Soundproofing walls in a wooden house: a variety of materials and installation tips

The advantages of a wooden house over stone buildings are attracting more and more people to such buildings. An environmentally friendly, warm and cozy house, which retains heat for a long time, is an indicator of the refined taste and a certain wealth of its owner. In addition, the wooden house is not electrified, and dust is practically not collected in it. However, for a comfortable stay always need sound insulation.

What is soundproofing for?

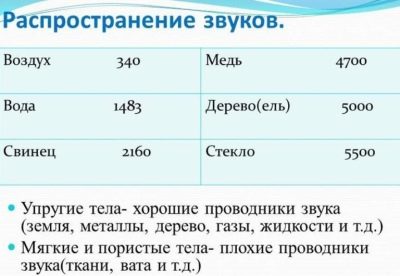

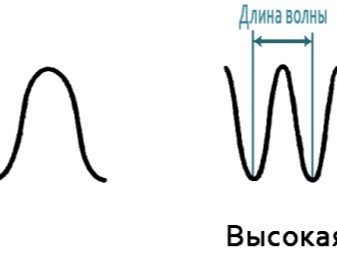

Along with a lot of advantages, the tree is an excellent conductor of sound, and the structure of it has many resonant frequencies at which the sound is amplified several times.This property of wood products is used when creating musical instruments, making special resonance panels for concert halls.

However, in a built wooden house, a huge amount of sounds amplified by resonance, and even those that are simply transmitted through the walls without amplification, will bring a lot of trouble to the owners who want to relax in silence. That is why the construction of wooden houses necessarily take into account the need for sound insulation using modern materials.

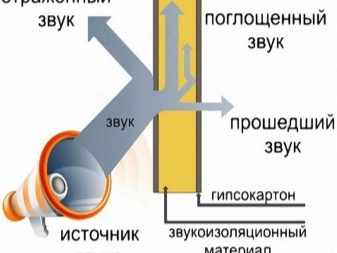

It should be borne in mind that according to the principle of implementation there are two main types of sound insulation:

- sound insulation is the implementation of a number of measures to reduce the penetration of sounds from outside into a residential area;

- sound absorption - carrying out measures to reduce the passage of sounds from the room to the outside.

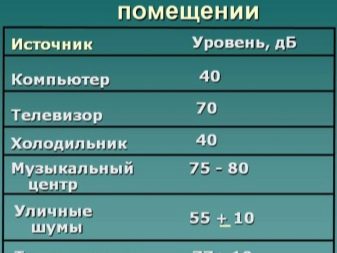

When planning soundproofing measures, the permissible noise level requirements should also be considered. In particular, for residential premises the maximum daily level is set at 40 dB, and during the day 30 dB. This level can be measured with the help of special devices - sound level meters. Raising the level of sounds (noise) above these limits significantly reduces the comfort of being in the room, and the level of 120 dB is already dangerous for the hearing organs.

Specifying the factors affecting the noise level in the room, it should be noted that:

- whisper creates a sound level of 20 dB;

- quiet speech - 40 dB;

- noise from a passing car - about 80 dB;

- music player - an average of about 90-100 dB;

- fireworks and firecrackers - up to 130 dB.

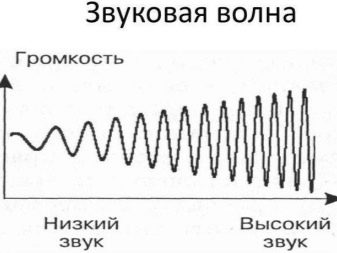

Types of noise

Before planning measures for carrying out noise insulation, it is necessary to take into account the main sources of noise and the types of noise from which it is necessary to protect the interior of a wooden house. External noise can be divided into several types.

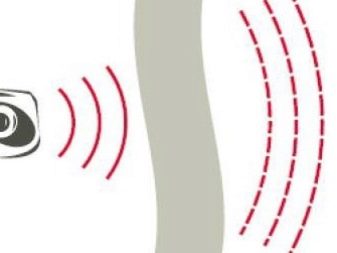

Acoustic

These are sounds propagating through the air and representing acoustic waves. Sources of such noise can be both conversations of neighbors, and working audio equipment (players, tape recorders, amplifiers, tape recorders, TV), sounds from the operation of engines of cars, the voices of animals.

