TEN for a water heater: what is it?

Water heating equipment today is widely used in everyday life. Device configuration includes a variety of elements responsible for their functioning. In the list of such parts is to provide heating elements.

Special features

Electric water heaters are in great demand, due to which such products are represented on the market in a great variety. The demand for such devices is due to the high cost of hot water supply, as well as the periodic disconnection of hot water in some areas.

The latest models of boilers have a special element, due to which water is heated in a closed container. It is an internal battery.Such a device is called TEN. Based on the accepted abbreviation, TEN stands for "tubular electric heater."

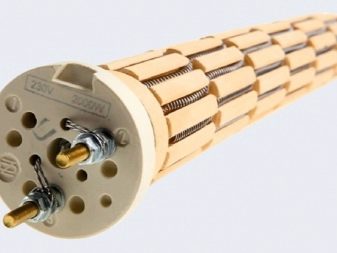

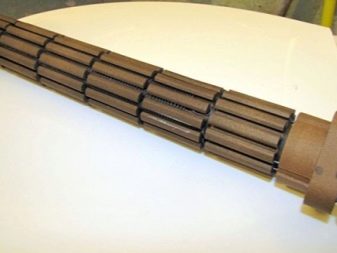

A device is assembled from a wire helix, which is placed in a metal sheath, due to which the wires do not come into contact with water, but heat the tube. In the heater, such a part is inside, contacting in the process of working with water. As a result of the passage of current through the heating element, the fluid in the boiler heats up. The metal tube, as a rule, is made of stainless steel or copper alloy. Elektroteny are the main elements of water tanks of any type. The power supply of the device is the electrical network.

Everyone knows that water and electricity together pose a danger to humans, which is why manufacturers are trying to produce appliances with a high level of safety.

Heating elements installed in water heaters can be of two types. Each type of element has specific features.

Device and species

In order to make the right choice when purchasing electrical equipment, it is necessary to study the characteristics of all the available varieties. TENY are closed or open.

Wet or open items work by direct contact with the liquid in the tank. The configuration of the element has a classic look, a similar detail is present in any electric kettle. If a part of this group fails, its replacement will not require complex work. An open heating element contains magnesium oxide and quartz sand inside its tube. These components belong to the type of heat-conducting substances. The nichrome wire acts as a basis of TENOV.

Manufacturers produce various water heaters with open-type heating elements. Based on the distinctive features of products, products can be classified.

- According to the method of fastening elements can be nut or flange. The latter type is divided into cast and stamped products.

- An important point - the presence of the anode socket. Devices with a nut may not have an anodic attachment or may be manufactured with additional fasteners on the flange.

- The shape of the heating elements can be standard straight or curved in different directions.

- According to the type of raw material for the tube, the elements can be made of copper or steel.

The following positive characteristics are inherent to elements of open type:

- the main advantage of wet heating elements is the high rate of water heating;

- products with this type of heating element have a low cost;

- quality products are additionally covered with vitreous enamel, which reduces the risk of corrosion and scale formation on the basis of the part.

The disadvantages of wet heating elements include a low level of product safety, as well as a significant reduction in heat transfer due to the formation of scale on the surface of the tube. As a result, more electricity will be expended to heat the fluid in the boiler. In addition, the poor quality of urban water adversely affects the service life of such products.

Elements of the closed type assume placement inside a special ceramic flask which provides heating of water. The part itself is not in contact with the fluid, due to which it received the name "dry" PET. There are high safety requirements for the flask, so the product is made from steatite or magnesium silicate.The raw material used for the manufacture of the heating element is stainless steel.

Such a configuration involves heating the fluid by transferring heat to the enclosure.

TENY of the closed type have the following advantages:

- devices have a high level of safety during operation, due to which the occurrence of a circuit is not possible;

- devices are convenient and easy to use;

- similar types of water heating products have a long life;

- devices are economical;

- in case of malfunction, the product can be repaired.

The disadvantage of such heaters is the fact that the details of the closed type are made specifically for each model of the water heater. For this reason, in the event of a breakdown, the fuel element can only be replaced with a similar part, which sometimes causes some difficulties.

Check

Manufacturers do not emit any specific requirements regarding the maintenance of electric water heaters with heating elements. However, there are a number of recommendations that allow to increase the operational life of products, as well as to ensure its uninterrupted operation.

First of all, it is necessary to control the process of heating water by a boiler and to note even minimal changes during operation. Signs indicating a malfunction of the heating element in the device may be an increase in electricity consumption, as well as a decrease in the heating rate of the standard tank volume. The specialist can better check and diagnose the water heater for malfunctions, however, with minimal knowledge of the device and its components, you can do this kind of work yourself.

When purchasing a device with a heating element for heating water, it is worthwhile to be prepared in advance for the fact that over time, both the heating element and the magnesium anode will need to be removed and replaced. Since these parts in the device are consumables, they burn out over time.

The developed magnesium alloy can be determined by visual inspection. If such a problem is detected, the anode must be replaced. The operational period of heating elements without such a component is reduced many times. A number of boiler manufacturers recommend replacing this element each year.

