Plumbing: technical specifications and types of communications

An integral part of any housing construction is the design, which provides not only the layout of the premises, but also the installation of communication systems. Regardless of whether a private house or municipal real estate will be erected, the installation of water supply and sewerage is considered a prerequisite for the operation of the building. These systems are placed inside and outside the structure, taking into account the established rules and regulations.

General device and purpose

Plumbing and sewage are a single system that combines a number of activities aimed at providing the building with water and draining drains. Thanks to a complex of engineering devices and facilities, water is supplied to consumers from natural sources, undergoing preliminary treatment.

In order for the water supply to be uninterrupted, in communications it is necessary to provide for the storage of stocks, this allows us to provide water to various economic objects and settlements. Therefore, the main tasks of the water supply system include: getting water from the source, controlling its quality in accordance with the requirements of users and direct transportation to the sampling points. Such supply, as a rule, is carried out from local or centralized sources and has its own water supply scheme.

Designing communications depends on the choice of water source. For large and industrial sites, centralized sources are usually chosen, and special tanks are used for the local fence. As for the hot water supply, it is most often installed in the form of a closed water intake, where heating and subsequent transportation take place.

For residential premises, the norm of hot water in the water supply system provides for the lower limit of + 60C and the upper + 75С.

Depending on the operational purpose of the building, the following types of water supply are distinguished:

- industrial;

- fireman;

- negotiable;

- household and drinking;

- for the supply of hot water.

Fire water supply is allowed to combine with other systems, including production and drinking water. As for drinking water supply, it cannot be used with objects that simultaneously transport water that does not meet sanitary standards. In order for the communication system to cope with the tasks, they are provided with the following facilities:

- water intake stations responsible for the intake of water from a natural source facility;

- pumping stations that create the required pressure during transportation and deliver water to a predetermined height;

- treatment and purification facilities that improve water quality;

- water supply systems and conduits;

- spare and control tanks.

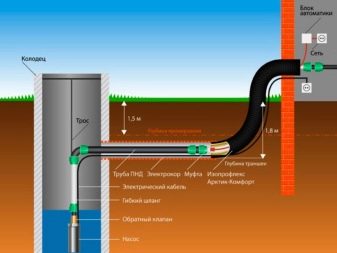

Outdoor network

Modern plumbing systems are a complex network, the main component of which is considered an external pipeline. He is responsible for the supply of water from wells, reservoirs or storage facilities to the consumer, the central water supply can be laid both on the surface and underground. The first installation option is the cheapest, characterized by fast installation. In this case, the water supply system is fixed on elevated supports and additionally covered with insulation. If the design of the pipeline provides for the main intersection, then the laying of pipes is performed in underground tunnels or trenches.

The external network, as a rule, consists of structures responsible for cleaning and storing water and various pumping equipment. At the same time, filtration is carried out not only in the fence, but also in the outermost water supply system. Depending on where the water will be used, there are several types of outdoor water supply.

- Technical. It is intended exclusively for production facilities. Often, in order to save money in technical plumbing, only partial cleaning is established, and they can reuse the treated resource.

- Fire. It is used for fire extinguishing systems. A similar network is additionally supplied with special equipment and hydrants.Usually, the fire water supply system is made dead-end, this allows it to be combined with household and technical supplies.

- Household. Transported water in such water supply is used for drinking and is thoroughly cleaned.

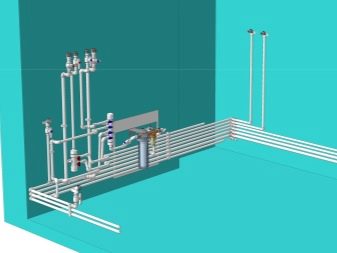

Internal system

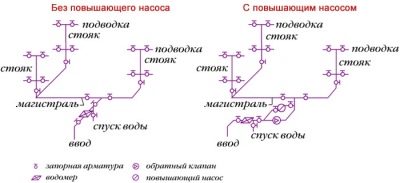

The water supply system also has an internal system consisting of a network of pipes passing inside the building and leading communications to the water intake points. Since the external pipeline can have different pressures, the internal water supply is arranged in two ways.

- No booster pumps. The water supply in this case is due to the pressure in the external network, and the water supply system includes an inlet, a water meter, pipes, a riser and a supply pipe. This type of supply is ideal both in a private house and in urban apartments. It is characterized by simplicity, has no additional devices, except for the pipeline.

- With periodic or permanent sediment. Such a system is selected when the external network is not provided with the necessary pressure to transport water, or if it is necessary to deliver it to high and remote water intake points. As a rule, water supply systems with pumps are installed in large buildings with a height of more than 50 m, hotels, rest houses and industrial facilities.

