Rollers for sliding gates: features and installation

Convenient sliding gates are used not only in the residential area, but also at the entrance to the enterprise, which solves the problem of organizing an effective access control. In addition, these structures show the level of technical and general culture of an organization.

Special features

Trouble-free operation of sliding gates, smooth and silent movement, an unstressed stop at the end of the movement - all this, first of all, is provided by rollers, more precisely a roller system.

Supporting parts assume the entire load from the weight of the gate, so they must meet the basic requirements:

- Dimensions should not increase the dimensions of the carriage.

- High wear resistance.

- There must be good access for maintenance or replacement.

- The material of the rim of the roller should provide silent movement along the guides.

Device

The mechanism of sliding gates consists of a set of parts that in the assembly ensure smooth movement, as well as reliable unstressed fixation at the end of the movement.

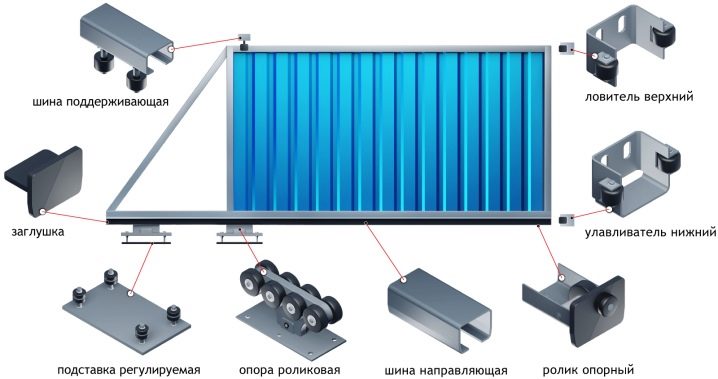

In most designs, there are necessarily such details:

- Guide beams working profile, which are fixed at the level of travel. They provide a stable target position during movement.

- Restrictive adjustable rollers (usually two pairs) and catchers in the composition of a metal support that hold the door structure in a vertical position, which eliminates their oscillations, tilt or fall.

- End rollers allow the gate to smoothly enter catchers.

- At the top and bottom of the rack they place catching portals, which take part of the load from the weight of the gate.

- A rubber plug protects the rail against precipitation and dirt.

- Roller bearings are matched to each type of gate.

- Sliding gates carriages or supports. The gate carriages must be installed very precisely on the carrier beam.The subsequent trouble-free and smooth operation of the entire circuit depends on their quality installation.

- The carriage with rollers in a set.

- For end or knurling rollers, a protective cap in the form of a rubber plug is required.

- Management of the entire structure can be carried out electrically or manually.

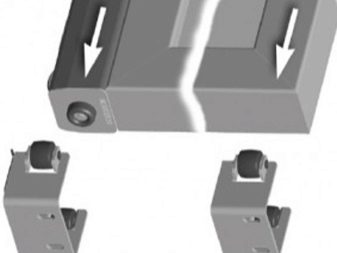

Design features of the carriage

The carriage is mounted on a plate that is attached to the foundations of the gate through technological openings. From 6 to 8 rollers connected in pairs are mounted on the bracket (such as the rocker arm). The arrangement of these parts allows the carriage to have constant contact with the inner surface of the guide beams. Lubrication of the roller bearings should ensure smooth sliding at all temperatures.

The size of the base of the carriage may be different. It all depends on the possibilities of its attachment to the foundation (through anchors or by welding to steel mortgages in the foundation) after all the adjustments and adjustments of the position of the main details of the structure. Technological carriage holes allow you to adjust its position.

Kinds

Types and designs of sliding gates provide carriages with rollers.The type of these elements determines the frame, canvas, drive, foundation, pillars, as well as the order of installation.

There are several options for sliding gates.