Water heaters of the latest generation are designed to operate for 20 years (provided proper use of the device). This is explained by a number of changes made to the configuration of devices that relate to the use of double wire for heating elements instead of single wire. This feature allows the element to work for some time, even if one of the parts is broken or broken. But even in this case, it is necessary to immediately replace the faulty heater with a new element.

It is necessary to highlight the most common types of problems that may arise during the operation of heating parts in the devices:

- leaving the boiler of cold water instead of hot can tell about failures in the connection of the heating element with the device thermostat;

- if alternating switching on and off of the device occurs, it is worth assuming that too much scale or lime deposits accumulated on the heater;

- also in the course of errors during installation, an air interlayer may form in the purchased device, which will act as an obstacle for the heating part that conducts the heating of the liquid entering the container.

Timely detection of malfunctions in the operation of heating elements with a thermostat allows you to diagnose and fix the malfunction in time, reducing the risk of more serious problems with the boiler.

To carry out an inspection with your own hands, it is worth preparing a spare heating element, as well as a special tester. Since in some cases it is impossible to detect a problem in the course of visual inspection of the health of the components of the device, the tester helps to identify deviations. It is an electrical measuring device with which it is possible to conduct a comparative analysis of the existing characteristics of the device and the resistance values with the parameters declared by the manufacturer for a specific boiler model.

Replacement

After checking and determining the nature of the failure of the heating element, in which you want to replace the part, you should proceed to the task. The algorithm for its implementation consists of several successive steps.

- The first step is to disconnect the device from electricity.

- Next, you need to drain all the water that is in the tank.

- Then it is necessary to remove the water heater from the fixings in order to provide the most comfortable conditions for repair work.

- To gain access to the heating element, which is located inside the boiler, you need to unscrew the mounting of the lower bar of the device. Before removing anything, it is best to take a picture of the original wiring layout. This will facilitate assembly after replacing the failed part.

- The next step is to disconnect all available wires that lead to the heating element.

- After that, the item can be removed from the tank.

- In some cases, after cleaning the tubular from plaque (with the integrity of the body), you can try to install the cleaned element back. Often, such manipulations help to restore the operation of the device.

- If the described method has not brought results, it is necessary to install a new heating element.

- After this, it is necessary to assemble the tank body in the reverse order.

Clearing

Since most of the apartments and houses that use hot-water tanks, receive hard water from the central water supply, on heating elements of the wet type with time a raid and scum forms.Such neoplasms partially block the conductivity of heat or even exclude it altogether. Elements burn, but do not heat the liquid in the tank.

The first clear sign that plaque has accumulated on the parts is an increase in the amount of electricity consumed by the device.

If time does not respond to such alarming signals, then a small crust can reach large sizes. In addition, it gradually grows over the entire surface of the heating part.

The main threat posed by the raid is that it is able to completely seal the heater. In the course of working with such a crust, it will heat up even more. As a result, either the device will blow or the protective relay will work and the water heater will turn off.

Periodic cleaning will save money and prolong the life of the part. To solve this problem, you can use one of the cleaning options:

- mechanical cleaning of the element;

- chemical cleaning method.

In the first case, work should be carried out with a wet part, as this will facilitate the process of descaling. During mechanical cleaning, a hard iron brush or knife is used.When clearing plaque, it is necessary to comply with all safety measures and try not to damage the base of the element. After performing this cleaning, the surface of the heating element is cleaned with sandpaper.

For chemical cleansing, there is a large amount of household chemicals on sale, the main purpose of which is to remove scale and plaque.

The most suitable composition will be a cleaner for electric kettles. TEN is cleaned in containers with water and cleaning agent, where it is completely immersed.

There is a more gentle version of the composition for cleaning, it is acetic acid. You should work with it in the same way. To increase the effect, you can put the container with the item on a small fire.

When cleaning the parts, you should avoid contact of chemical compounds with rubber seals, which is located on the element.

From the effects of aggressive compounds, the material may lose its properties (first of all - elasticity). As a result, the heating tank will flow.

For how to replace or clean the water heater with your own hands, see the following video.

Tips and tricks

Before purchasing a water heater, any consumer wonders what type of heating element will be the best choice for a device. To choose a more suitable type of detail, you should familiarize yourself with the specific features of each variety, as well as take into account the advantages and disadvantages.

- Flange elements are standard components of water heaters. According to experts, as a result of their operation, the maximum contact between the heating element and the liquid is achieved. However, corrosion and plaque over time will negatively affect the operation of the heater. Many manufacturers have resorted to additional developments that help slow down the accumulation of plaque on the surface, but open types of elements still fail much faster. In addition, maintenance of wet heating parts is quite complicated.

- Heaters of the closed type have an indisputable advantage - their operational life is many times longer compared with the elements of the wet type. This is due to the lack of contact of the housing part with water, which eliminates the negative impact of low-quality fluid, which provided the city.

- In addition, manufacturers of water heating tanks that use closed-type heating elements cover the inside of the tank body and the mounting flanges with special protective enamels. Means are composed of steklofarfor or titanium, which act as a barrier against the formation of scale, as well as the occurrence of corrosion of the surface of the water-heating device.