Soundproofing Isover "Soundproofing": application

Sound insulation is important in both residential and industrial premises. And here the construction market offers many different options from different manufacturers. Particular attention should be paid to the brand Isover, characterized by high performance. The advantages and disadvantages of the sound insulation material “Sound Protection” from this brand will be discussed in this article.

Special features

There are three foam materials commonly used for residential, commercial and industrial insulation:

- extruded polystyrene (XPS);

- expanded polystyrene (EPS);

- polyurethane (PUR / PIR).

Each type has individual characteristics and specific advantages and disadvantages for building applications. Foam is recommended for places where high mechanical properties and low weight are required.

Widely used roller made of mineral wool, which provides a high level of acoustic insulation in partitions, walls and floors to meet the acoustic requirements in domestic and non-residential premises. Rolls are produced 600 mm wide, which simplifies their installation. Non-combustible mineral wool insulation has the necessary fire resistance. The material is made from 86% recycled glass.

Excellent acoustic properties and sound insulation provide a high level of sound insulation in partitions, walls and floors. Thermal conductivity of 0.036 W / mK - meets the requirements of standards. No additional attachment required.

Isover (sound protection) Acoustic Slab is a mineral wool glass slab, supplied in a width of 600 mm, to match the standard spacing between the spikes. The material provides a high level of acoustic performance in wall cladding systems, partitions and modular building applications.

All Isover products are tested and approved for use with plasterboard and acoustic systems, with a warranty period of use when used as part of gypsum systems.

High-quality mineral wool is easily processed, cut and installed.

The strength properties of a flexible material are resistant to damage during storage, during transport and on site during installation.

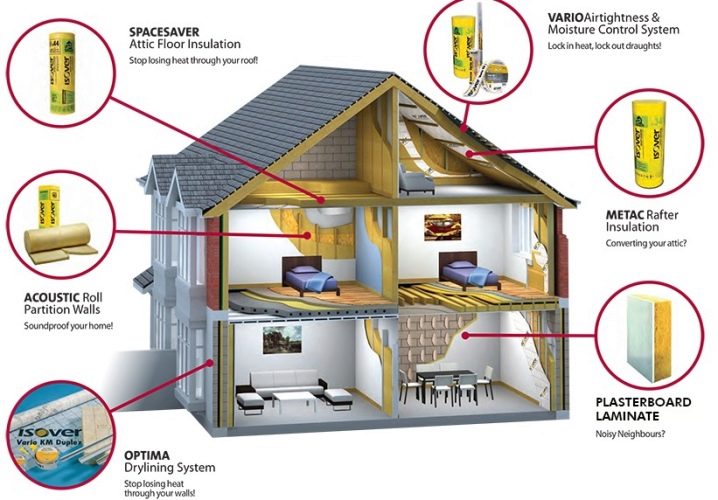

Widely used in construction:

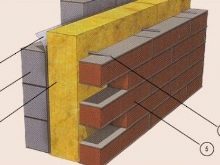

- external walls - masonry;

- external walls - wooden frame;

- internal floors;

- internal partitions - metal case;

- internal partitions - lumber;

- fire roof - rafters;

- separation of the walls.

Advantages and disadvantages

Isover has developed a new formaldehyde-free binder from renewable raw materials. This binder used in glass wool containing a high percentage of recycled glass gives a new product Isover New Glass Wool, offering the following guarantees: declared thermal and mechanical characteristics, installation comfort, environmental protection. Isover New Glass Wool was launched in Italy in 2014 and is gradually being introduced in other countries.

Among the main advantages:

- thermal conductivity of 0.035 W / mK for insulation;

- excellent acoustic performance and sound insulation;

- excellent fire safety;

- heat insulation;

- permeable breathable insulation;

- improves energy efficiency and reduces heating and cooling costs;

- Made from recycled glass, so it retains heat well;

- low carbon footprint;

- easy installation

Among the disadvantages:

- in spite of relatively high humidity, excessive wetting of the material is not allowed, therefore the heat-insulating structure, for example, on the facade or the roof, must necessarily provide a reliable waterproofing layer;

- Since for any production of mineral wool used ultrafine fiber, having a relative rigidity during its installation, the smallest particles can get into the eyes and respiratory tract.

