The subtleties of sound insulation and sound insulation of walls in the apartment

Own apartment is a place where people hope for calm and pleasant atmosphere. But these expectations are not always met. To make them more real, you have to defend against extraneous sounds.

Special features

In private homes and cottages, there is usually enough installation of high-quality double-glazed windows. Sometimes soundproofing is still mounted on the walls, but this is only if the road or railway is near. In a city apartment the situation is different, you have to defend yourself from noise coming from the bottom, from above, and even from the sides. In addition to protection from the sounds that occur in the apartments of the neighbors, we have to think about soundproofing, that is, not to disturb anyone.

The sounds themselves also differ, which cause inconvenience to the tenants of apartment buildings. In private housing, they mostly fight airborne noise coming from different distances from outside. The exception is if there is a vibrating mechanism nearby or a vehicle is moving. But in apartments dominated by structural noise: they are distributed on the materials of the structure. Winning even a very loud TV behind the wall is much easier than coping with the sound of a perforator working at low revs or echoes when a thing falls.

Even the most advanced and well thought-out acoustic protection will not work if there are various defects in the apartment structures. Cover the structural and airborne noise of the same material is unlikely to succeed. In different rooms need a special approach.

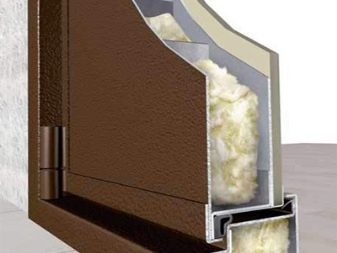

Moreover, some solutions are suitable for floors, others for walls, and still others for ceilings or doors. Only by taking into account all this, you can achieve real silence.

Causes of noise

Factors that provoke noise, there is a mass, and you have to deal with them in advance. In many cases, it turns out that the solution of the problem must be systemic, it is necessary to suppress the sound waves coming from everywhere.Impact noise can be associated with a wide variety of events, actions of people at any time of the day. If the sound insulation is weak, it will give the impression that the noise comes from the walls and ceilings, but in reality it is usually created by apartments from above. But even with quality protection, it would seem that any channels of sound passage (even sockets or just cracks in the walls) can devalue the efforts made.

Do not always blame the neighbors. Of course, there are very unpleasant personalities, trying, as it were, to torment everyone else (or simply ignoring the interests of the people around them).

But extraneous sounds can also be generated:

- flaps;

- water meters;

- elevators;

- thermal points;

- pump systems and boilers;

- the movement of water in the heating system and other equipment.

Although most engineering equipment is located in basements or on special technical floorsand sometimes in extensions, yet the sound in his work gets to the living rooms. After all, those water pipes carry it out perfectly, and it’s impossible to avoid their entry into the apartment itself. Technical noise can be constant (when the pumps are hot and cold water supply), or periodic (typical of booster pumps and drainage equipment).The best solution is the removal of engineering systems in separate buildings. But nothing depends on the tenants themselves, and the shortage of land in populated areas forces one to choose noisier options.

It is recommended to be interested in the management company and in resource-supplying organizations in the specifics of the performance of equipment and its installation. After all, the sound of the pump may be louder or quieter depending on the equipment of a special foundation. According to standard norms, it is required to create acoustic discontinuities, to exclude rigid connections between sound distribution channels and walls and floors.

But for reasons of economy, many firms refuse such measures. If one cannot overcome their resistance, then all that remains is to cover their own housing (which in most cases they do).

Types of materials: advantages and disadvantages

Modern sound-proofing materials should provide not complete suppression of extraneous noise (this is possible only in the isolation chamber with multi-million expenses), but their reduction to an acceptable level.

The main requirements are:

- lack of additional fatigue from sounds;

- the ability to focus on something;

- quiet night rest.

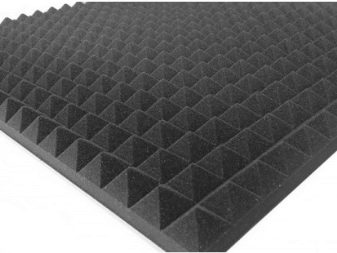

Foam is quite widely used. Since almost all the substance is formed by gas (a solid mass only holds it), the overall density is insignificant, because the use of foam is convenient. This material is made both in the Russian Federation and abroad. The constructions used do not ignite and do not rot, indifferently transfer contacts with microorganisms.

