be remembered that the tank must always be water when it is connected. Even a small amount of air entering the boiler can damage the heater and, therefore, it will need to be changed. Therefore, when working in the water supply system or during a break in the water supply, the power source must be disconnected.After restoring the flow of water, you first need to expel all the air by opening the hot water tap until water runs out of it.

Review and connect storage water heaters, see the following video.