Species

Isover is based on the finest fibers obtained by smelting minerals. Mineral insulation can have a different thickness and several linear dimensions depending on the intended use and the recommended installation technology.

Wood fiber panels, the newest product from Isover, provide several advantages.These weatherproof but breathable panels resist pressure and are easy to install. Together with high-quality thermal and sound insulation from fiberglass and an assortment of air-tight products Vario, they form a new set of safe and effective solutions for wood construction.

Isover is an insulation that breaks the previously known principles of thermal performance. An innovation that is more than a simple product:

- best thermal performance on the market, with a lambda value λ = 5.2 mW / (mK);

- first vacuum insulation for ACERMI certification;

- the first vacuum insulation offered as part of a fully adjustable Optima VIP system;

- the first time the insulation system was supported by a digital tool that offers the best configuration, optimizing the thermal performance of the wall.

Ultimate Protect is a complete fire protection system for air ducts. U Protect, now with innovative black veneer, gives good aesthetics. Other benefits:

- fire protection - Ultimate Protect meets the highest standards of fire protection, Euroclass A1 and has excellent fire resistance (up to 2 hours in accordance with EN1366);

- quick and economical installation - Ultimate high elasticity makes cutting, bending or filling faster and more efficiently than ever to isolate ducts and passages;

- saving time and materials - one layer instead of two, without glue between the joints;

- a light weight - Ultimate up to 3 times easier conventional solutions.

Airtightness and humidity system The Vario Xtra offers optimum performance and a revolutionary installation system. It expands the possibilities of design and, most importantly, provides greater safety from moisture.

The manufacturer offers a wide range of effective solutions for pitched and flat roofs, wooden frame walls. The Vario XtraFix fastening tape is designed for optimal performance, which allows you to quickly and efficiently use existing features.

Isover Multimax Lambda 030 fiberglass is a mineral wool product with the best thermal performance on the market. It has the same heat resistance as other mineral wool, but with a smaller thickness, which saves space in occupied attics and walls. The newest product has been successfully tested and proved effective in practice.With the product, the attic will remain wider, it will be possible to preserve the usable area, while it is easy to achieve the necessary level of comfort inside the room.

The main lines of this material are classified by type depending on the areas of their application in construction. For example:

- "Master";

- mineral wool;

- Isover "Warm House";

- Isover "Warm Walls";

- Isover "Warm Roof";

- "Quiet House";

- "Acoustic";

- "Standard";

- Isover "Sauna".

The following types can be attributed to the universal purpose of the material:

- Optimal;

- Profi;

- Classic;

- Extra.

Very often, in the very name of the isolation, there is a “hint” to the destination. Each of the above insulators has its own characteristics, which correspond to its field of application.

Specifications

Isover produces flooring materials, interior partitions, ceilings and suspended systems, and wall materials are divided into those used for interior surfaces and building facades.

Marking means:

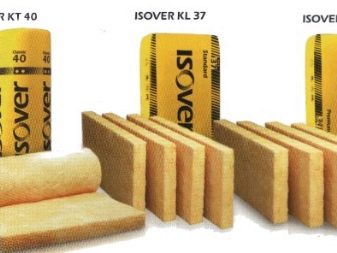

- CT-II - elastic mat in roll;

- CT - elastic mat in roll;

- KL-A - elastic plate;

- KL - elastic plate;

- RKL - rigid, fiberglass-reinforced on both sides;

- RKL-A - waterproof rigid plate (with tongue-and-groove connection);

- RKL-EJ - increased stiffness plate (with groove-tongue joint);

- SKL - semi-rigid plate;

- VKL is a rigid plate.