The duration of operation of the foam fully justifies the investment in it.

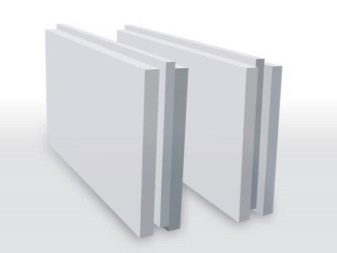

But the environmental characteristics are extremely weak, and the foam can not be called a durable material. Much stronger products from expanded polystyrene. They endure bending attempts with a force of 5 and even 6 times more. Because for partitions and other areas where there is a risk of mechanical destruction, polystyrene foam is better suited. It is important to bear in mind that this substance is denser and is produced using a different technology.

It is necessary to take into account that expanded polystyrene, which has not undergone a special treatment, has the category of ignition G4.

This means that it can ignite:

- match light;

- blowtorch or gas burner;

- welding spark;

- soldering iron;

- short circuit.

When burning polystyrene, the temperature very quickly rises to 1200 degreesthat is detrimental even to the surrounding structures of steel and concrete. Only special additives reduce the risk of ignition and flame temperature. But even they, if the substance does catch fire, do not make smoke less toxic to humans. In the construction and repair it is allowed to use only the polymer, which itself decays in the absence of igniting energy. High-quality polystyrene foam is made of granules with smooth edges, the geometry must be maintained flawlessly.

The third leader of the sound insulation market is polyurethane foam. Like the two previous solutions, it is a cellular substance filled with gas. In addition to rigid PU foam, foam rubber is also included in this category by chemical composition.

Reinforced variety favorably stands out:

- small pass of heat;

- ability to protect covered metal from corrosion;

- ease;

- elimination of cold channels (when used correctly);

- compliance with the most stringent environmental standards (installation of such material in household refrigerators is allowed).

Polymer acoustic protection can be sprayed onto almost any material.

No matter what the surface is, whether it is made from pine boards or steel plates, it will be securely covered. The geometric shape of the insulated structure also does not play the slightest role. Polymer coating in cold blood will transfer contact with acid and even with the soil. But lighting it with direct sunlight is undesirable, then it will not be possible to provide the standard 25 years of service.

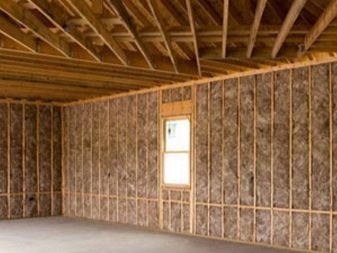

Mineral, also basalt wool, will help block the passage of sounds through walls, various partitions and even ceilings. To simplify the work using special plates or rolls. Protective qualities with the same layer are identical, the choice is made according to personal preferences and for a particular situation. Such material completely eliminates the risk of fire, release of toxic substances. Even when mineral wool is surrounded by fire and warmed to 1000 degrees, it will not melt and will not flow in a burning stream.

Basalt wool is indifferent to various caustic substances. It is hard to imagine that something will appear in an ordinary apartment that can destroy it chemically.And if that happens, the acoustic impairment will be the least important consequence. In addition, the mountain wadded material does not decompose under the action of microscopic fungi and bacteria. All their activity is incapable of causing him even the slightest harm; the shortest period of operation, confirmed in practice, is 30 years.

Noise-insulating wadded materials and other porous layers can be used in close conjunction with sheets of gypsum plasterboard. Such assemblies well delay noise and increase thermal protection. But it will not be easy to mount them, and a fair amount of dust will stand out. In addition, in small rooms such a move is reckless, you will have to add to the wall thickness up to 120 mm. Quite good results are achieved with the help of decorative panels.

They are produced by processing fiber of coniferous wood using a special technology. Installation of such panels is not difficult, and on top of them you do not need to make any other finishes. But the cost of decorative blocks is quite palpable for most people. The roads are also such an option as polyurethane plates, but their characteristics help to ensure silence even in recording studio studios.The total thickness of the sheet does not exceed 1.5 cm, and he himself will be easy and installed without any difficulties.