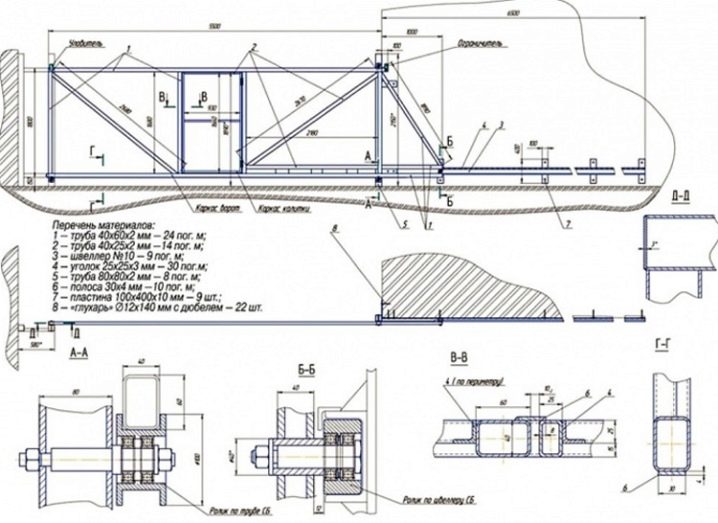

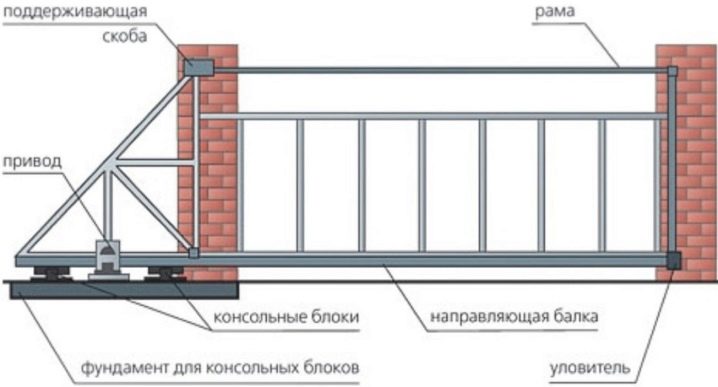

Cantilever

In this type of gate, there are usually two carriages with four pairs of rollers, along which the guide beam moves with a bearing part attached to it. It is also connected to the frame and the leaf gates.

The guide beam can be located in the middle of the blade or on the top of the frame. It depends on the operating conditions of the sliding gate. In the open position, the fabric of the construction enters the bracket with stops, and then rests on the fixing element.

Suspended

In such constructions, the reinforced guide profile rests on the pillars of the gate or is mounted in the opening of the garage wall, and the roller system rests on the top beam. At the same time, the rollers themselves are placed at the edges and center of the frame.

With lower guide (rail)

In these embodiments, the blocks of the carriages are fixed on the lower beam of the frame, and the rollers move along the guide beam or rail. Such simple sliding doors require constant care for the contact surfaces.

In order to ensure long and reliable operation of all nodes of the sliding gates, you need to take a responsible approach to the choice of the main node - the carriage with rollers. This unit creates the conditions for a silent, smooth and effortless movement of a heavy structure.

How to choose?

During the selection of the sliding gate system, it is recommended to follow these criteria:

- Installation location supports with roller carriage.

- On bearings of which performance was a set of rollers assembled

- What material are created roller kits.

- How is the process of hardening the material of the rollers or wheels.

- What bearings are installed in the supports.

- Country, company, manufacturer of a specific batch of blocks.

- The price of blocks or the whole set, the amount of work and payment for the services of masters.

The strength of the assembled sliding gates depends on the fulfillment of certain requirements:

- The design must withstand the load of the total weight of the structure.

- The dimensions of the opening must ensure the safe passage of a particular type of transport to a private territory or yard, warehouse, garage of the enterprise.

- The height of the installed wings should not interfere with the movement of vehicles.

- It is necessary to use durable and lightweight materials that support the fulfillment of all requirements at the level of quality standards.

The materials from which the main parts of the sliding gates are made should ensure their trouble-free many years of work. Durable and lightweight designs provide convenience and minimal physical effort for mechanical drives, as well as power consumption for automatic ones.

Assembly work

Fencing and gates - a single whole security system. Its durability and reliability of work depends on how the installation of all parts, especially the pillars connecting the fence with sliding structures. The basis of the gate supports are pipes. It is better to use the former elements in the work - they will be cheaper, but in terms of strength they will not yield to new ones. After facing it is impossible to determine what is inside.

- The diameter of the pipes is coordinated with the total load that will affect the poles from the severity of the gate, as well as wind and snow exposure.