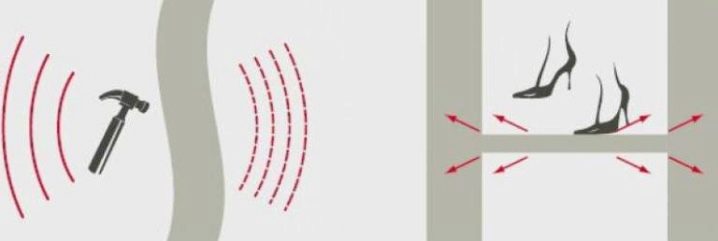

Drums

This type of sound is transmitted fairly well and directly to solid bodies, to which a shock or vibration effect is applied. Such sources include, for example, perforators, hammer blows, the tramp of people walking, the sound of objects falling on the floor, the sound of a train moving along the rails.

Combined Noises

This is the presence of noise, both acoustic and shock. For example, the same punch creates two types of noise. When the nozzle is exposed to the surface, frequent blows are created, and acoustic noise is generated from the operation of the perforator engine.

Thus, when carrying out noise isolation, it is necessary to take into account which sources of noise are nearby, and from which type of noise it is necessary to isolate the room. In addition, the intensity of the sound (its volume) should be taken into account.

Types of noise insulation and its installation

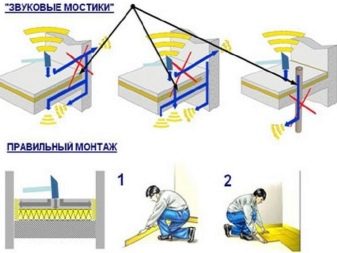

First of all, for effective sound insulation, it is necessary to eliminate sound bridges in the room that occur at the joints of wooden parts and beams. Through these bridges, sounds are transmitted very efficiently; in addition, in these places additional resonant frequencies arise at which the sound is amplified.

When conducting sound insulation of premises, various materials and compositions are used, such as piercing mats, ready-made slabs of various materials, rolled sound insulation, spraying liquid compositions.

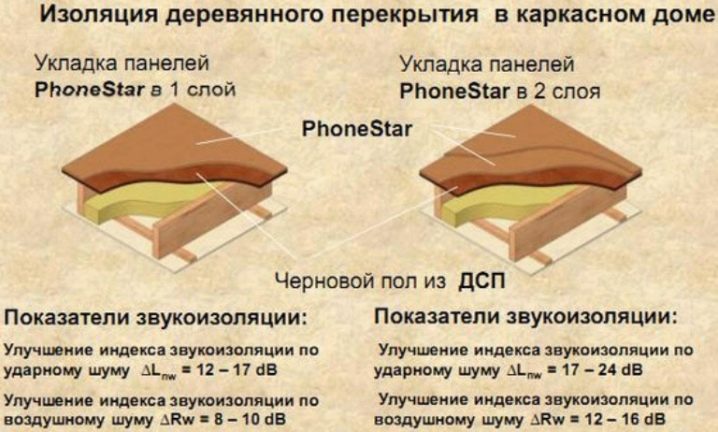

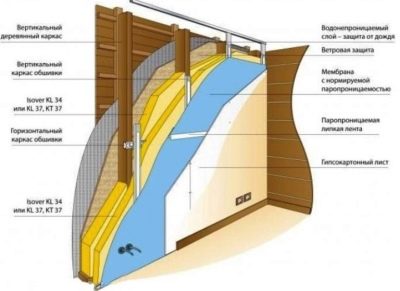

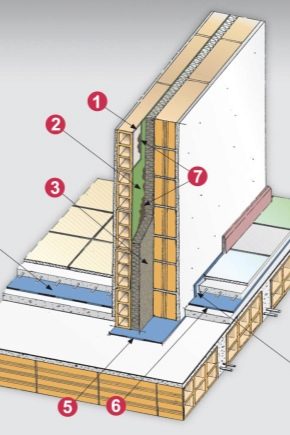

The use of this or that material depends on the type of construction of the walls, floor and ceilings of the room. Thus, in the case of frame design, it is necessary to fill the inside of the wall with special sound-proofing materials, and in this case the wall consists of three parts (two covered outside and an internal sound-proofing).