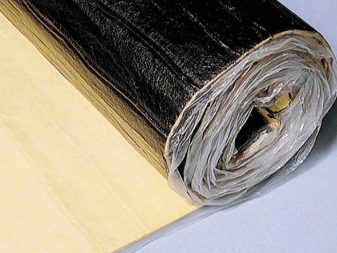

Attention should also be paid to the insulating membrane. In thickness, they reach a maximum of 3.5 cm, can be used in conjunction with other insulating systems.

The flexibility of the membranes and the ability to bend them at an angle simplifies practical application. In some cases, instead of membranes or other specific means, combined (heat- and sound-absorbing) elements are used. To create such panels use the already listed polymeric materials and some other substances; Each block has three layers.

It is important to understand the difference between foam and foam. (in the first group of materials, the cells are clearly demarcated, and in the second, they are directly connected). The developers are trying to pores occupy the maximum volume, and each of them was as small as possible. Among the foam plastics, an exceptional absorbing quality is demonstrated by the Mipora. Especially it is necessary to say about honeycombs, which are formed by a correctly repeated selection of cells going through. The outer shell of the cells is formed from cotton fabric or from kraft paper and so on; it is impregnated with various resins.

The effective noise absorbing properties have ZIP-panels. They use a combination of soft and strong layers (glass wool or mineral wool and gypsum fiber, respectively). It is possible to install such panels without creating a pre-metal frame. To secure the blocks to the surface, there is enough of the nodes provided in the construction itself. It should be borne in mind that each spare parts panel has a mass of up to 20 kg, therefore not everyone can put them on their own.

You can set up panels made of mineral wool with your own hands. But technology turns out to be more difficult and must be maintained scrupulously. Be sure to have to form a frame, in the intervals of its component parts and lay out the material.

Note: if the noise is very strong, you should put several layers of wool at once. Outside, the prepared assembly is sewn up with the help of a plasterboard.

Self-adhesive sound insulation helps in the case when there is no desire or ability to make a full frame. But reducing the thickness of the structure by 20-30 mm at the same time is accompanied by a weakening of the protective properties. On top of the combined panels, put plaster or glue wallpaper. Alternatively, the use of branded mounts, exposed at the corners.An alternative to the panels is the use of roll materials, overlapped with various finishes; but the acoustic parameters are even worse.

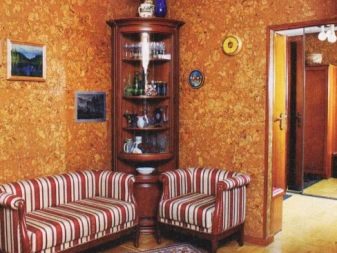

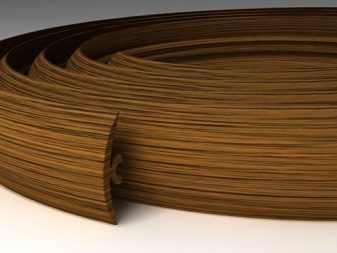

Those who strive for impeccable environmental friendliness in the apartment actively use cork coating. Manufacturers and sellers heat interest in him, talking about the impeccable characteristics of such a material. It is mainly used in the manufacture of footwear, bottle caps, rescue equipment for water transport. 3/5 of the total mass used in these industries is converted into waste, which is used in sound insulation. A solid concentration of gases helps to successfully contain not only sound, but also heat.

It is noted that it is best to hide behind a plug from high frequency noise.

When someone screams on the street or in the next apartment, when dogs bark and cats meow, when the TV is on, it helps effectively. But the vibration and low frequencies are delayed less.

To reduce the sound volume by 40 dB, you can only 10 mm plugs, demonstrate comparable performance:

- 15 mm of mineral wool;

- 0.1 m quality boards;

- 0.3 m of aerated concrete;

- 0.7 m brick.

It is important to understand that the best results are achieved if the oak bark is located in front of a source of loud sounds. And this means that the same 10 mm plugs will not help protect against those who like to watch TV shows at night. Sound suppression will be limited to only 20 dB. For comparison, the background street noise is 70 or 80 dB, the usual sounds in a working office or official institution - from 50 to 60 dB. What is really good is the elasticity of the cork, its zero absorption of moisture and antistatic properties.