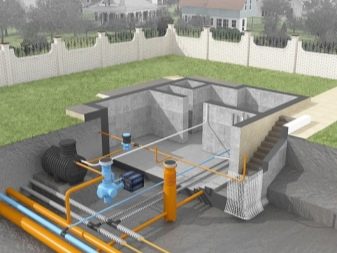

In order for water to flow to consumers smoothly, in addition to pumping plants, water supply systems are supplemented with special tanks in which its supply is kept. The volume of tanks is determined depending on household needs, usually their capacity is calculated at 20% of the daily consumption.

Water pressure tanks are the main components of the internal water supply system and are equipped with special pipes and valves. They are recommended to be placed in a well-lit and ventilated room.

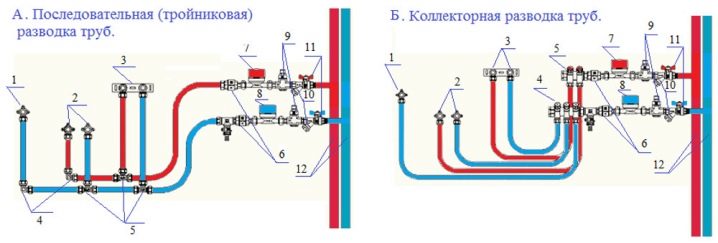

If the project provides for zonal supply, then each section should have individual trunk lines, they are usually laid in technical floors. Inside the structure of the water supply network is done open with divorces. In some cases, also used and hidden installation of pipes, located in the mines and furrows of the walls. For this purpose, in the places where the reinforcement is installed, the connections are fixed, and the inspection hatches are fixed.

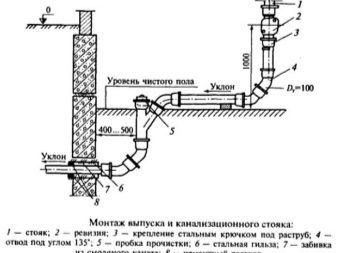

In addition, internal systems should be laid with a gradient of 0.002–0.005, this will ensure that water is removed from the mains to suitable pipes and appliances. If the communication is located in the lower points, it is desirable to make a trigger device.

During the installation of internal plumbing attention is paid to the installation of valves. She put on liner to the faucets, toilet, flush cisterns and washbasins.

Pipe materials

When installing the plumbing, it is important to pay attention to the choice of the material from which the pipes are made, since not only the cost of their installation will depend on this, but also the service life. In order for the systems to reliably last more than a dozen years, during the acquisition of pipes it is necessary to take into account that they will be subjected to pressure and chemical exposure to water. Therefore, it is recommended to give preference to durable and reliable material. To date, the sale can be found several types of pipes.

Copper

Such pipes are widely used in various engineering services, including water supply. The main advantages of copper pipes include:

- high pressure resistance;

- low and high temperatures;

- no deformation during heating;

- this material provides the highway durability;

- spectacular appearance.

As for the shortcomings, such systems:

- installation roads;

- their installation is time consuming and requires special soldering technologies;

- if during operation the copper system leaks, the damaged area must be completely cut out and replaced with a new one.

As a rule, copper plumbing is used for distilled water, as they have the ability to connect with toxic elements.

Chlorinated water adversely affects the physical characteristics of copper. Copper systems are also rapidly destroyed by stray current.

Metal plastic

They consist of a thin metal pipe covered outside and inside with layers of plastic. There are many advantages of such water supply systems:

- they have a small diameter;

- easy to repair;

- easy to install;

- perfectly tolerate temperature drops.

But choosing the installation of communications from metal-plastic pipes, it is worth considering that they require regular maintenance, are expensive, are afraid of shocks and can be destroyed by ultraviolet rays.

Steel

Depending on the coating material, the products are divided into galvanized and uncoated. Installation of such plumbing is carried out with the help of special threaded connections, couplings, tees or welding. Steel systems are characterized by high rigidity, durability and long service life. Despite the positive properties of these pipelines, they are subject to the formation of rust and inorganic deposits inside. In addition, their installation is time consuming.

Galvanized

While giving preference to this type of pipe, it is important to carefully seal the connections when installing them. This can be done with the help of flax, pre-saturated with linseed oil or paint. Do not handle threads with synthetic solutions. The advantage of galvanized pipelines is their reasonable price and easy installation, a minus - a small service life.

Plastic

They are a good material for the construction of water supply, as they are:

- durable;

- do not corrode;

- have low thermal conductivity;

- low weight

Plastic systems can be laid in a hidden method. Installation of pipes is quick and easy, but they cannot be used to supply hot water.

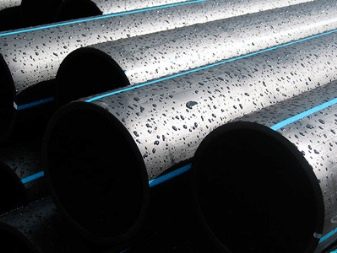

HDPE pipes

They are made from polyethylene under low pressure, therefore they are durable and are excellent for water supply of both technical and drinking water. Such pipes are popular in modern construction because they have high elasticity and resistance to freezing. At low temperatures, they do not burst and allow you to transport both cold and hot water. In the system, the pipes are joined by welding or soldering, installation is easy, because polyethylene bends well.