- In the case of a limited thickness between the outer parts of the wall, sound and heat insulator are used as polyethylene foam or polyurethane.

- To reduce sound transmission between the wooden parts of the house is used glass wool sound insulators and other materials. They are placed between beams and logs, eliminating the direct contact of the wooden parts of the structure. As well as to reduce the level of sound transmission and vibration, beams are wrapped with special construction felt, and a polypropylene or cork substrate is placed under the floor. Such works are made during the construction of the house, since later it will be difficult to perform them.

- Very simple but very effective is flooring in places of emphasis on sound insulators without rigid attachment to the base. Thus, it turns out "floating floor", not connected to the rest of the structure. This provides a very high quality sound insulation.And it also uses the option of mounting floors on damper support springs or brackets, which requires the use of special springs (brackets), designed for heavy loads. The load is calculated based on the total weight of the floor with furniture plus the weight of several people (depending on the floor space).

- For more inter-floor noise and heat insulation Between the ceiling and the floor of the next floor most often keramzite crumb fall asleep. It is light, but it performs its functions perfectly. Sometimes sand is also dropped, but it is necessary to significantly increase the overall strength of the structure, given that the total weight of the structure will increase, use stronger materials for the ceiling. In order to reduce the total weight in the sand add leaves or sawdust.

You can start soundproofing and do it yourself, gradually applying certain methods.

In particular, one should begin with a thorough sealing of all the cracks through which the sound passes, with a special mastic or putty. Voids made to install electrical switches are filled with mounting foam.Seal the entrances of water and gas pipes into the house with elastic sealants.

In the implementation of interior soundproofing soundproofing materials feature in the voids of the wall partitions. Often sound insulation is combined with heat insulation through the use of heat insulating materials, lined with plasterboard.

In general, insulation of walls in a wooden house requires an integrated approach with the elimination of all possible sound conductors in the room. This also takes into account the location of the air ducts, which, especially made of wood, are excellent conductors of sounds both indoors between the rooms from the neighbors, and outside - into the room.

Cork soundproofing It is known for a long time, it was used in the construction of various houses and buildings. For example, on the Black Sea coast in Gagra (the former name of Gagra), a small castle was built specifically for the rest of the royal family, in which slabs of cork were laid in all walls and doors in order to increase the effectiveness of sound insulation. Thus, the sounds from the outside practically do not penetrate the rooms of this building.

Nowadays, balsa wood panels are also used for interior decoration. Such panels, in addition to the excellent appearance, successfully perform the function of sound insulation. Sound insulation membranes made of cork wood are used not only for finishing houses, but also in the construction of professional recording studios, where high-quality soundproofing of the room where sound recording takes place is crucial for obtaining high-quality sound.

As well as the sound insulation of a wooden structure can be made with the use of modern special liquid adhesives. The quality of sound insulation is at a fairly high level.

Very often, foam insulation, polyurethane and other materials are used for sound insulation, which quite successfully absorb a sound wave, are not subject to corrosion and are very durable.

In addition to the main activities for sound insulation, it is necessary to take into account other methods that allow a little to reduce the level of noise entering the room.

In particular, it is the replacement of wooden windows with modern double-glazed windows, the installation of high-quality seals on all doors of the house,installation of upholstered furniture in the room, which successfully absorbs sounds, using wall carpets when decorating a room, and exterior wall covering with sound-proofing materials.

It should be noted that if the wooden parts do not fit tightly and there are gaps, they may rattle, resulting in acoustic resonances at different frequencies. This becomes noticeable, for example, when working with high-quality sound equipment. At a certain volume at low frequencies, a peculiar hum can occur, which is transmitted throughout the house and disturbs others.

Taking into account all the features and requirements for sound insulation, the use of modern materials will provide comfort and quietness, make a comfortable stay in a wooden house.

The video below provides detailed installation instructions for an independent frame soundproofing cladding.