Cork soundproofing comes in the form of sheets or rolls. The rolls are relatively thin, do not reach 1 cm, but sheet coverings can reach up to 50 mm. The thinnest designs are used for decorative needs, they look good. Without additional processing, you can use the so-called white agglomerate, but the black variety will have to cover from moisture and contact with air. It will not be possible to buy a sprayed cork layer in the store, but some companies are promoting such services for an individual order.

In addition to decorative properties, it is necessary to take into account the compatibility of noise insulation (sound insulation) with the underlying material. Quite often, urban apartments are built of aerated concrete.By itself, it helps a lot in suppressing sounds, but still requires additional cover.

If external sounds are relatively weak (you need to lower them by only 2-4 dB), use:

- plaster;

- decorating plates;

- multilayered designs.

The last two options, it should be noted, are suitable for more effective protection. We must not forget that the figures, called by manufacturers, of reducing the intensity of sounds are achieved only with strict adherence to technology, closing of all seams and elimination of interfering factors.

For additional cladding, gypsum-based slabs are recommended. Good results are obtained by aerated concrete covering with foam plastic and polystyrene foam, they reduce airborne noise by 30-36 dB.

How to choose?

But the choice of the option of sound insulation can not be done correctly, if we consider only its own properties and characteristics of the trimmed surface. A lot of people care about the insulation of the ceiling. Upstairs in the house constantly someone walks, lays out beds or sofas, prepares food, watches TV. Washing machines are turned on, repairs are being made, and so on. Even the most polite and correct people cannot avoid these noises, because then they should not live at home at all.

Acoustic protection of the ceiling with mineral wool in the form of plates is quite effective, but absorbs 0.15-0.2 m in height. It is obvious that in low premises such a measure is impractical. In addition, cotton wool should be thoroughly isolated, because in its pure form is harmful to health. Polyurethane foam is recommended for ceilings due to the dense adhesion to the surface, stopping a good impact and atmospheric noise. It effectively prevents the penetration of sounds from the apartment itself to the outside.

But in case of fire, PPU burns with the release of toxic substances. It is safer to use self-adhesive tape with a seal, it is clean in sanitary and environmental terms, besides it prevents the outflow of heat. But the tube will help protect against shock noise, and then when placed at the top of the laminate or concrete poured into the screed. It is very important to choose the type of mounting and layout of the insulating structure. If you make mistakes, even the best materials will be almost useless.

Most people choose ceilings with gypsum plasterboard with an acoustic layer of:

- PUF;

- traffic jams;

- basalt wool;

- coconut fiber.

First, an element isolated from vibration or an autonomous frame is placed, then there is a layer that absorbs sound, and only then comes the turn of drywall or stretched acoustic ceiling. Self-shelter with drywall is attractive because of its simplicity. But it will be necessary to measure all the same all the sizes and to verify the lines on the level, to mount the framework. Protect from noise has not only interroom floors, but also interior partitions.

Their cover can be provided with a loaded vinyl layer of 0.3 cm. In commercial networks, it is referred to primarily as a noise block. The density of the material is very high - up to 5 kg per 1 square. m. This is important, because the heavier the surface, the worse it conducts sound.

Vinyl film elastic, waterproof; mineral dust is added to it for greater effect. Single-layer sound reduction is 25 dB, and if it is doubled, it will increase to 32 dB.

Interestingly, the attachment of loaded vinyl can be done with nails and staples for a construction stapler. Some home masters successfully use even clerical pins.But the most reliable method is considered landing on glue. It is recommended to choose quick-drying mixtures designed for a substantial load. Noise block well complemented by cork panels or sheets.

Isolating interior partitions, it is necessary to close with a putty all the cracks and cracked areas, to seal the recesses for sockets and channels for wiring. It should be sheathed and the door. In some cases, strict adherence to these recommendations eliminates the need for protective materials. Even with a barrier thickness of ½ brick, a good building material suppresses up to 45 dB of sound. That is, it excludes, for example, eavesdropping or extremely complicates it.

But here only the laid out special shell can provide more serious protection. In this case, it is recommended to use cork panels or wallpaper.