Polyvinyl chloride

Unlike other types of material, these products are characterized by high rigidity, due to which they are widely used for laying open and closed water supply lines. The pipes are suitable for transporting not only hot and cold water, but also for heating systems, have a neat appearance and high strength. The pipes are inexpensive, they are joined by gluing and fittings. There are no visible defects in polyvinyl chloride.

Polypropylene

In terms of their technical properties, they are in many ways similar to polyethylene pipes, but they are much cheaper and are connected by welding. In addition, such systems are durable, durable, meet all building standards and requirements, but during their joining, you need to pay attention to the quality of the soldering, otherwise leakage is possible.

Water treatment facilities

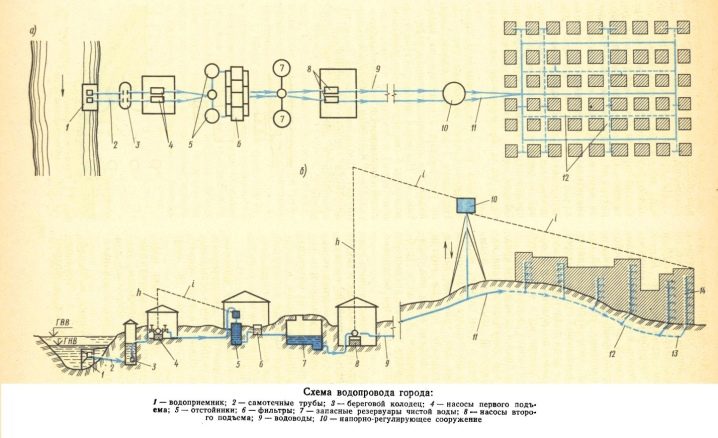

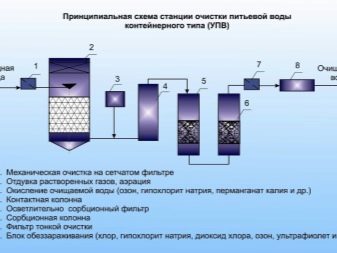

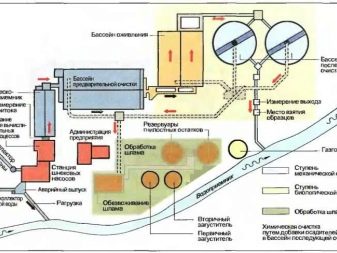

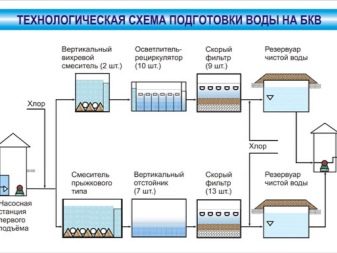

The water supply system provides transportation of water to the consumer from various natural sources, which may contain organic and mineral elements in a dissolved, colloidal or suspended state. In order for the water quality to meet all standards, during the installation of communications, an additional wastewater treatment plant is built. The most common options are small water treatment with gravity movement of water. Most often they can be found in urban water supply.

In this case, the cleaning system looks like this: water is pumped by the pumping station, after which it flows down independently into the treatment tank. Then it is collected in tanks, processed and filtered, the purified resource is taken up by the pumps of the second station.

In addition, buildings in settlements can be erected by multi-stage and single-stage schemes., the choice of which depends on the quality of the water supplied from the source. Thus, the two-stage purification scheme provides not only the clarification and disinfection of water for economic and technical purposes, but also its carbonation and coagulation.As a result, in horizontal tanks, water is filtered using flocculants, then necessarily chlorinated.

Typically, a cleaning facility consists of:

- containers for clean water;

- filter systems;

- sump;

- floater chambers;

- mixers;

- wash tower;

- storage of slaked lime and coagulant;

- consumable tanks;

- pumping station;

- warehouse for the storage of activated carbon and sodium.

In the case when water is purified by a single-stage system, it is filtered and clarified without the use of sumps. Sometimes wastewater treatment plants are supplemented with devices for defluorization and water softening. Such stations are usually observed in drinking water pipelines. As for the purification of groundwater, which will later be transported for economic purposes, they are only disinfected. If groundwater contains many hard components and iron in its composition, they are also softened and iron-free.

To speed up the cleaning process, special additives are used that contribute to the adhesion of small particles, after which they settle to the bottom of the tanks and are eliminated using vacuum filters placed both at the beginning and at the end of the system.

In addition to clean water reservoirs, they also install septic tanks in the sewage treatment plants, thanks to which the water is cleaned from large particles and discharged for more thorough filtration.

For small water systems, you can also install a septic tank and a digester, performing the role of biological treatment.

For information on how to assemble plumbing for a quarter, see the following video.