Sealant for sound insulation: features of choice and application

In the modern world, the problem of sound insulation is becoming more acute. The gaps remaining after the installation of windows and doors, drywall and other panels can deliver a lot of inconvenience. Noisy neighbors or sewage, the sounds of the street - all this can be muffled with soundproofing sealant.

Composition and properties

Soundproofing sealant is made of special resins, the density of which contributes to the reliable blocking of the filled space.

Silicon-containing substances in its composition increase strength and flexibility.

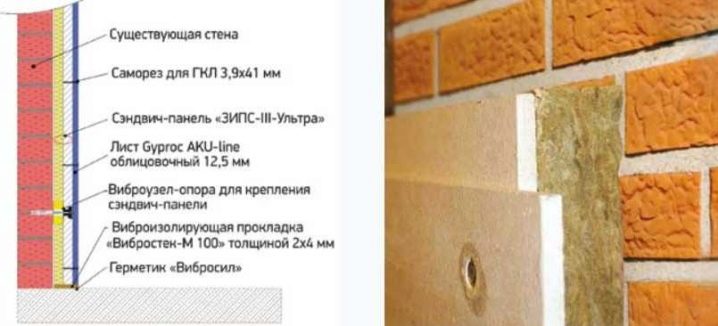

Noise reduction is not the only advantage of such a sealant. It also prevents the spread of structural vibrations in the components of the soundproofing structure,which makes it vibroacoustic.

The density of the surface layer is the main indicator of sealant quality. If it is below 300 g per square. m, then for soundproofing such a sealant is not suitable.

Application

The basic rules of use practically do not differ with other types of sealants.

Tips for sealing the seam look like.

- Surface cleaning. For good adhesion of the sealant to the surface, it must be cleaned and degreased. Professionals advise you to pre-glue the mounting tape along the seam.

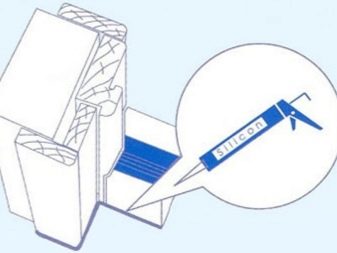

- Application The sealant is evenly distributed over the filling space. If the sealing of the vertical seam occurs, then start from the bottom. Filling is recommended to be carried out gradually.

- Rubber sponge will help evenly distribute the composition.

- The formation of the seam must be done before the sealant hardens. If this is not done on time, its effectiveness will decrease significantly.

- After the seam is completely filled, the masking tape and excess material must be removed.

It is easy to deal with the application of a sealant, the main thing is to follow safety precautions, protecting eyes and exposed skin from getting into the composition.Still not frozen sealant is easy to wash off with soapy water.

What you should pay attention to?

Currently, a wide range of sealants is available on the market, but not all are suitable for sound insulation. Consider the main options.

- Acrylic. Designed for sealing compounds that will be subjected to constant mechanical stress.

- Polyurethane foam. Its main purpose is to fix windows and doors, as well as to prevent deformation of fasteners.

- Silicone. It is designed to seal the seams of soundproofing structures.

From the foregoing, it follows that only a silicone sealant is suitable for soundproofing a room.

Its advantages are:

- can be used on virtually any surface;

- suitable for sealing any types of seams;

- the surface of the seam does not crack;

- resistant to ultraviolet radiation and weather conditions;

- does not shrink;

- differs in high heat stability.

The sealant tube must be sealed, without dents or damage. Container drips mean violations in transportation or storage. This product is not recommended to buy. All labels must be read clearly.It is necessary to pay special attention to the date of manufacture and shelf life.

When storing it is important to observe the temperature regime not lower than 15 degrees Celsius.

Which sealant to choose?

As mentioned above, the sealing compounds are quite widely represented on the market. Consider the most popular options.

"Vibrosil" - is an acoustic sealant, providing a high degree of insulation at the joints in soundproofing structures. By damping noise in the structures, its own sound insulation is enhanced. It is applied on all types of surfaces, the price of "Vibrosila" varies from 290 to 310 rubles.

The sharp smell of such a sealant can cause poor health. Before performing work, open doors and windows and wear a respirator. After drying, the smell disappears.

"Maksforte", as well as the previous option, is vibration-proof. Suitable for use in various types of seams. It reduces the vibration load in building structures, taking on the role of a damping layer. Made from Belgian raw materials.

Buyers note a complete absence of smell when applied. For one tube you will have to pay around 300 rubles.

The main advantage of sealant brand Tytan is its versatility. It can be used both in construction and repair, without making a distinction between internal and external works.

Manufacturers are talking about innovative technologies for manufacturing products that guarantee increased strength and heat resistance. The average price for a tube is 200 rubles.

Green glue - This is an imported soundproofing sealant from the United States. The company specializes in sound insulation, and even patented several formulations that have been specially tested. Such a composition is considered the most reliable.

A huge disadvantage is the price and volume. Sealant is supplied in tubes of 828 ml for 1450 rubles each. The price of domestic counterparts is indicated for a 300 ml tube.

Properly selected sealing compound will help save time and money.

About sound insulation of risers heating with sealant, see below.