A fairly good silencing is achieved even when applied on one side only. Alternative - placement under the wallpaper panels ZIPS. In wooden and prefabricated houses, experts advise to prepare sound insulation immediately for ceilings, floors and walls, starting work with the most minor flaws.

Removing the plaster and the concrete mass around the pipeline and replacing them with acoustic sealants helps prevent sound from spreading through the pipes. You can do without them, if you put between the pipe and the wall boards, wrapped with vibration insulation. Mineral wool is mainly chosen as its. The entire crate is mounted exclusively through an insulating layer. Gaps are left around the edges so that it does not touch the walls.

The fight against noise occurring in the apartments below is most effective with the help of floating floors. Above a layer of vibration insulation on a flat lining put bars. They can not be mounted and docked with the walls. Then fix sheets of gypsum fiber in two layers, on top of which is placed the final coating. A different approach is practiced for soundproofing in a frame house.

Sound damping from below is done:

- carpet;

- linoleum with a substrate;

- carpeting.

This is due to the fact that the use of thick ceilings between floors is impossible. Bearing elements simply will not stand them. More rigid coatings, such as laminate or parquet, should be laid under a cork or polyethylene substrate.Basalt threads or glass fiber should precede tile and porcelain stoneware in a model floor cake. A very important and thorough planning, in particular, the rejection of large windows or an increase in their number.

Even the most reliable windows will let the sound through more actively than walls. As for the walls themselves, liners are made in them based on polyethylene foam or oak bark. The second variant is identical to the first one when noise is suppressed, but it allows optimizing gas exchange. Plasterboard decorative structures on the ceiling not only create a favorable appearance. With the help of air cavities formed by them, acoustic waves are effectively extinguished.

In frame houses all guides, as well as racks, should be attached by means of sound insulation tape of increased elasticity. Braking the transition of waves from the walls to the floor, in the opposite direction helps the installation of a plinth with a soft perimeter. If, nevertheless, a rigid structure is forced to be used, completely sealed polymeric gaskets are placed under it.

In any case, if it is possible to apply a material that simultaneously suppresses sound and heat, it should be used.

Differences in the composition of the acoustic protection are manifested between separate rooms. So, for the kitchen only non-combustible sound insulation will be an acceptable choice. Many experts recommend the use of fireproof SoundGuard panels. According to the manufacturer, they many times reduce the shock wave and reduce the sound energy, regardless of its frequency. Certified flammability category - G1, fire-fighting properties correspond to the category KM1.

Returning to the sound insulation of the floor in the rooms of the apartments, including the kitchen, it is worth pointing out the main weakness of the mineral wool. The optimal result is achieved only with the layout of panels from 2.5 cm. A good choice can be moisture-resistant plywood. But it is advisable to use materials that are less susceptible to moisture. Carpets will have to be abandoned, just like in the bathroom, but carpet and linoleum perform well.

Alternative way: face trim with a tile lined bottom with sound-absorbing structures.

For their manufacture take:

- polyethylene;

- cork rolls;

- cellular or pore-rich materials.

It is better to refuse concrete floating floors if it is necessary to minimize the load and keep the height of the room unchanged. Dry screed is preferred technical simplicity and efficiency of creation. Concrete or draft flooring may be used as a base. Above them is put a vapor barrier, overlapped with mineral wool or EPS slab. Whether granulated sound-insulating material is poured on top depends solely on the strength of the resulting noise.

It can be considered proven that double protection, in which substances of different densities are used, copes well with percussion and air sounds. On top of the backfill, gypsum fiber plates are usually placed. According to them, they glue and attach a second line of plates with screws, making a shift so that the seams do not cross anywhere.

The advantage of a dry screed is a thickness of 3-4 cm with very solid protective qualities. To do without any connections (both fasteners and glue) helps prefabricated floor.

The final coating is placed on a thin layer that provides sound insulation. It is usually made from polymers and coated with rolled materials.

It is also allowed to use:

- boards with dowels;

- parquet flooring;

- MDF plates.

Cork surface is created mainly in bathrooms.There it performs three functions at once - decorates the room, additionally attenuates the sound and covers the substrate from the water. Regardless of the option chosen, you should remove all debris and thoroughly seal the existing defects. Many materials are laid only by beacons, which needs to be clarified further. When choosing it is useful to understand what overlap is worth doing and how much this will affect the need for acoustic protection.