- The length of the prepared foundation depends on the chosen character of the installed gate system.

- The choice of material for the foundation must be particularly strict, because for many years it will experience all sorts of loads: weight, wind and weather. Water ingested, freeze and pose a particular danger to the concrete foundation.

During the laying of reinforced parts in the prepared and filled with mortar base, special attention is paid to the correct position of anchors and embedded strips. While the concrete of the foundation stiffens and hardens, the framework and the door leaf are being prepared. When the frame with the trim and the foundation is ready, set the carriage.

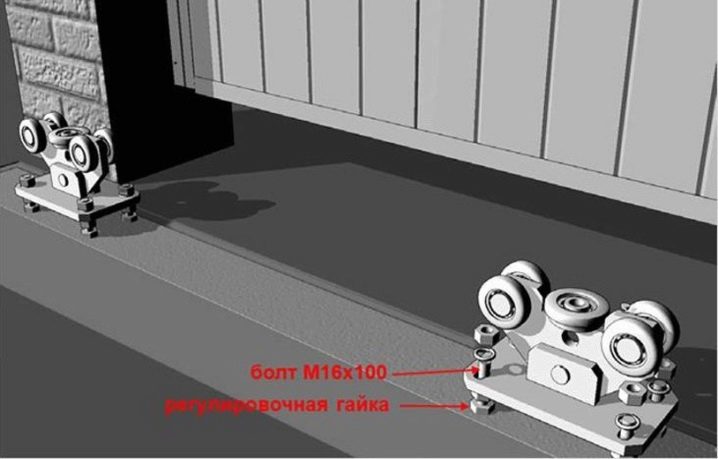

Carriage mounting options

The carriage with rollers is fixed in different ways - by installing on anchors, on studs and welding to the embedded strips.

- Anchors are installed as accurately as possible.

- Holes in the base plate do more for possible adjustment.

- The studs are put into the embedded plates after marking with the support of the carriage and threading under them.

Installation on anchors and studs provides the ability to replace the carriage if necessary, although the process of subsequent adjustment can take quite a long time.

Welding of the carriage base plate should be done after all adjustments. These works should be carried out in places convenient for welding, as well as in areas of cutting, if necessary.

Amateur masters are advised to weld the carriage to the base support. If you put an industrial carriage with rollers, it is better to attach it with pins.

Mounting sequence:

- A guide rail joins (welded) to the finished door frame.

- We adjust the position of the carriage with rollers; under the supports we install the adjusting elements.

- We put the finished structure on the rollers of the support carriage ..

- We put the end roller and bracket-limiter from lateral vibrations.

- Check the smoothness of the movement of the whole structure, the noise level.

- We mount (welding) catching portals.

- We control the correctness of the installation of all nodes.

In the process of installation it is necessary to use a quality tool, as well as construction levels to control horizontal position and verticality. All welds must be cleaned and primed. Anti-corrosion measures and painting should be done carefully, creating protection and respecting aesthetics. Of course, the money question plays a significant role,but reliability and durability is more important, so when choosing materials and components for their gates, the issue of quality should prevail.

What to lubricate?

Skillful maintenance of sliding gates ensures a long service life.

They are designed for 50,000 cycles (closing-opening), and this can guarantee work for decades. Rollers for sliding, suspended and sectional doors on the rail are under heavy loads and need lubrication. The use of liquid and grease is impractical because they adhere to dust and dirt, because of what often have to clean the parts of street constructions.

It is better to use a dry lubricant - it significantly reduces rolling friction and is easy to use. This mixture is inexpensive, and you can buy it in technical outlets. However, more often such lubricants are sold in shops selling bicycles and spare parts for them.

Professional tips

Solving the installation of sliding gates, try to use more parts and blocks of industrial production. Ready roller carriages of many well-known brands will last smoothly for many years.

Alignment of all sizes, installation of carriages and guide beams entrust experienced craftsmen. By the maintenance of the gate should be treated carefully, to make preventive maintenance a regular exercise. This will significantly increase the turnaround time.

When installing self-made sliding gates, you must have good skills in welder and builder, as well as be able to understand the drawings. If you have confidence in your abilities and familiar experts, feel free to start work.

Installation of the gate with his own hands, see below in the video.