In private residential construction, the most frequently used material is “Classic”, indicated by the letter “K”. It, in turn, is divided into:

- Isover KL 34 - very soft plates with high heat-shielding properties, used to isolate surfaces without load;

- Isover KL 35 - a material with a slightly higher density, which is usually used for the same purposes as for the 34th version, that is, to insulate roofs, walls and partitions;

- Isover 37 - most often used to insulate floors, roofs and ceilings;

- Isover kt - it is usually used for warming basements or mansards.

The type Isover Classic Plus is also very popular. Its characteristics are the same as in the usual "classic." These two varieties differ only in thickness. "Classic" comes in mats 50 mm or 75 mm. In the "Classic Plus" this figure is 100 mm. There are other varieties of Isover format 1170x610x50 mm, designed for different purposes (Isover RKL, Isover OL and so on). For example, Izover Classic has the following characteristics:

- thermal conductivity coefficient - V 25 g - 0.041 W / mK, at 10 g - 0.038 W / mK;

- density - about 15 kg / m3;

- fire resistance - NG;

- water absorption - no more than a day - 0.08 kg / m;

- width - 1220 mm;

- length - 6150 mm;

- thickness - 50 mm.

Payment

Inexperienced builder is difficult to independently calculate the amount of insulation that needs to be spent on the room. Simplify the task of online calculators that do an excellent job with the task in a matter of seconds.

For independent calculations, it is necessary to bear in mind many factors and be able to use formulas.

- For a wall, it looks like this: R = 3,5-R.

- For the ceiling as follows: R = 6-R.

When the difference is found, it is necessary to determine the thickness of the material by the formula p = R * k, where: p is the desired thickness of the material; k - thermal conductivity.

Mineral wool and foam should always be 10 centimeters thick. This indicator is considered optimal.

The amount of insulation per room is calculated using the formula V = L * h * σ, where:

- V is the volume;

- L is the perimeter length of the surface;

- h is the height of the room;

- σ is the material thickness.

Application

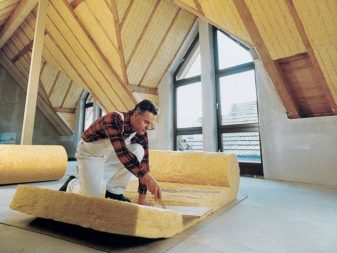

Manufacturers Isover recommend using insulation masters for:

- insulation of the walls of prefabricated houses;

- heat and sound insulation of internal partitions;

- insulation of walls made of stone and wooden houses;

- wall covering inside;

- thermal insulation of floors both above and below;

- insulation of roofs in residential homes;

- communication pipes.

Bases are usually insulated with polystyrene foam. When using Izover for this purpose, it is necessary to additionally organize a very high-quality waterproofing.

Useful tips

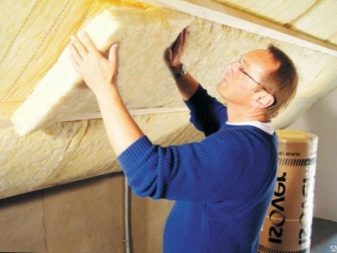

The first step to a standard installation for a 600 mm workpiece with a roll width of 1220 mm is to cut it in half to get two strips 610 mm wide. Due to this, mats are tightly installed between racks or stacked between lags. As the reviews demonstrate, this solution helps to save a lot. For all products, the manufacturer provides the necessary certificates.

If the insulation strip is not further cut into plates, this will help avoid the formation of cold bridges. To eliminate the installation of non-standard location of the studs, before cutting it is necessary to measure the distance between the frame elements, not forgetting to add a distance of 5 mm. An insulated attic roof or structure is secured with a waterproof film before installing insulation on the outside of the roof.After installing Isover insulation, it is necessary to tighten the internal vapor barrier, which is stretched horizontally starting from the floor.

Review on soundproofing Isover you can see in the next video.