Mounting Patterns

Experienced builders do not recommend soundproofing as long as there is no complete scheme for it. If it is decided to use sheets of drywall, the frame is necessarily fastened with an indent of 20 mm from the surface of the walls. It is very good when absorbing acoustic waves are placed under the profile. The protective solutions themselves are distinguished by a minimum thickness and the largest allowable layer. Tip: you should not choose a scheme with a very small thickness, because miracles do not happen, and only a certain layer really dampens sounds.

So, for liquid absorbing materials, you can count on a positive result when applying a layer of 30 mm. But for oak cork in rolls, this figure is 8 mm,but it is limited in its capabilities. GVL and GKL, becoming barriers to the sound waves, also protect well against it. A prerequisite is the gap from the skin to the capital surface of at least 30 mm. Therefore, the total thickness of the "pies" sometimes reaches 40 mm.

Really thin can be called acoustic boards made of soft wood fiber. Its layer ranges from 10 to 30 mm. Decorative finishing blocks that are 12-25 mm thick resemble them.

How to make yourself?

Before buying expensive materials or even calling a professional team, you need to consider that everything can be done with your own hands, and is relatively inexpensive. Create noise insulation begin by examining the joints. Defects and holes, grooves in them are closed with foam or specialized sealant. But if this does not solve all the problems, you should carefully measure the problem surfaces and calculate their area.

It is necessary to make sure in advance that the source of the problems is determined correctly. Acoustic oscillations are fancifully distributed, and they can get into a “sounding” wall or floor by constructions that are not recognized by sensations.The measurement results even for people with good memory should be recorded on paper or in the notes of a smartphone. Then there will be no risk of buying too much or too little material. When soundproofing both the floor and the wall, you should tear off the baseboards and carefully examine their joints, if necessary, blow out suspicious places with foam.

If plates are used, they are fixed in series. Tack a small amount of glue will help to eliminate shedding. Putting the first row, it will be much easier to understand where to drill the wall for fixing the horizontal crossbar. Similarly, work is carried out from the lowest point to the top line. The line of plates resting against the ceiling is cut off so that all areas are closed completely.

We must not forget that many slab materials can emit fine dust. Its danger to health has long been noted by practitioners. Therefore, experienced craftsmen always work in mittens and wear a respirator. At home, a gauze bandage can replace it at least in part. It is necessary to take care that there is a gap between the horizontally oriented bars and wall panels, if this rule is not followed, sound will penetrate.

Usually, a porous tape is glued on top of them, similar to the one used for pasting windows before the onset of cold weather. Even amateurs can handle the installation of the panels themselves. But the last block is the hardest to mount. Outlets are displayed on new wall surfaces.

It should be borne in mind that such sound insulation will not protect against surface shocks, for example, from slamming windows and doors.

Manufacturers and reviews

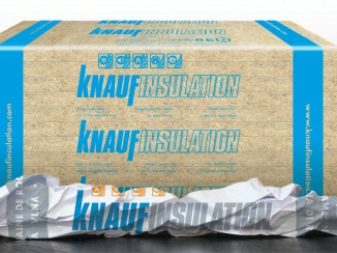

Consumers, of course, are not only interested in the cheapest sound insulation, but also the best, which occupies weighty positions in the ratings. Just knowing all the details about it, you can not buy instead of a real product of dubious product quality. Good results are obtained by the use of acoustic partitions. Knauf "Insulation". They are made in the form of mats or slabs, characterized by high elasticity. Carefully designed technology provides good sound containment.

For lovers of domestic products, it is useful to pay attention to acoustic foam rubber, which:

- suppresses even the strongest echo;

- removes the effect of unintelligible speech;

- Eliminates the echoes of the background music.

The best acoustic foam comes in the form of slabs "Flexakustik", released their Russian firm Acoustic Group. Polyurethane foam is used to obtain this material. The large thickness and well thought-out relief improve the aesthetics of the structures, the products are safe for people. You can apply them in the simplest way, that is, gluing. The problem can only be in high prices.

Panels can be an attractive solution. "EcoZvukoIzol". When creating them, quartz sand is used, and the cardboard profile has as many as 7 layers. Each mat in thickness reaches 1.3 cm, its mass is about 18 kg, the decrease in noise is 38 dB. There is no need to use the frame, the design is simply glued to the walls and easily cut.

Difficulties may be associated with the severity of these products and the fact that, if careless, the filler can pour out.

Mineral-based slab brand "Schumanet" is formed from basalt fiber, and one of the faces is covered with glass fiber. It allows the mat to maintain integrity and does not allow the fibers to change position. From above it is possible to impose other sound-proof panels.Judging by the reviews, "Shumanet" perfectly manifests itself in the bathrooms and in rooms where there is a risk of fire. The fee for such a product is small, and its environmental properties are impeccable.

However, it is necessary to take into account the likelihood of dust and the need for wrapping spandbodom, if the design is not 100% sealed. When calculating the total cost of a material, its thickness and safety level cannot be ignored. Products manufactured in the Russian Federation, on average, are not worse than their foreign counterparts. And given their notorious adaptation to local specifics, they will be even better. It is recommended to always require a quality certificate upon purchase.

Russian soundproofing SonoPlat Kombi favorably differs the widest field of use.

The manufacturer claims that it can be applied:

- in the creation of interior partitions;

- in improving the acoustic properties of walls and floors;

- when forming sound-blocking screens.

Reviews confirm such a favorable assessment. Importantly, the panels allow you to create thin systems without a frame. Multilayer cellulose blocks filled with sand are backed with softwood.It is allowed to be laid directly on aligned walls (with the help of light substrates and folded parts at the ends). Such a method excludes externally visible borders and gaps.

Consumers say that in some cases, such plates do not justify the hopes placed on them. "StopZPUK BP"It is distinguished by the optimal combination of acoustic and thermal characteristics. The composition of the plates includes basalt, able to survive the heating to 1000 degrees. It will not bite the mouse, and water will not harm it. Damage caused by microorganisms is excluded.

Due to its low density, it is possible to protect the house as a whole or individual rooms without undue stress on the foundation. The method of installation is about the same as that of mineral plates. It is required to create a frame with a pitch of 60 cm, laying the gap with an insulator. “Stop Sound BP” also has weak points - it does not save very well from strong noises and vibrations.

The point is in low density, since it is impossible to deceive the laws of physics.

Interesting opportunities opens up "Soundline dB". Unusually, the fact that it is produced according to the scheme, which is used in the formation of windshields for vehicles.Two particularly resistant to moisture sheet of plasterboard with a thickness of 0.8 cm padded with sealant. It is elastic, because at two boundaries the sound stream is weakened. According to independent testing, this product burns very badly.

If it ignites, there will be little smoke, and its toxicity is limited. The manufacturer guarantees compliance with sanitary and hygienic standards of the vehicle. Triplex will have to be mounted in approximately the same way as the GCR constructions. Need only screws of a certain thickness. The mass of the panels and their significant dimensions can cause significant inconvenience.

Tips and tricks

In order to guarantee the exclusion of extraneous sounds into the apartment, it is necessary, apart from windows, walls, ceiling and floor, to isolate door openings using rubber pads. The standard parameter Rw does not take into account such a circumstance as the presence of noisy equipment in modern apartments. So, according to its value, light walls made of gypsum plasterboard can outstrip brickwork of identical thickness. And if you focus on the conversations of people, on phone calls and alarm clocks, on the work of televisions - that's all it is.But if the neighbors have a home theater or a music center, the situation changes.

When choosing a partition design, it recommends matching the options at a third-octave frequency. Low-frequency noise prevention is most effectively done with fences made of dense material. Contrary to the common misconception, it is not possible to install loud equipment in one place. The wrong choice of location will not allow you to avoid worry for your neighbors, even with very strong acoustic protection. It is advisable to remove all sources of noise from living rooms.

The number of cameras in a plastic window is much less affected by its protective properties than is commonly believed. Where to pay attention to the overall thickness of the glass and the packages separating it. The widest packages with heavy glass of various thickness - this is a guarantee of peace and tranquility in the house. When choosing the option of partitions, the stiffness is more significant for the correct assessment of their acoustic parameters than the number of layers and filling. The total mass also has a positive effect.

Soundproofing Tips - in the next video.